Silane cross-linked peelable semi-conductive external shielding material and preparation method thereof

A silane cross-linking and semi-conductive technology, which is applied in the field of silane cross-linking peelable semi-conductive outer shielding material and its preparation, can solve problems such as difficulty in forming effective cross-linking products, less cross-linking parts, and difficulty in ensuring products, and achieves Maintain smoothness, high degree of cross-linking, and increase the effect of ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

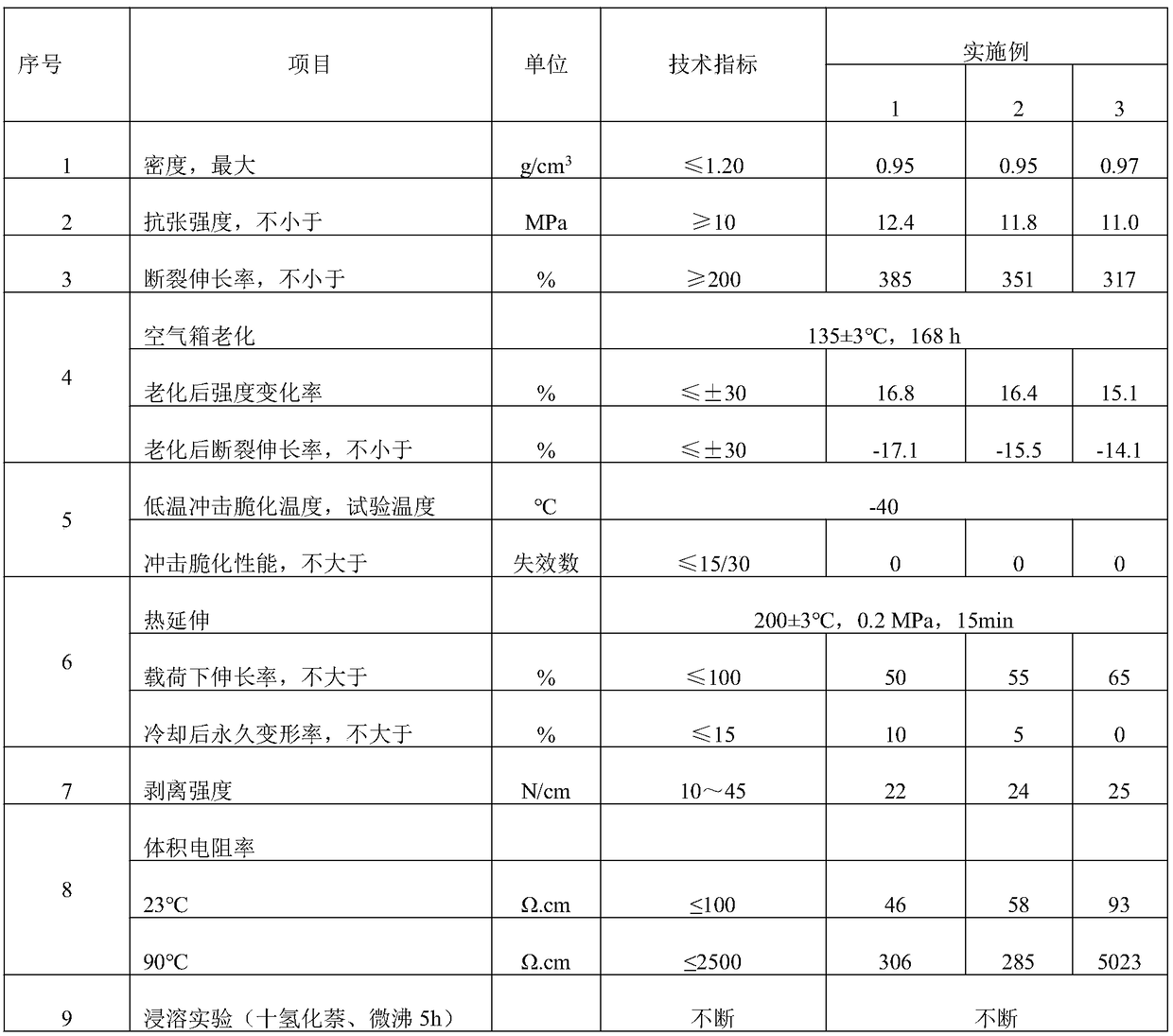

Examples

Embodiment 1

[0025] This embodiment provides a silane-crosslinked peelable semiconductive outer shielding material that can be effectively crosslinked, and its raw materials include:

[0026] Material A, 100 parts of ethylene-vinyl acetate copolymer, 1.5 parts of vinyltriethoxysilane, 0.3 part of dicumyl peroxide, 0.8 part of antioxidant 300, 8 parts of white oil.

[0027] Material B, 100 parts of ethylene-vinyl acetate copolymer, 105 parts of conductive filler (graphene), 10 parts of white oil, 6 parts of methyl silicone oil, 2 parts of TAS-2A, 0.6 parts of zinc stearate, 1 part of dilauric acid Dibutyltin, 0.8 parts Antioxidant 300.

[0028] The preparation method of the effectively cross-linkable silane cross-linking type peelable semi-conductive outer shielding material is as follows:

[0029] (1) The above-mentioned A material is passed through an automatic metering device, and the material is automatically fed into the twin-screw for mixing, grafting, extruding, granulating, and dry...

Embodiment 2

[0034] Material A, 100 parts of ethylene-vinyl acetate copolymer, 2.5 parts of vinyltriethoxysilane, 0.6 part of dicumyl peroxide, 0.6 part of antioxidant 300, 6 parts of white oil.

[0035] Material B, 100 parts of ethylene-vinyl acetate copolymer, 125 parts of conductive filler (carbon nanotube and carbon black mixture), 15 parts of white oil, 8 parts of methyl silicone oil, 3 parts of TAS-2A, 0.8 part of zinc stearate, 1.5 parts of dibutyltin dilaurate, 1.3 parts of antioxidant 300.

[0036] The preparation method of the effectively cross-linkable silane cross-linking type peelable semi-conductive outer shielding material is as follows:

[0037] (1) The above-mentioned A material is passed through an automatic metering device, and the material is automatically fed into the twin-screw for mixing, grafting, extruding, granulating, and drying to obtain the graft A material; the temperature of each section of the extruder is sequentially: the first zone 125°C, 160°C in zone 2,...

Embodiment 3

[0042] This embodiment provides a silane-crosslinked peelable semiconductive outer shielding material that can be effectively crosslinked, and its raw materials include:

[0043] Material A, 100 parts of ethylene-vinyl acetate copolymer, 3.5 parts of vinyltriethoxysilane, 0.8 part of dicumyl peroxide, 0.3 part of antioxidant 300, 5 parts of white oil.

[0044] Material B, 100 parts of ethylene-vinyl acetate copolymer, 145 parts of conductive filler (conductive carbon black), 18 parts of white oil, 10 parts of methyl silicone oil, 4 parts of TAS-2A, 0.8 parts of zinc stearate, 2.5 parts of dilaurel Dibutyltin acid, 1.8 parts of antioxidant 300.

[0045] The preparation method of the effectively cross-linkable silane cross-linking type peelable semi-conductive outer shielding material is as follows:

[0046] (1) The above-mentioned A material is passed through an automatic metering device, and the material is automatically fed into the twin-screw for mixing, grafting, extruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com