a degumming method

A degumming method and degumming technology, applied in the degumming field, can solve problems such as damage to the surface of the pasted object, erosion of the surface of the pasted object, etc., and achieve the effects of reduced peel strength, appropriate peel strength, and high residual glue removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

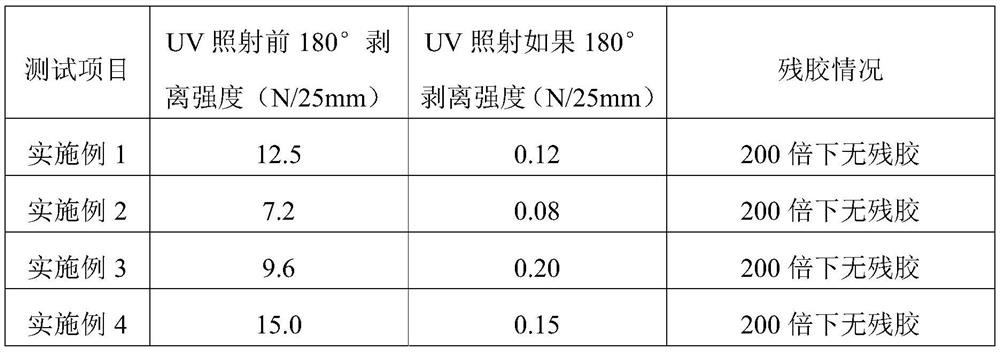

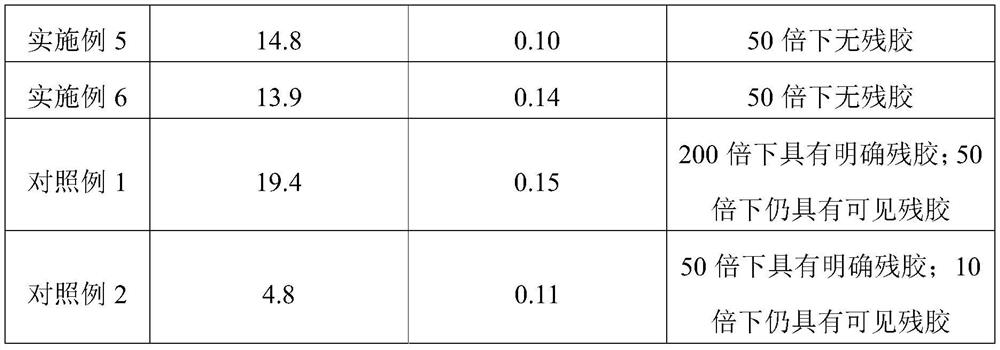

Embodiment 1

[0032] The UV adhesive reducing film of the present embodiment comprises a substrate layer, a UV adhesive reducing adhesive layer and a release film layer which are laminated in sequence, wherein the material of the substrate layer is PVC, and the composition of the adhesive layer is as follows:

[0033] Acrylic glue (solid content is about 40%): 100 parts;

[0034] Photoinitiator TPO: 0.8 parts (ie 2% of the original gum solid content);

[0035] Isocyanate curing agent: 0.2 parts (that is, 0.5% of the original rubber solid content).

[0036] In addition, the thickness of the substrate layer is about 100 μm; the thickness of the UV adhesive reducing layer is about 20 μm; the thickness of the release film layer is about 38 μm.

[0037] The degumming method of this embodiment uses the above-mentioned UV mucous-reducing film to carry out the UV glue remaining on the surface of the SUS board, and the degumming steps are as follows:

[0038] Paste the above-mentioned UV mucous-re...

Embodiment 2

[0041] The UV adhesive reducing film of the present embodiment comprises a base material layer, a UV adhesive reducing adhesive layer and a release film layer which are laminated successively, wherein the material of the base material layer is EVA, and the composition of the adhesive layer is as follows:

[0042] Acrylic glue (solid content is about 40%): 100 parts;

[0043] Photoinitiator 1173: 1.2 parts (ie 3% of the original gum solid content);

[0044] Isocyanate curing agent: 0.32 parts (ie 0.8% of the original rubber solid content).

[0045] In addition, the thickness of the substrate layer is about 100 μm; the thickness of the UV adhesive reducing layer is about 25 μm; the thickness of the release film layer is about 50 μm.

[0046] The degumming method of the present embodiment adopts the above-mentioned UV mucous-reducing film to carry out the UV glue remaining on the surface of the glass plate, and the degumming steps are as follows:

[0047] Paste the above-mentio...

Embodiment 3

[0050] The UV adhesive reducing film of the present embodiment comprises a substrate layer, a UV adhesive reducing adhesive layer and a release film layer which are laminated in sequence, wherein the material of the substrate layer is PVC, and the composition of the adhesive layer is as follows:

[0051] Acrylic glue (solid content is about 40%): 100 parts;

[0052] Photoinitiator MBF: 0.4 parts (i.e. 1% of the original gum solid content);

[0053] Isocyanate curing agent: 0.24 parts (ie 0.6% of the original rubber solid content).

[0054] In addition, the thickness of the substrate layer is about 100 μm; the thickness of the UV adhesive reducing layer is about 22 μm; the thickness of the release film layer is about 40 μm.

[0055] The degumming method of this embodiment uses the above-mentioned UV mucous-reducing film to carry out the UV glue remaining on the surface of the SUS board, and the degumming steps are as follows:

[0056] Paste the above-mentioned UV mucous-reducin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com