Carrier tape, carrier tape manufacturing apparatus, and method of manufacturing carrier tape

A carrier tape and tape-like technology, which is applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problems of breakage of the punch 202, increase in manufacturing cost, reduction in tensile strength and bending stiffness, etc. Possibility of breakage, improvement of tensile strength, effect of shortening manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

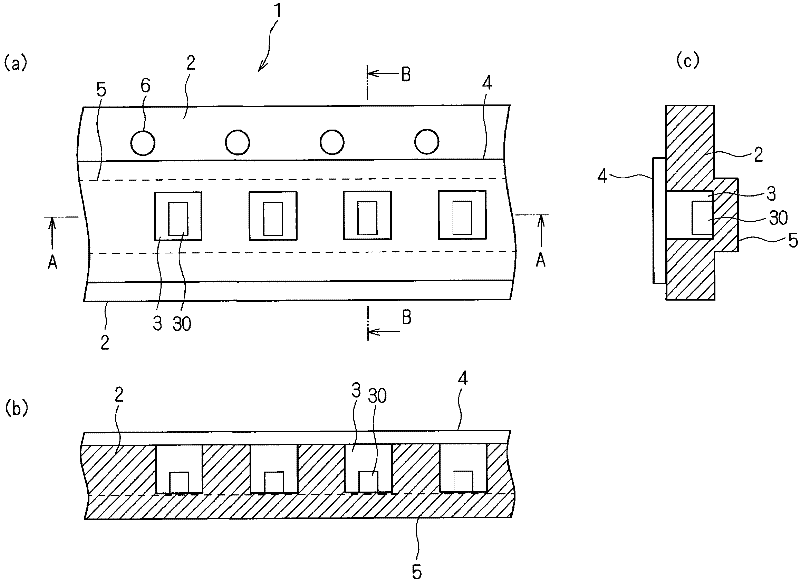

[0061] figure 1 It is a plan view and a cross-sectional view of the carrier tape according to the embodiment of the present invention. figure 1 (a) is a top view of the carrier tape 1, figure 1 (b) is the A-A sectional view of the carrier tape 1, figure 1 (c) is a B-B sectional view of the carrier tape 1 . The carrier tape 1 is a carrier tape composed of a strip-shaped base material 2, and includes a plurality of recesses 3 formed on the surface (one side surface) of the base material 2 for accommodating electronic components 30. Cover 4, which closes the opening of the recess 3; and a protrusion 5, which is formed on the other side of the base along the longitudinal direction of the base 2, and has It spans the length of more than two recesses 3 . Guide holes 6 are provided in the substrate 2 of the carrier tape 1 in parallel with the recesses 3 , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com