A Force-Limited Compression-Release Mechanism

A technology of releasing mechanism and pressing rod, which is applied to the power supply system of aerospace vehicle, etc., can solve the problems of inability to guarantee the internal pressing force of the solar blanket, loss of support and protection of the solar blanket, damage to the parts of the solar blanket, etc. The effect of tightness of small spacecraft resources, easy overall layout, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

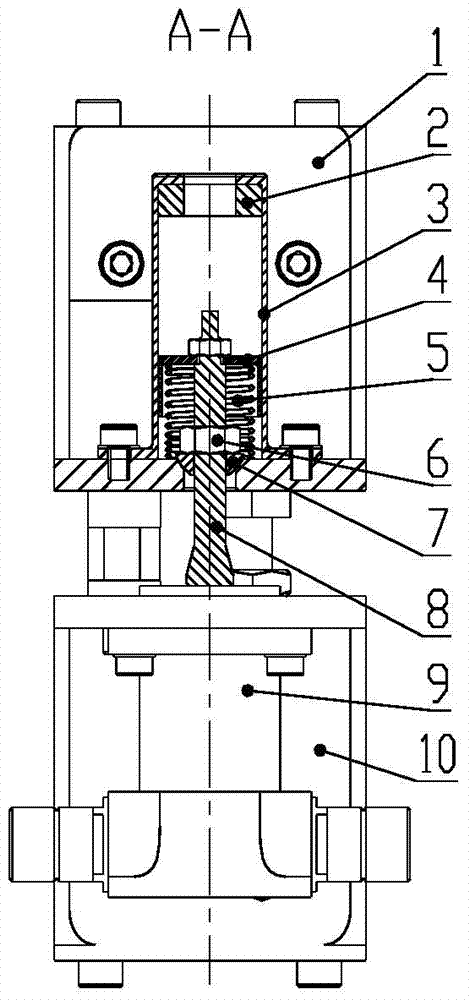

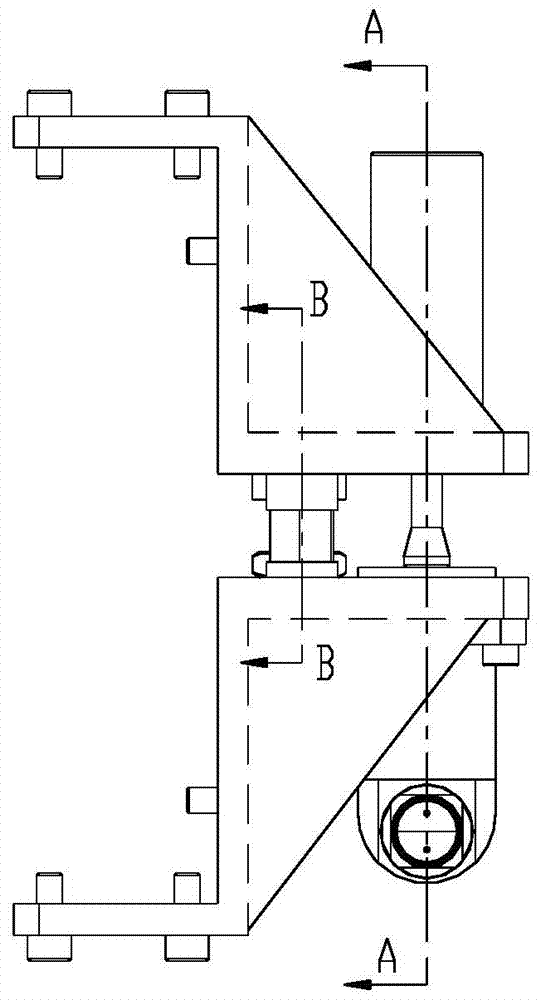

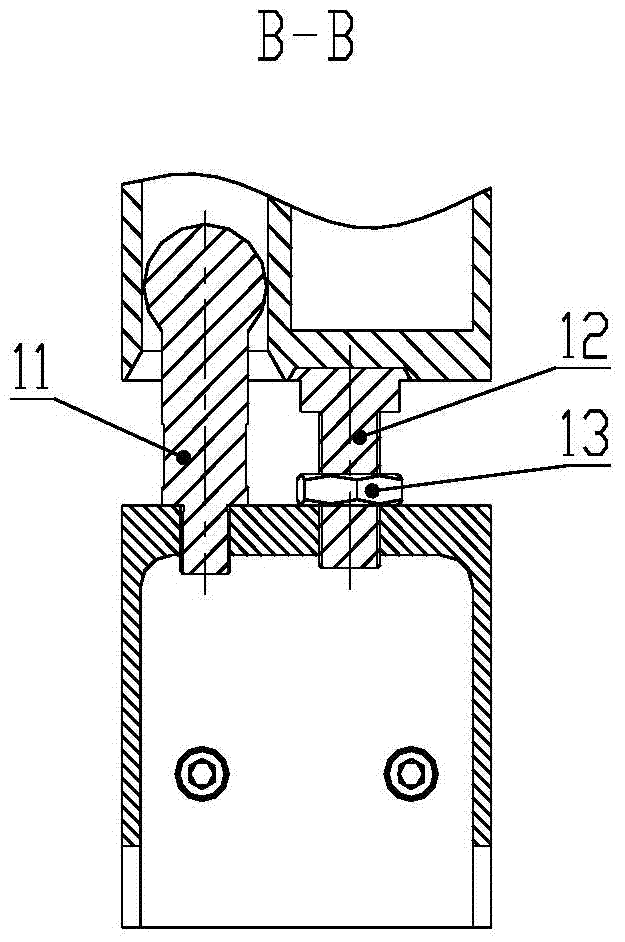

[0022] The invention provides a force-limited compression release mechanism, such as Figure 1 ~ Figure 3 As shown, it is mainly composed of a pressing component and a base component.

[0023] Among them, the pressing assembly is fixed on the side of the upper box board of the sun blanket, and consists of a pressing rod 8, a spherical pad 7, a lock nut 6, a separation spring 5, a spring sheath 4, a shock pad 2, an escape cap 3 and a pressing The compression rod mounting seat 1 is composed of a "Z"-shaped structure, the upper end surface and side of the compression rod mounting seat 1 are fixed to the side of the upper box board of the sun blanket, and the compression rod mounting seat 1 is provided with a through hole in the middle of the lower end surface, the compression rod 8 passes through the through hole and is connected with the base assembly, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com