Patents

Literature

62results about How to "Increase the sealing specific pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

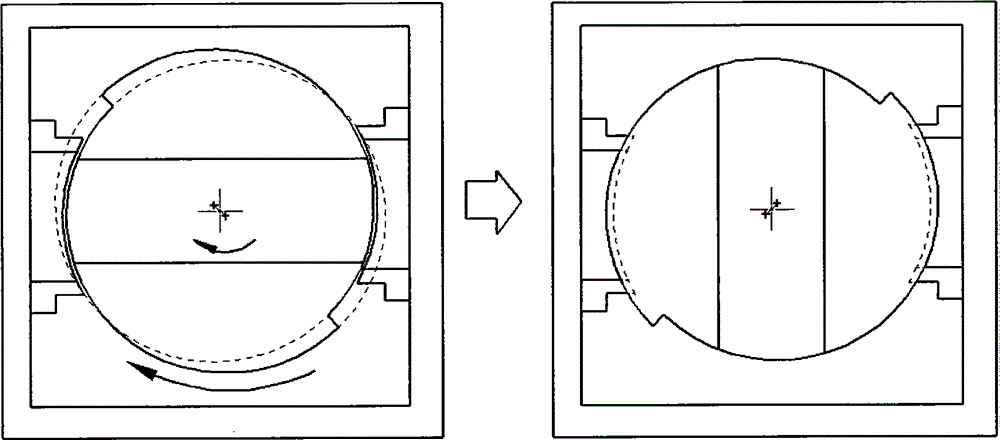

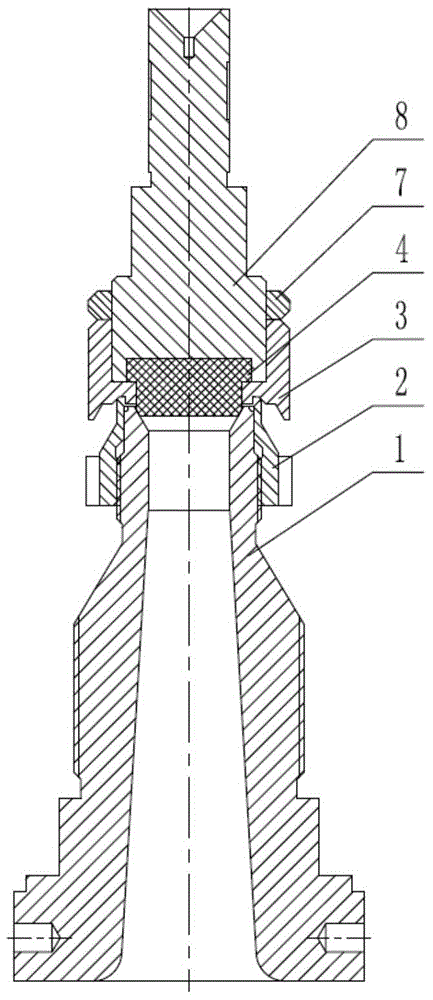

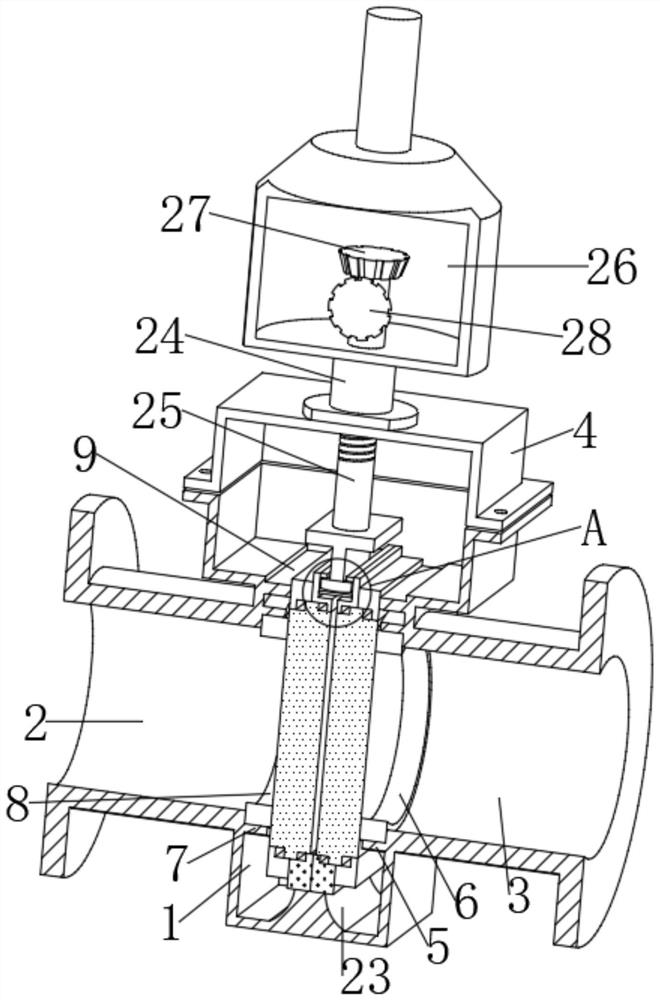

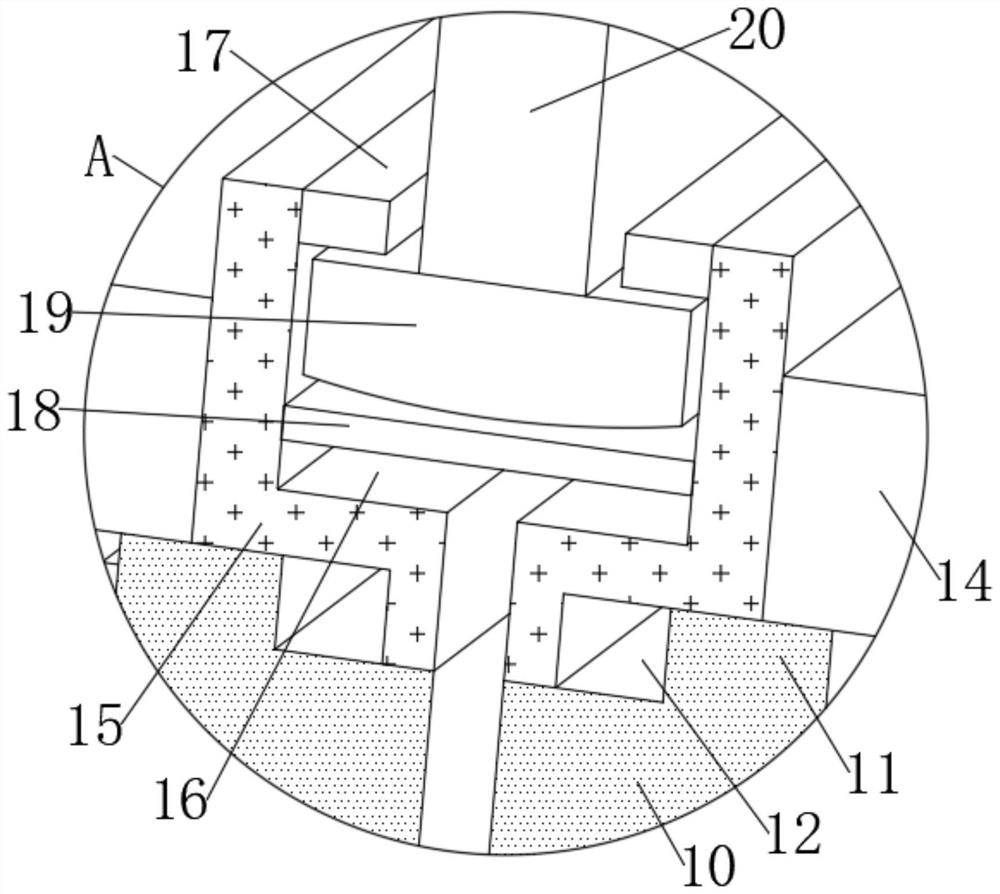

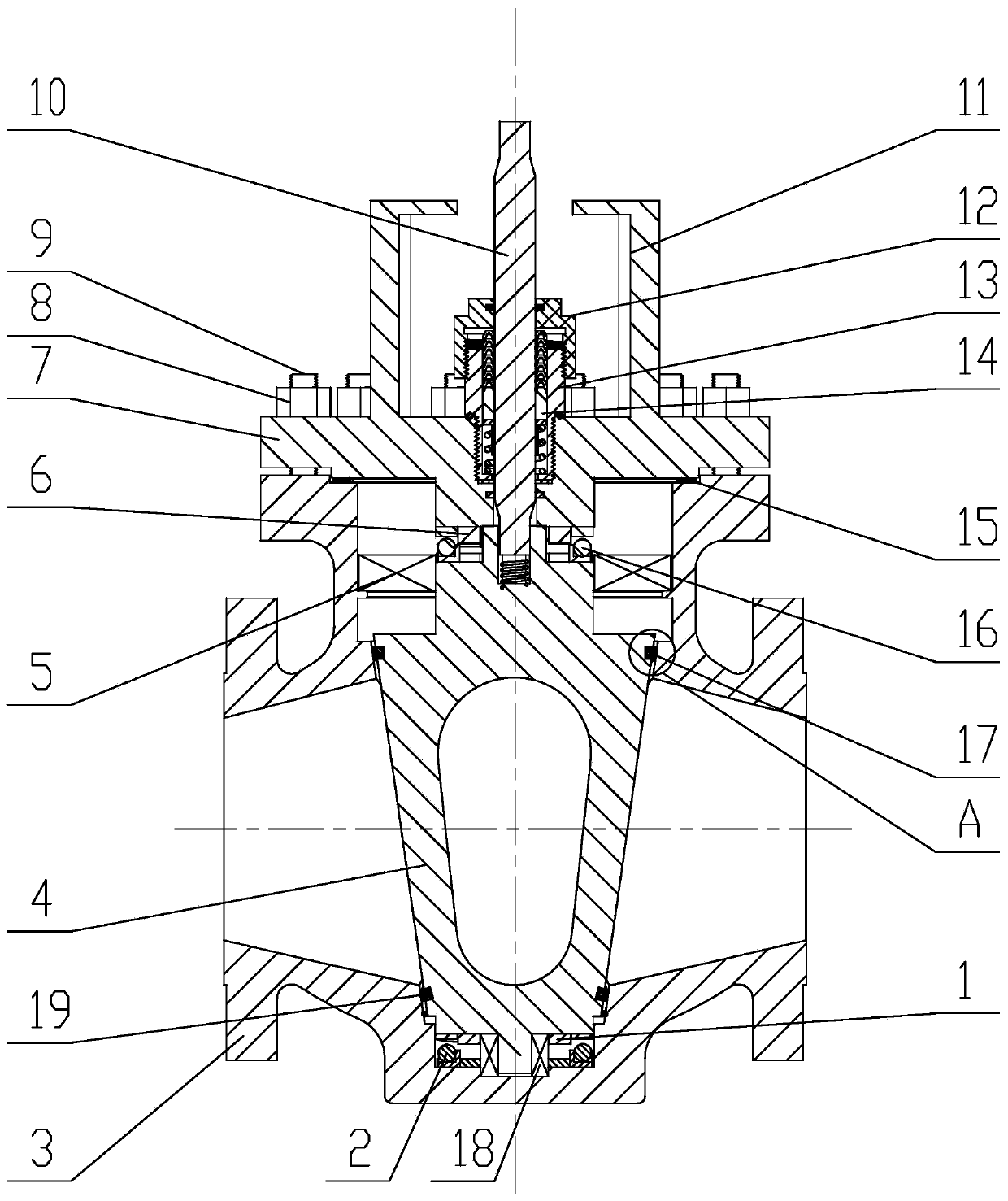

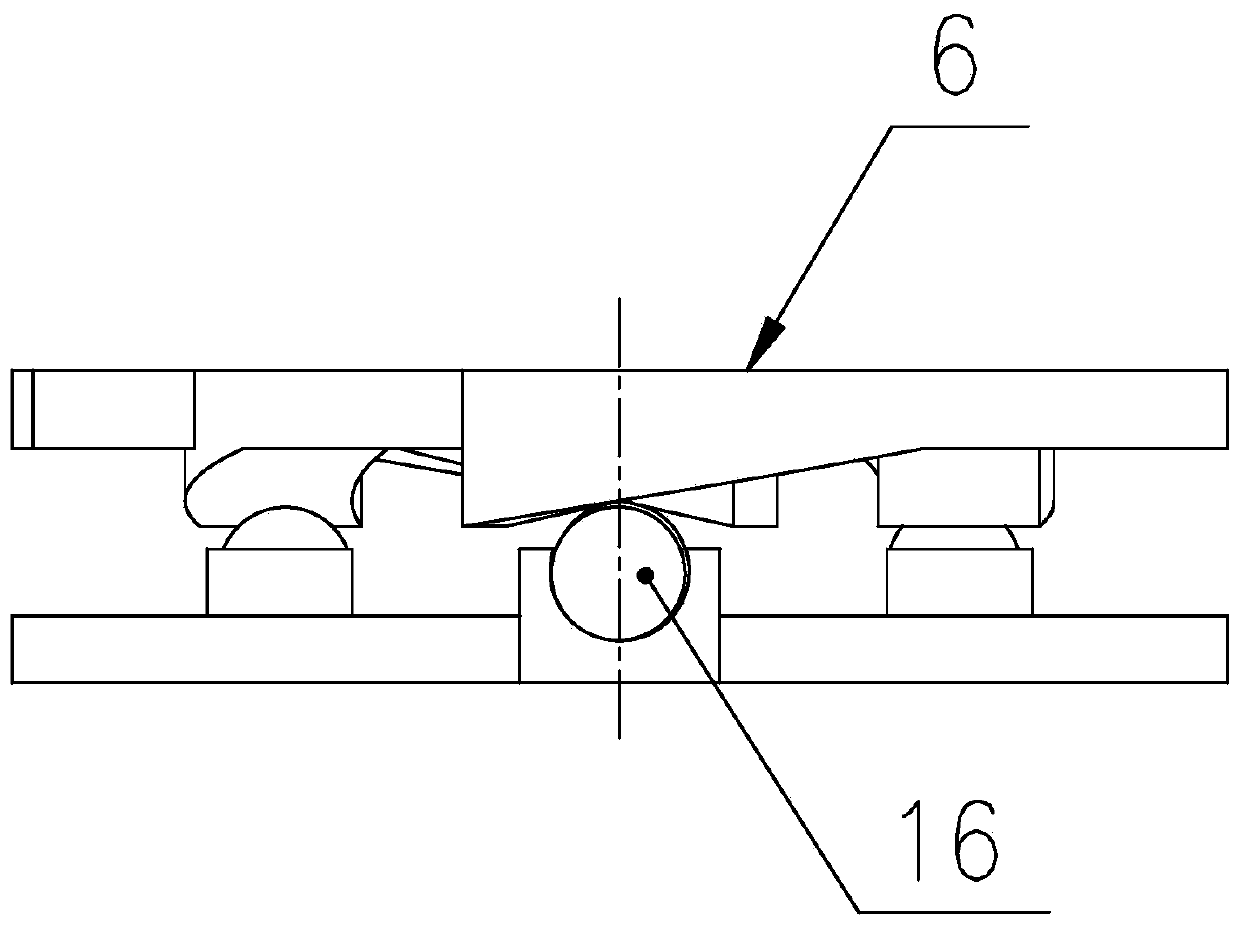

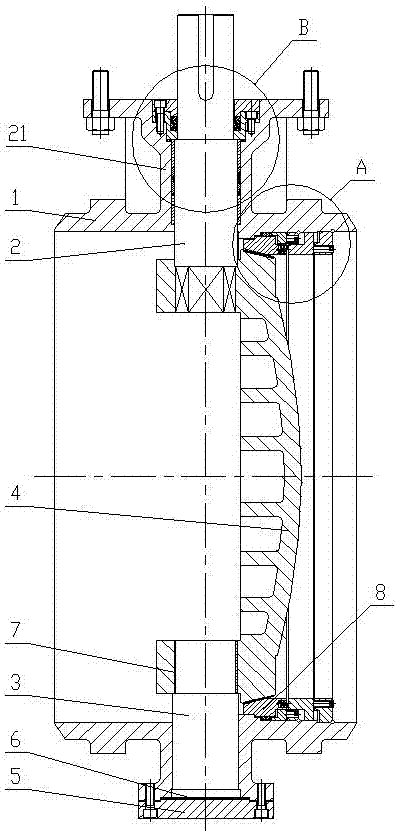

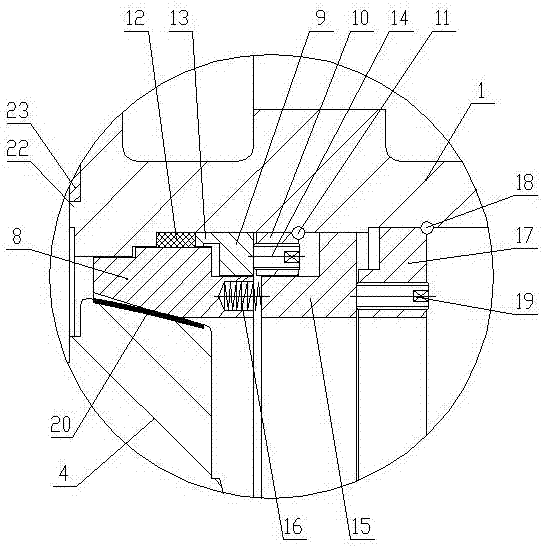

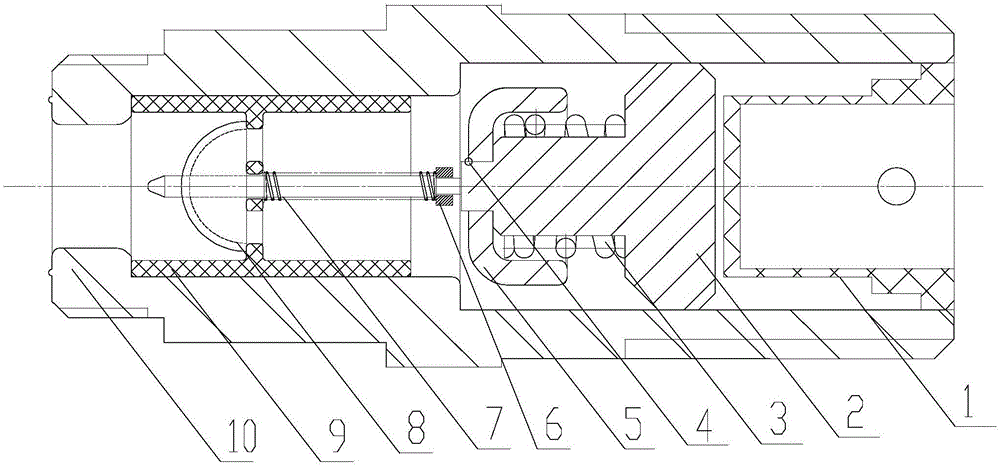

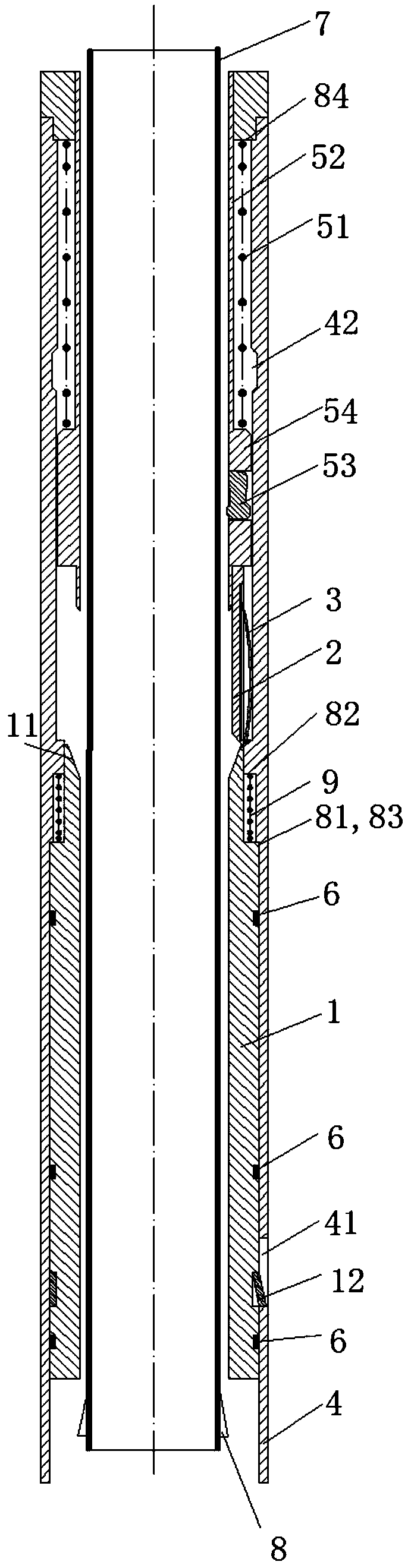

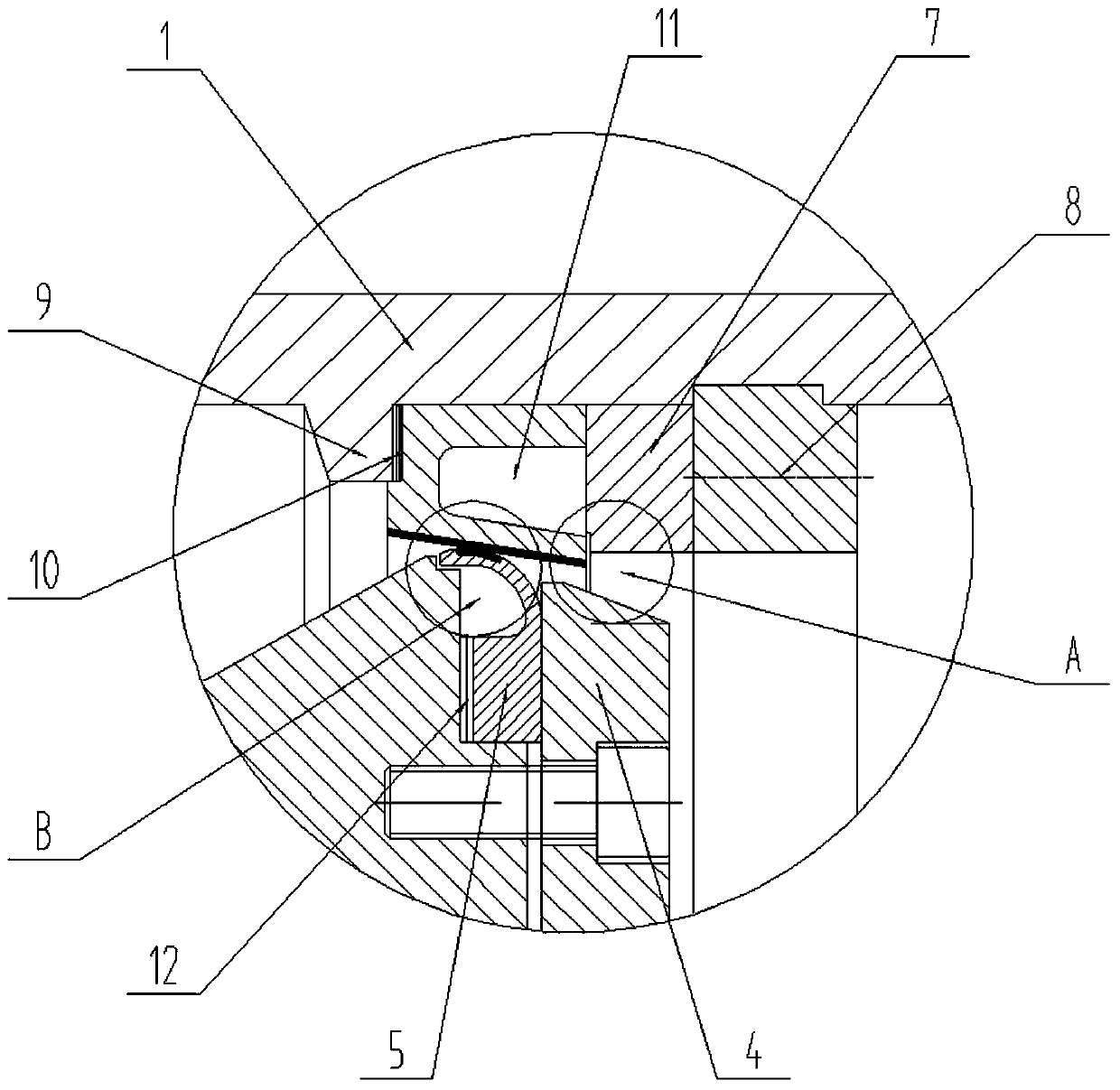

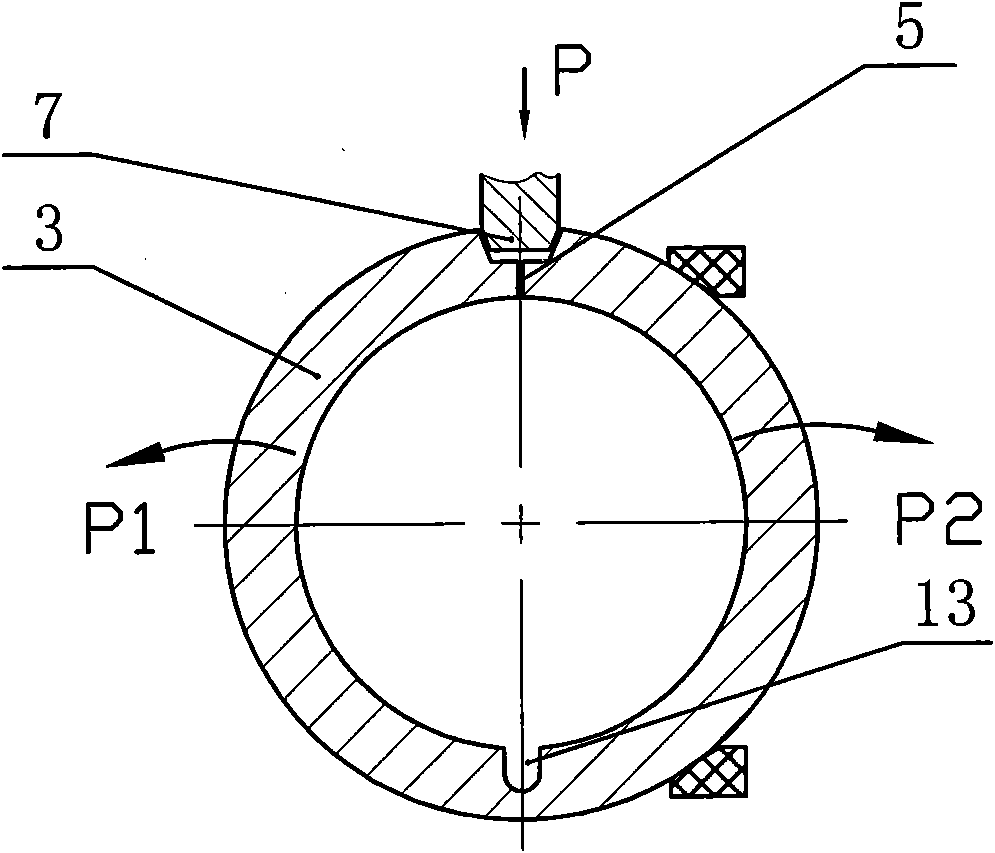

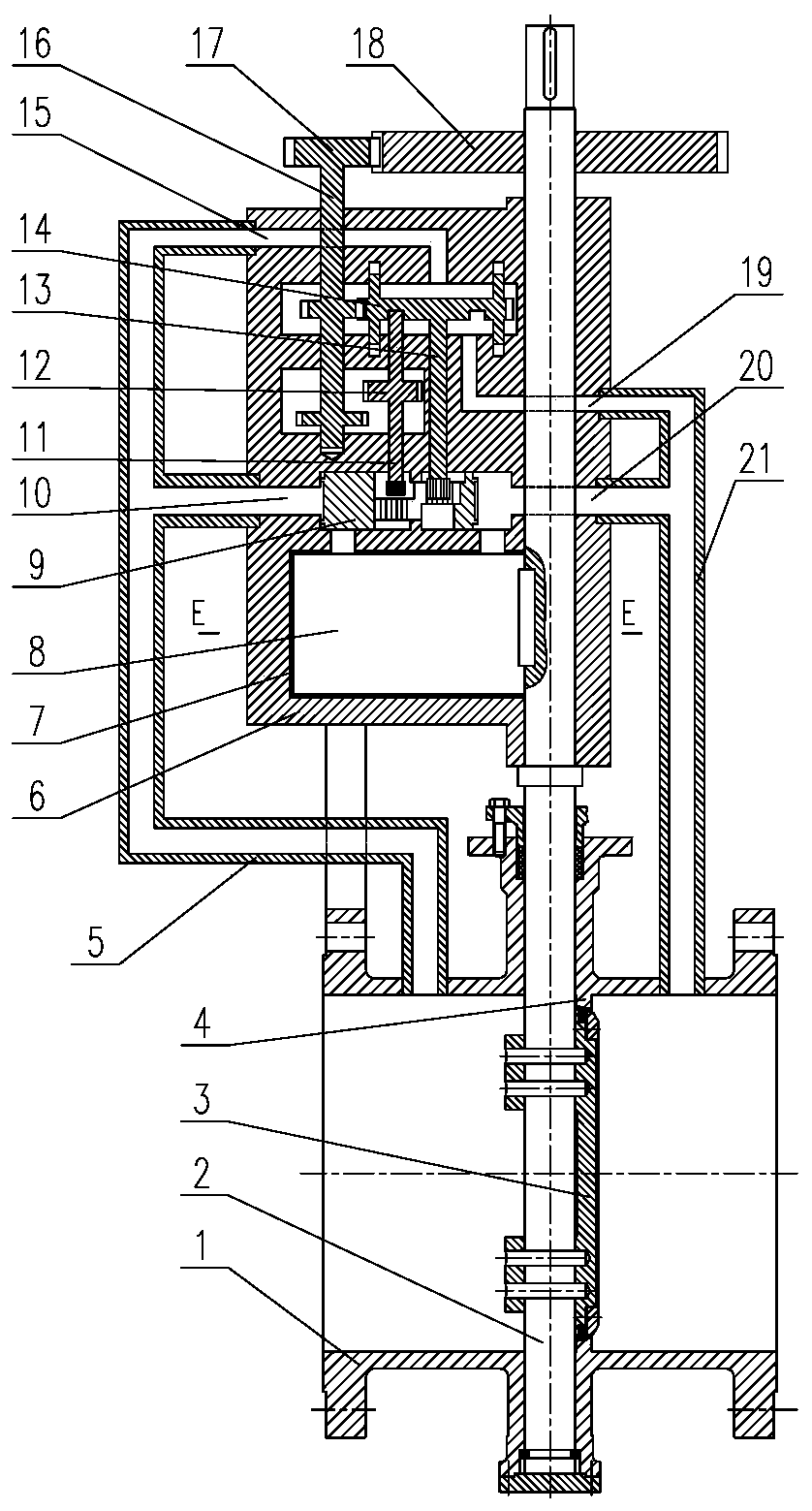

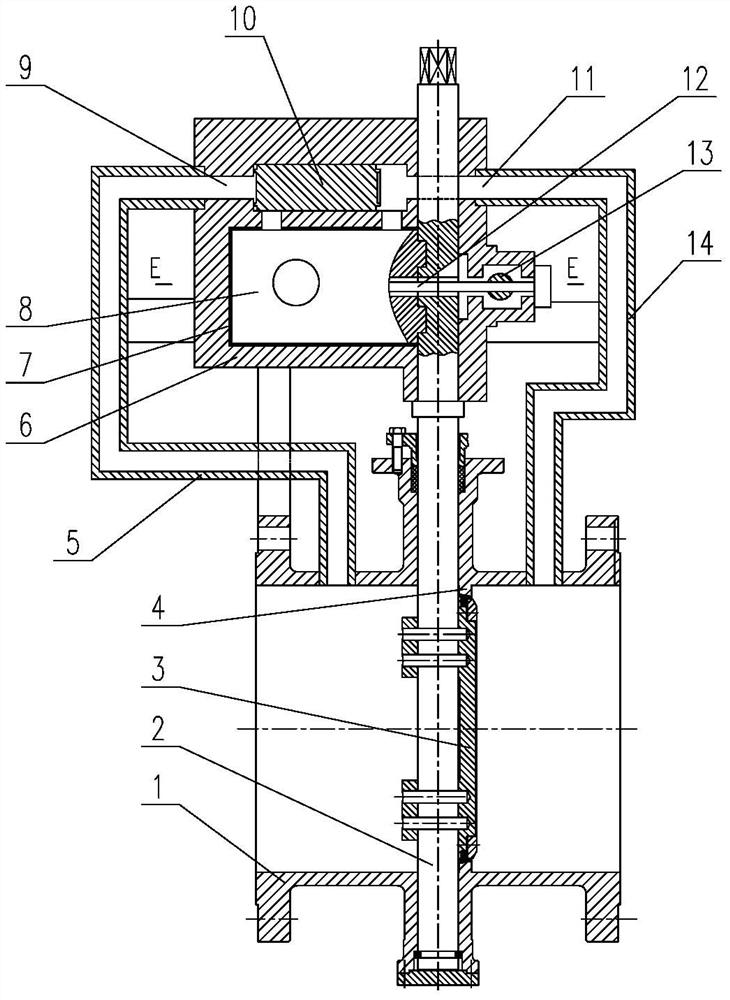

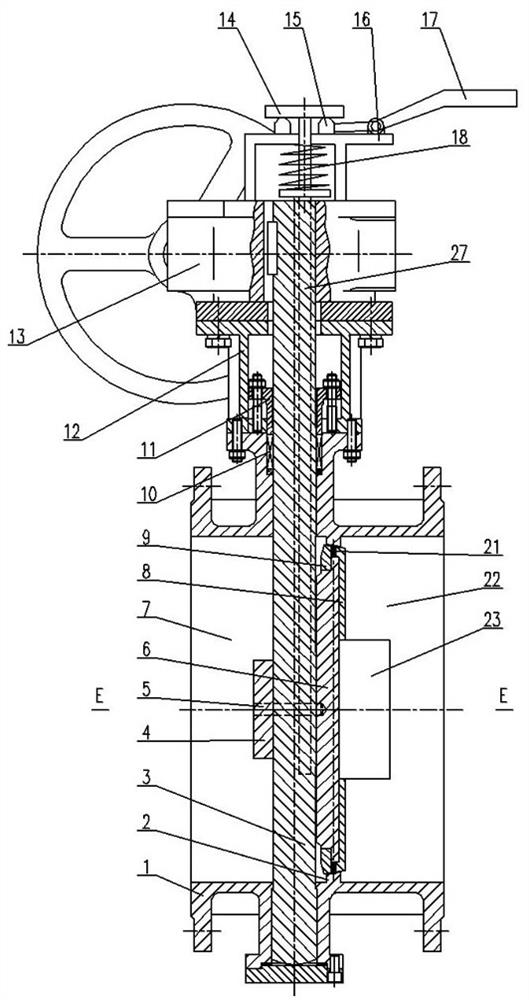

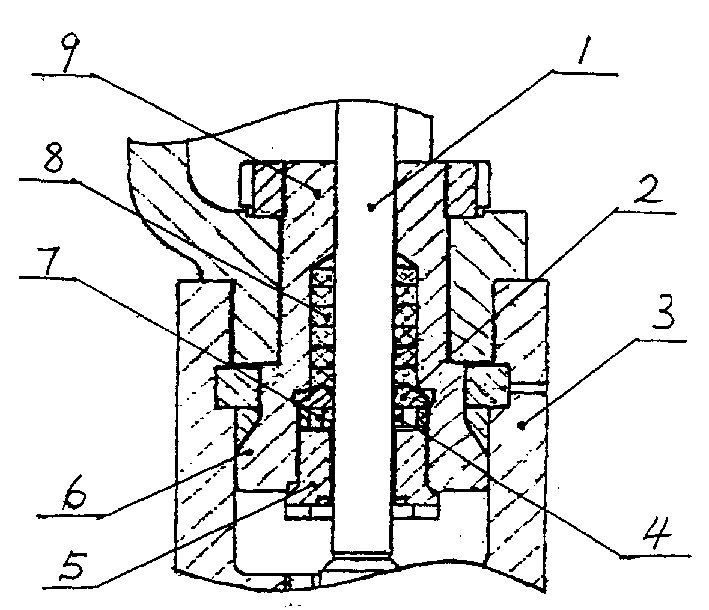

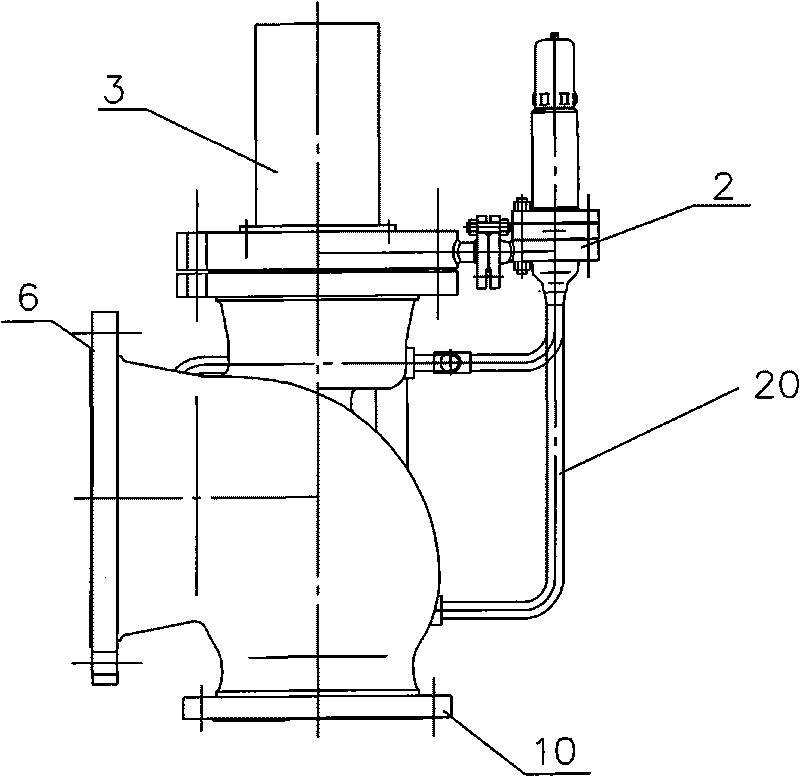

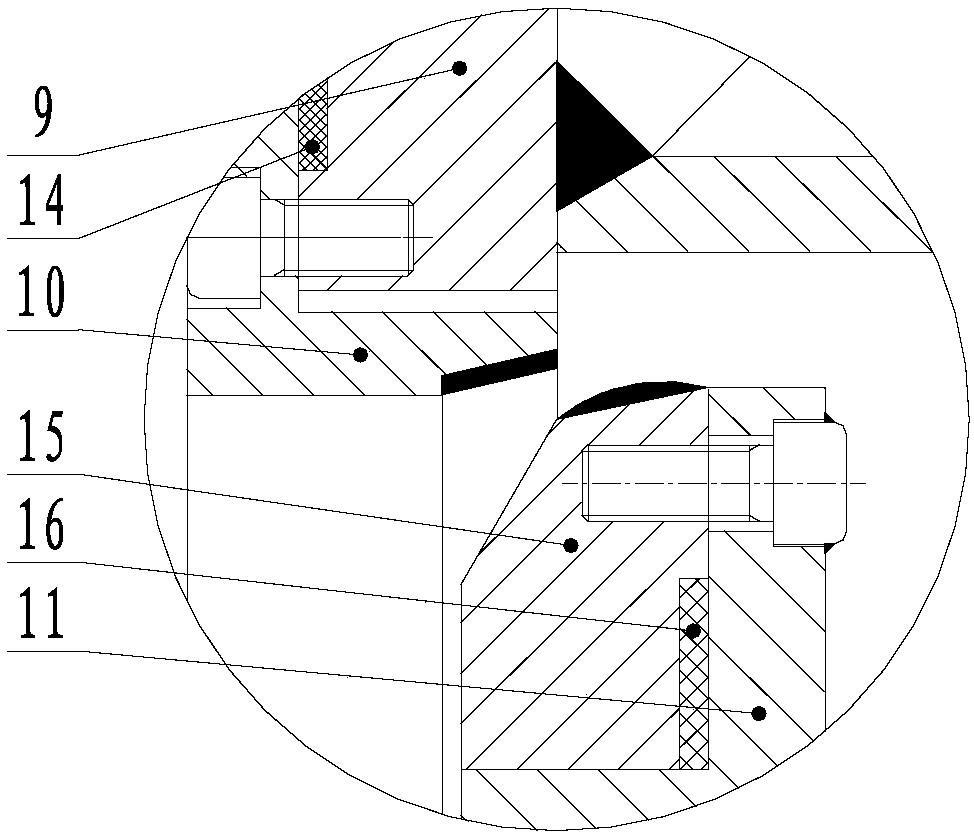

Forced seal valve capable of conducting eccentric double-spherical-angle stroke operation

InactiveCN105370909AIncrease the sealing specific pressureGuaranteed tightnessPlug valvesSpherical angleEngineering

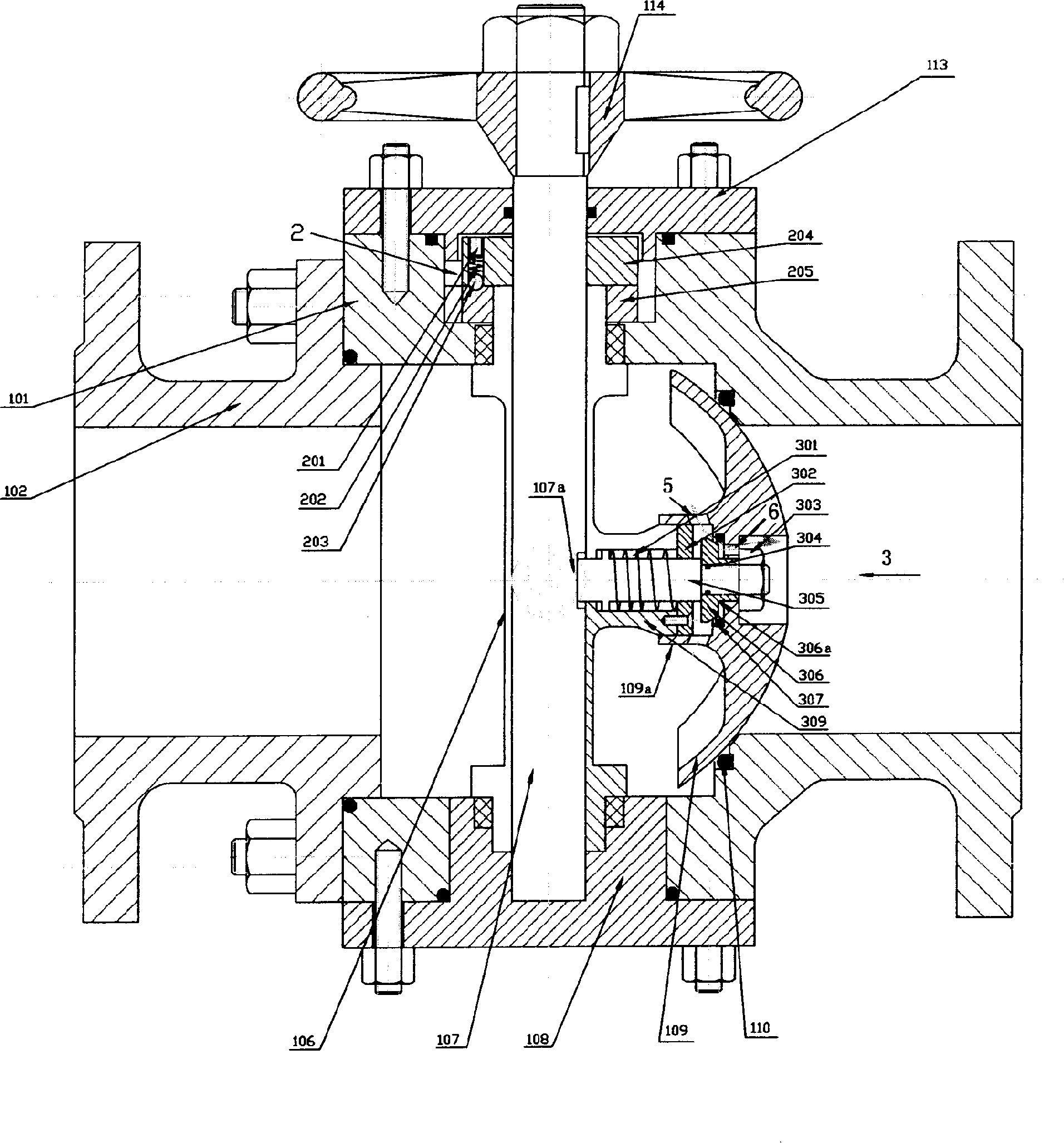

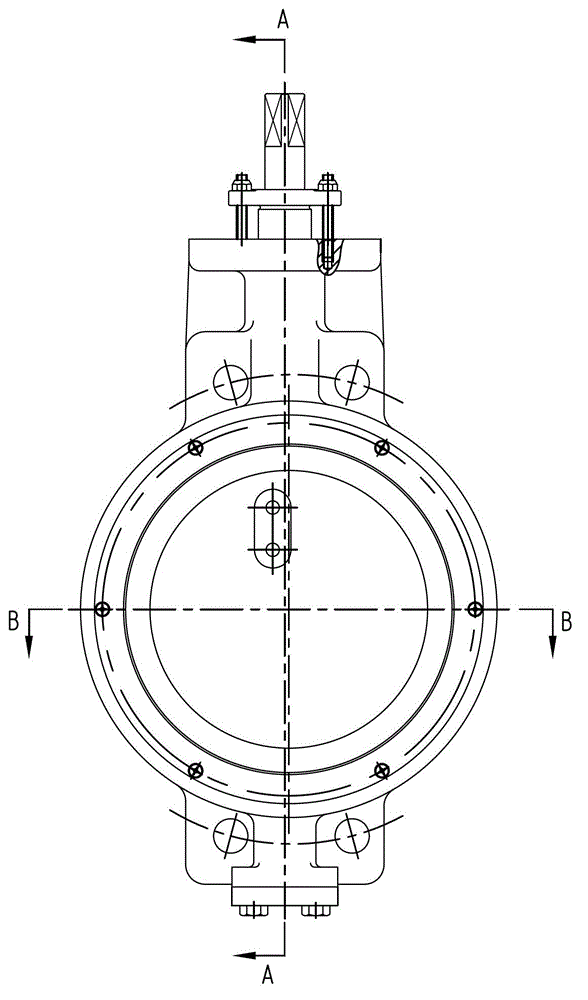

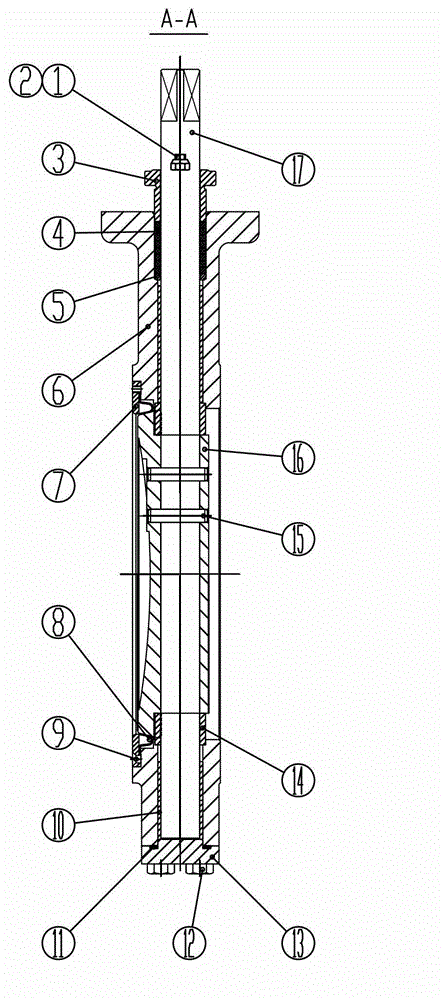

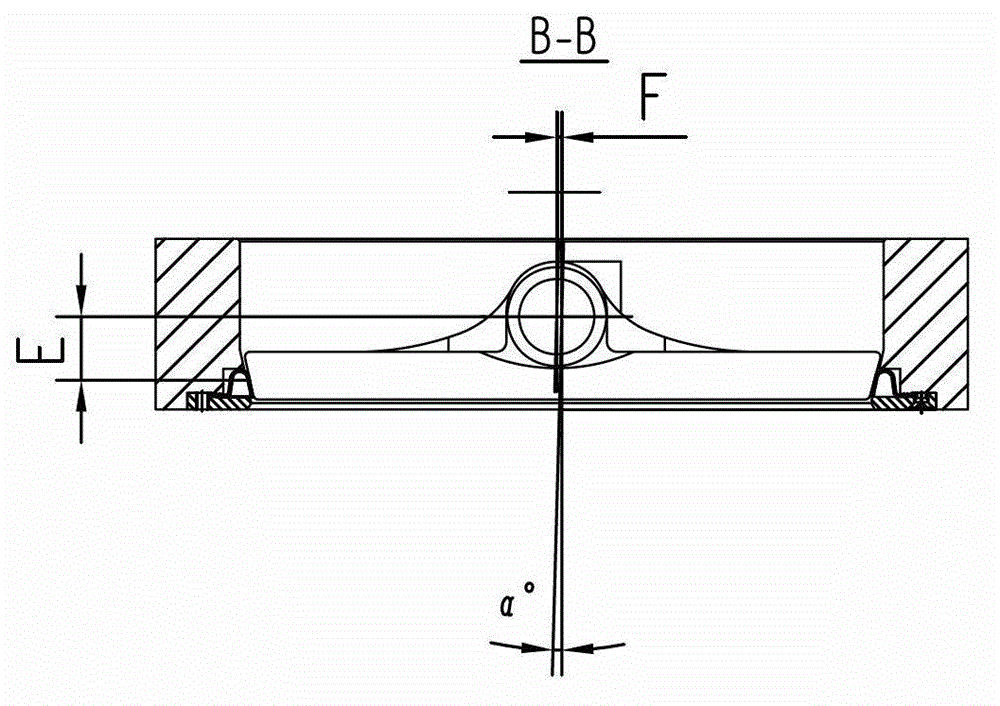

The invention relates to a forced seal valve capable of conducting eccentric double-spherical-angle stroke operation. The forced seal valve mainly comprises a valve body, an opening and closing piece, a valve deck, a valve rod, valve bases, a valve base supporting plate, an operation mechanism, a blowdown valve and the like. The opening and closing piece comprises two eccentric spherical structures. By means of the eccentric structures, when the valve rod drives the opening and closing piece to rotate, two eccentric spherical faces can both move in the axis directions of the downstream valve base and the upstream valve base, and therefore the effect of pressing or releasing the valve bases is achieved, and forced sealing of the opening and closing piece, the downstream valve base and the upstream valve base under the specific valve position is achieved. In addition, a module can be formed by the opening and closing piece, the valve rod, the valve bases, the valve base supporting plate and the valve deck, the whole module can be pulled out of the valve as a whole after fastening pieces through which the valve deck and the valve body are connected are detached, and therefore easily-damaged parts of the valve can be replaced in a modularized manner.

Owner:JIANGSU RELIABLE MECHANICAL EQUIP CO LTD

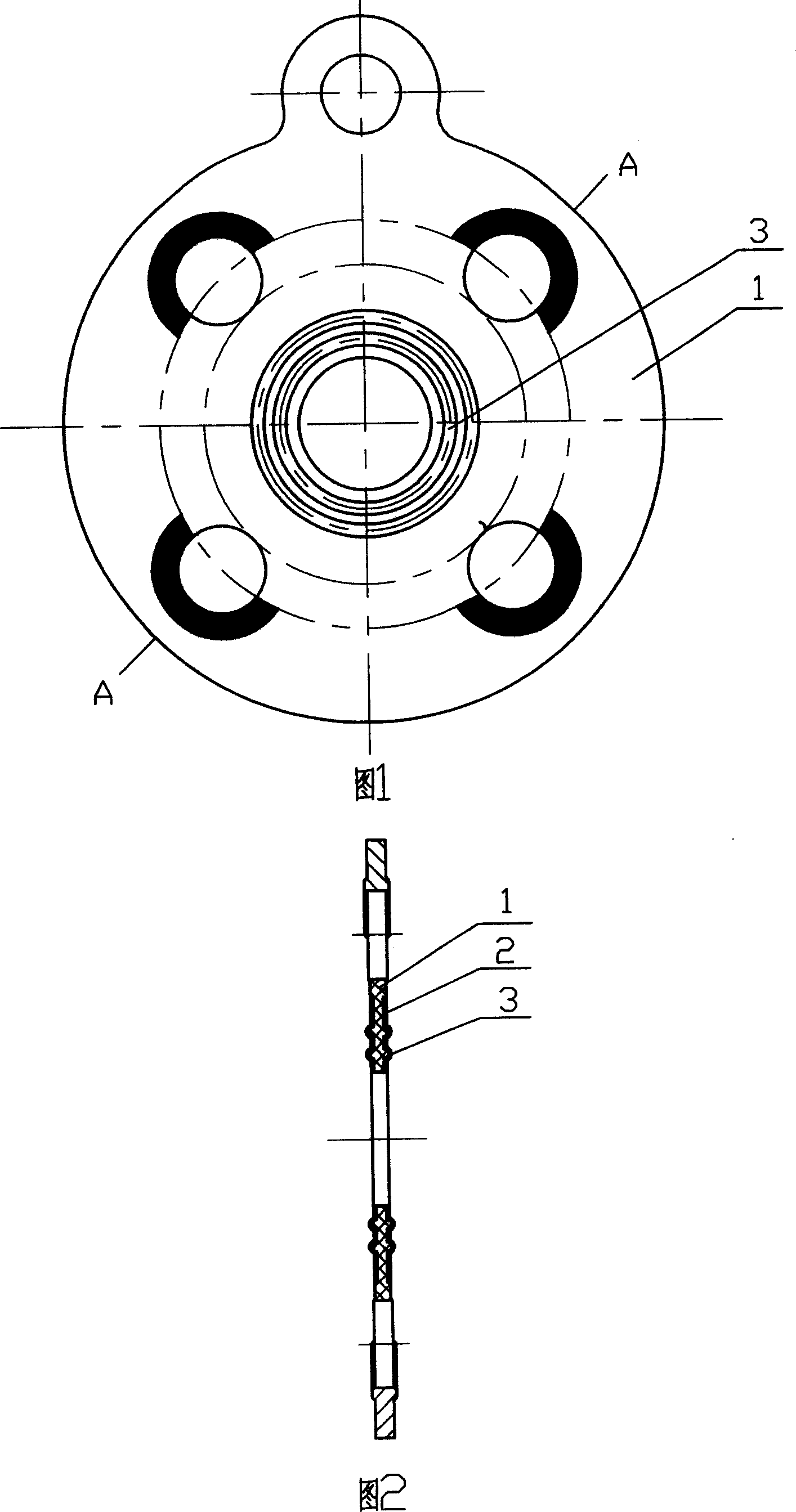

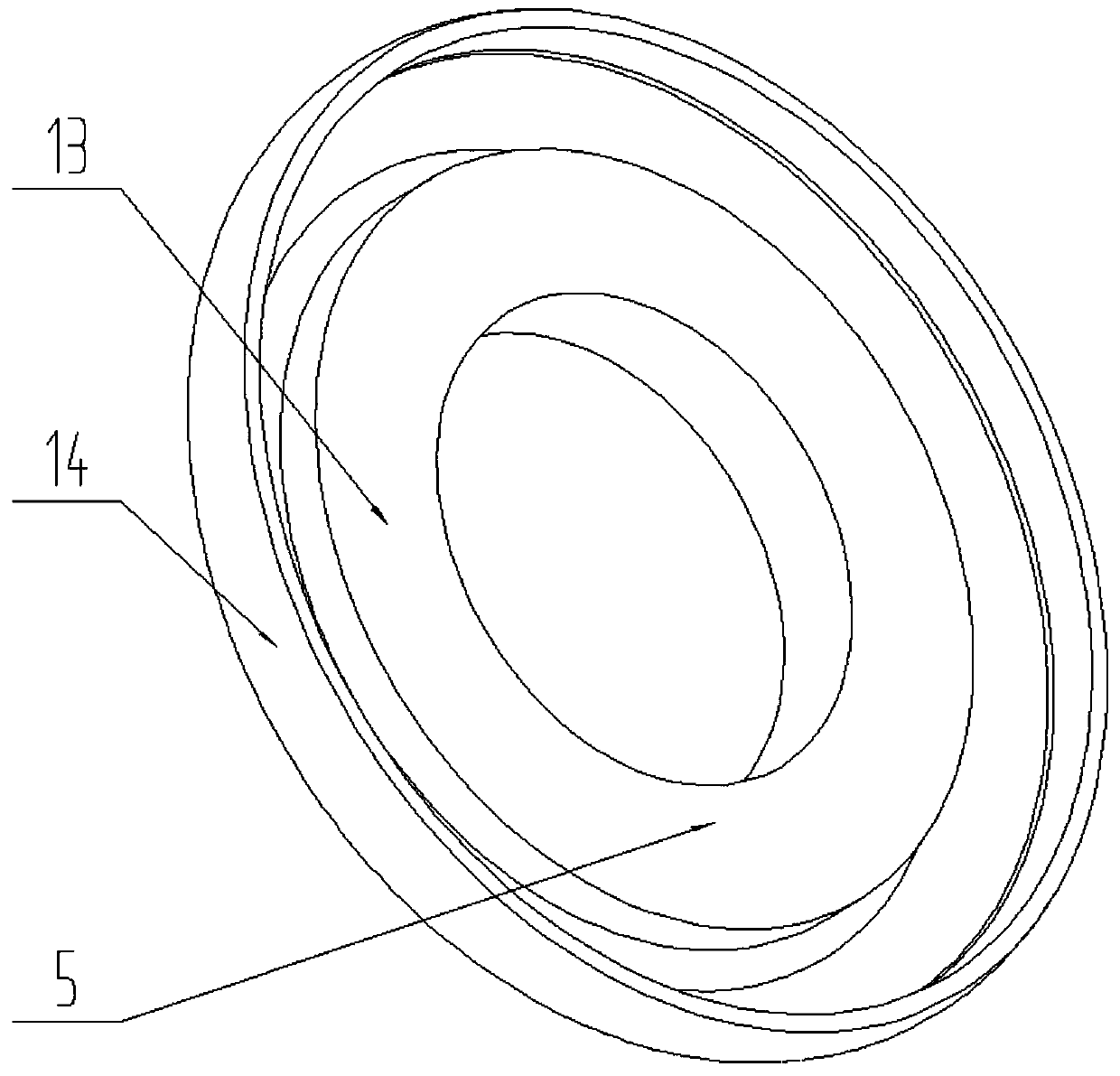

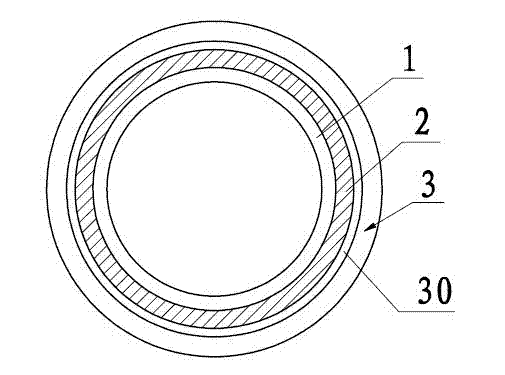

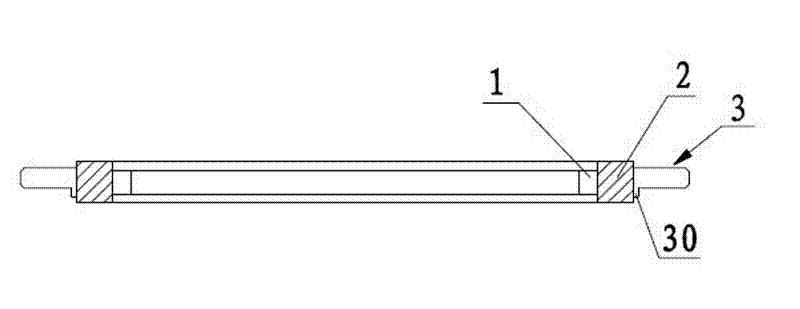

Manufacturing process of polytetrafluoroethylene composite elastic body shim and product thereof

The invention relates to the production of politef multiple elastic cushion, which mainly solves the issues of poor elasticity and strength of the politef production, with smooth surface and good sealing performance. It uses glue smelting, pre compression forming, machining the politef cushion using lathe machine tools, overall surface activation, applying sticking glue, sticking the rubber cushion and the politef shell, sulfur forming, and trimming to get the final product. The cushion comprises rubber cushion coated with politef shell with several protruding waterlines.

Owner:浙江国泰萧星密封材料股份有限公司

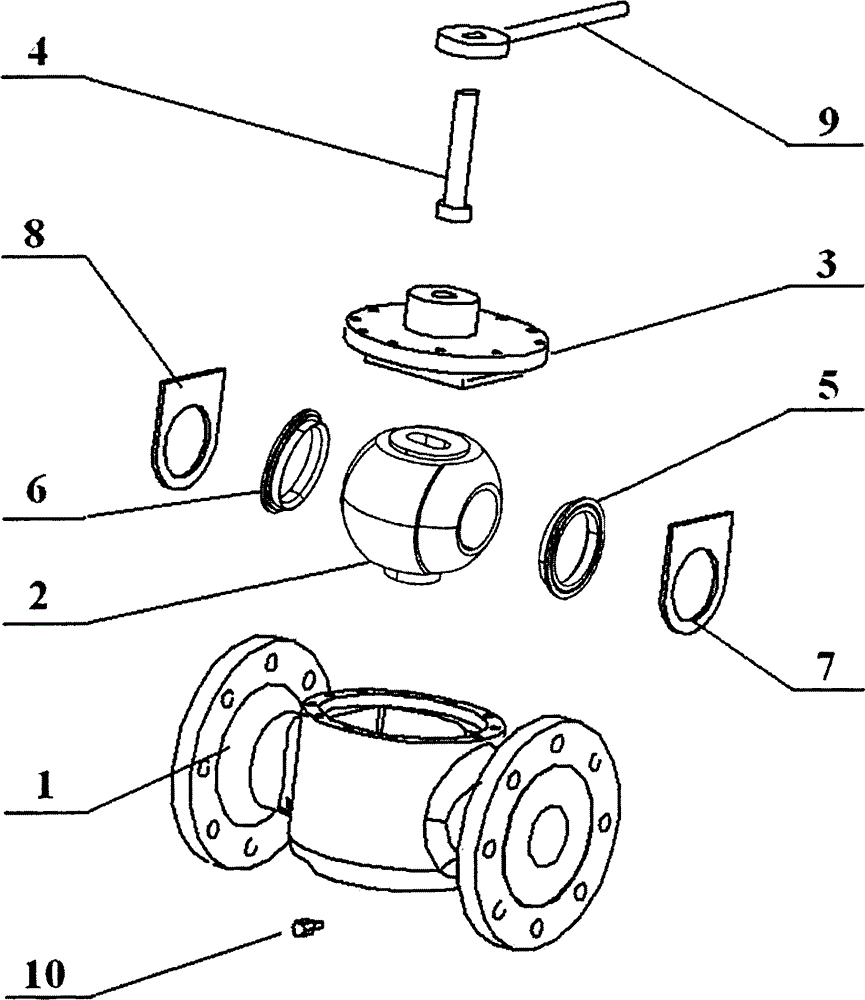

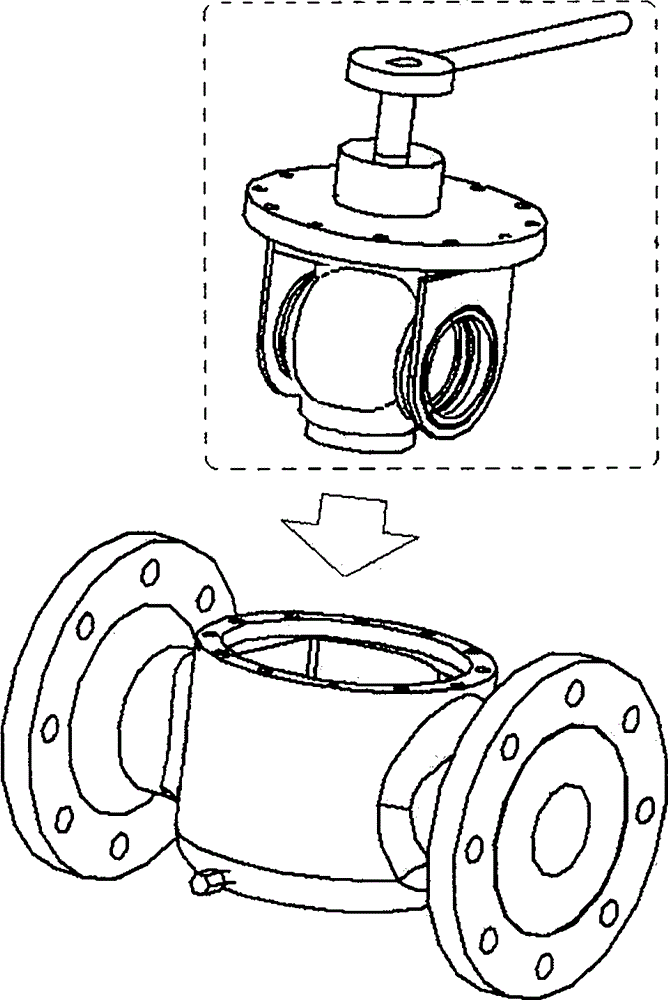

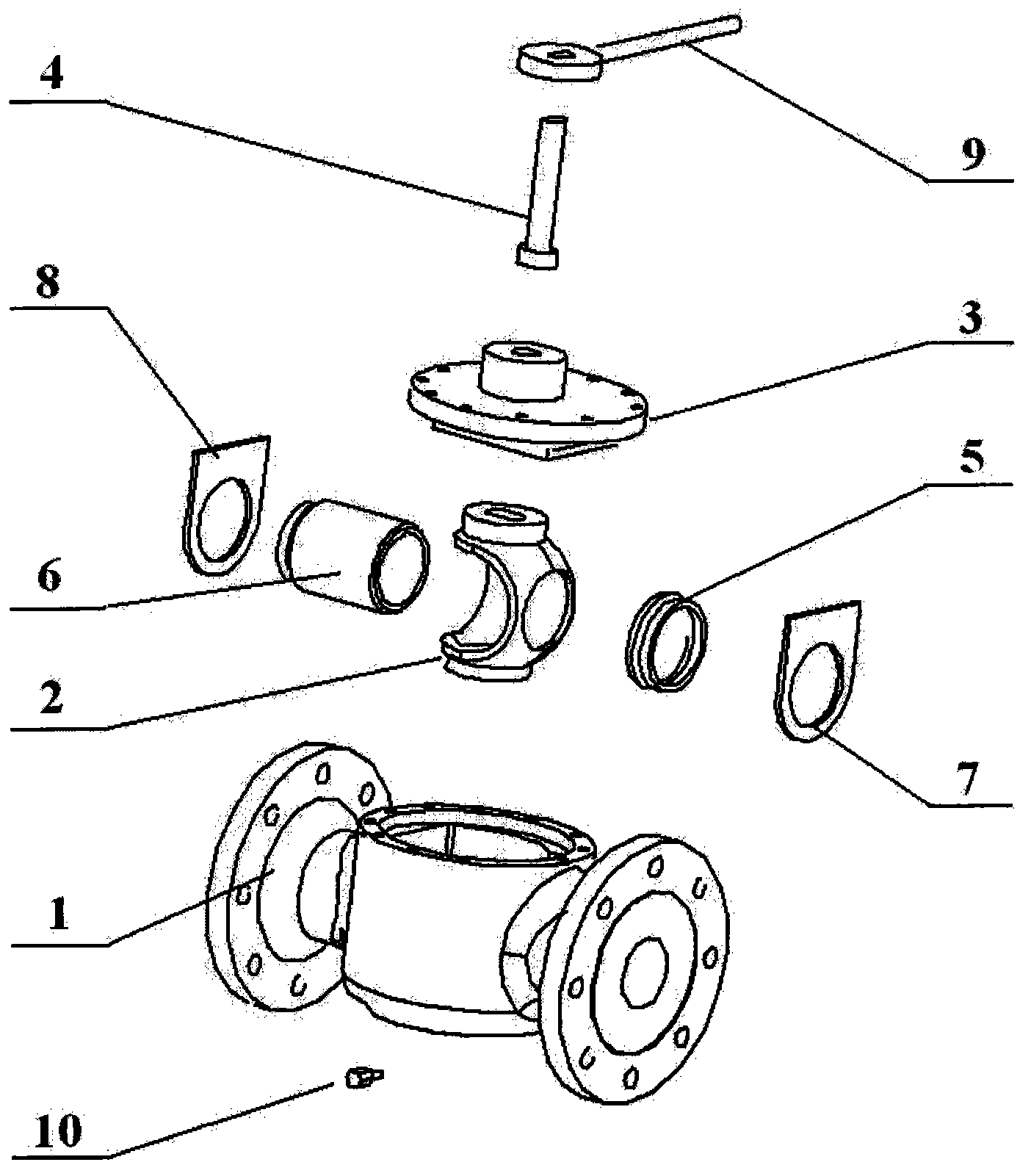

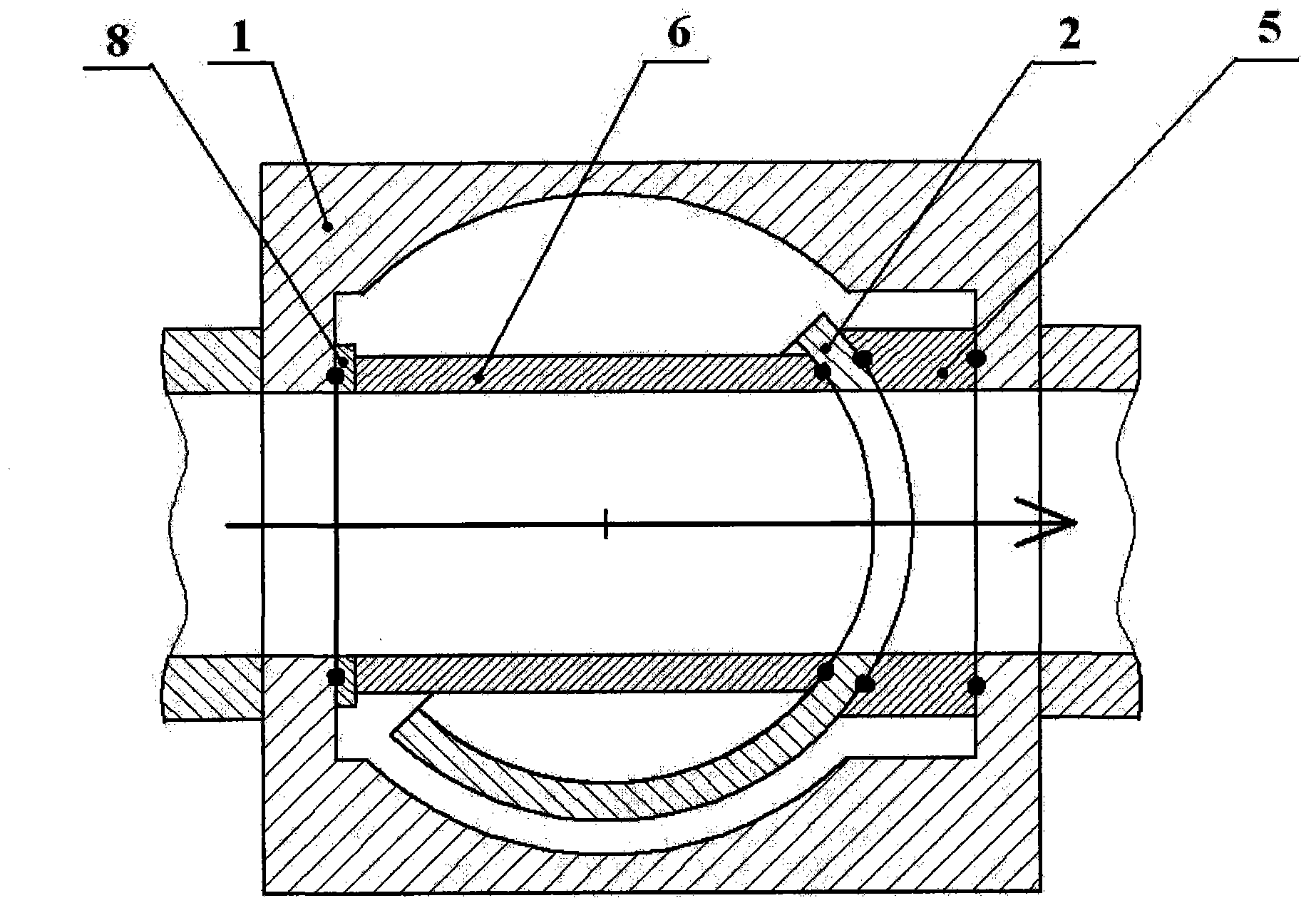

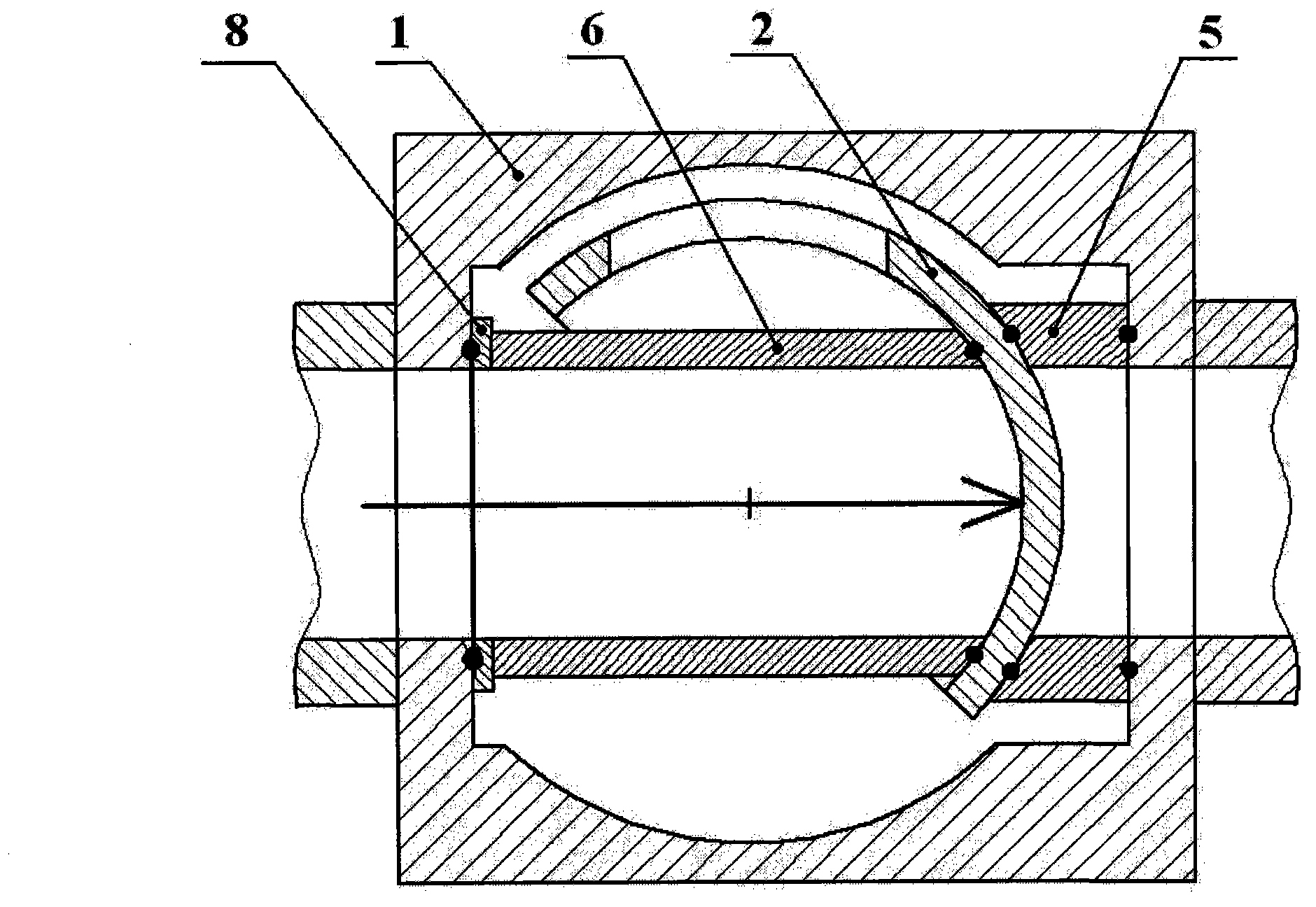

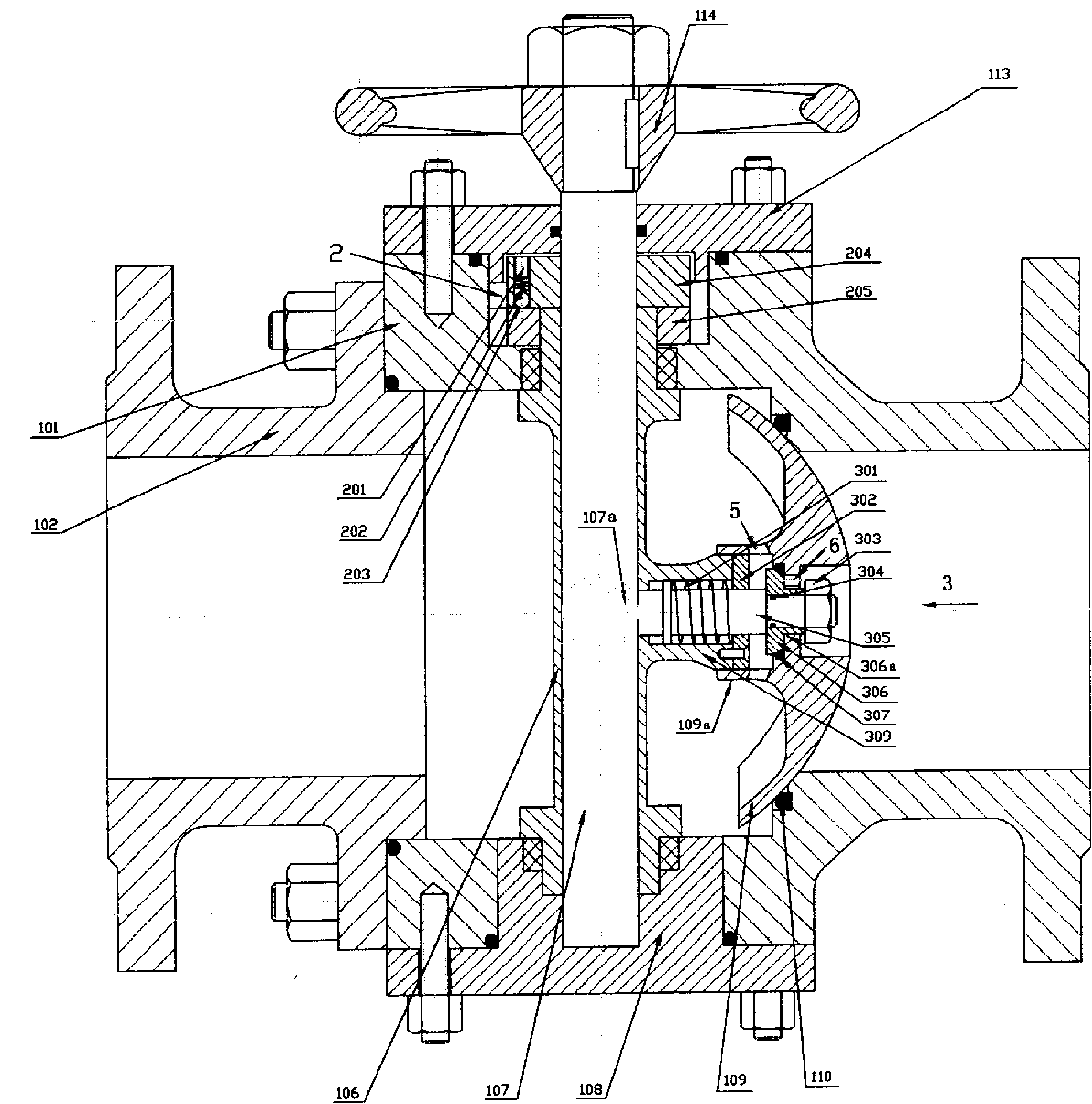

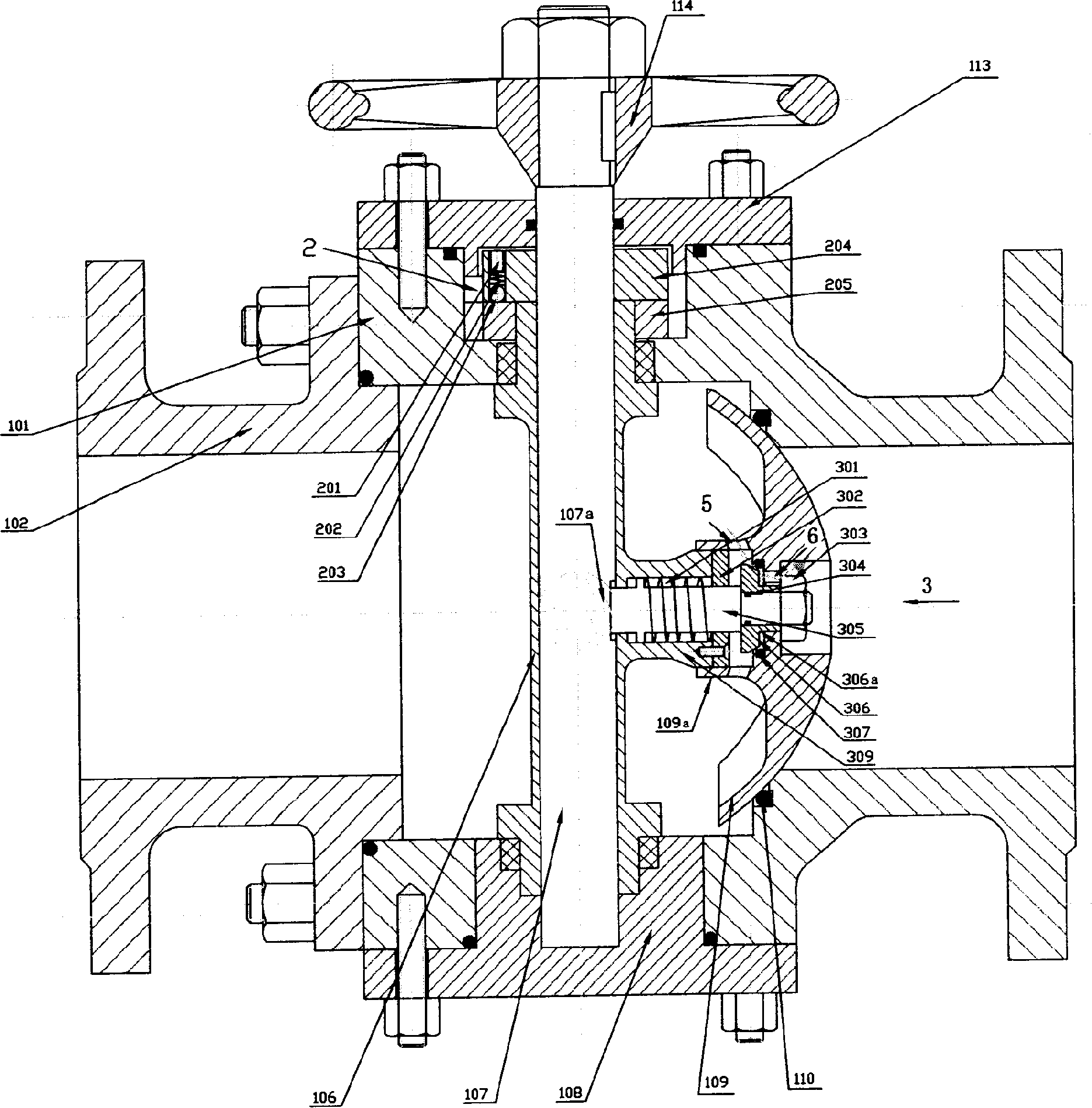

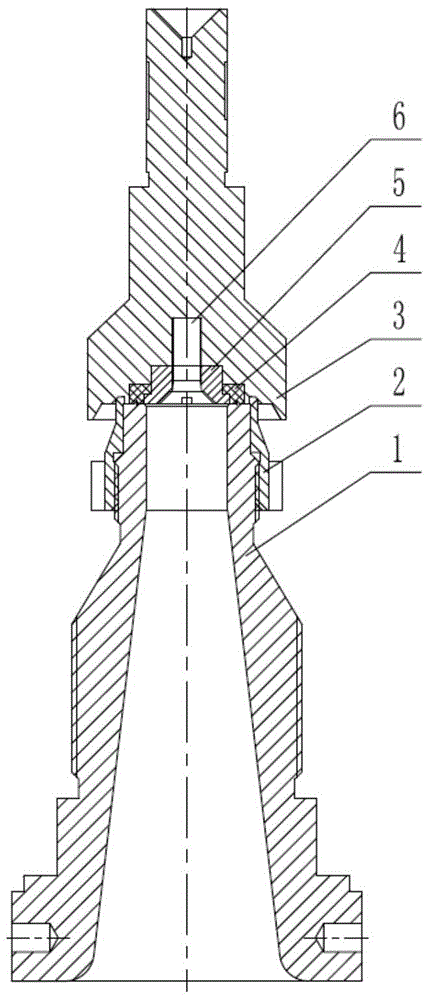

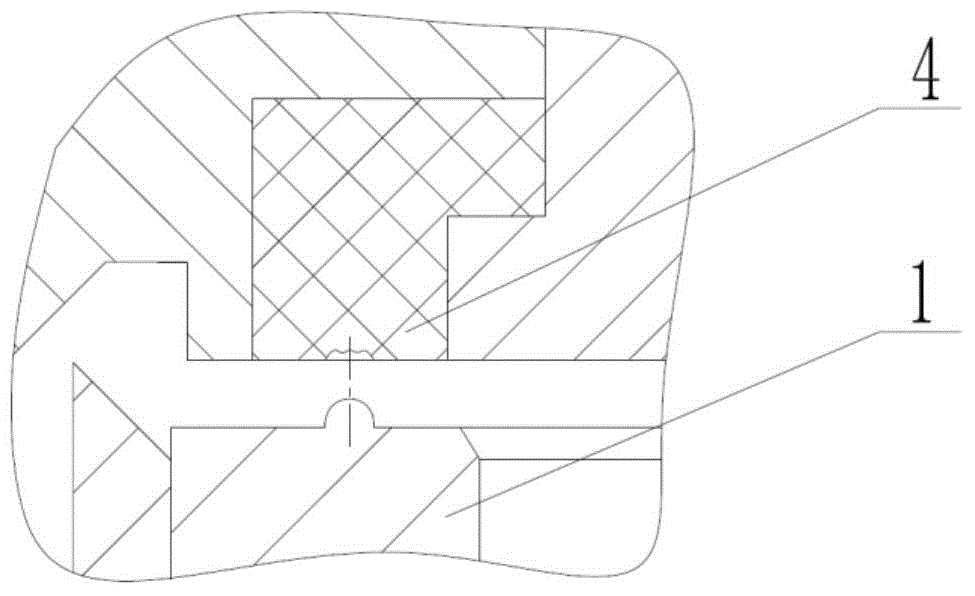

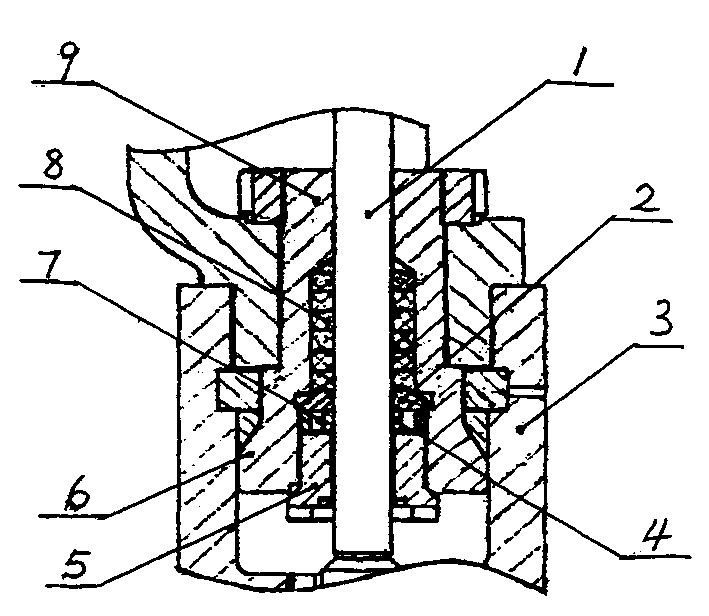

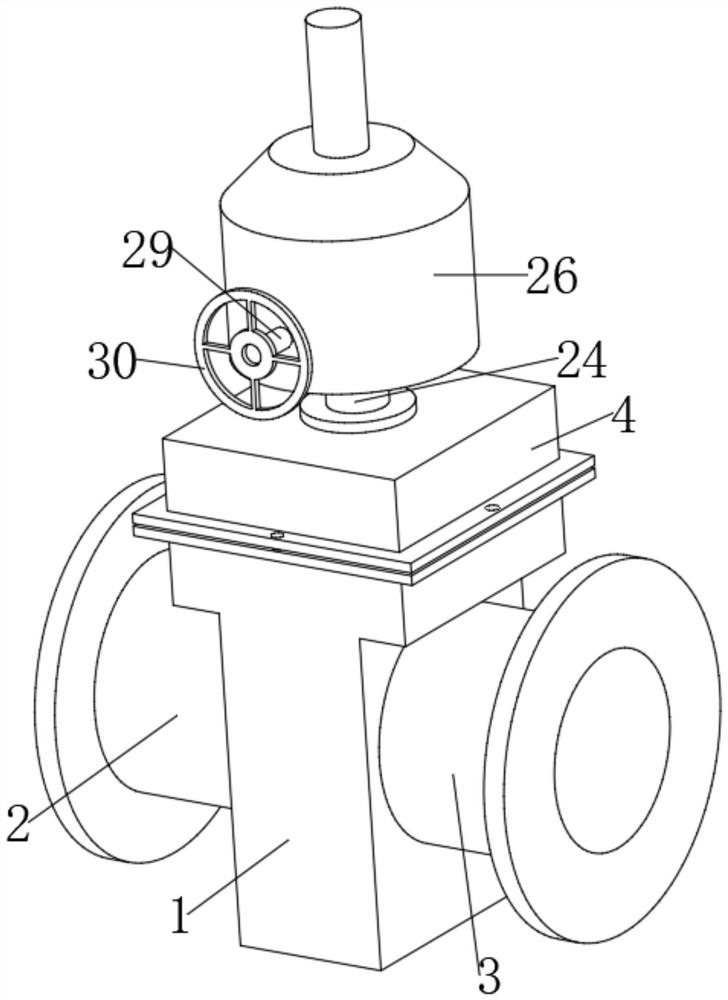

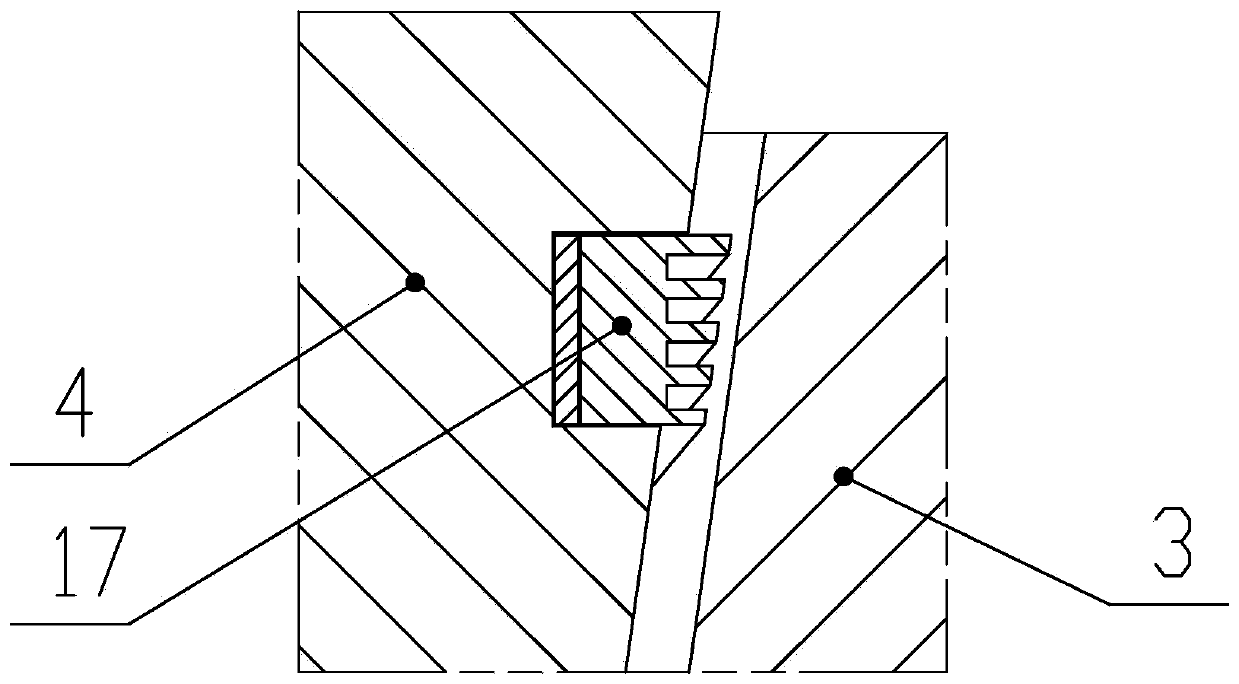

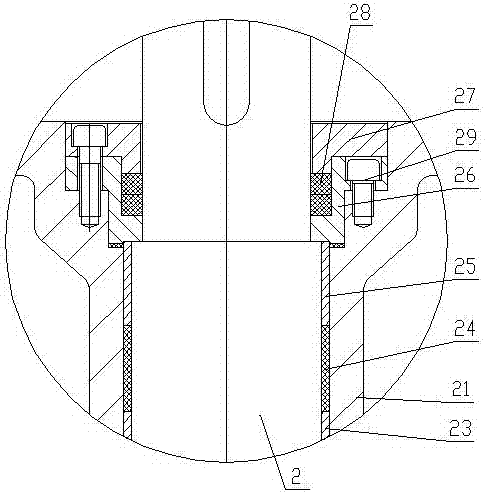

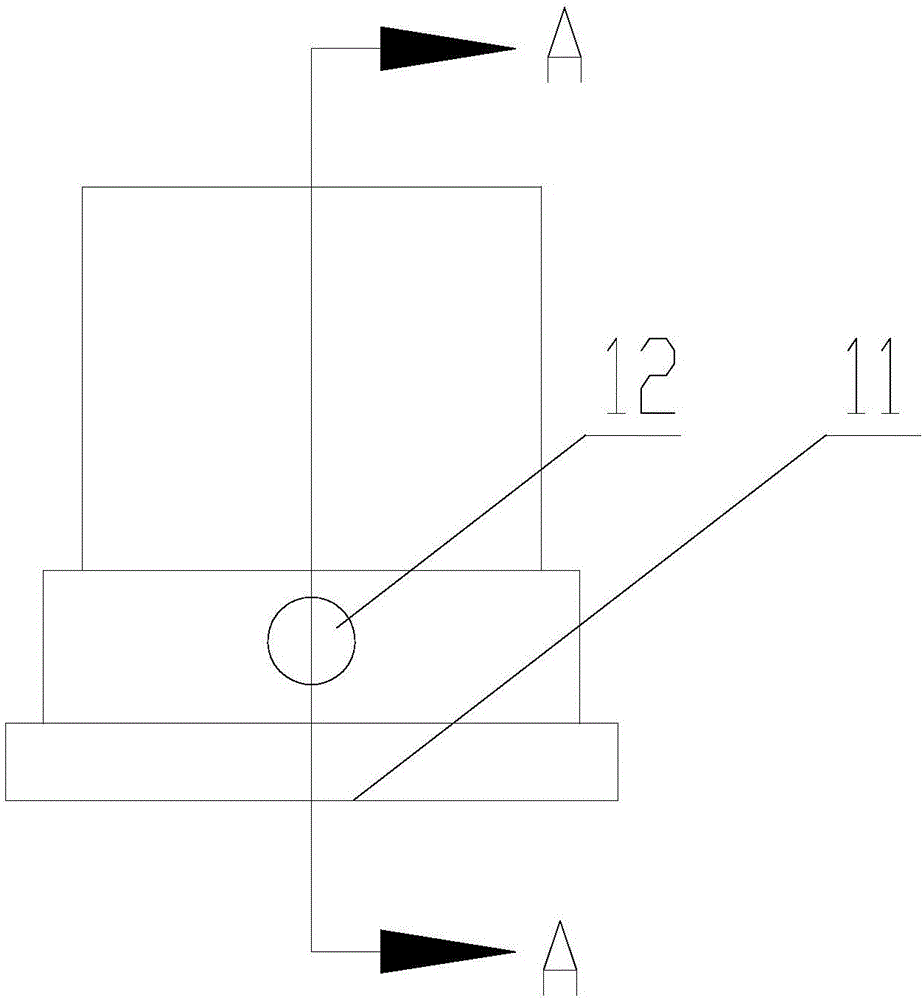

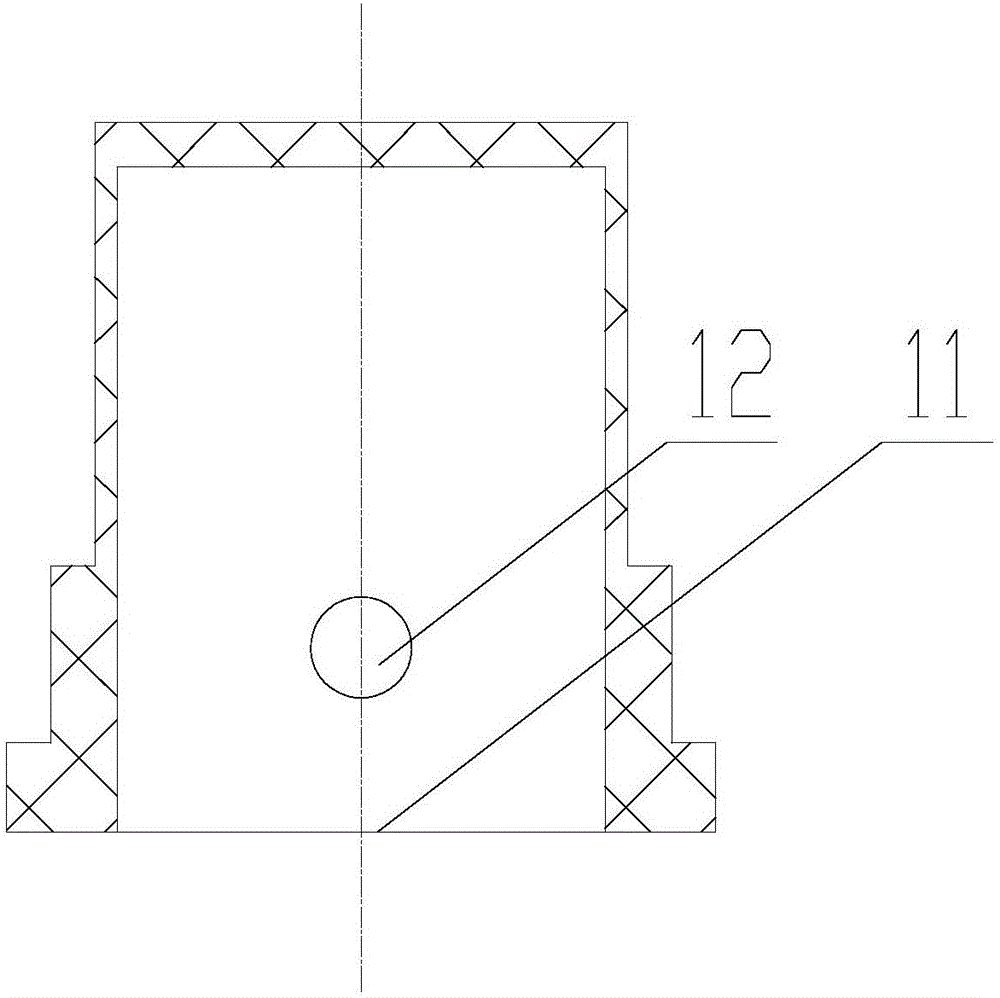

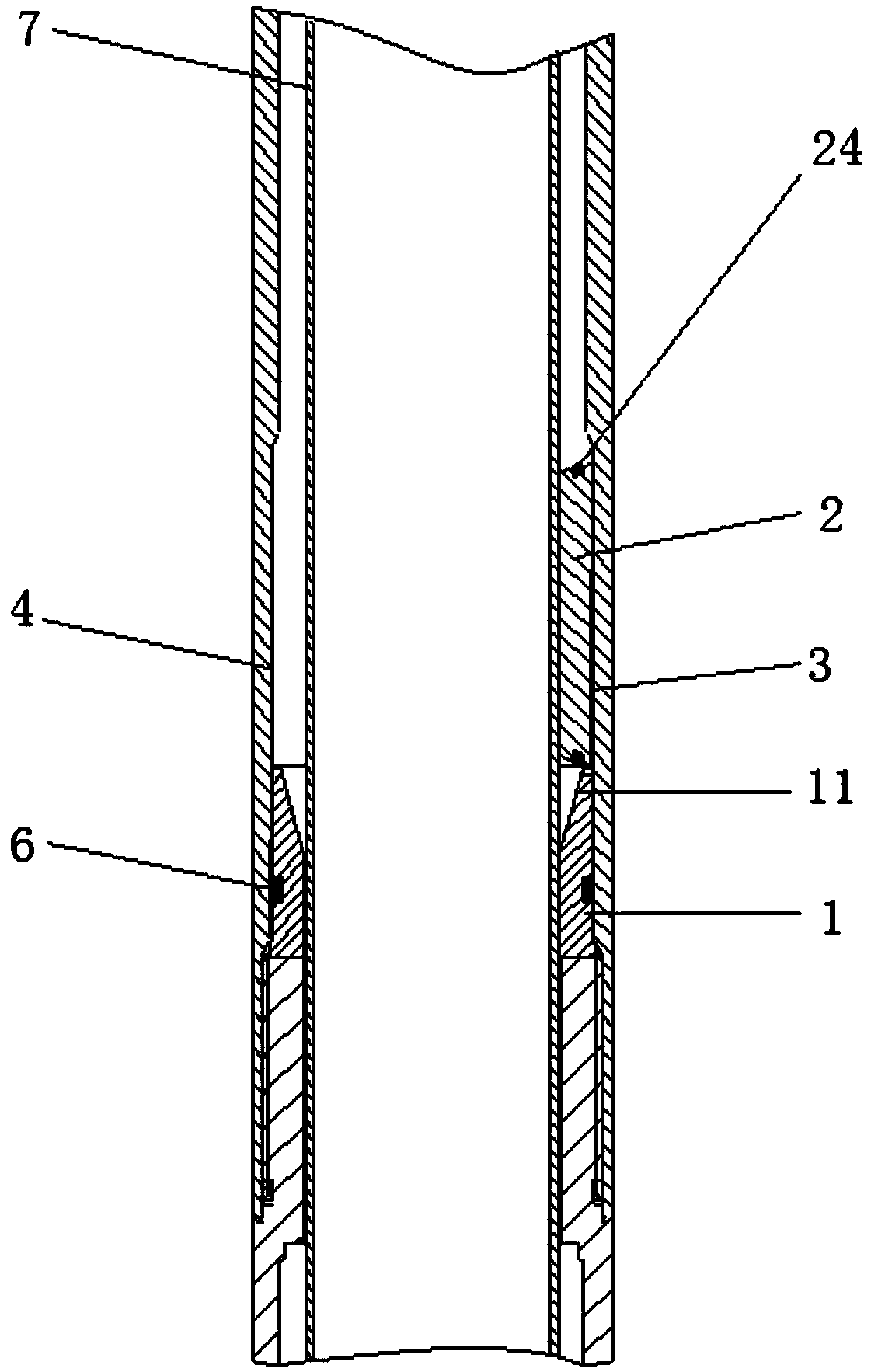

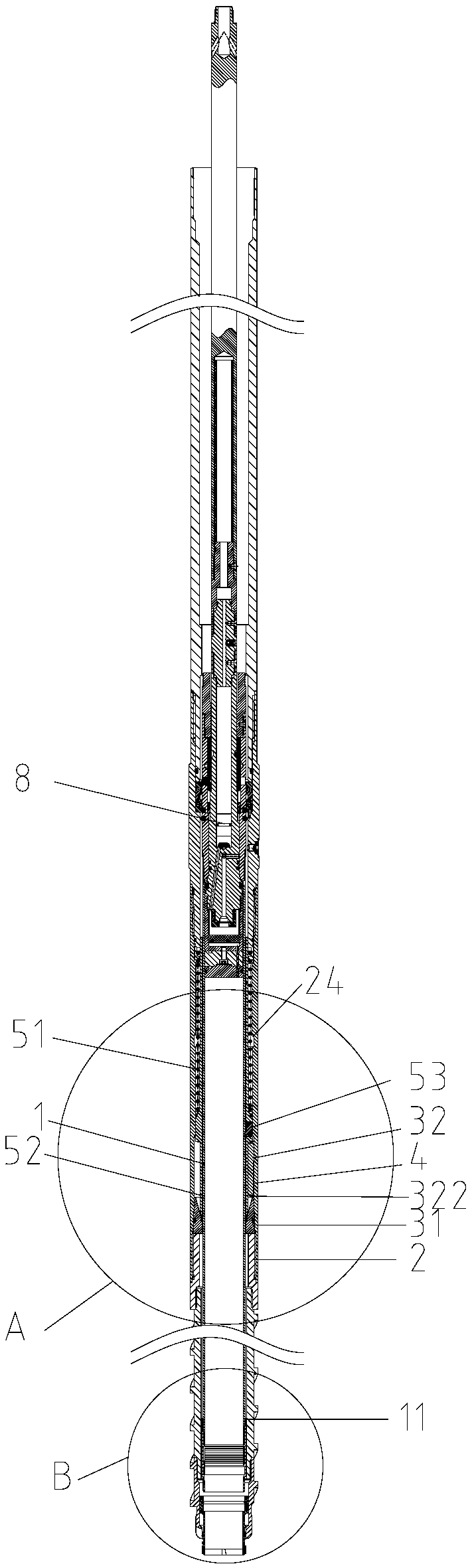

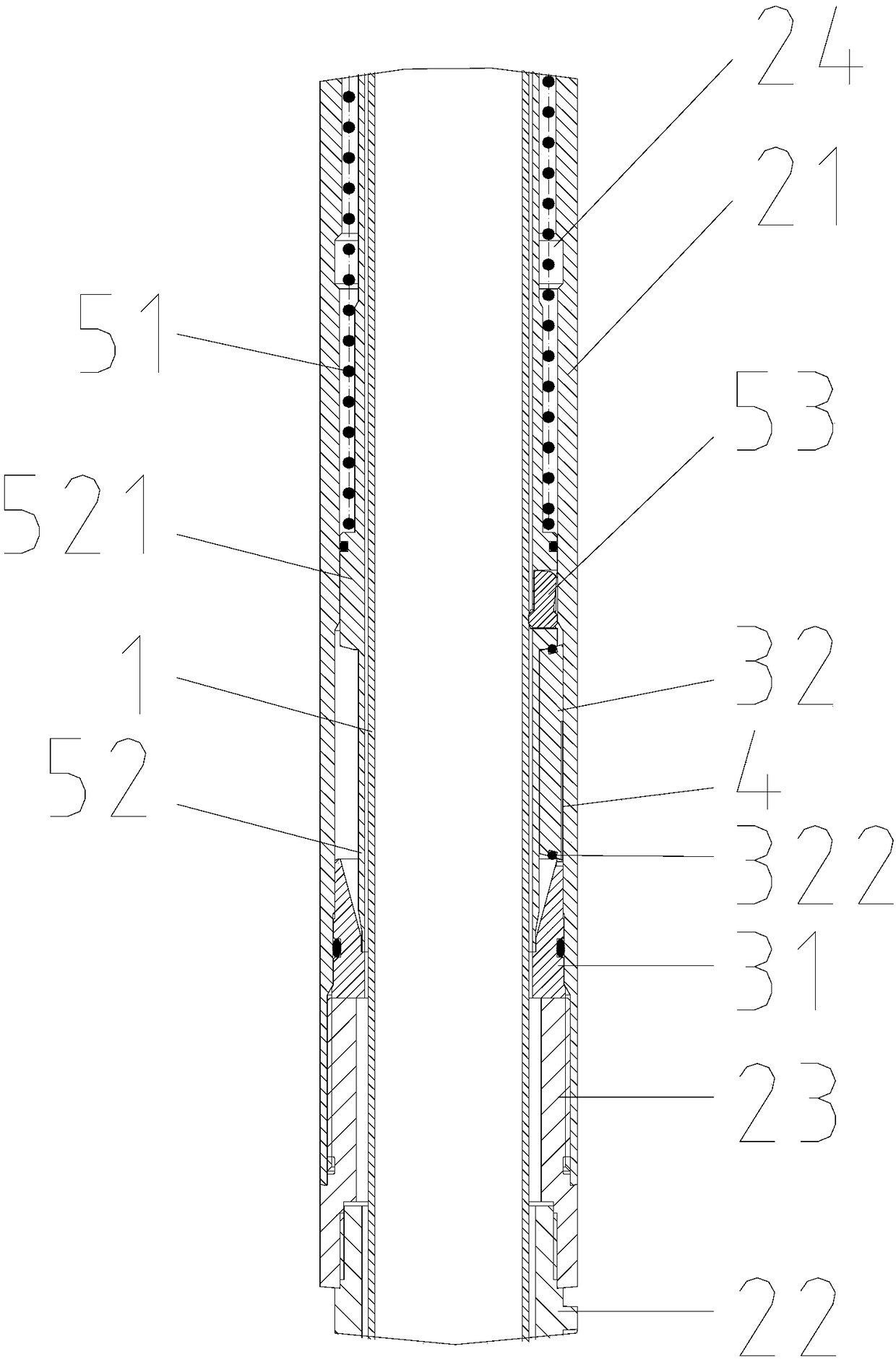

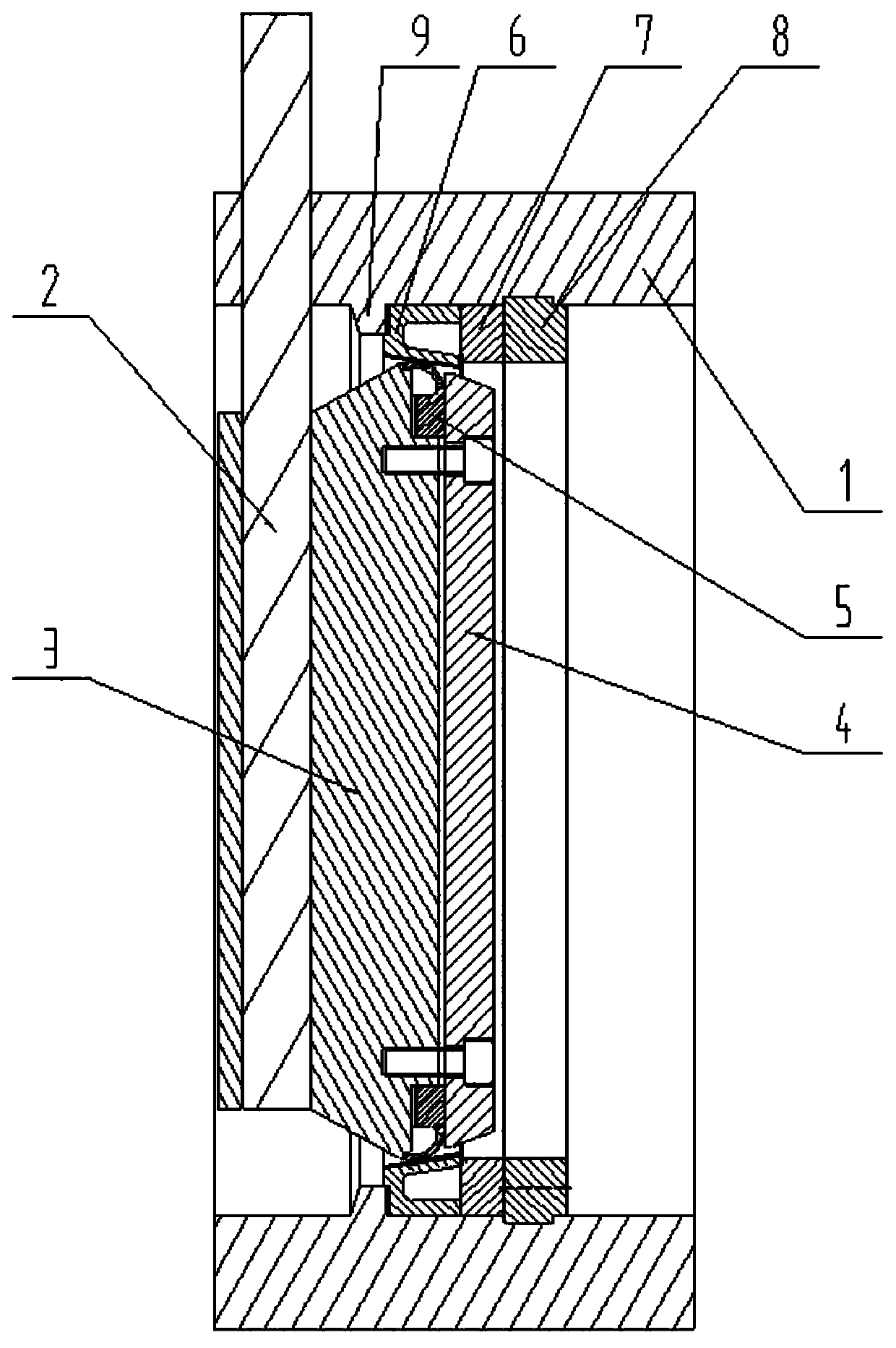

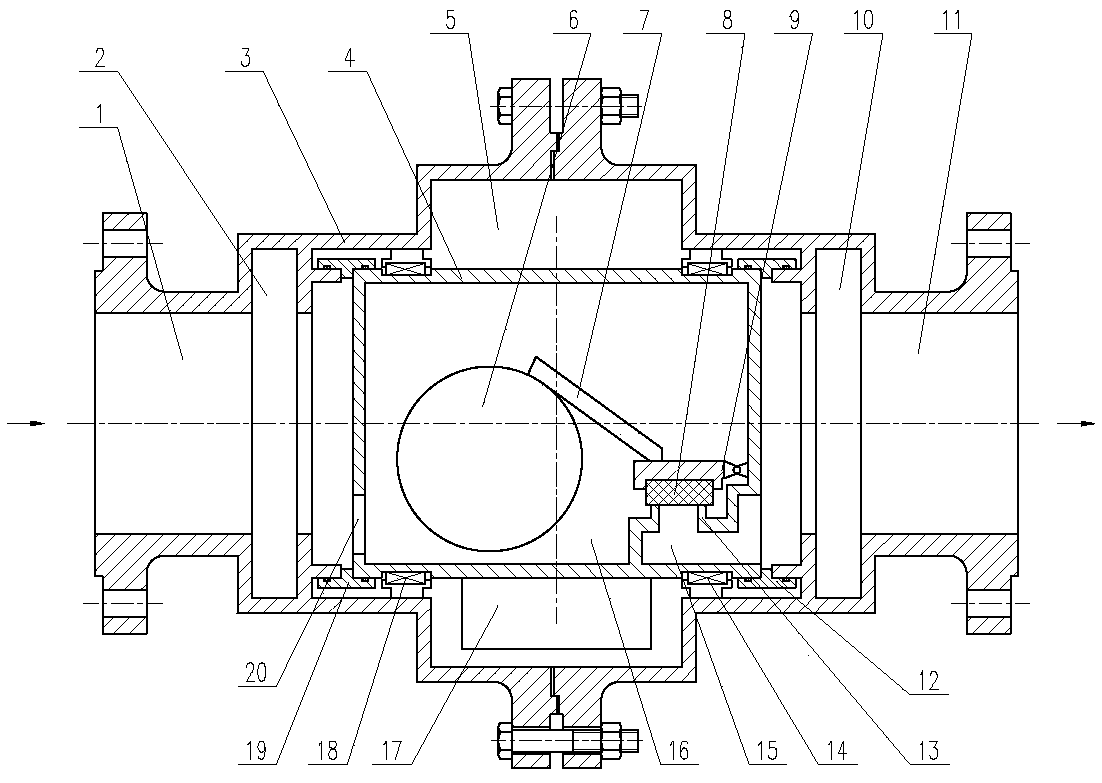

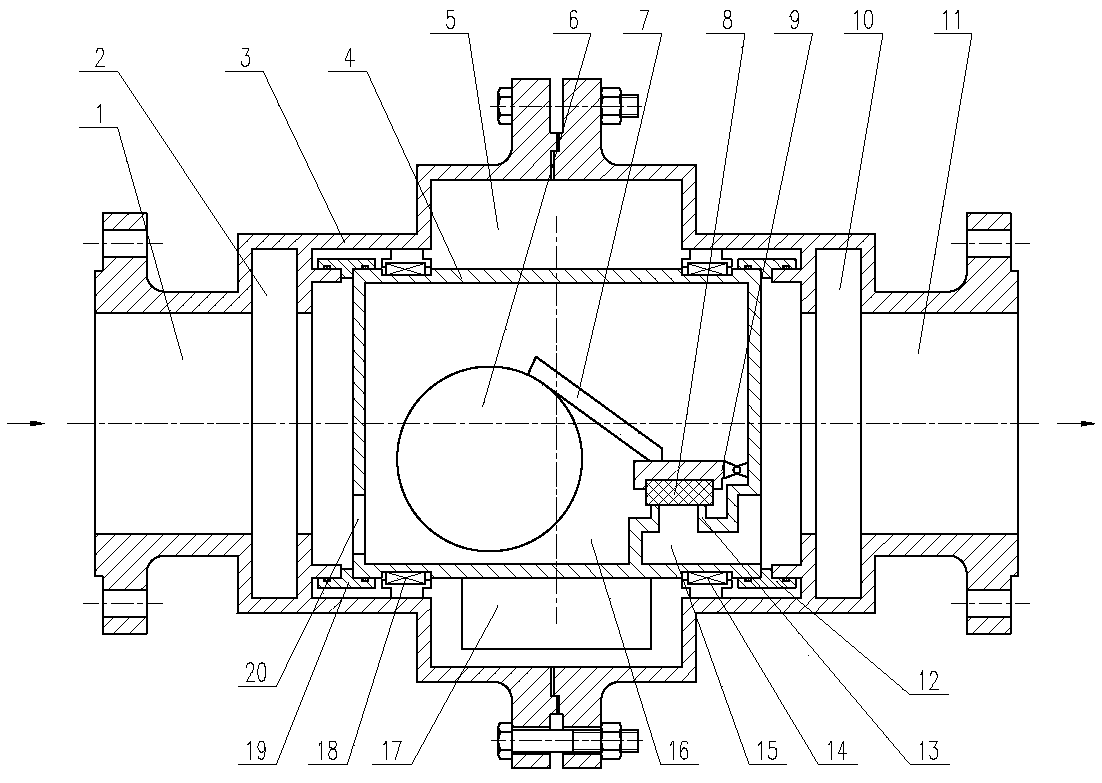

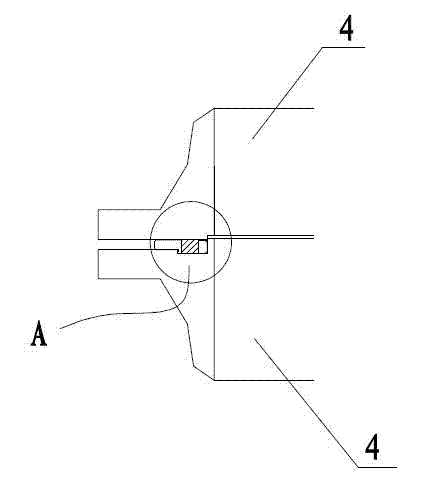

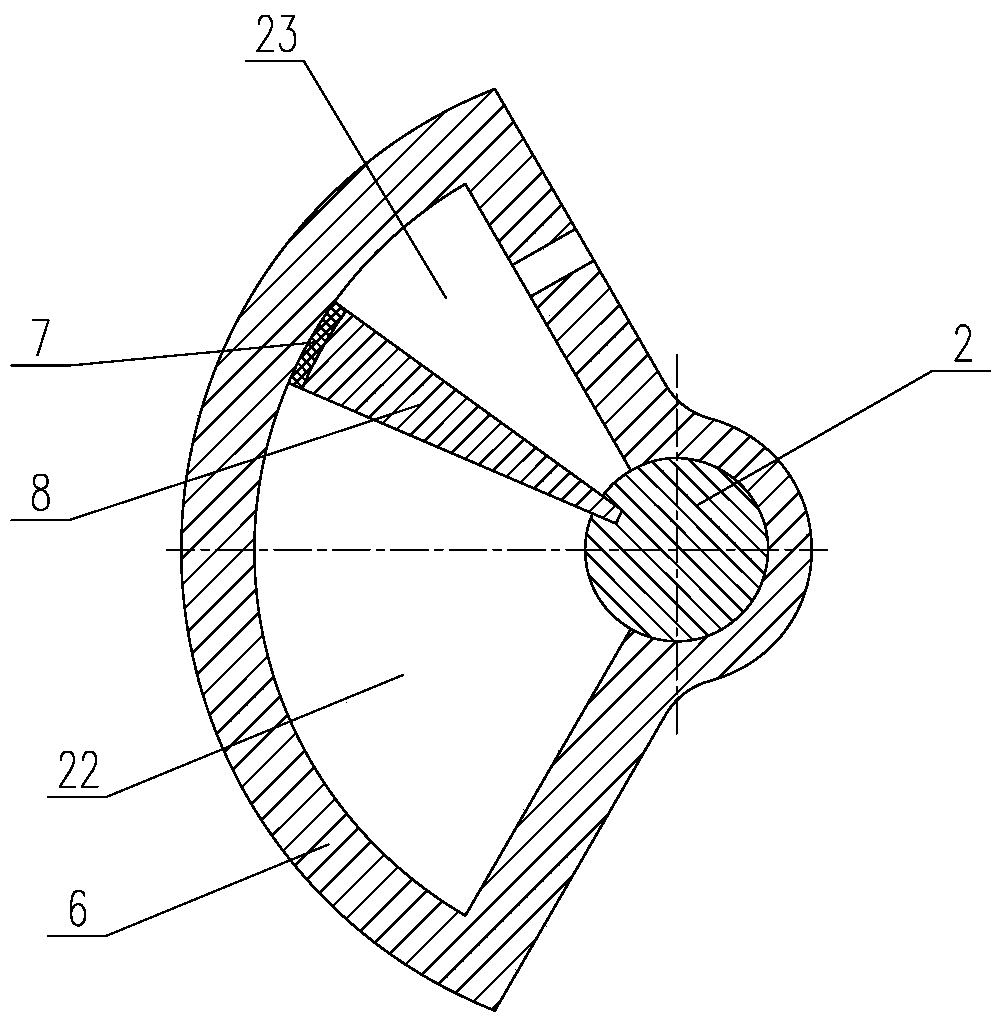

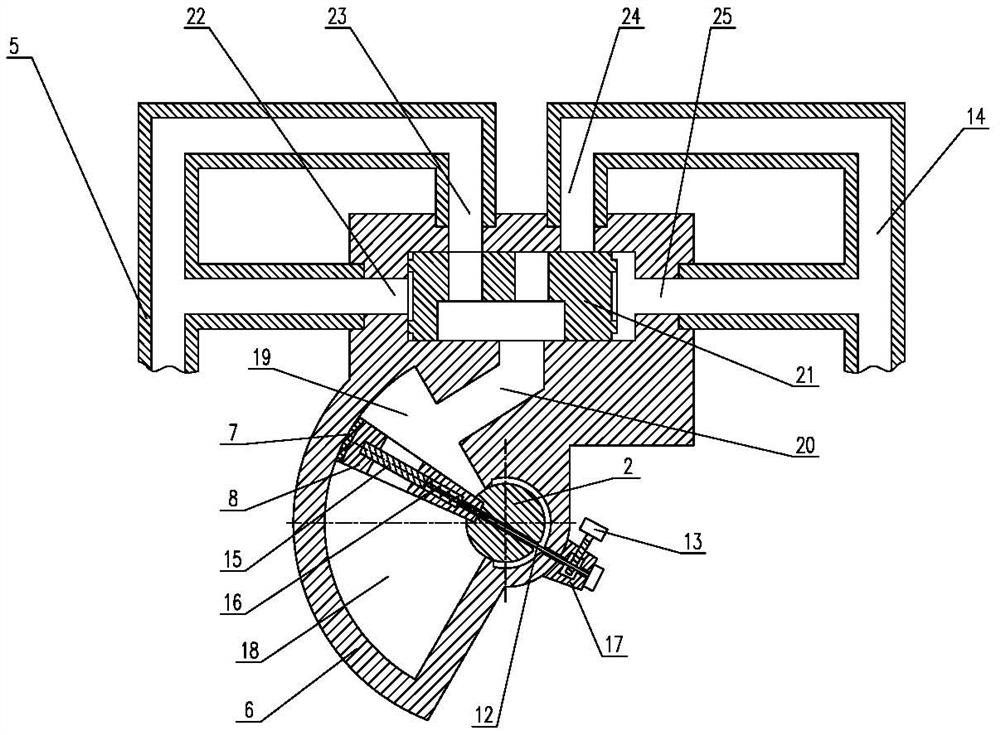

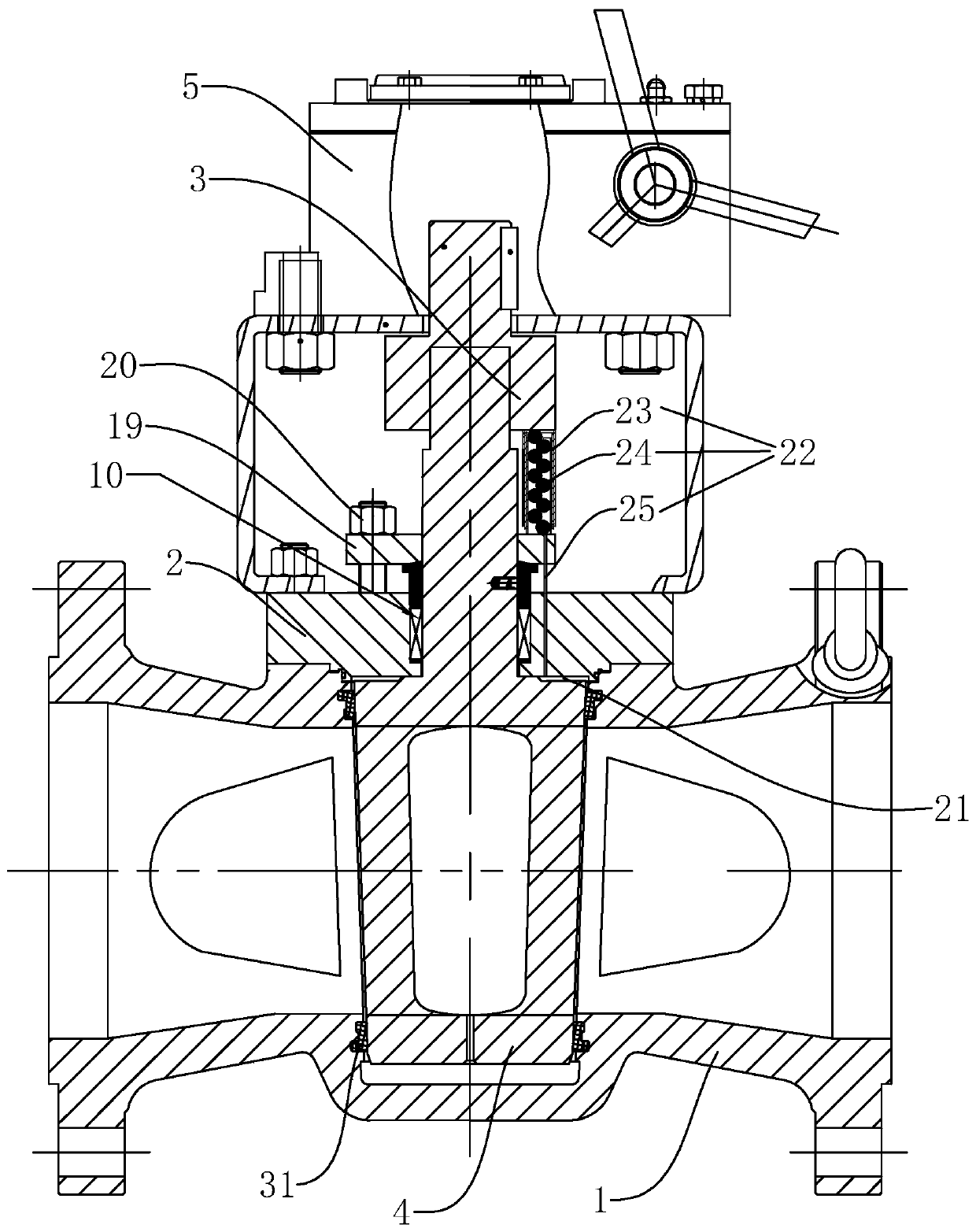

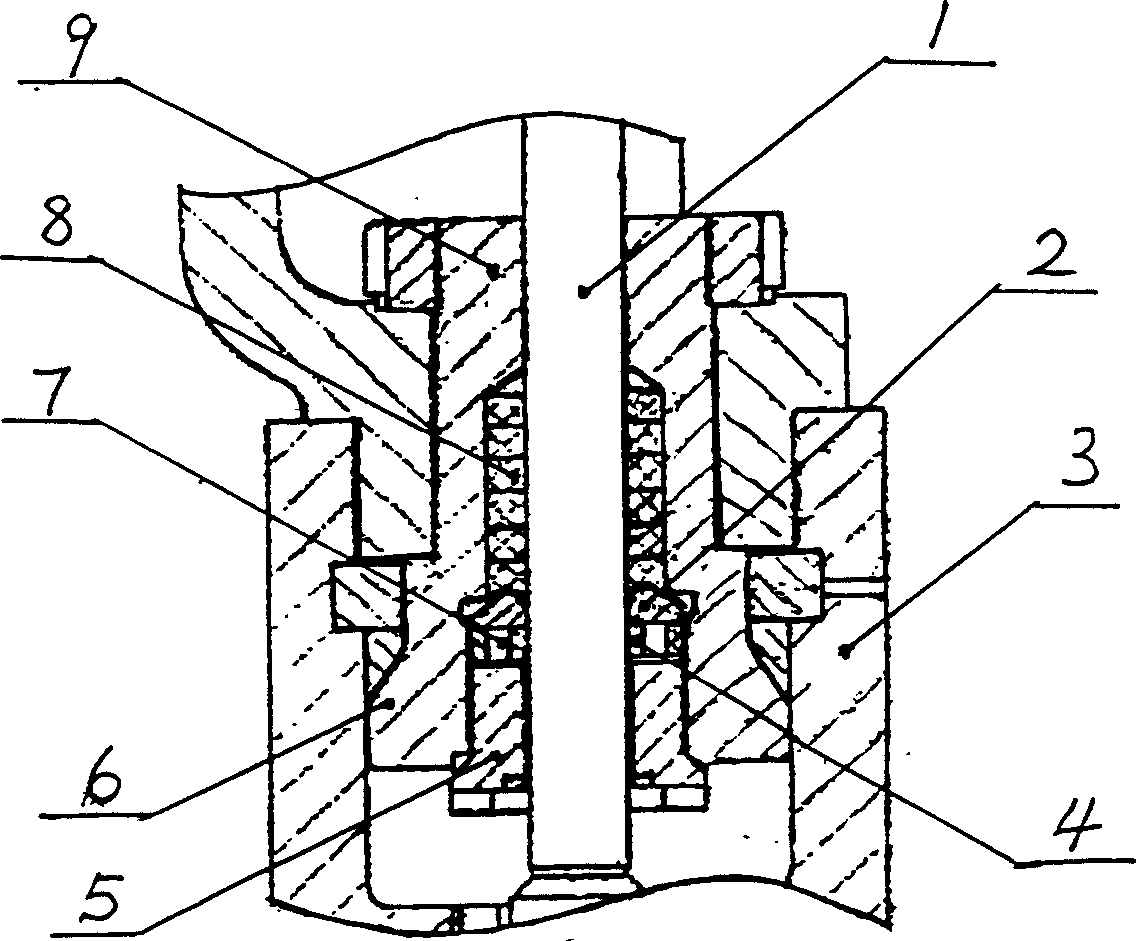

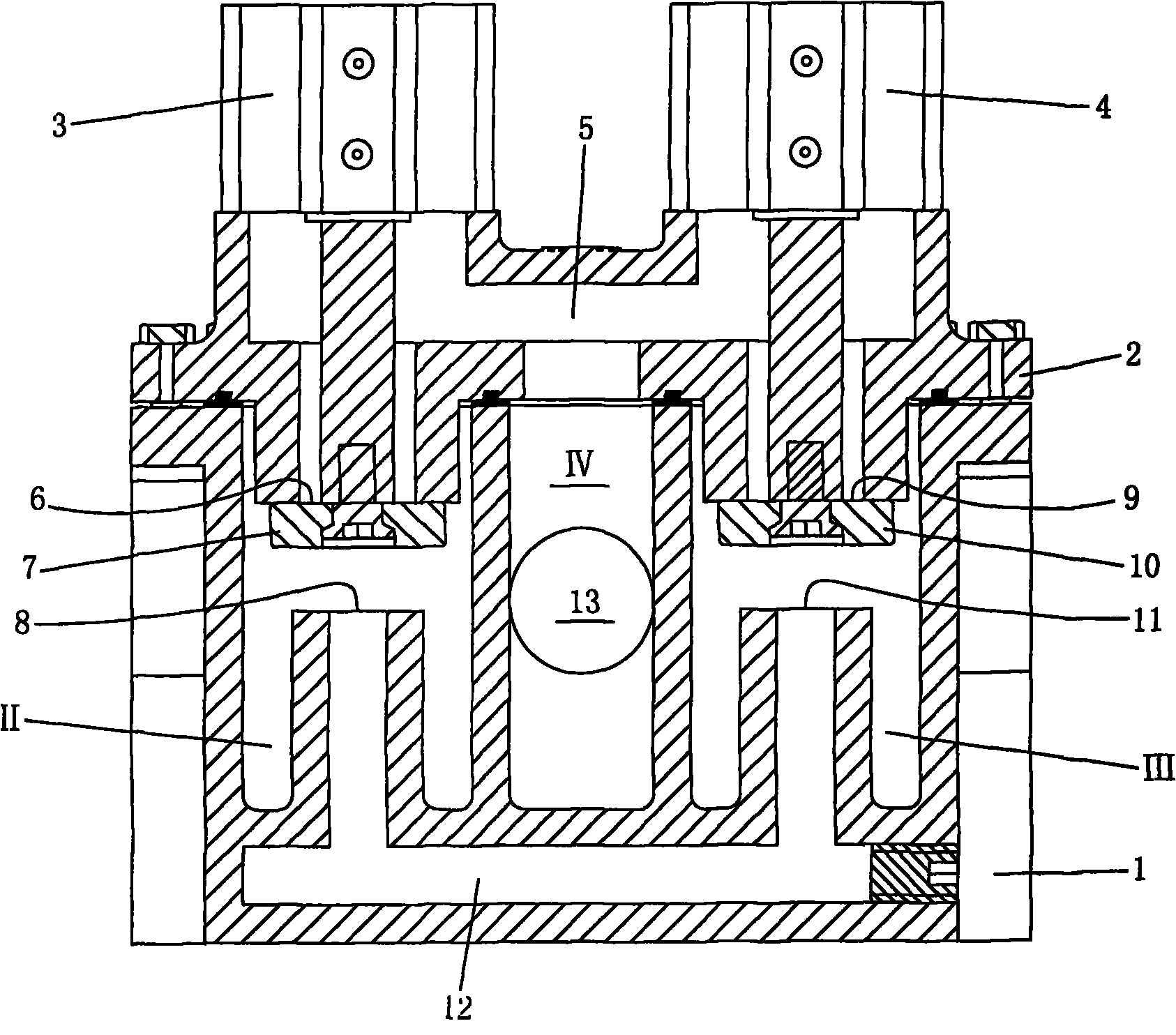

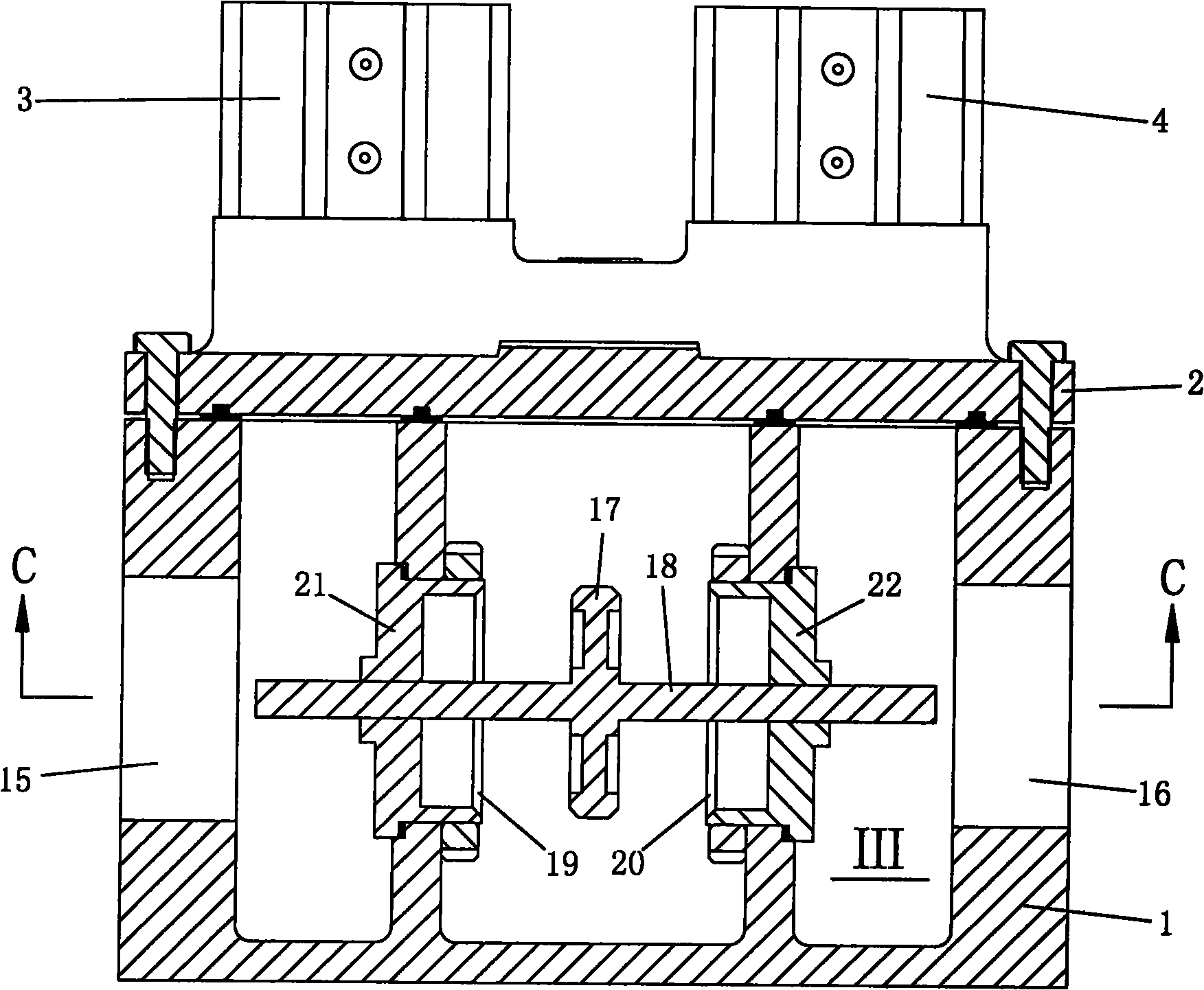

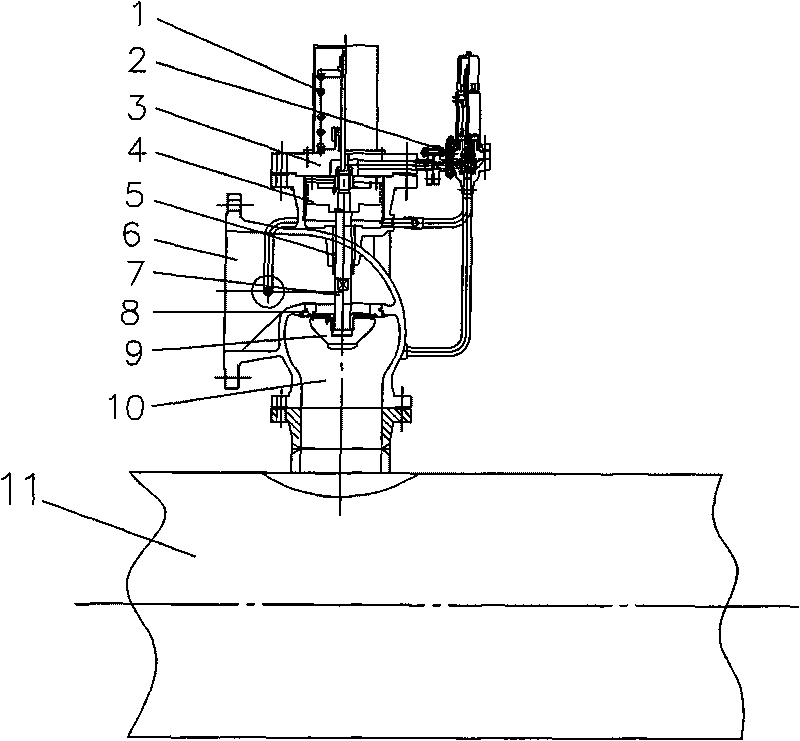

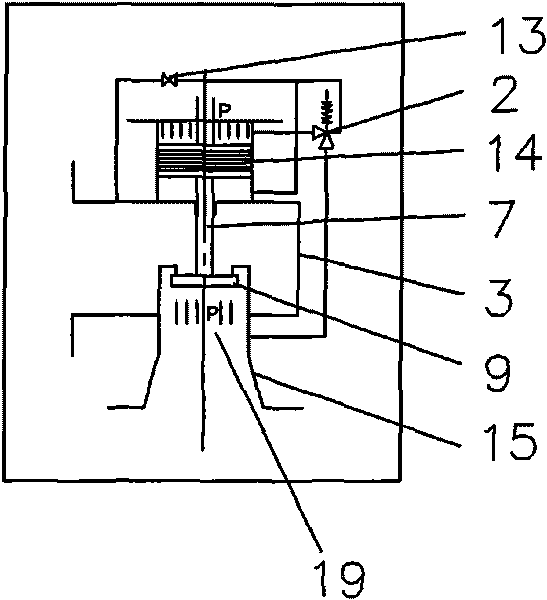

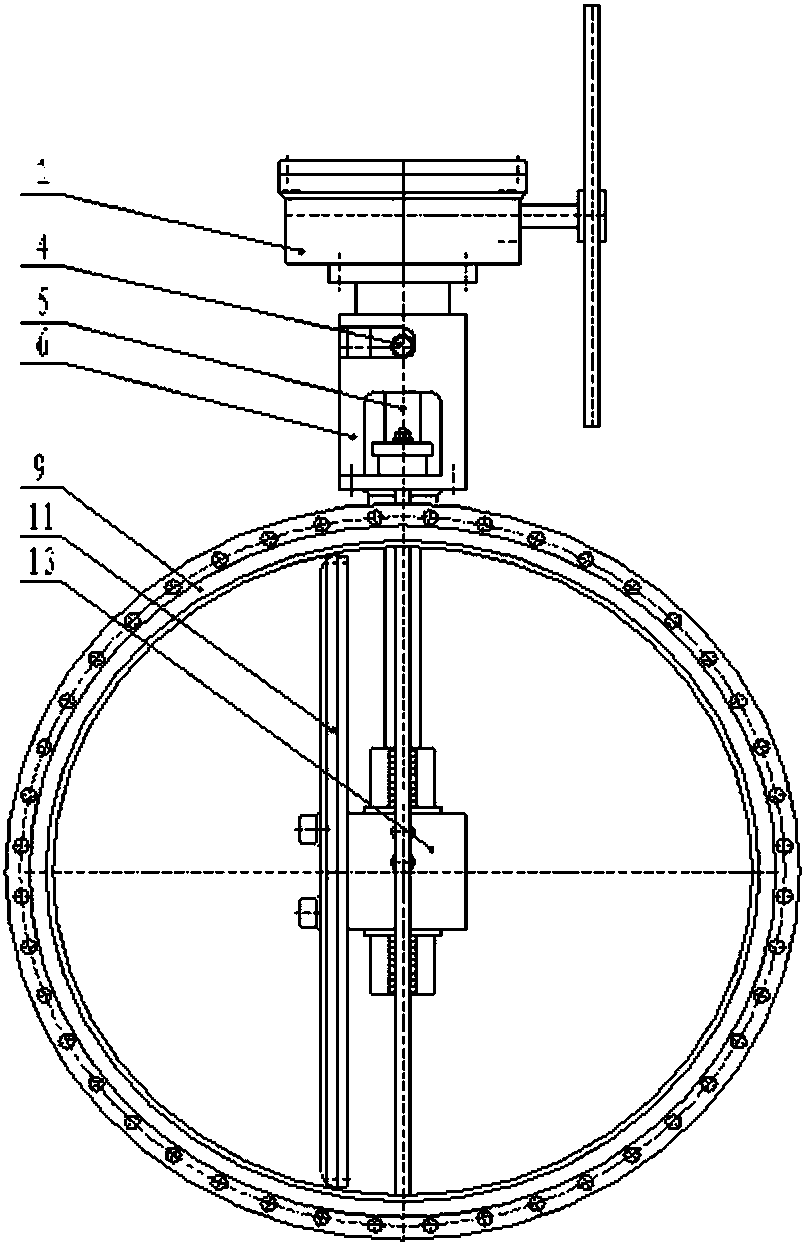

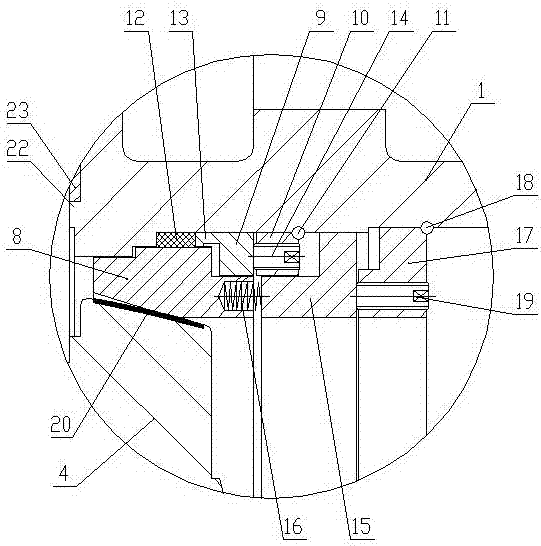

Forced seal valve with modular design and angular travel operation

InactiveCN104132157AIncrease the sealing specific pressureSealing specific pressure is smallPlug valvesComputer moduleModular design

The invention relates to a forced seal valve with a modular design and angular travel operation; and the main parts of the forced seal valve comprise a valve body, an opening / closing piece, a valve cover, a valve rod, a valve base, a guide cylinder, a valve base support plate, a guide cylinder support plate, an operation mechanism and a blow-down valve. The opening / closing piece is arranged between the valve base and the guide cylinder, and the convex surface and concave surface thereof are mutually eccentric spherical surface structures; and the thickness of each place of the opening / closing piece can be adjusted through adjusting the opposite positions of the spherical centers of the convex spherical surface and the concave spherical surface, so that the seal specific pressure between the opening / closing piece and the valve base can be adjusted when the valve is positioned in different valve positions, and the valve can be forcedly sealed in several valve positions. In addition, the opening / closing piece, the valve rod, the valve base, the guide cylinder, the valve base support plate, the guide cylinder support plate and the valve cover can be produced to one module; and after a fastening piece for connecting the valve cover with the valve body is dismantled, the whole module can be pulled out from the valve, so that the wearing parts of the valve are modularly replaced.

Owner:JIANGSU RELIABLE MECHANICAL EQUIP CO LTD

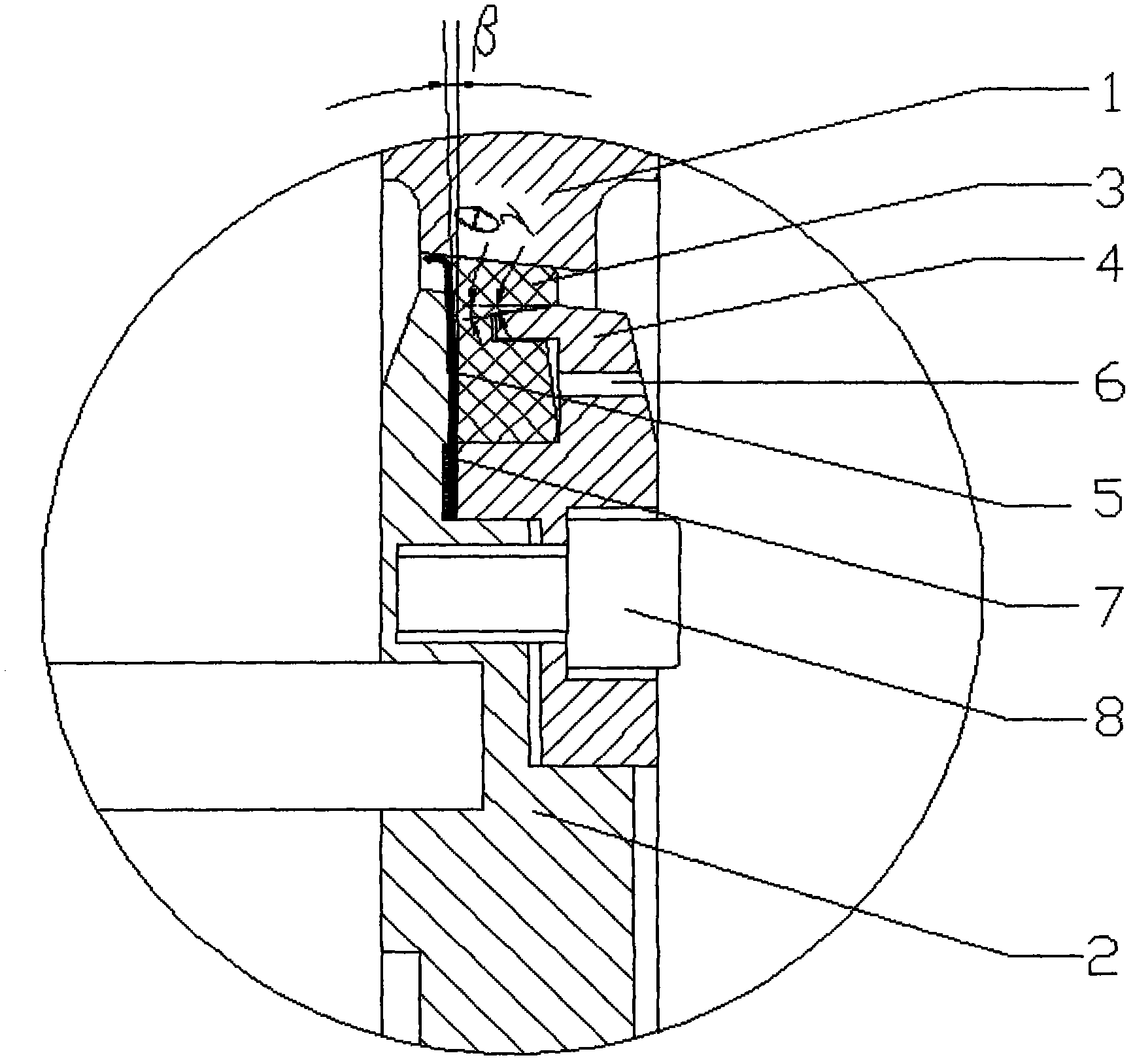

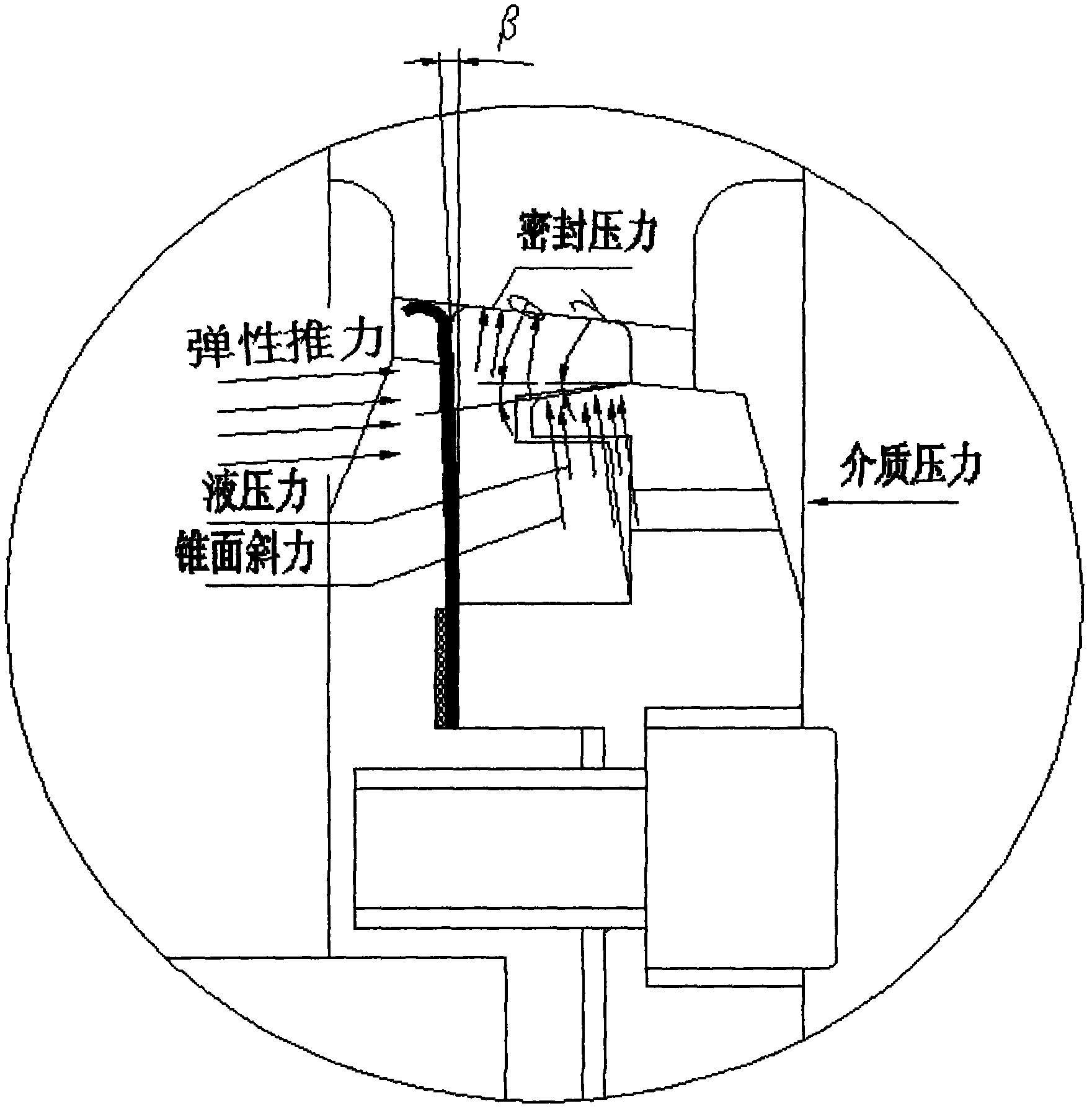

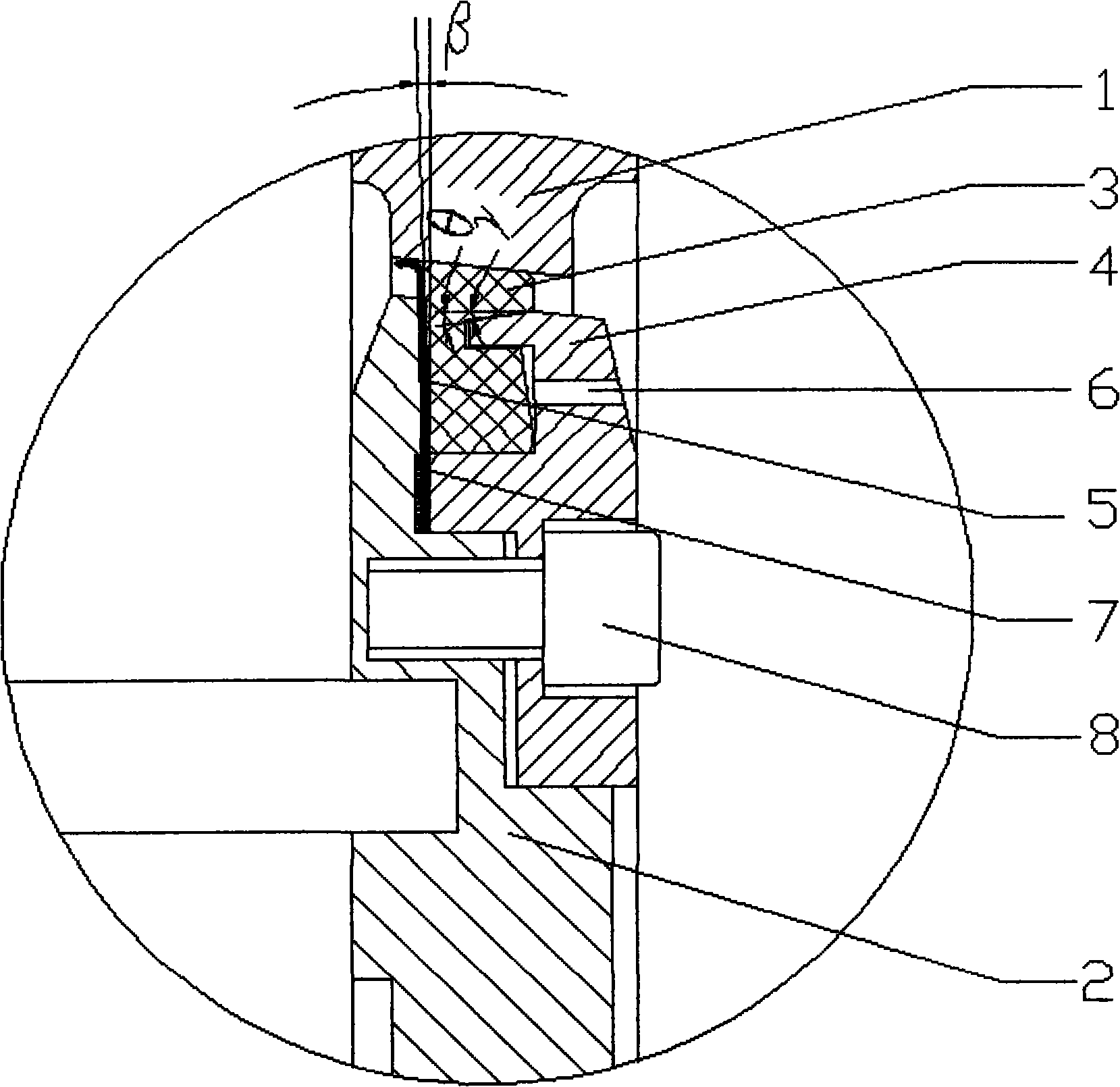

Two-way pressure-bearing fluororubber fireproof butterfly valve

The invention relates to a two-way pressure-bearing fluororubber fireproof butterfly valve, which comprise a valve body and a butterfly plate. The valve body is provided with a valve seat; the butterfly plate is provided with a sealing ring which forms a sealing pair with the valve seat, and a pressing plate which clamps and fixes the sealing ring on the butterfly plate from the right side of thesealing ring; the sealing surface of the sealing ring is a front conical surface of which the apex is positioned on the right side; a closed internal gap of a cavity is formed between the sealing ring and the pressing plate; the pressing plate is provided with a pressure guide through hole for communicating the cavity with a space on the right side of the pressing plate; the left side face of thesealing ring is an internal conical surface of which the apex is positioned on the right side and a bus and a central line form an included angle of 90 degrees to beta; and an elastic fireproof ring is arranged in a gap area between the left side face of the sealing ring and the butterfly plate. Through designs of the cavity, the pressure guide through hole and the elastic fireproof ring, the butterfly valve integrates various functions of two-way sealing, fire prevention and fine adjustment, has a simple structure, high manufacturability, low processing difficulty and a wide pressure application range, and is particularly suitable to be used under high pressure.

Owner:SUNGO VALVES GRP CO LTD

Valve

InactiveCN1654866ADifferential pressure decompressionReduce pressure differencePlug valvesOperating means/releasing devices for valvesEngineeringCam

This invention relates to a valve, which comprises main valve with upper and down holes, valve petal, valve bar and handle wheel fixed or electric device and assistant structure. It is characterized by the following: the said valve bar comprises main axis and assistant axis; the valve bar main axis is located with one bias wheel and one guiding valve with hole on one side of the assistant axis; the guiding valve is located with one guiding valve. Due to the guiding valve, the whole valve shall not contact with sealed ring during rotation process to avoid friction force.

Owner:金庆明

Bi-directional sealing elastic tri-eccentric butterfly valve

InactiveCN102943885AEven by forceLow friction and torqueSpindle sealingsLift valveEngineeringButterfly valve

The invention relates to a bi-directional sealing elastic tri-eccentric butterfly valve which has the characteristics that a packing seat, a packing component and a packing gland are successively installed to a packing box of the valve body and are fixed by locking nuts and screw rods, and then, the packing box is sealed; the packing component is pretightened by tightening the locking nuts on the screw rods, and a valve plate is fixedly connected with a valve rod through a straight pin; the axis of the valve rod is eccentric with the center of the valve plate and the center of the sealing surface of the valve plate, and the tapered axis of the sealing surface of the valve plate deflects from the cylindrical axis of the valve body; a thrust ring is installed between the valve body and the valve plate, vertical positioning is performed based on the upper and lower surfaces of the axis housing on the back surface of the valve plate as well as the stepped surfaces of the thrust ring, and the valve plate rotates around the valve rod to close or open the valve. The bi-directional sealing elastic tri-eccentric butterfly valve has the advantages that the sealing surface of the valve plate has uniform stress, and the friction and the torque are low, thereby reducing wear and effectively prolonging service life; sealing pressure ratio of a sealing ring to the valve plate can be increased to realize bi-directional sealing, and mediums cannot leak from the connection between the sealing ring and a pressing ring or the valve body.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

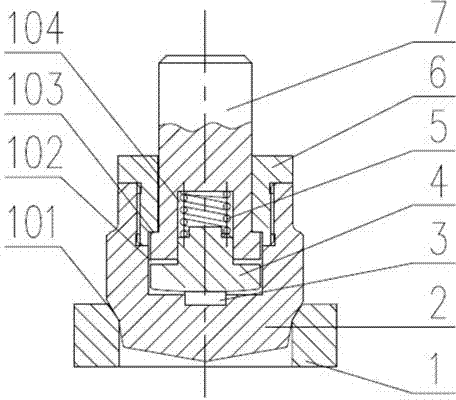

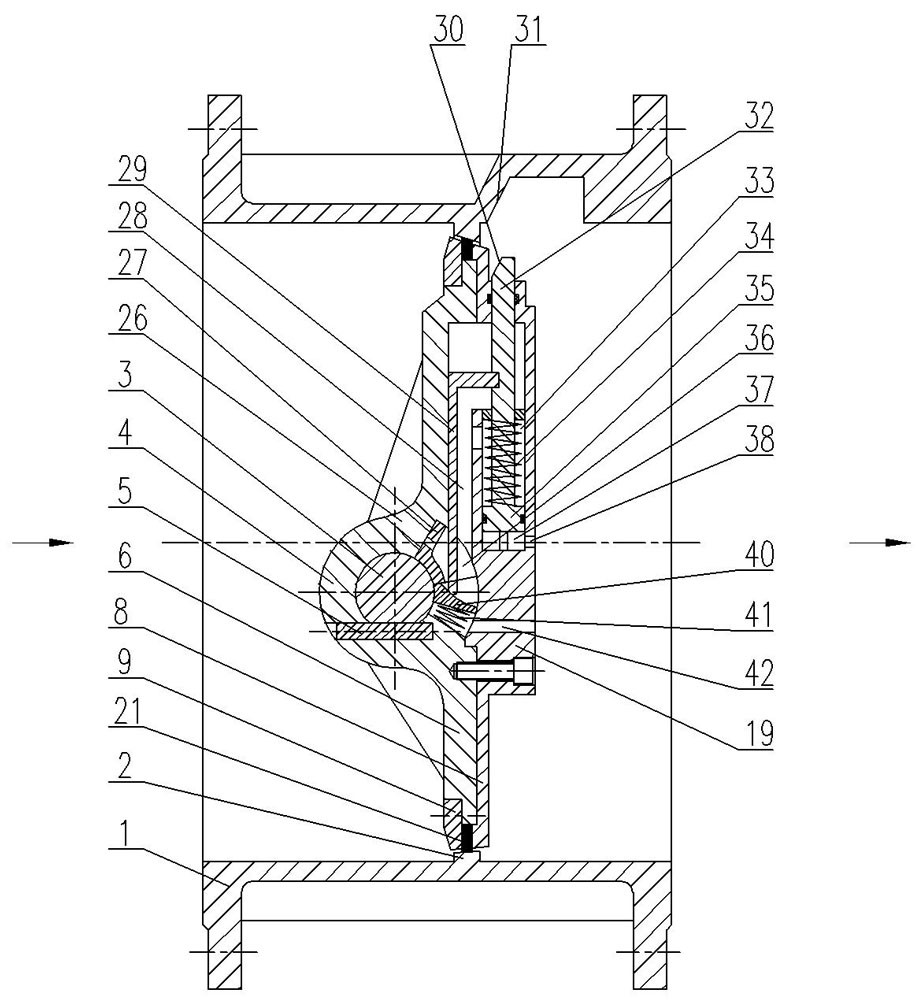

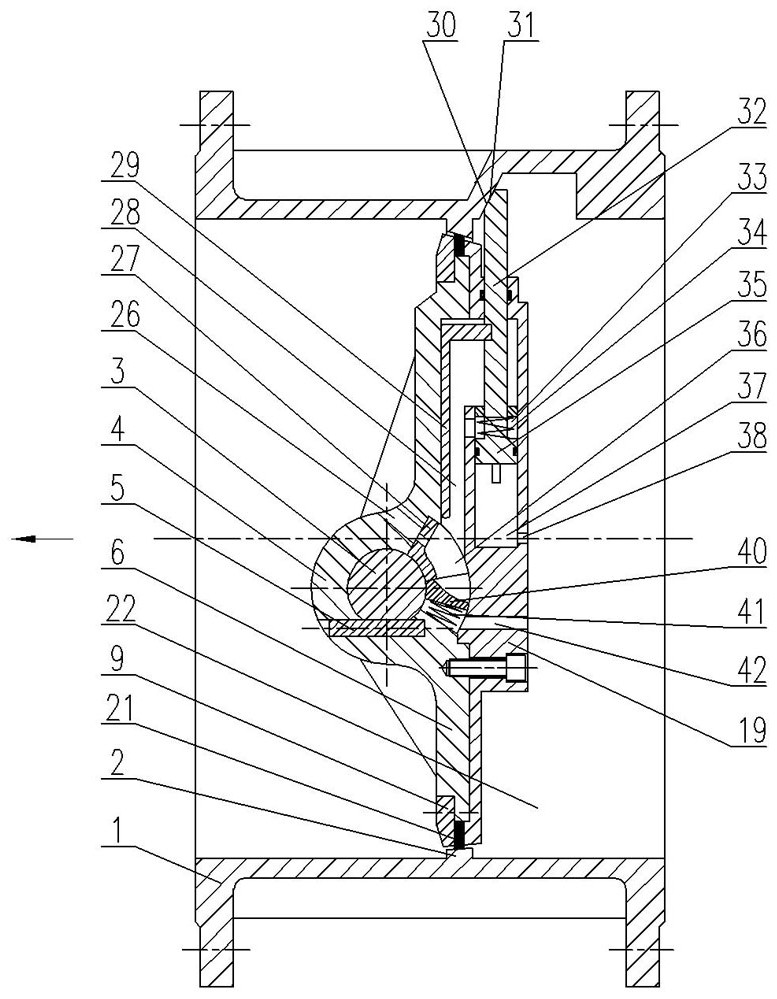

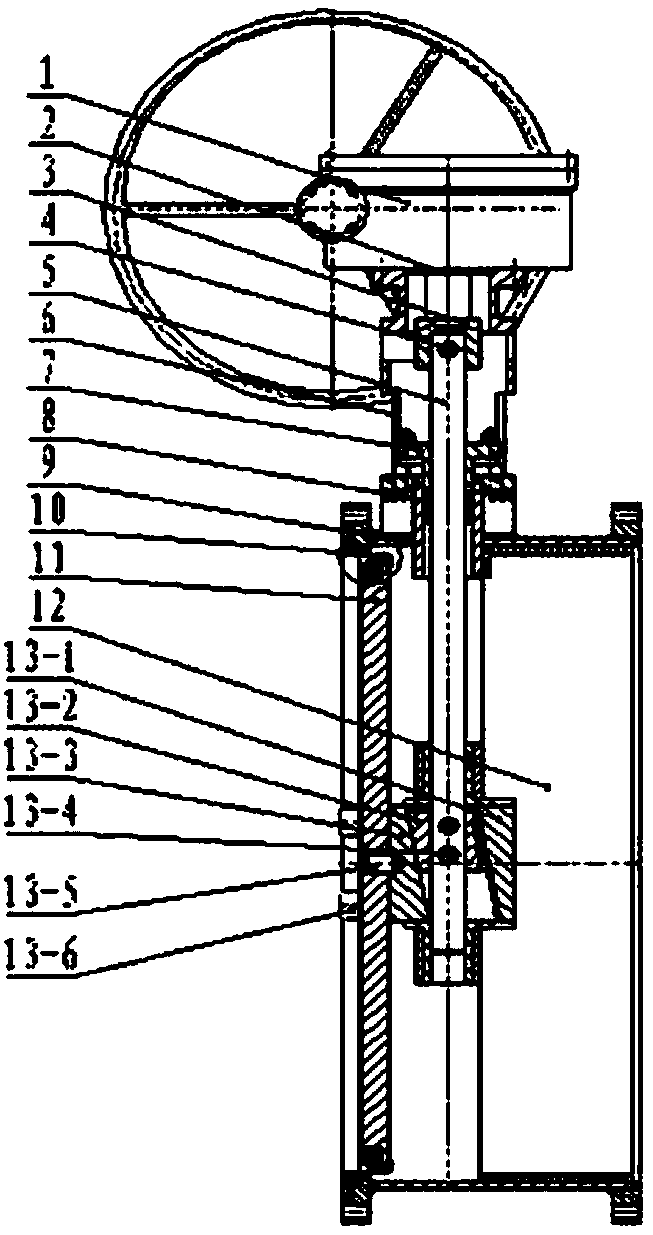

Conical surface soft sealing structure for safety valve

ActiveCN104455496ASolving Valve Leakage ProblemsAccurate openEqualizing valvesSafety valvesEngineeringSafety valve

The invention provides a conical surface soft sealing structure for a safety valve. The conical surface soft sealing structure comprises a boss-shaped valve seat. The top end of the valve seat is embedded into the bottom of a groove-shaped recoil disc. The top end of the valve seat is connected with the bottom of the recoil disc through a lower adjusting ring in a threaded mode. A groove in the recoil disc is filled with a T-shaped sealing block. The lower end of the T-shaped sealing block stretches into the top end of the valve seat. A guide rod is arranged above the recoil disc. The guide rod is connected into the recoil disc in a threaded mode. The guide rod and the recoil disc are fixed to prevent loosening through a locking nut. The guide rod presses the sealing block embedded in the recoil disc. Meanwhile, the recoil disc has the function of a pressing block. The sealing block, the recoil disc, the guide rod and the locking nut form an integrally-moving assembly. A conical surface sealing mode is adopted for the sealing face where the valve seat makes contact with the sealing block. By means of the conical surface soft sealing structure for the safety valve, it is guaranteed that the valve is opened precisely, sealed reliably, discharged stably and capable of returning back to the valve seat at the right moment at the normal temperature ranging from -46 DEG C to 200 DEG C and at the low temperature ranging from -46 DEG C to -200 DEG C.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

High-temp. high-pressure valve rod active seal mechanism and gate valve adopting said seal mechanism

InactiveCN1460806AIncrease the amount of deformationImprove sealingSpindle sealingsSlide valveEngineeringHigh pressure

The present invention relates to a high-temp. high-pressure valve rod action sealing mechanism and a gate valve made up by adopting said sealing mechanism. The valve cover of said sealing mechanism has the packing chamber whose opening is directed towards the internal cavity of the valve body, in the packing chamber there are successively placed several layers of packing material, packing pad and packing nut from top to bottom, the valve rod can be passed through the valve rod hole of the centre of said mechanism, on end is connected with gate board and its another end of is connected with hand wheel, the packing material and packing pad are tightly combined together by means of packing nut.

Owner:HUADONG VALVE

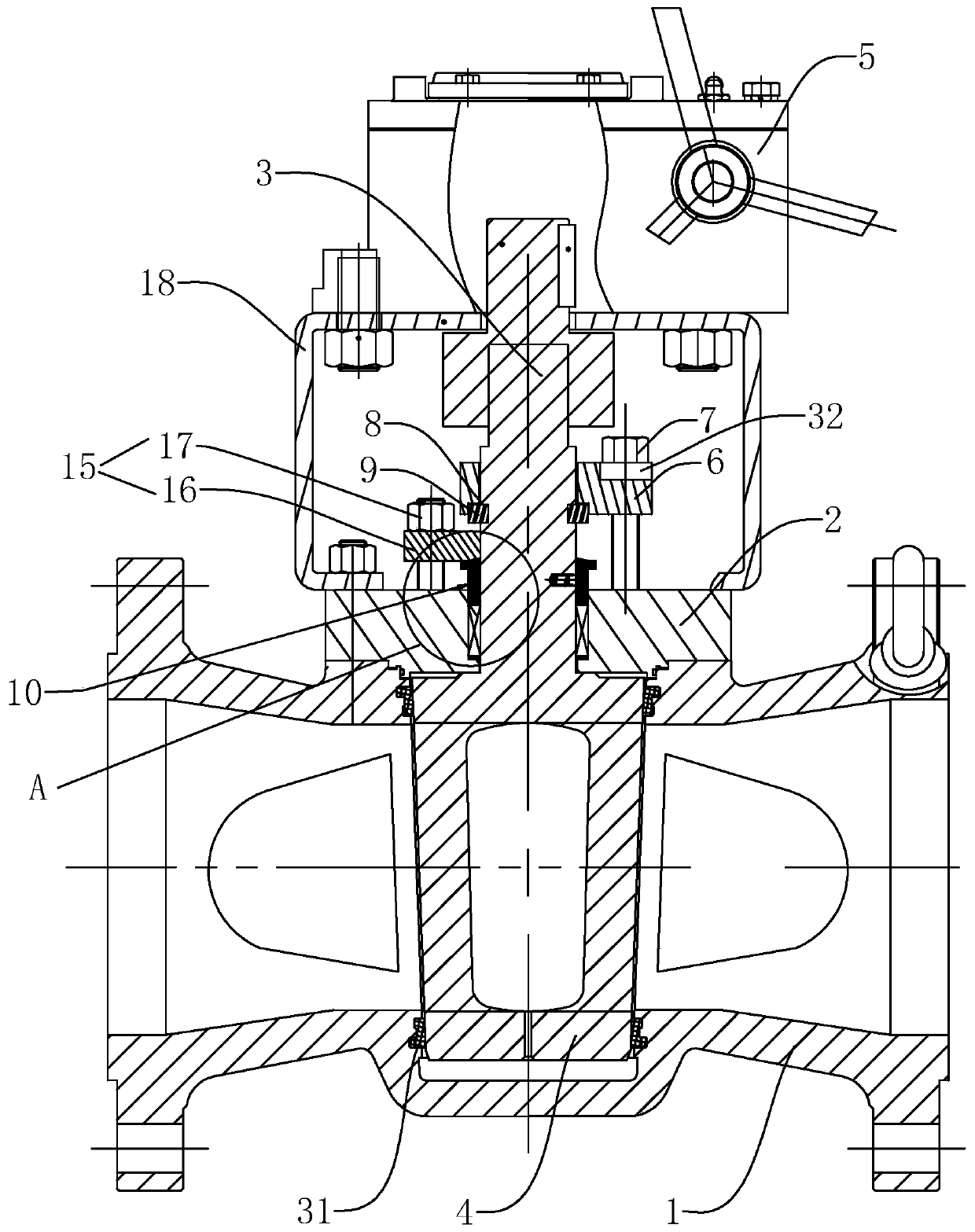

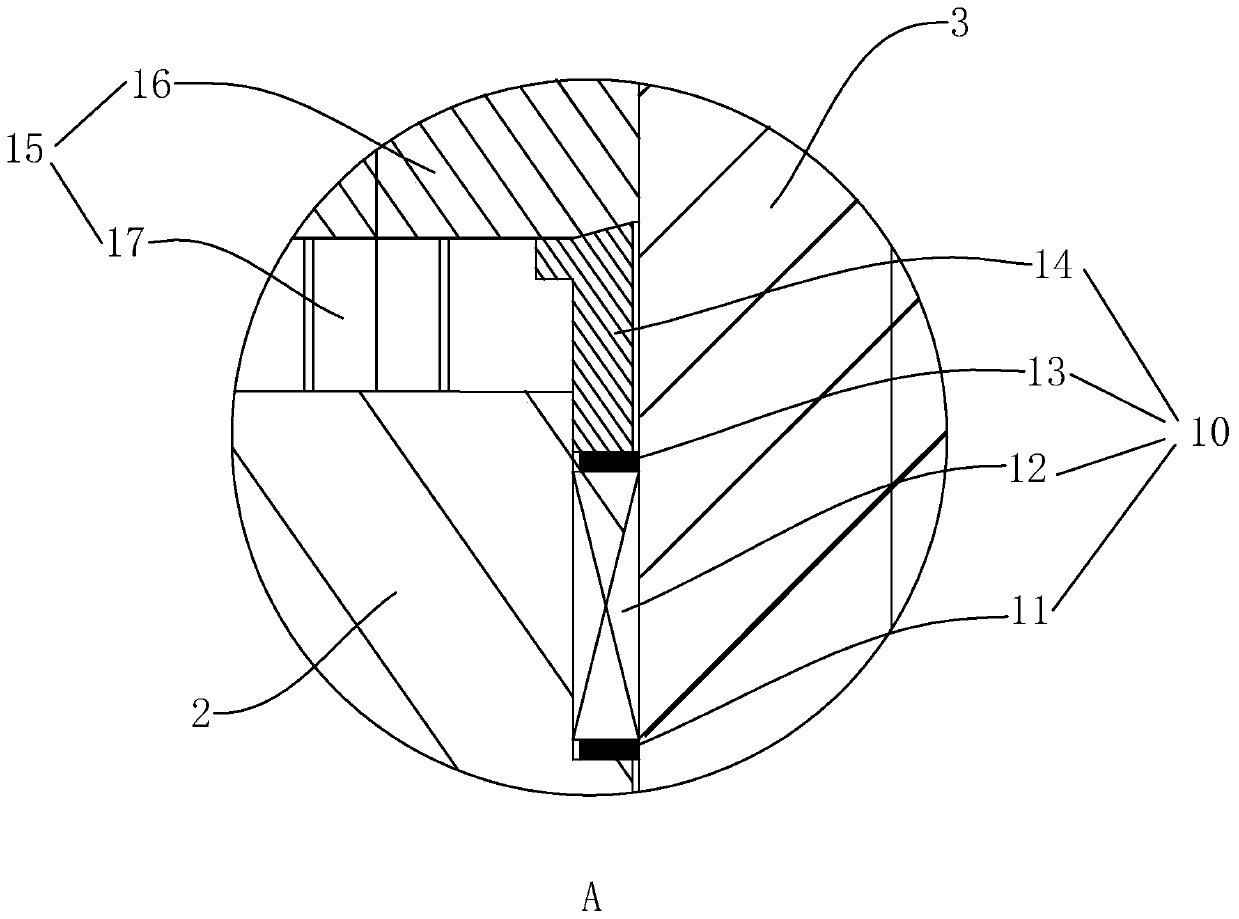

Elastic-seal valve seat structure of fixed ball valve

InactiveCN105508647AIncrease the sealing specific pressureStable and efficient sealingPlug valvesEngineeringMedium pressure

The invention relates to an elastic-seal valve seat structure of a fixed ball valve. One side in the valve body adjacent to a valve ball is provided with an inner step; the inner step and the flow channel of the valve body are arranged coaxially; an elastic support body, a support ring, a filler and a valve seat are arranged in the inner step; one end of the elastic support body abuts against the bottom surface of the inner step, and the other end of the elastic support body abuts against the support ring; the other end of the support ring abuts against the filler; the filler abuts against the valve seat; one side of the valve seat towards the valve ball is provided with a spherical groove; an O ring is embedded in the spherical groove; and the O ring contacts the valve ball. Under the driving actions of the elastic compensation force provided by the elastic support body and the medium pressure, the O ring is forced to adhere to the valve ball to generate elastic deformation, thereby forming the reliable seal. Since one end of the filler adopts an inner conical surface structure, the elastic compensation force acted by the elastic support body on the support ring and the medium pressure can be laterally decomposed to enhance the seal specific pressure, so that the seal is stable and efficient.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Hydraulic forced sealing flat gate valve

PendingCN114857292AImprove sealingReduce lossHydro energy generationSlide valveClassical mechanicsEngineering

The invention belongs to the technical field of flat gate valves, and particularly relates to a hydraulic forced sealing flat gate valve which comprises a valve body, two gate plates which are symmetrically distributed on the two sides are arranged in the valve body, limiting parts are arranged at the tops and the bottoms of the gate plates, the limiting parts and the gate plates are of an integrated structure, first grooves are formed in the two sides of each limiting part, and the first grooves are communicated with the first grooves. The opposite faces of the two limiting parts are fixedly connected with reset springs, the other sides of the reset springs are fixedly connected with first valve seats, the opposite faces of the two first valve seats are fixedly connected with second valve seats, and the opposite faces of the two second valve seats located on the upper portion are provided with second grooves. A piston and a pressing block are arranged between the two second grooves, the pressing block is arranged above the piston, and a boss is arranged in the bottom of the valve body. According to the invention, the two gate plates are expanded or contracted through hydraulic transmission, so that forced sealing is realized, and abrasion to the outer surfaces of the gate plates is avoided.

Owner:TEJI VALVE GRP

Plug valve for high-pressure and high-frequency occasion

The invention discloses a plug valve small in opening and closing friction torque and good in sealing performance for a high-pressure and high-frequency occasion. The plug valve comprises a valve body, a valve deck, a plug body and a valve rod, and further comprises a compressing structure, a jacking structure, a first sealing structure and a second sealing structure. According to the plug valve,rolling friction of upper balls and an upper slope face is used for reducing driving torque needed when the valve is turned off, and meanwhile the plug body is driven downwards and drives a sealing element downwards to be in tight fit with the sealing face of the valve body to achieve compressing sealing; the rolling friction of lower balls and a lower slope face is used for reducing driving torque needed when the valve is turned on, and meanwhile the plug body is driven to move upwards and drives the sealing element to instantly disengage from the sealing face; and abrasion between the plug body and the sealing face of the valve body is greatly reduced, and the driving torque is further reduced. Meanwhile, an upper bearing and a lower bearing are arranged on the plug body, friction forcegenerated by huge blind plate force can be greatly reduced, and the plug valve has wide market prospects.

Owner:潘世永

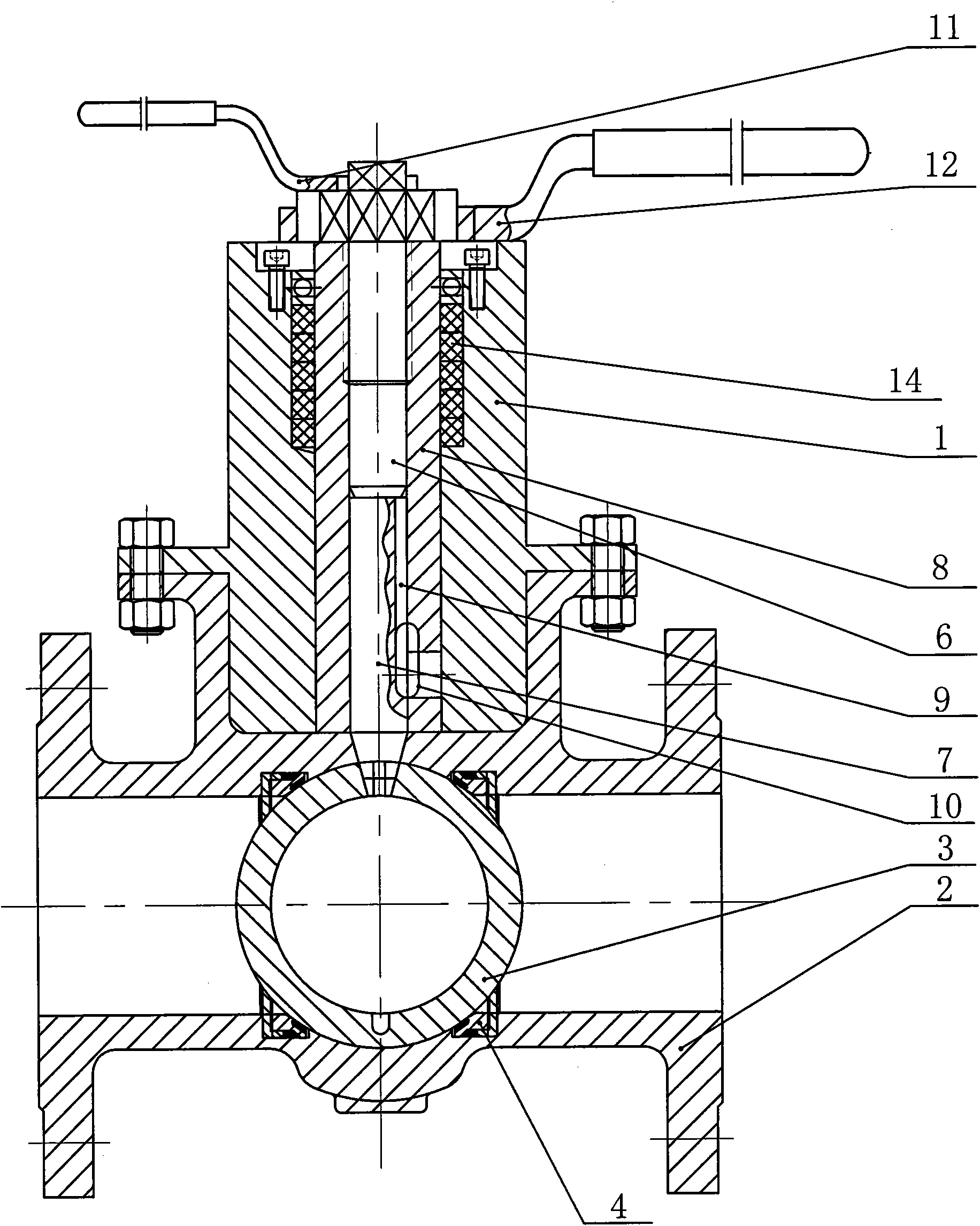

High-temperature-pressure-resistant double-direction rigidity seal rotary ball valve with pretension compensation movable valve seat

PendingCN107420573AStable and durable preloadGood primary sealing effectPlug valvesValve housingsEngineeringButterfly valve

The invention provides a high-temperature-pressure-resistant double-direction rigidity seal rotary ball valve with a pretension compensation movable valve seat, and the rotary ball valve comprises a valve body, a valve rod, a jacking rod and a valve clack. It is presumed that the center line of the valve body is arranged in the horizontal direction from left to right, the valve rod stretches into the valve body from top to bottom, and the valve rod is rotatably connected with the valve body through a sealing assembly; the jacking rod stretches into the valve body from bottom to top in the radial direction of the valve body, and the jacking rod is fixedly connected with the valve body; the lower end of the valve body is provided with a bottom cover and a sealing gasket, wherein the bottom cover and the sealing gasket are used for blocking the jacking rod; the center line of the valve rod and the center line of the jacking rod are overlapped; and the valve clack is arranged inside the valve body, the lower end of the valve rod is fixedly connected with the upper portion of the left side of the valve clack, the lower portion of the left side of the valve clack is rotatably connected on the jacking rod through a shaft sleeve, and a movable valve seat sealing structure is arranged between the right side portion of the valve clack and the circumferential inner wall of the right side of the valve body. According to the high-temperature-pressure-resistant double-direction rigidity seal rotary ball valve with the pretension compensation movable valve seat, the structure process is easy to achieve, the design is reasonable, the sealing effect is good, the adjustment is easy, the maintaining and changing are convenient, the rotary ball valve is of a novel structure, advantages of flap valves and advantages of ball valves are integrated, and the rotary ball valve is a pioneering and innovative novel valve.

Owner:王瑞卿

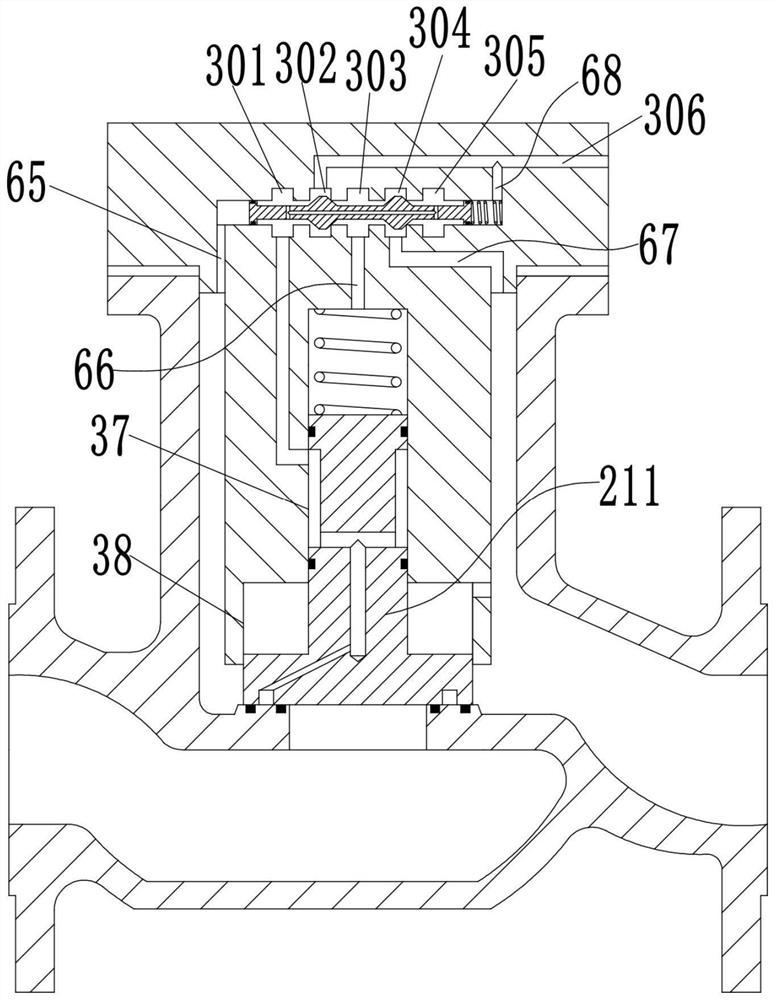

Overflow high-temperature cut-off valve

ActiveCN106352122AAchieve automatic shutdownQuick cutEqualizing valvesSafety valvesProtection mechanismEngineering

The invention relates to an overflow high-temperature cut-off valve and belongs to the technical field of balance valves. The overflow high-temperature cut-off valve comprises a filtering mechanism, a high-temperature protection mechanism, an overflow protection mechanism and a valve cover, wherein the filtering mechanism, the high-temperature protection mechanism and the overflow protection mechanism are arranged in the valve cover in sequence; the high-temperature protection mechanism comprises a bracket, a spring I, a temperature sensing body and a sealing head; the bracket is positioned between the filtering mechanism and the sealing head; the spring I is sheathed on the bracket and is in a compressed state when being installed between the bracket and the sealing head; the temperature sensing body is positioned on one end of the bracket facing to the sealing head; the overflow protection mechanism comprises a spring II, a valve clack and a protective frame; the valve clack is arranged in the protective frame; the spring II is sheathed at the connecting position of the valve clack and the protective frame; and the valve clack and the sealing head are connected by a plug. The overflow high-temperature cut-off valve is applied to disconnection or connection with a gas pipeline, and has the advantages of under-pressure, overflow, high-temperature protection and filtering functions and the like.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

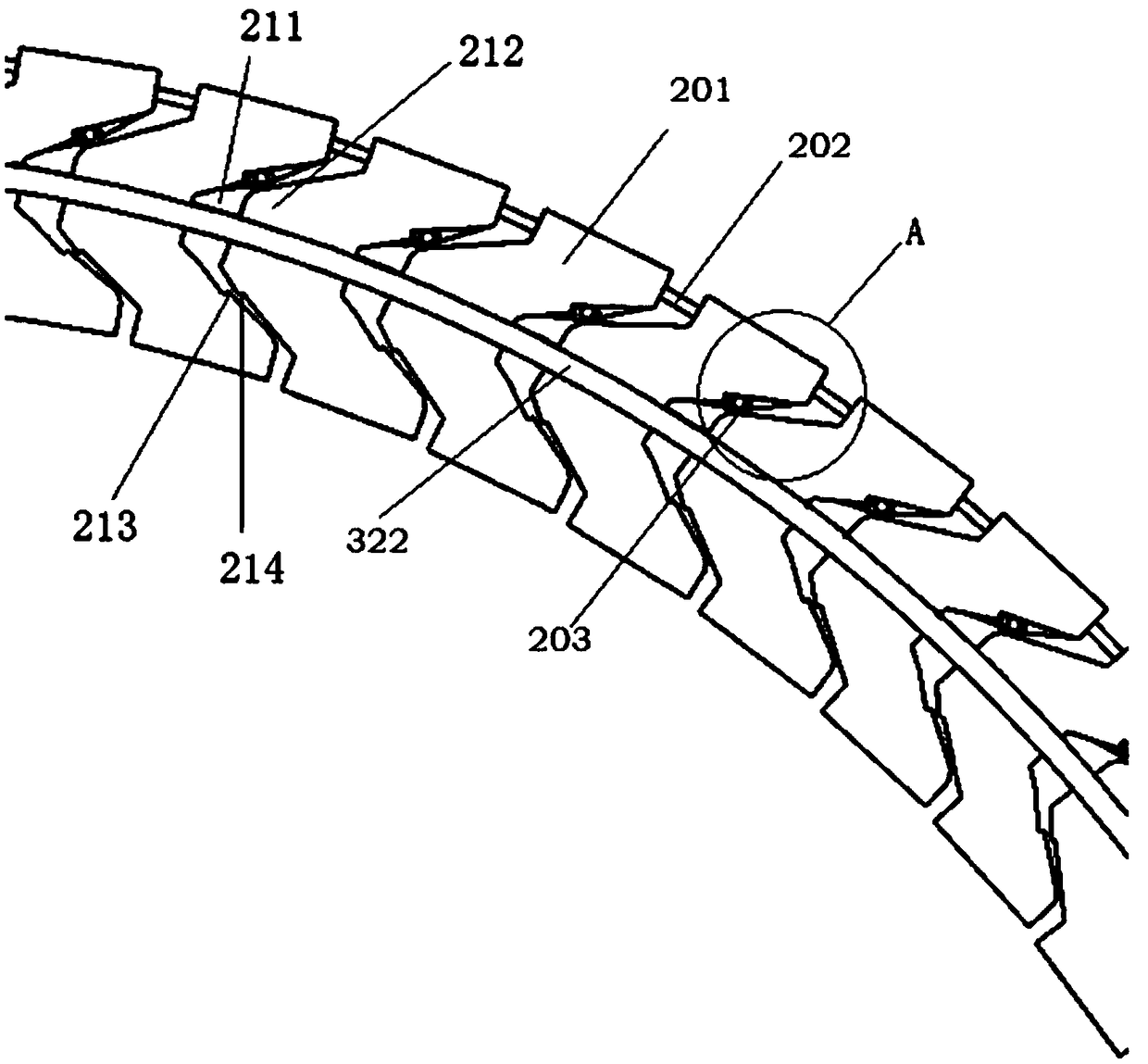

Flap structure capable of being automatically triggered

PendingCN108916393AIncrease the sealing specific pressureImprove sealingOperating means/releasing devices for valvesLift valveRock coreEngineering

The invention relates to a tipping structure capable of being automatically triggered. The tipping structure comprises a tipping valve, an outer cylinder, a core cylinder and a trigger mechanism, wherein the trigger mechanism comprises a trigger inner cylinder and a trigger block, the trigger block is arranged in a through hole of the side wall of the trigger inner cylinder, a protrusion part matched with the trigger block is arranged on the core cylinder, and an avoiding opening matched with the triggering block is formed on the inner wall of the outer cylinder; elastic clamping teeth are arranged on the outer wall of a valve seat, and the elastic clamping teeth are operationally abutted against the through hole on the side wall of the outer cylinder; one end of a spring piece is connected with a valve clack in a sliding mode, and the other end of the spring piece is connected with the outer cylinder; when the core cylinder is located in the valve seat, the lower ends of the elastic clamping teeth are abutted against the through hole, and the valve clack is opened and is located between the trigger inner cylinder and the outer cylinder; and when the core cylinder is lifted upwardsto a certain height, the valve clack returns to the top surface of the valve seat to be in sealing contact with the valve seat, and the trigger inner cylinder is pressed on the valve clack. Accordingto the tipping structure, when the valve is closed, the valve clack is pressed by the trigger inner cylinder, the sealing specific pressure is large, and the sealing performance is reliable; and triggering can be conducted outside the outer cylinder during butt joint operation, so that automatic opening is realized, and the rock core can be pushed into a test cabin from the core cylinder.

Owner:SICHUAN UNIV +1

Anti-impact stop valve sealing structure

InactiveCN103206547ASolve the deformationFix damageLift valveValve member-seat contactsAxial forceVALVE PORT

The invention discloses an anti-impact stop valve sealing structure. A valve clack is arranged on a valve base, the contact surface of the valve clack and the valve base forms a sealing surface, a recessed hole is arranged in the valve clack, a wear-resisting gasket is mounted at the bottom of the recessed hole, a buffer cover is arranged on the wear-resisting gasket, one spring is sleeved at the top of the buffer cover, one spring is tightly contacted with an inner hole retracted at the bottom of a valve rod, the end portion of the valve rod is provided with a boss, and a locking nut is connected with the valve clack to be locked tightly and then to press on the boss on the end portion of the valve rod. The anti-impact stop valve sealing structure has the advantages that the problem that the sealing surface of the valve is deformed or damaged caused by impact from rapid axial force can be effectively solved, service life of a stop valve sealing pair is prolonged, and sealability is good.

Owner:SHANGHAI KAIWEIXI GRP CO LTD

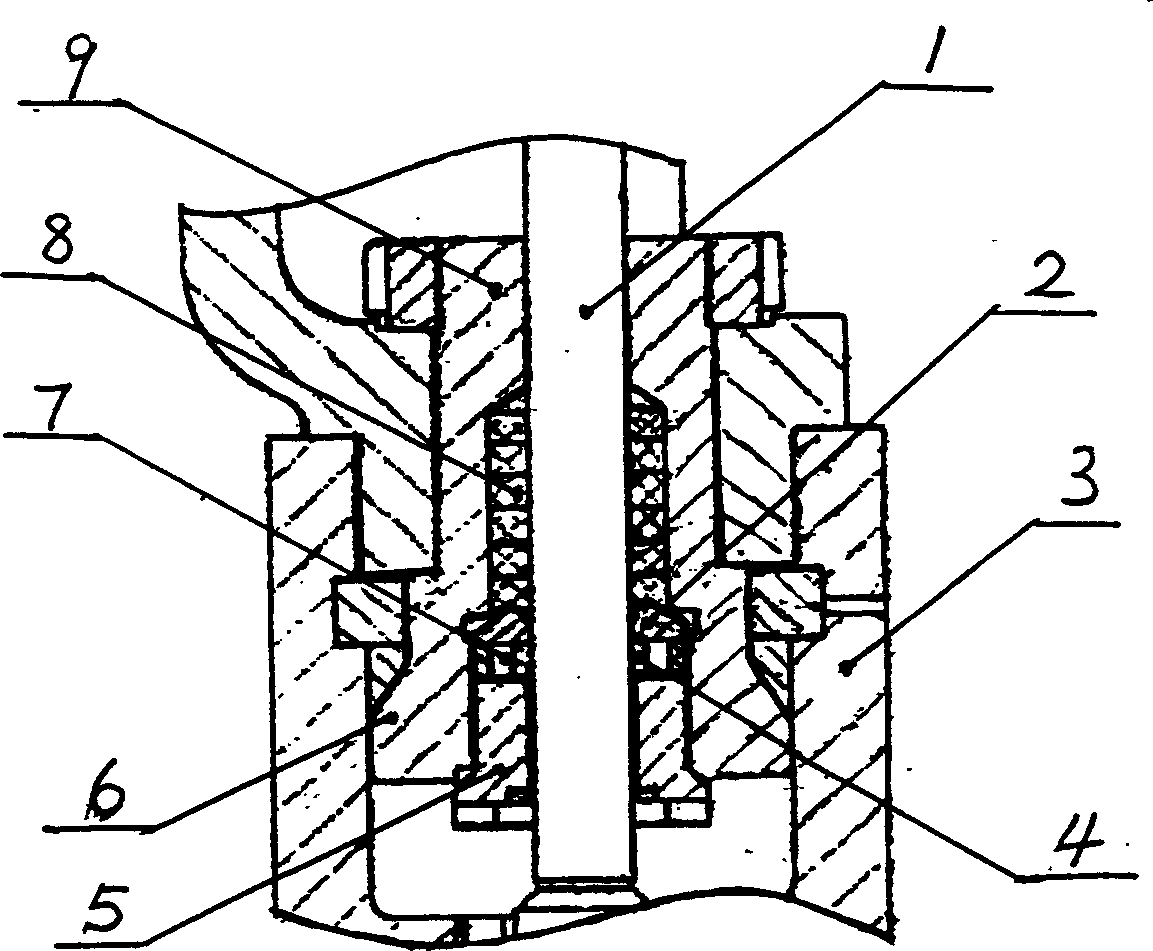

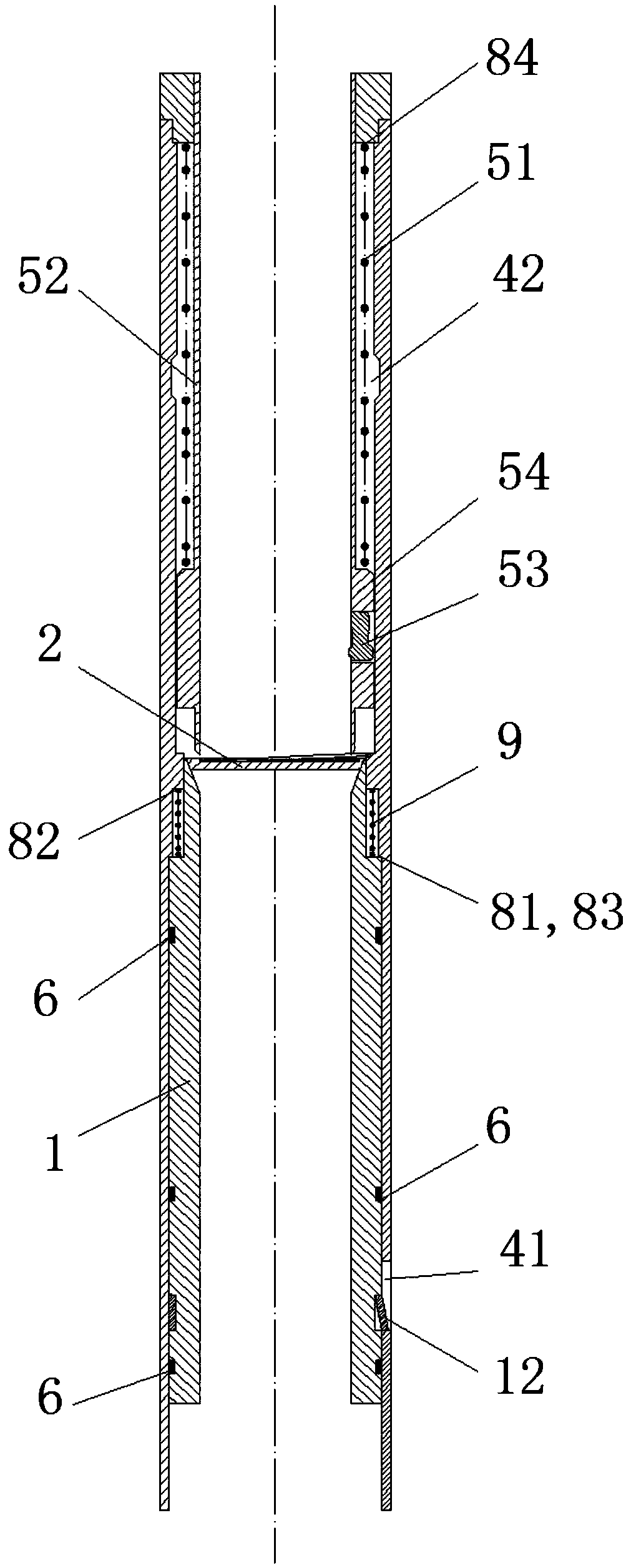

Core barrel sealing structure capable of increasing sealing specific pressure

ActiveCN109505993AImprove deformation abilityWith reverse self-locking characteristicsLift valveCore removalSelf lockingEngineering

The invention relates to a core barrel sealing structure capable of increasing the sealing specific pressure. The core barrel sealing structure comprises a core barrel, a drilling machine outer barrel, a chain mail flap valve and a trigger mechanism. The chain mail flap valve comprises a valve seat and a chain mail valve clack. The trigger mechanism comprises a trigger inner barrel and a trigger block. The trigger block is arranged in a through hole in the sidewall of the trigger inner barrel. The inner wall of the drilling machine outer barrel is provided with a receding port matched with thetrigger block. When the core barrel is located in the valve seat, the valve clack is opened by 90 degrees and is located between the trigger inner barrel and the drilling machine outer barrel. When the core barrel is lifting upwards to a certain height, the valve clack returns to the top surface of the valve seat to make sealing contact with the sealing surface of a valve port, and the bottom ofthe trigger inner barrel is pressed on the valve clack. The core barrel sealing structure achieves lower-end sealing through the chain mail flap valve. The deformability of the valve clack is high andcan automatically adjust the sealing matching position and is high in matching success rate and reliable in sealing performance. Moreover, the valve clack has the reverse self-locking property duringpressure maintaining and pressure bearing and also is pressed by the fallback trigger inner barrel. The sealing specific pressure is large. The sealing performance is reliable.

Owner:SHENZHEN UNIV +1

Double-elasticity high-temperature-resistant high-pressure-resistant bidirectional sealing double-eccentric hard sealing butterfly valve

PendingCN111594621AExtended service lifeGuaranteed that the valve seat can be deformedLift valveEngineeringButterfly valve

The invention discloses a double-elasticity high-temperature-resistant high-pressure-resistant bidirectional sealing double-eccentric hard sealing butterfly valve, and relates to the field of valve. The butterfly valve comprises a valve body, a valve rod and a butterfly plate, wherein the valve rod penetrates through the butterfly plate and is rotationally arranged on the valve body; a positioningstep, a valve seat, a check ring and a fixing ring are sequentially arranged on the inner wall of the valve body; an elastic sealing groove is formed in the side, close to the check ring, of the valve seat; an adjusting gap X is formed between the valve seat and the check ring; a butterfly plate matched with the valve seat is fixed to the valve rod; a pressing plate ring is arranged at the end, deviating from the valve rod, of the butterfly plate; a butterfly plate sealing ring is embedded between the butterfly plate and the pressing plate ring; the butterfly plate sealing ring comprises a clamping part and a bowl-shaped elastic sealing component arranged on the outer ring of the clamping part; the clamping part is arranged between the butterfly plate and the pressing plate ring; the outer side face of the bowl-shaped elastic sealing component is an outer cone sealing face; a limiting boss is arranged on the side, close to the butterfly plate sealing ring, of the butterfly plate; andan adjusting gap Y is formed between the limiting boss and the end of the bowl-shaped elastic sealing component. The butterfly valve has the advantages of being capable of achieving bidirectional sealing and long in service life.

Owner:HENAN YUDA VALVE MFG

Expansion type metallic seal ball valve

InactiveCN101660617AIncrease the sealing specific pressureEliminate gapsSpindle sealingsPlug valvesEngineeringHigh pressure

The invention relates to a metallic seal ball valve, in particular to an expansion type metallic seal ball valve which is used in high-temperature high-pressure medium occasions, and comprises an upper valve body, a lower valve body, a ball body arranged in a cavity of the lower valve body, a valve rod assembly used for driving the ball body, a valve seat and a seal structure, wherein the ball body is provided with a perforative through hole; the spherical surface of the ball body is provided with a penetrating deformation lance which is positioned in the same plane as the axis of the throughhole; and the valve body assembly is matched with the ball body in a rotating way and matched with the lance in an opening and closing way when the ball valve is closed. As the deformation lance is arranged on the ball body, when the ball valve is closed, the lance of the ball body is widened by the valve rod assembly, and the ball body is enlarged, thus eliminating the gap between the ball body and the metallic valve seat, realizing the seal, further improving the sealing effect, meeting the requirement of being used at high temperature and under high pressure. In addition, when the valve isopened, the ball body is diminished and separated from the valve seat seal surface; and frictional resistance is not generated when in rotation, therefore, the operation is labor-saving.

Owner:方建生

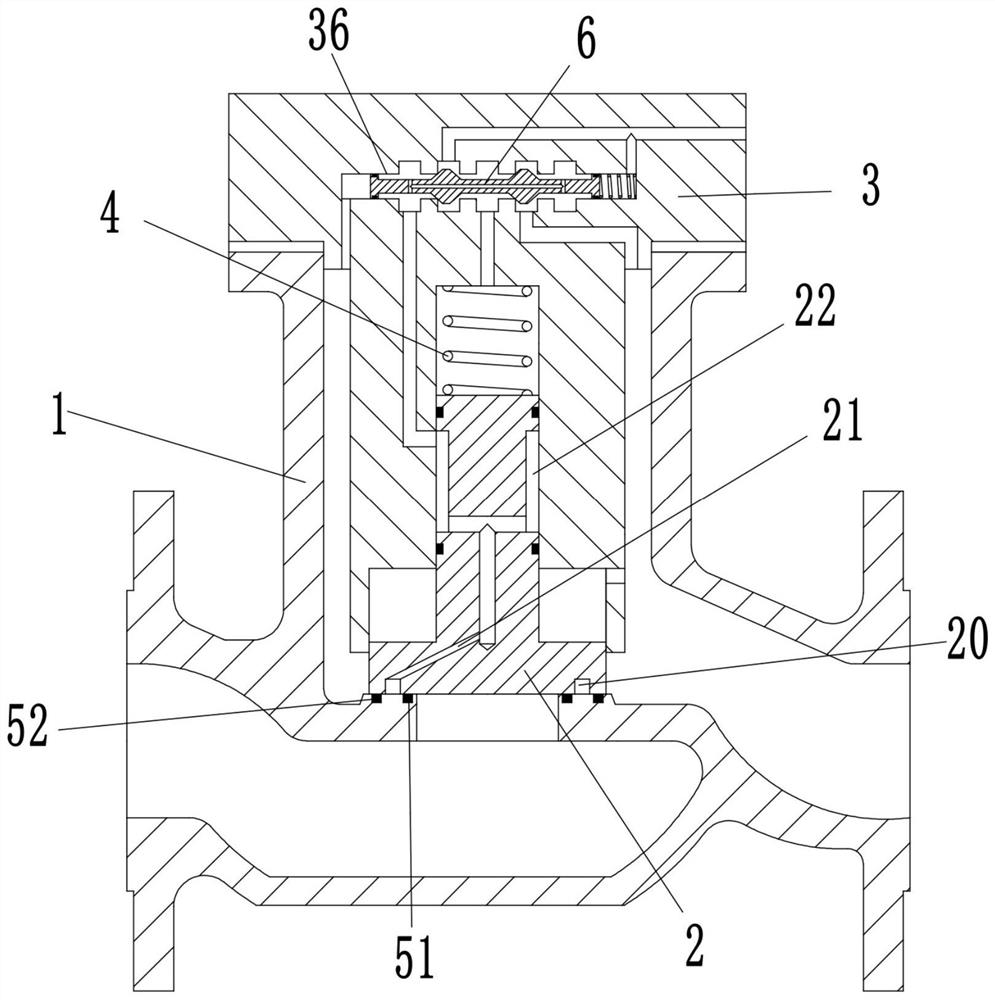

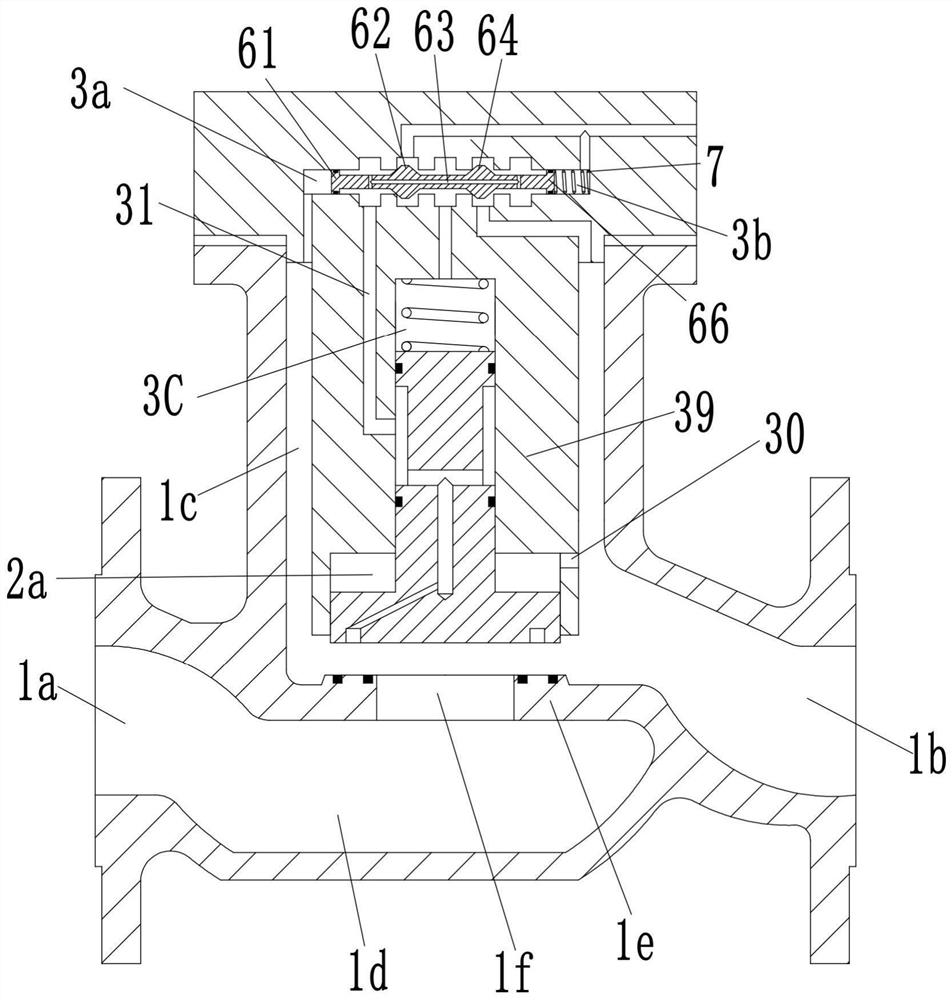

Double-valve-body drain valve and assembly method thereof

ActiveCN109973810AIncrease the sealing specific pressureAvoid clutterValve members for absorbing fluid energySteam trapsBody axisEngineering

The invention relates to a double-valve-body drain valve and an assembly method thereof. The double-valve-body drain valve and the assembly method are characterized in that an outer valve body and aninner valve body are further included, the interior of the outer valve body is provided with an inlet passage, an inlet anti-flushing groove, an outer valve body middle cavity, an outlet anti-flushinggroove and an outlet passage, the inlet anti-flushing groove is of a circular arc groove structure and is arranged between the inlet passage and the outer valve body middle cavity, the outlet anti-flushing groove is of a circular arc groove structure and is arranged between the outlet passage and the outer valve body middle cavity, the inner valve body is of a bucket-shaped structure and is transversely arranged in the outer valve body middle cavity, and the inner valve body can rotate in the outer valve body middle cavity by 360 degrees with respect to the inner valve body axis; and a floating ball, a connecting rod, a valve flap and a valve seat are all arranged in an inner valve body middle cavity, the valve seat is arranged at the bottom of the outlet side of the inner valve body middle cavity, a water inlet hole is formed in the end surface of the inlet side of the inner valve body, the water inlet hole communicates with the inlet anti-flushing groove, and an aligning block is arranged at the position of an outer circle of the inner valve body. The double-valve-body drain valve and the assembly method have the advantages that the installation orientation is not affected, thesteam leakage resistance is good, and the assembly method has high precision and high qualification rate.

Owner:BEIFA GRP BEIJING VALVE

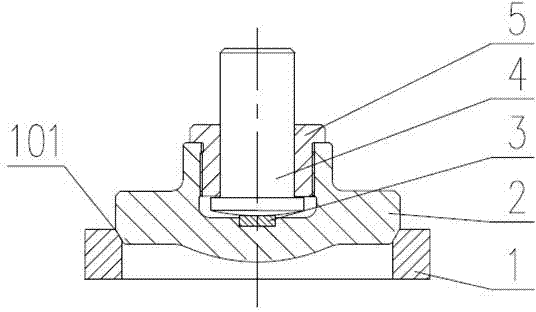

Seal gasket for flange face sealing

InactiveCN102518890ASelf-tightening effectIncrease the sealing specific pressureFlanged jointsEngineeringMaterials science

The invention relates to an inner metal ring, an outer metal ring and a nonmetal seal ring inlaid between the inner metal ring and the outer metal ring. The axial thickness of the inner metal ring is smaller than that of the nonmetal seal ring, and the axial thickness of the outer metal ring is smaller than or equal to that of the nonmetal seal ring. When the seal gasket is mounted, sealing is achieved through face contact between the nonmetal seal ring and a flange. When pressure of a seal medium is increased, the inner metal ring can be stressed to radially expand to extrude the nonmetal seal ring, so that sealing specific pressure of the nonmetal seal ring and the flange face is increased, and sealing is better. In addition, when the pressure of the seal medium is decreased, the inner metal ring shrinks, and the sealing specific pressure restores. Therefore, the seal gasket is higher in resistance to pressure and temperature fluctuation, better in sealing flexibility, and less prone to strain fatigue and creep relaxation.

Owner:SUZHOU BMC SEALING TECH CO LTD

Two-way sealing butterfly valve

ActiveCN110081190AIncrease the sealing specific pressureImprove sealingOperating means/releasing devices for valvesLift valveEngineeringButterfly valve

The invention relates to a two-way sealing butterfly valve. The two-way sealing butterfly valve is characterized in that a supercharging device, a medium flow direction control mechanism, a left inletconnecting pipe and a right inlet connecting pipe are further arranged above a valve body, the left inlet connecting pipe communicates with a left cavity, and the right inlet connecting pipe communicates with a right cavity. The supercharging device comprises a supercharging tank, a supercharging plate and a sealing ring, the supercharging tank is internally provided with a control chamber with across section of a fan-shaped structure, the supercharging plate is arranged in the control chamber and divides the control chamber into a supercharging chamber and a breathing chamber, one end of the supercharging plate is fixedly connected with a valve stem, and the breathing chamber communicates with the atmosphere; and through cooperation of the left inlet connecting pipe, the right inlet connecting pipe and the medium flow direction control mechanism, media in the left cavity and the right cavity are controlled to enter the supercharging chamber, the supercharging plate is pushed by themedia in the supercharging cavity to generate acting force acting on a butterfly plate in the butterfly plate closing direction through the valve stem, the butterfly plate and a valve seat keeps sealed, and the advantage of being good in two-way sealing performance is achieved.

Owner:SHANGHAI HUGONG VALVE FACTORY (GRP) CO LTD

A two-way triple eccentric butterfly valve

ActiveCN110081189BIncrease the sealing specific pressureSolve the problem of good sealing only in one directionLift valveDecompression chamberEngineering

Owner:铭工阀门有限公司

Compensation type seal plug valve

The invention discloses a compensation type seal plug valve. The compensation type seal plug valve comprises a valve body, a valve cover and a valve rod. A valve cavity communicating with an inlet endand a discharging end is formed in the valve body, the end, in the valve cavity, of the valve rod is provided with a plug body, a bush is arranged between the plug body and the valve body, the crosssectional area of the end, away from the valve rod, of the plug body is smaller than that of the end, close to the valve rod, of the plug body, the end, away from the plug body, of the valve rod is inkey connection with a driving device capable of driving the valve rod to rotate, the end, outside the valve body, of the valve rod is provided with an adjusting pressing plate, one side of the adjusting pressing plate is provided with a first fastener in a penetrating manner, and one end of the first fastener is in threaded fit with the valve cover. The plug valve has the advantages that the plugvalve has the compensation type seal structure, the seal failure caused by wear between the plug and the bush after long-time use can be solved, and the service life of the plug valve is prolonged.

Owner:浙江福瑞科流控机械有限公司

Metal butterfly valve

InactiveCN112032324AImprove sealingSealing is not affectedPressure relieving devices on sealing facesLift valveEngineeringButterfly valve

The invention discloses a metal butterfly valve. The metal butterfly valve comprises a valve body and a valve rod, wherein a butterfly plate, a valve seat, an inlet cavity and an outlet cavity are arranged in an inner cavity of the valve body, the butterfly plate and the valve seat are matched in a sealing mode, the inlet cavity and the outlet cavity are located on the left side and the right sideof the butterfly plate respectively, the butterfly plate is eccentrically and rotationally arranged, the corresponding sealing face of the butterfly plate and the valve seat is a matched slope, the valve rod is arranged on the the valve body in a penetrating mode, the upper end of the valve rod is in transmission connection with a driving device, and the lower section of the valve rod is in transmission connection with the butterfly plate. The metal butterfly valve is characterized in that a leakage-proof device is arranged on the plate face, located on the outlet side, of the butterfly plateand comprises a box body, the box body is internally provided with a piston, a plug rod, a piston cavity, a spring cavity, a vent groove, an ejector rod, a first pressure guide hole and a second pressure guide hole, the outer end of the plug rod is movably arranged on the box body in the penetrating mode, a rod slope is arranged at the outer end of the piston rod, the inner end of the piston rodis connected with the piston, the piston is movably arranged in the piston cavity, and the piston cavity communicates with the outlet cavity through the first pressure guide hole; a body slope is arranged on the left side wall of the inner cavity of the valve body, and when the plug rod stretches out of the box body, the rod slope is in press fit with the body slope.

Owner:李祥庆

High-temp. high-pressure valve rod active seal mechanism and gate valve adopting said seal mechanism

InactiveCN1186550CIncrease the amount of deformationImprove sealingSpindle sealingsSlide valveEngineeringHigh pressure

The present invention relates to a high-temp. high-pressure valve rod action sealing mechanism and a gate valve made up by adopting said sealing mechanism. The valve cover of said sealing mechanism has the packing chamber whose opening is directed towards the internal cavity of the valve body, in the packing chamber there are successively placed several layers of packing material, packing pad and packing nut from top to bottom, the valve rod can be passed through the valve rod hole of the centre of said mechanism, on end is connected with gate board and its another end of is connected with hand wheel, the packing material and packing pad are tightly combined together by means of packing nut.

Owner:HUADONG VALVE

Regulating valve

InactiveCN112145715AImprove sealingIncrease the sealing specific pressureEqualizing valvesSafety valvesValve seatPhysics

The invention discloses a regulating valve. The regulating valve comprises a valve body, a valve cavity is formed in the valve body, a valve seat plate is arranged in the valve body, the valve seat plate divides the valve cavity into an upper valve cavity body and a lower valve cavity body, and an inlet pipe and an outlet pipe are arranged on the side face of the valve body; a valve hole is formedin the valve seat plate; a valve deck is fixedly installed at the upper end of the valve body, an unloading hole is formed in the outer side face of the valve deck, a protruding column is arranged onthe inner side of the valve deck, a first sliding hole is upwards formed in the lower end of the protruding column, a second sliding hole is upwards formed in the blind end of the first sliding holein the protruding column, a valve clack is slidably connected in the first sliding hole, a sliding block is arranged on the valve clack, a first cavity is formed in the first sliding hole, a second cavity is formed in the second sliding hole, and a pressure regulating spring is arranged in the second cavity; an annular unloading groove is formed in the lower end of the valve clack; and a valve control assembly is arranged in the valve deck. The regulating valve not only is reliable in sealing, but also can prevent the outlet side pipeline from being broken or exploded due to overlarge pressure.

Owner:邵玉刚

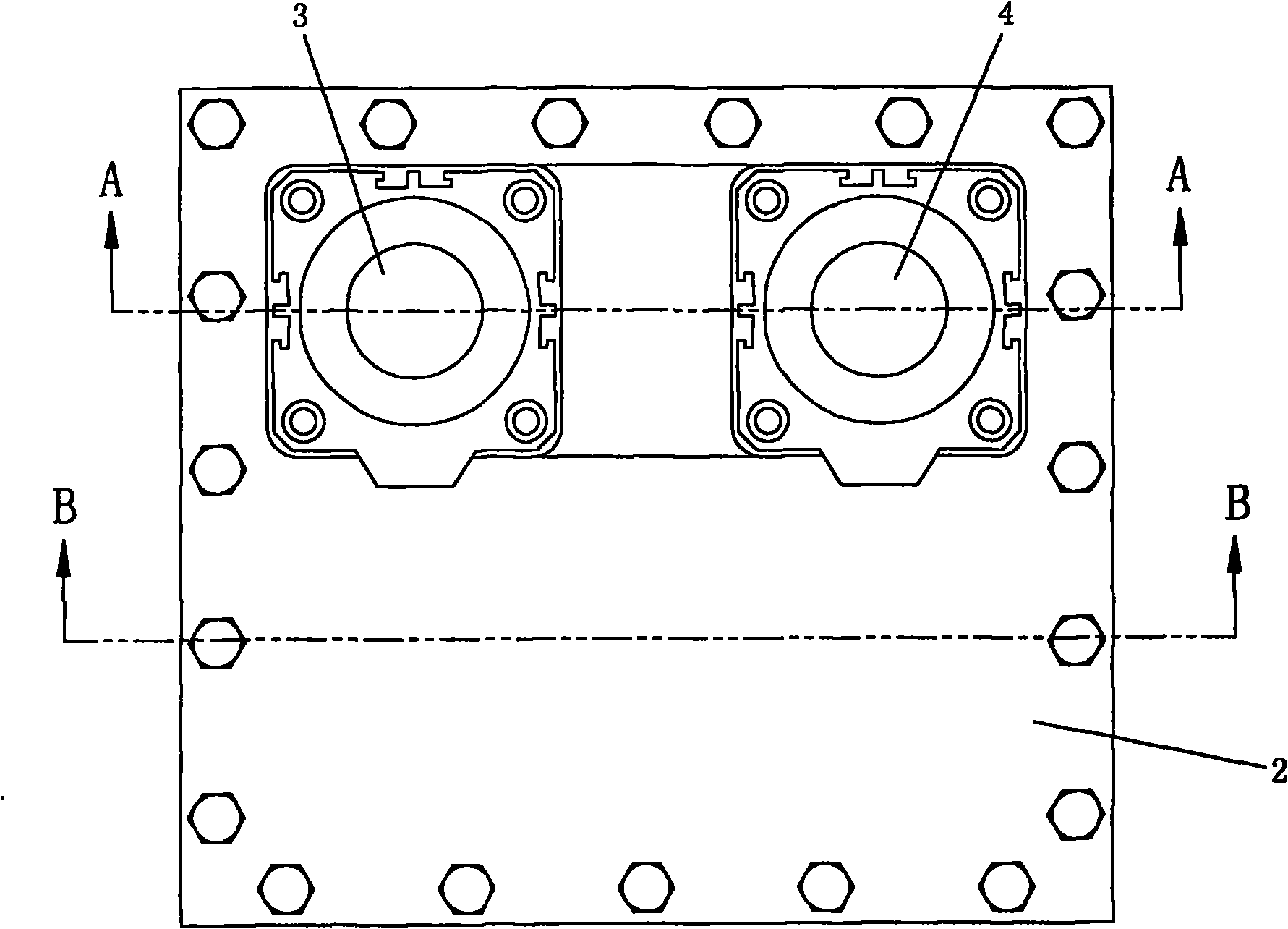

Four-way valve for absorption drying tower

ActiveCN102120125APrevent internal leakageIncrease the sealing specific pressureDispersed particle separationFour-way valveEngineering

The invention discloses a four-way valve for an absorption drying tower. The bonnet of a valve body is provided with a left cylinder and a right cylinder; an air intake chamber, a left tower air intake and exhaust chamber, a right tower air intake and exhaust chamber and a waste gas chamber are formed in the valve body; a sliding valve element is arranged in the air intake chamber; a left valve port is formed between the air intake chamber and the left tower air intake and exhaust chamber; a right valve port is formed between the air intake chamber and the right air intake and exhaust chamber; the side faces of the valve flap of the sliding valve element form seal pairs with the left valve port and the right valve port respectively; the valve flap of the sliding valve element is fixed on a valve rod; and the valve rod is in sliding fit with the central hole in a triangular support in the left valve port and the central hole in a triangular support in the right valve port. In the invention, the sliding valve element is formed by the valve flap and the valve rod, which are vulcanized together, and when the sliding valve element moves, the valve flap and the valve rod move together; and thus, the problem that string gas is easily generated in fit clearance between the valve flap and the valve rod with the valve flap arranged on the valve rod in a sliding manner in the original structure is solved, and internal leakage is avoided. The entire structure of the four-wavy valve is simple, the design is smart and the arrangement is reasonable.

Owner:ZHEJIANG LIXIANG VALVE MFG

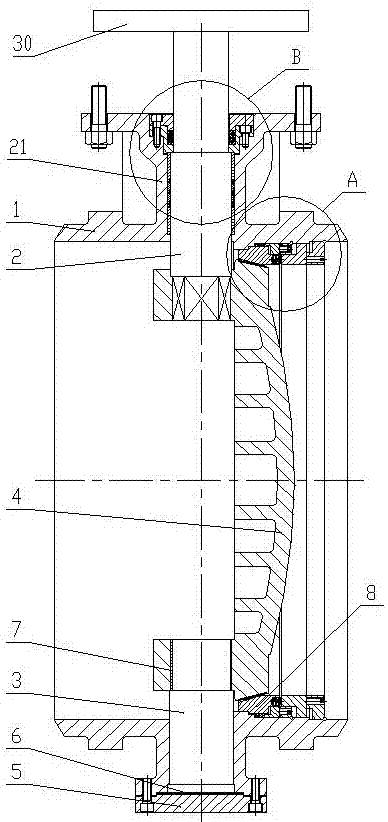

Heavy-caliber high-temperature pilot-operated type control valve

InactiveCN101725749AIncrease the sealing specific pressureLow costEqualizing valvesSafety valvesSpray nozzleEngineering

The invention relates to a heavy-caliber high-temperature pilot-operated type control valve. The control valve mainly comprises a main control valve, an auxiliary pilot valve and compression equipment, wherein the main control valve is communicated with the auxiliary pilot valve; the auxiliary valve is communicated with an outlet cavity of the main control valve through a bypass pipeline; the bottom of the main control valve is provided with a nozzle which forms an inlet cavity; and the inlet cavity is connected and fixed with the compression equipment. The control valve has the advantages that a sealing pair structure combined by an inverse valve clack and a valve seat effectively improves the seal specific pressure of high temperature working conditions, and ensures that the device is in a reliable sealing state before startup. Because the device is under the high temperature working conditions in running and acting processes, research and development on the structure of a movable part adopts a labyrinth piston ring which is made of a metal material and is arranged between a piston and a cylinder liner, and solves the problems of movability, friction and leakage of the structure in a high-temperature medium.

Owner:HANGZHOU WORLDWISE VALVE

Low-torque and two-way zero leakage all-metal sealing butterfly valve

InactiveCN108105401ASmall operating torqueClose fastLift valveValve housingsNeedle roller bearingValve opening

The invention relates to a low-torque and two-way zero leakage all-metal sealing butterfly valve. According to the technical scheme, the low-torque and two-way zero leakage all-metal sealing butterflyvalve comprises an actuating mechanism, a thread sleeve, a lead screw, a connecting shaft, a valve rod, a bracket, a packing gland, a valve rod packing, a valve body, a valve seat, a butterfly plate,a reinforcing rib, a wedge splitting sliding component, a valve seat sealing filler, an all-metal sealing ring, a butterfly plate sealing filler, needle roller bearings and rollers. The low-torque and two-way zero leakage all-metal sealing butterfly valve adopts metal hard sealing and active sealing, sealing specific pressure is high, and zero leakage and two-way sealing are achieved; wear-proof,temperature-resistant and corrosion-resistant alloy materials are overlayed on the sealing surfaces of the valve seat and the butterfly plate, so that the service life is long; in the valve opening and closing processes, the sealing surfaces are not in contact, no friction is caused, operating torque is little, and the closing speed is high; the valve seat and the butterfly plate are of detachable structures, and are simple in structure, convenient in overhaul and low in maintenance cost; and the valve plate is relatively thin, so that the flow resistance is little, the discharge coefficientis high, and the scope of application is wide.

Owner:樊东升

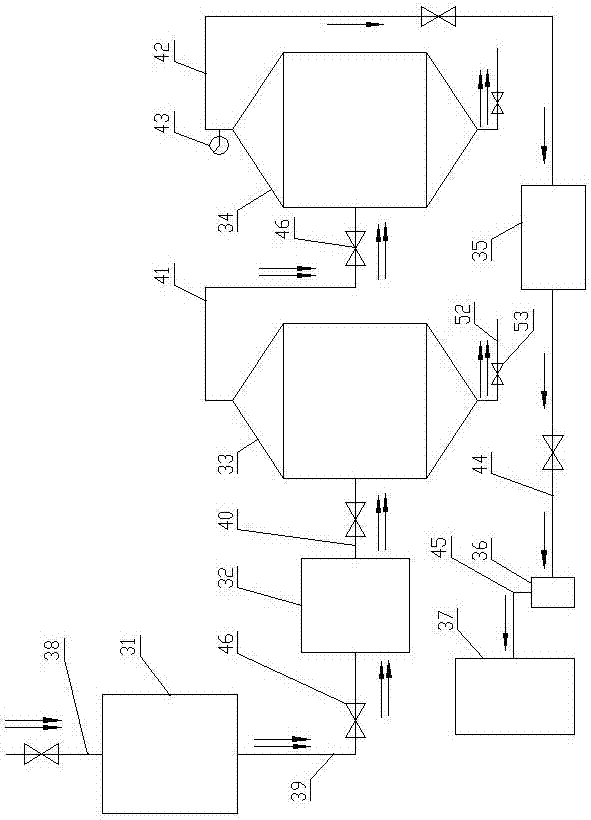

Biomass boiler smoke recycling system

InactiveCN107166426AEasy to separateStable and durable preloadCombustion processIndirect carbon-dioxide mitigationAir preheaterSulfur

The invention discloses a biomass boiler smoke recycling system comprising an air preheater, a spray-type dust and sulfur removal device, a first-stage smoke plenum chamber, a second-stage smoke plenum chamber, a gas dryer, an air compressor and a high-pressure air storage tank which are sequentially connected by pipelines; and each of the pipelines is provided with a manual regulating valve with the same structure. The biomass boiler smoke recycling system is reasonable in design; the energy of smoke is sufficiently utilized, the smoke is subjected to environment-friendly treatment, and carbon monoxide gas generated by incomplete combustion is separated and reutilized, so that the favorable energy-saving and emission reduction effects are achieved; and the manual regulating valves are good in high temperature and corrosion resistance, capable of achieving a favorable sealing effect and easily regulating the sealing performance and are convenient to maintain and replace.

Owner:秦硕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com