High-temp. high-pressure valve rod active seal mechanism and gate valve adopting said seal mechanism

An active sealing, high temperature and high pressure technology, applied to shaft seals, engine components, sliding valves, etc., can solve problems such as poor sealing and easy leakage of media, and achieve the effect of improving the sealing effect, improving the sealing effect, and increasing the sealing specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

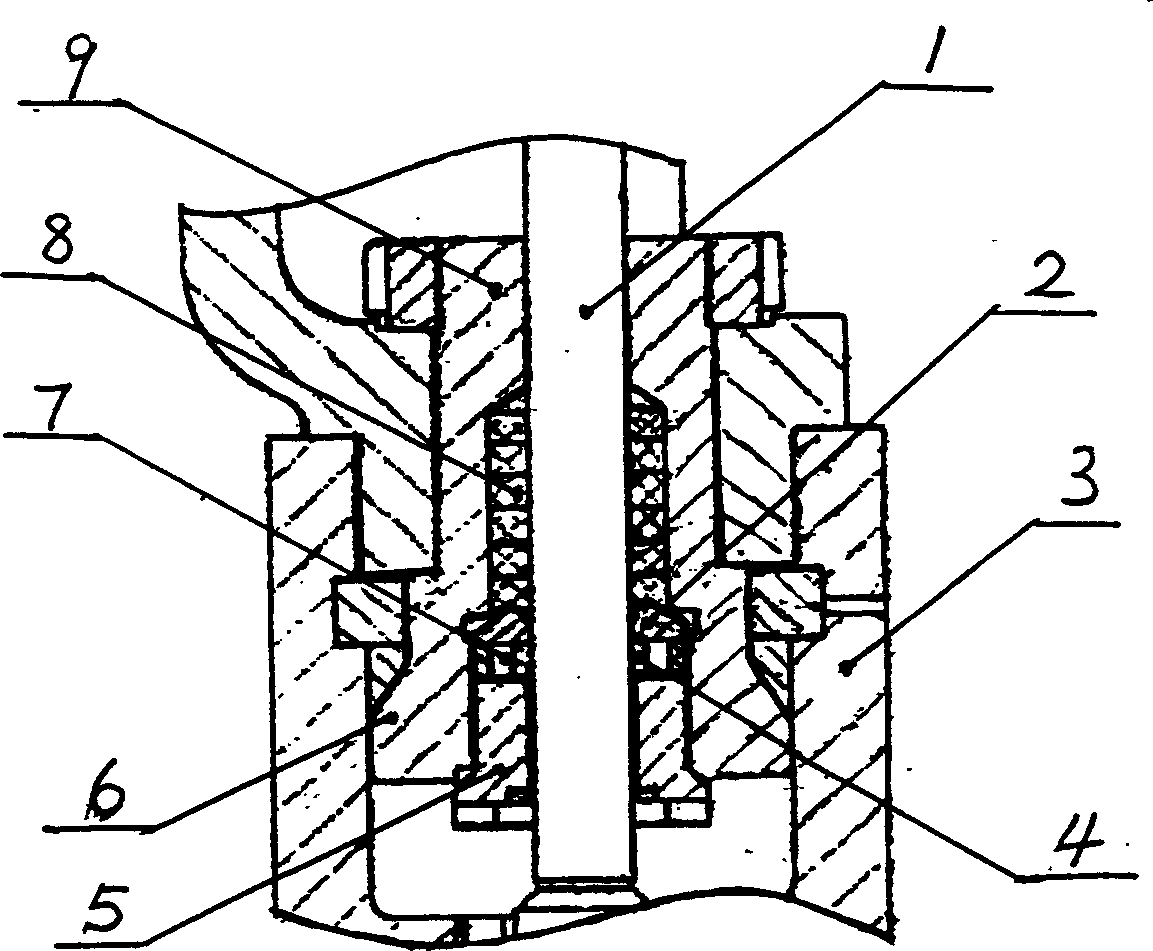

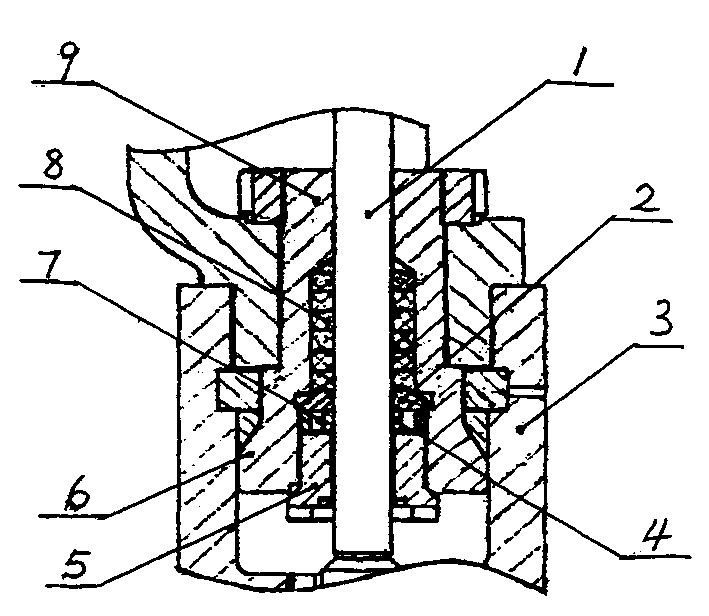

[0013] see figure 1 , the high temperature and high pressure valve stem active sealing mechanism provided by the present invention includes a valve cover 9, the valve cover 9 is provided with a stuffing box opening to the inner cavity of the valve body, in the stuffing box there are arranged several tightly pressed together from top to bottom. Layer packing 8, packing pad 2 and compression nut 4, the middle of described bonnet 9, packing 8, packing pad 2 and compression nut 4 are all provided with holes, and these holes are connected to each other to form the stem hole of this mechanism.

[0014] The packing pad 2 can be in the shape of a disc with unequal diameters up and down, and the diameter of its lower part is larger than that of the upper part. correspond.

[0015] The compression nut 4 may be provided with several axial through holes 7, and its upper surface may also be provided with an annular groove connected with the through holes.

[0016] Said compression nut 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com