Handrail-drive for an escalator or a moving walk

A technology for moving walkways and escalators, applied in escalators, transportation and packaging, etc., can solve problems such as handrails and driving wheels slipping, shortening the life of driving wheels and pinch wheels, and large pressing force of pinch wheels. The deformation is small, the deformation is not obvious, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The handrail drive device according to the invention is also suitable for moving walkways with panels. In this description only the term "escalator" is used, but the content of the described embodiments is also applicable to moving walkways.

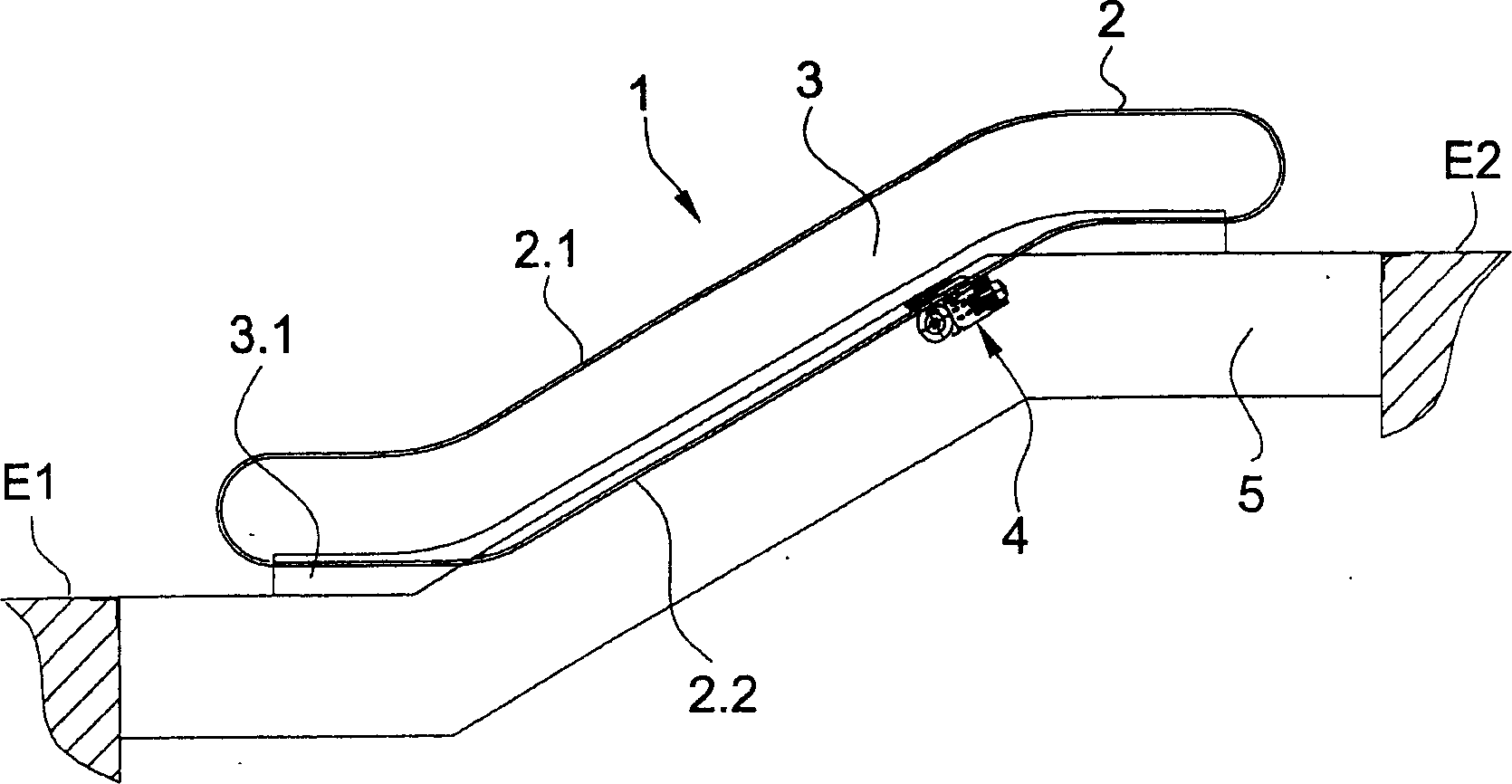

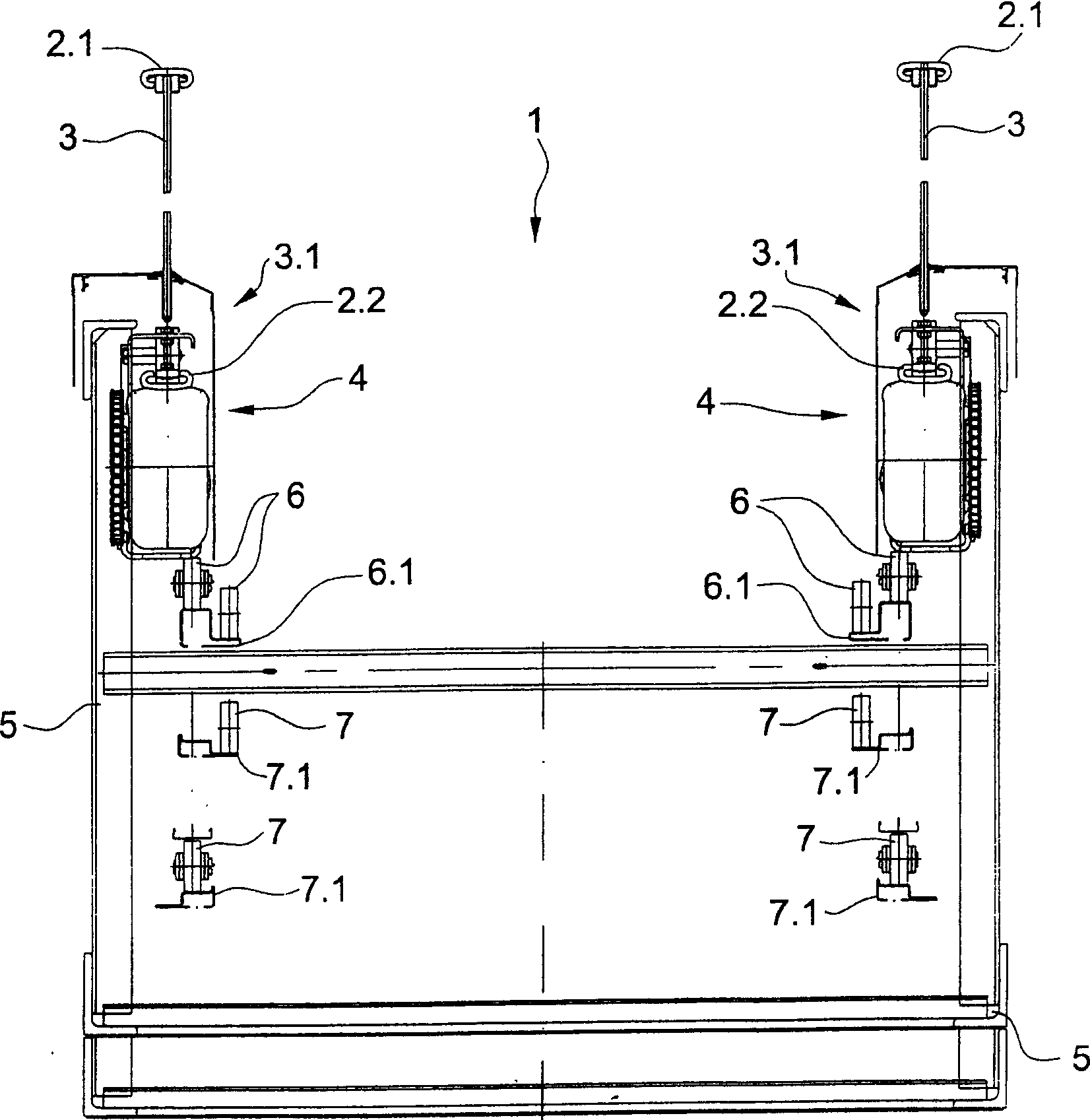

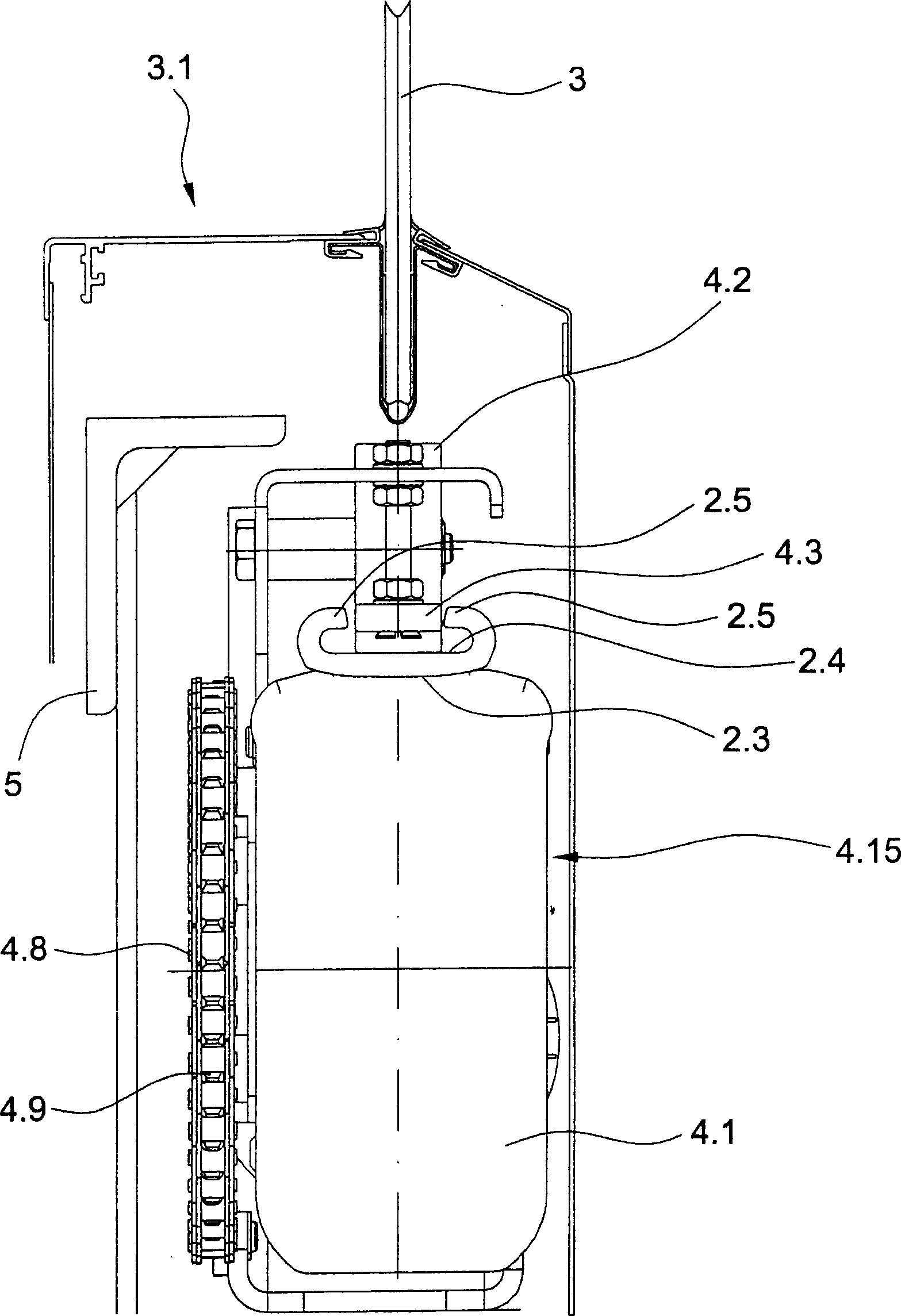

[0017] figure 1 It is a side view of the escalator 1, which connects the first floor E1 and the second floor E2 together. The escalator 1 has a step belt consisting of steps. The handrail 2 with the forward stroke 2.1 and the return stroke 2.2 is arranged on the guardrail 3, and the lower end of the guardrail is fixed by a guardrail seat 3.1. A handrail driving device 4 arranged on the frame 5 drives the handrail 2 . The frame 5 of the escalator 1 supports the guardrail seat 3.1. In the range of the upper end and the lower end of the escalator 1, a comb-tooth plate is provided, and the comb-tooth plate ensures reliable movement from the fixed part of the escalator 1 to the moving step belt or from the moving step belt to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com