Heating base and cooker utilizing same

A technology for heating bases and cavities, which is applied to cooking utensils, applications, and cooking utensil lids, etc. It can solve problems such as complex component relationships, increased structural complexity, and complex heating base structures, so as to avoid errors and facilitate assembly and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A heating base and a cooker using the heating base of the present invention are described in conjunction with the accompanying drawings.

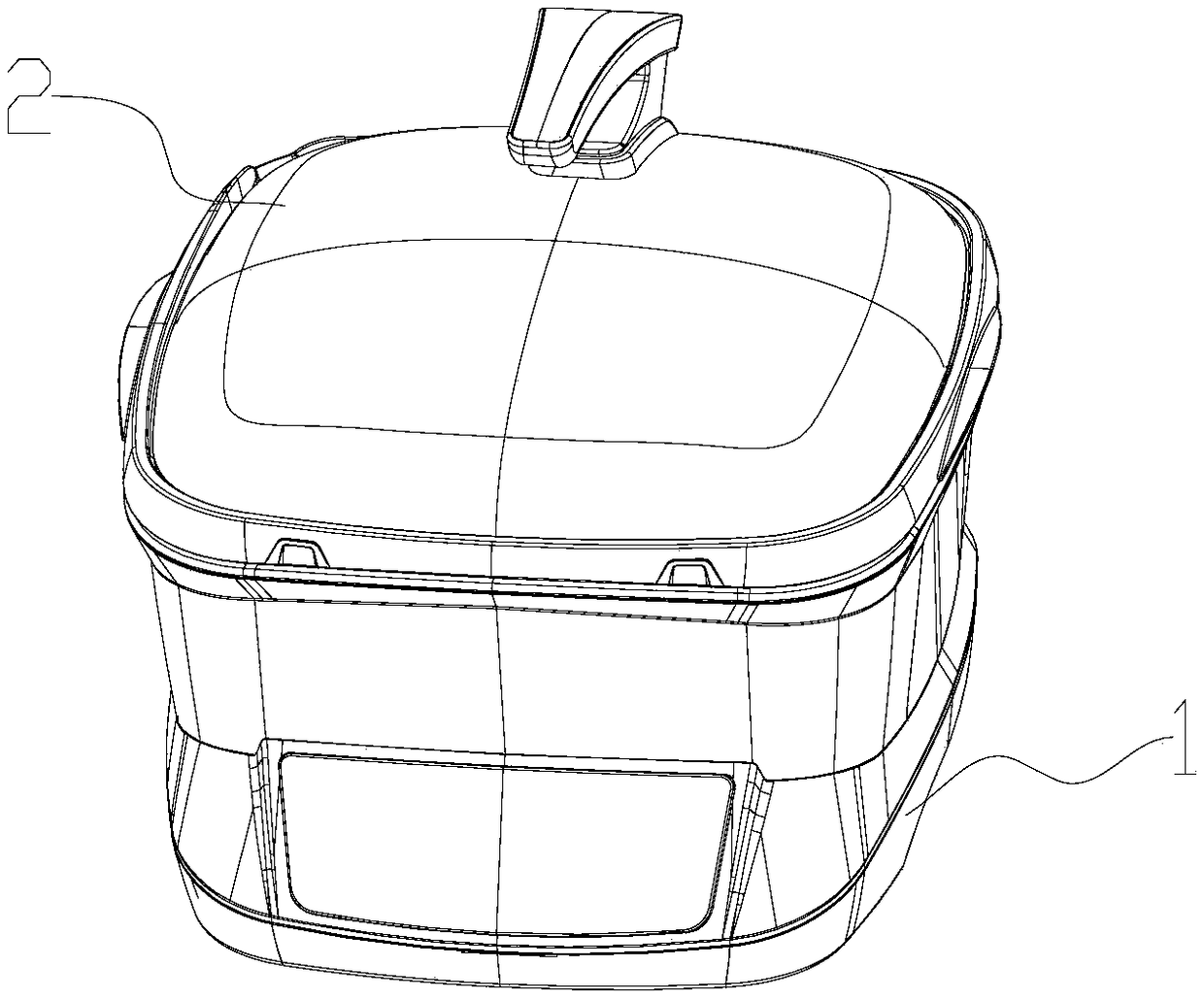

[0026] like Figure 2-8 As shown, a cooker includes a heating base, a cover body 2 and a pot body. The pot body is put into the heating base as a heated object to be heated. In addition, other containers that can be used to hold food can be used as heated objects. Put the object into the heating base for heating, and most of the heating bases in the prior art will monitor the temperature of the heated object and detect whether the heated object is placed. These structures are generally arranged on the heating base.

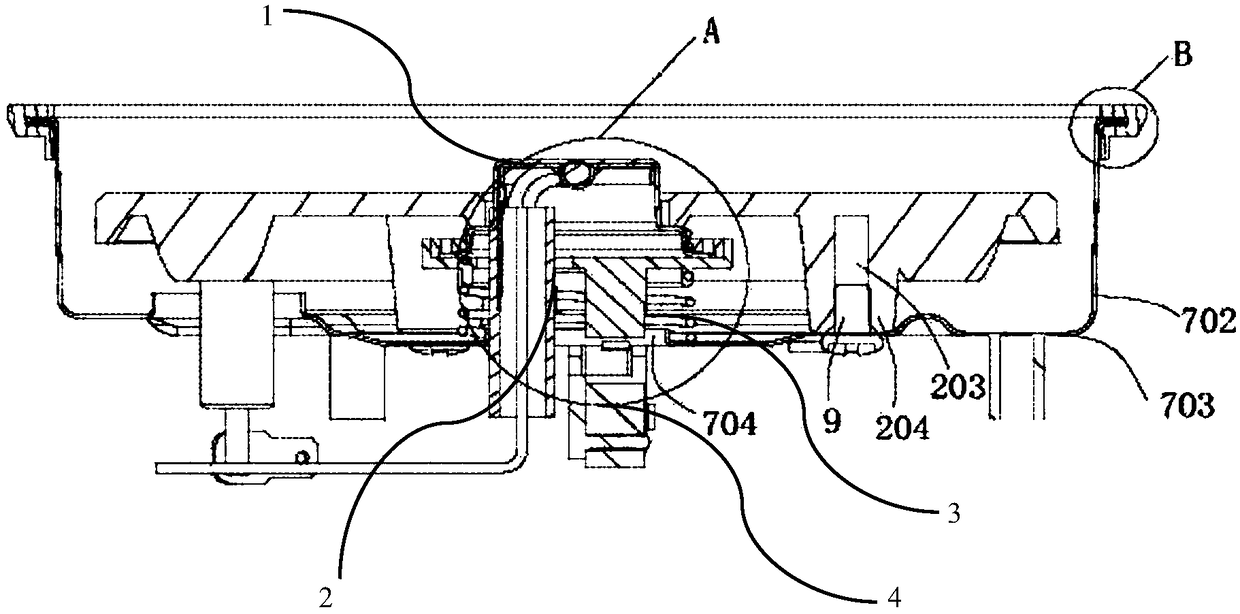

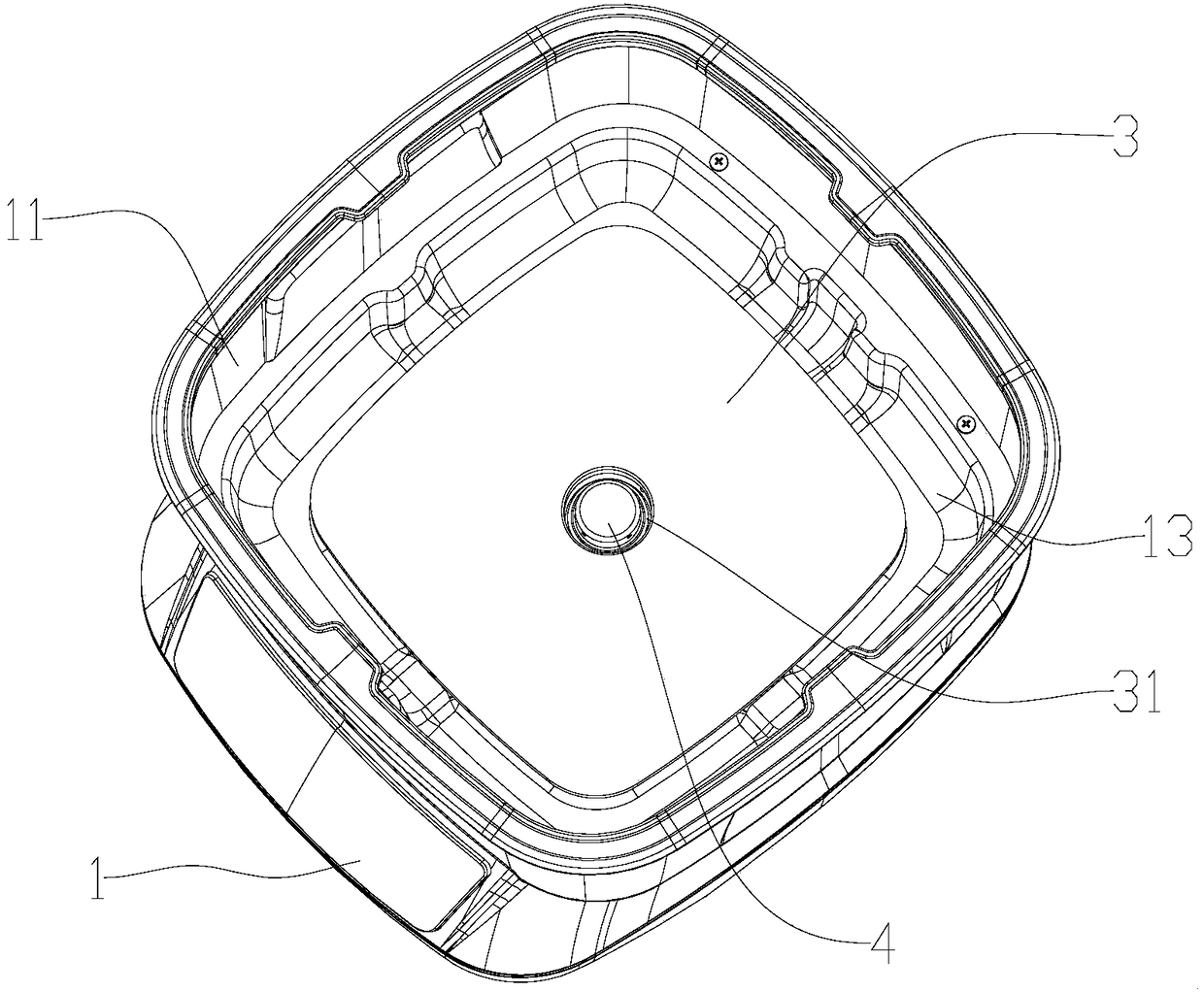

[0027] like Figure 3-4 , 8, the heating base includes the main body 1 of the base, the temperature detection component 4, the bracket 5, the spring 7, the micro switch 6, the heating plate 3 and the trigger plate 8, and the main body 1 is formed with a first cavity 11 and a second A cavity 12, the first cavity 11 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com