Metal butterfly valve

A butterfly valve and metal technology, which is applied in the field of butterfly valve improvement and invention, can solve the problem that the valve cannot maintain sealing, etc., and achieve the effects of increased sealing specific pressure, good sealing performance, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

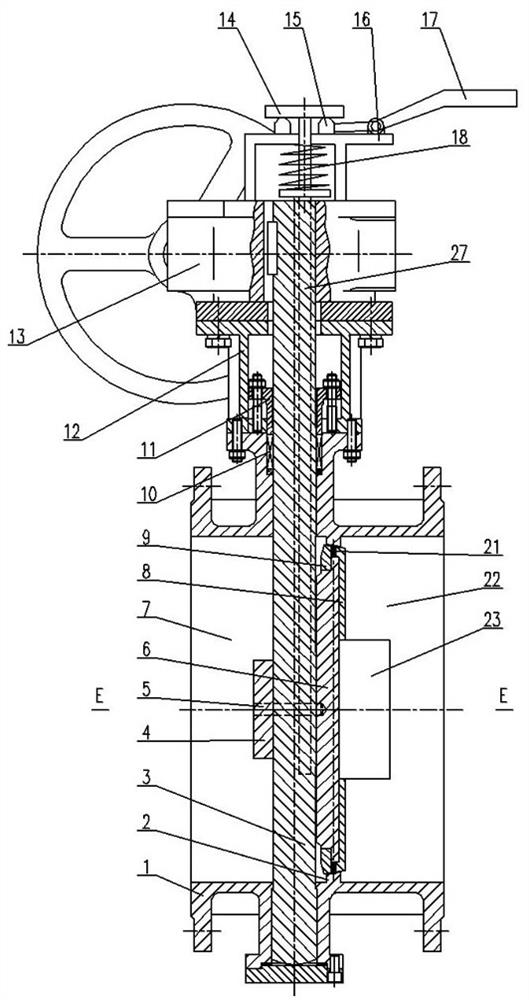

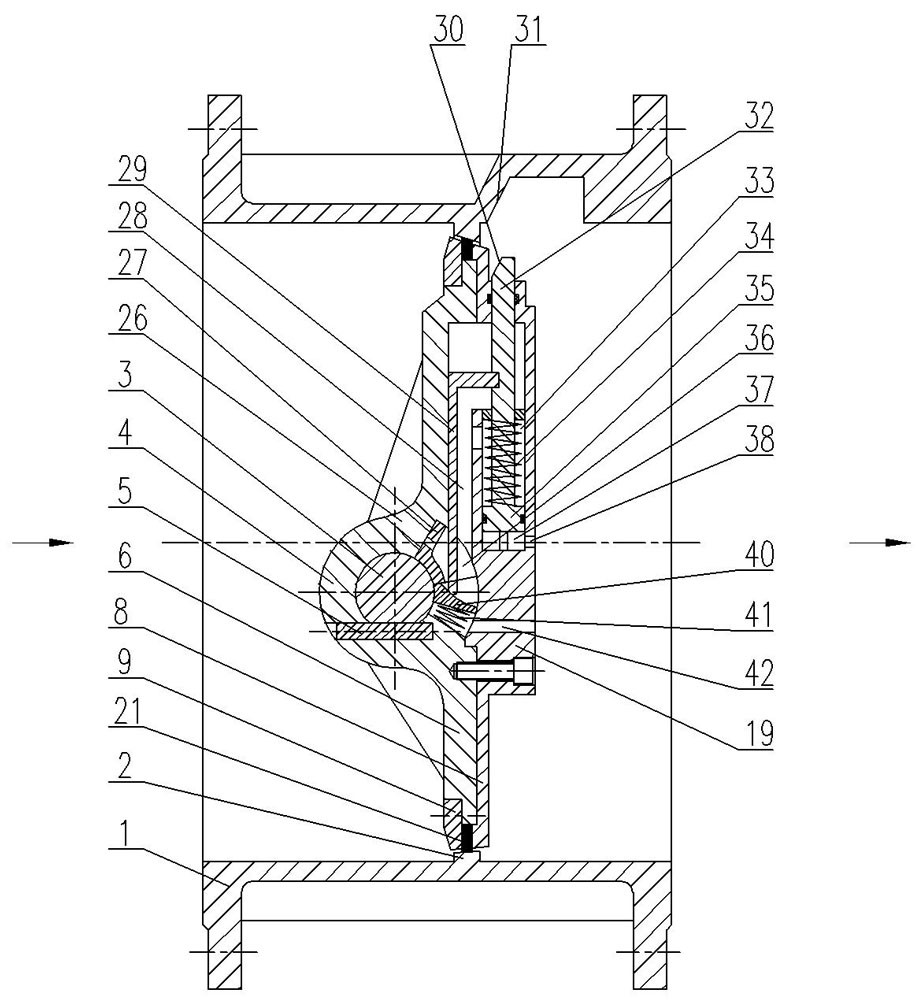

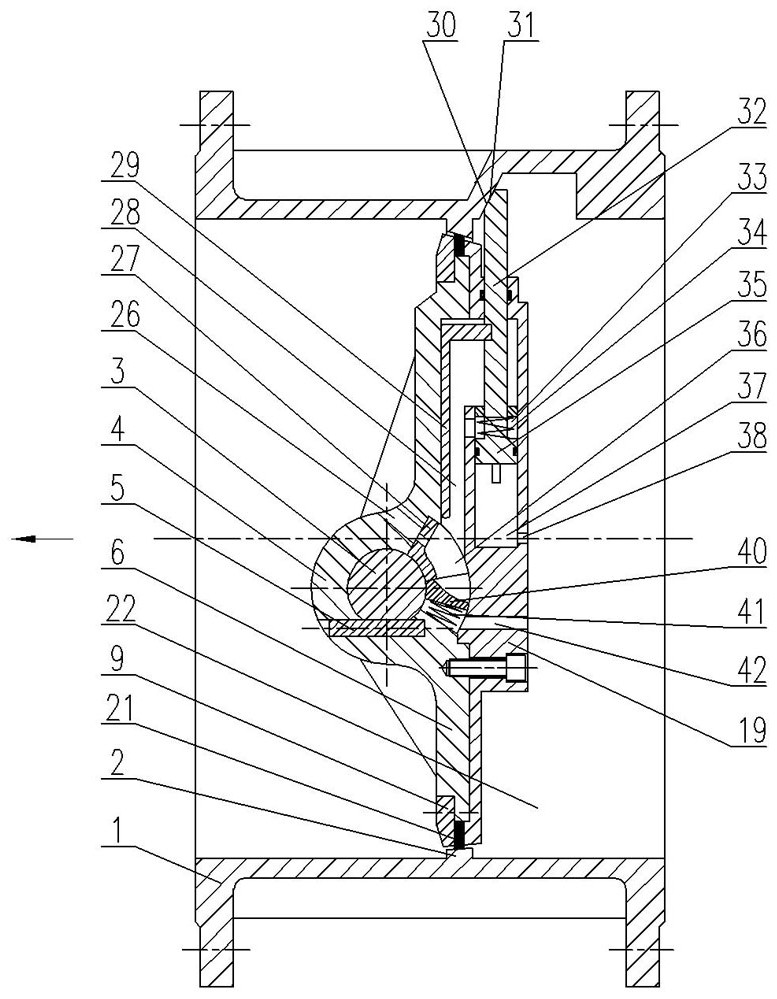

[0017] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. In this embodiment, the metal butterfly valve includes a valve body 1 and a valve stem 3, and the inner cavity of the valve body 1 is provided with a sealingly fitted butterfly plate 6 and a valve seat 2 as well as valves located on the left and right sides of the butterfly plate 6. The inlet cavity 7 and the outlet cavity 22, and the butterfly plate 6 can be rotated eccentrically, and the sealing surface of the corresponding butterfly plate 6 and the valve seat 2 is a matching inclined surface, and the valve stem 3 is rotatably installed on the valve body 1, and A packing 10 is provided between the valve stem 3 and the upper end of the valve body 1, and the packing 10 is pressed by a gland 11, and the upper end of the valve stem 3 is connected to the driving device 13 by transmission, and the driving device 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com