Sealing device capable of automatically compensating abrasion loss

A sealing device and automatic compensation technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of low utilization rate of sealing packing, unstable sealing effect, heavy maintenance workload, etc., and achieve the improvement of utilization rate and structure Simple, low-maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

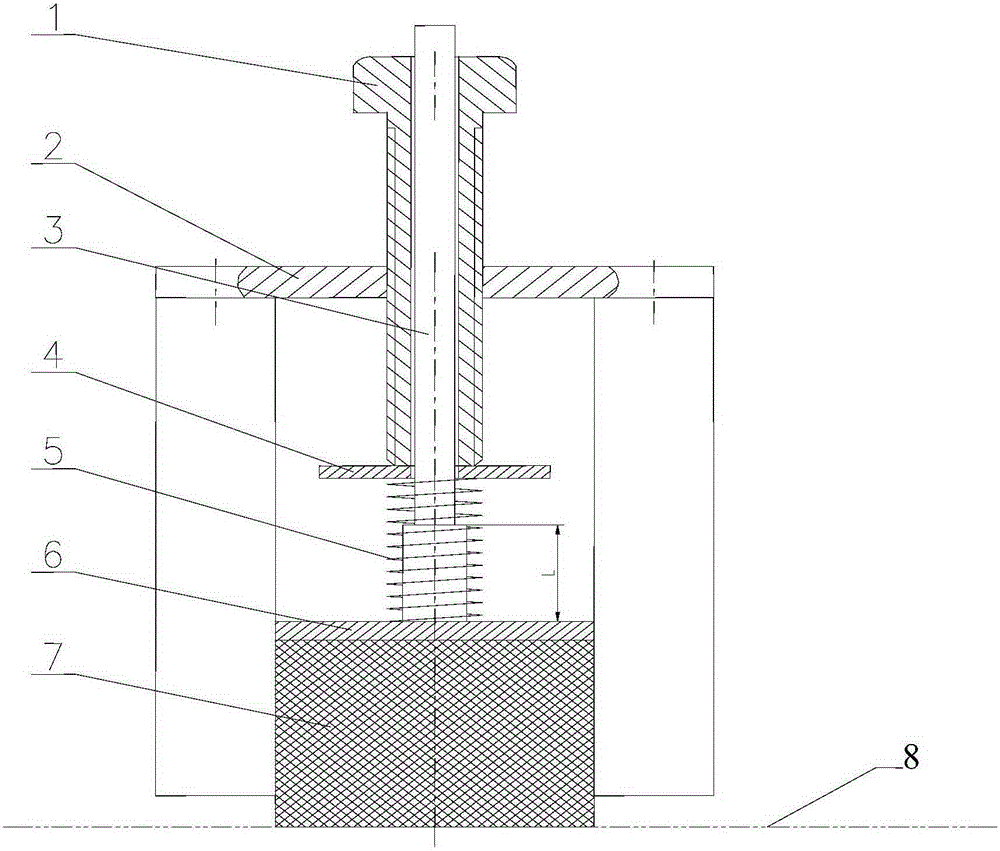

[0028] The adjusting screw rod 1 cooperates with the self-locking thread of the top cover of the sealing box 2, and the adjusting screw rod 1 is against the gasket 4. The gasket 4 pushes the spring 5 to make it deform elastically, and the spring 5 produces a thrust against the pressing plate 6 after elastically deforming. The pressing plate 6 presses the sealing packing 7 to make it closely adhere to the surface of the equipment to form a seal. The function of the gasket 4 is to digest the torsional force when the adjusting screw 1 is tightened, so as to ensure the stable performance of the spring 5 . The indicator rod 3 is fixedly connected with the pressure plate 6 and passes through the spring 5 , the washer 4 and the adjusting screw 1 . The length of the indicator rod 3 beyond the adjustment screw 1 is not less than the compression amount of the spring 5 relative to the height of the minimum load. The excess part is designed with a scale mark, which serves as an indicato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com