Conical surface soft sealing structure for safety valve

A soft sealing and safety valve technology, applied in the field of safety valves, can solve the problems of reduced sealing performance, reduced service life of the sealing block 4, and inability to ensure that they are in the same position, so as to achieve reliable sealing, accurate opening, and solve the problem of valve leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The tapered surface soft sealing structure for the safety valve according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

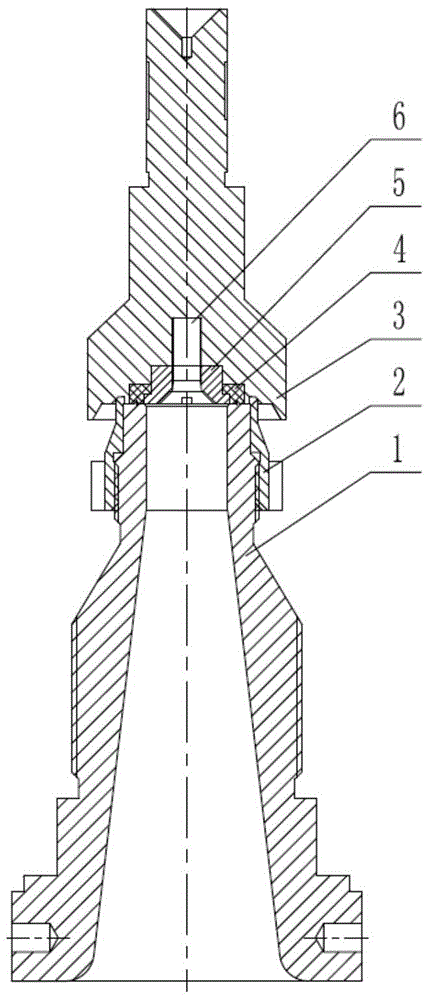

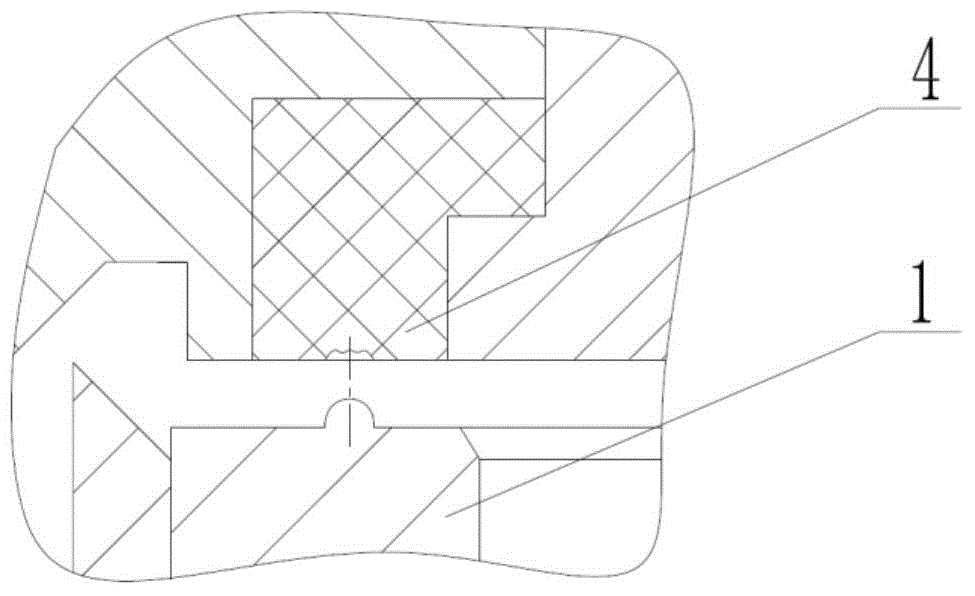

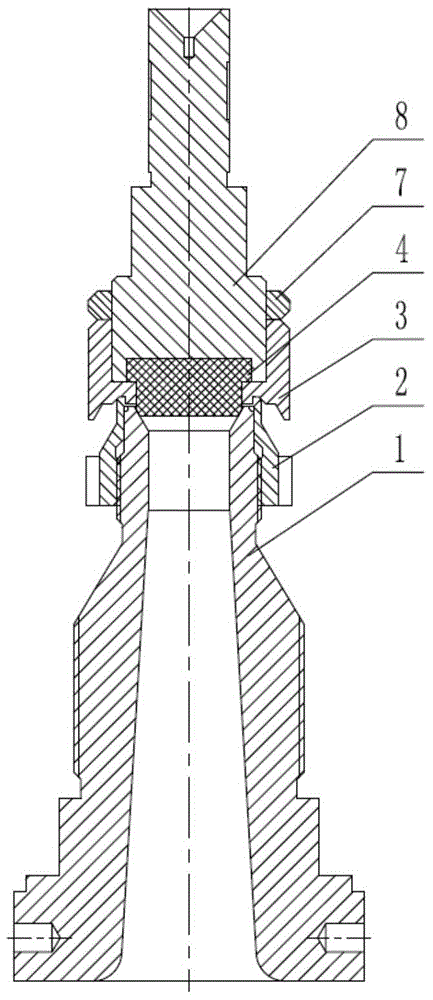

[0019] Such as image 3 As shown in the present invention, a tapered surface soft sealing structure for safety valves, which includes a boss-shaped valve seat 1, the top of the valve seat 1 is embedded in the bottom of the groove-shaped recoil disc 3, through the lower adjustment ring 2 Connect the top of the valve seat 1 to the bottom of the recoil disc 3 with threads. The gap between the recoil disk 3 and the lower adjustment ring 2 can be changed by adjusting the lower adjustment ring 2 , and a pressure accumulator structure is formed between the lower adjustment ring 2 , the recoil disk 3 and the sealing block 4 .

[0020] The groove of recoil disk 3 is plugged into "T" shape sealing block 4, and the lower end of this "T" shape sealing block 4 stretches into the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com