Biomass boiler smoke recycling system

A biomass boiler and flue gas recovery technology, which is applied in the field of boiler energy saving and emission reduction, can solve the problems of unsatisfactory implementation results and sealing failure, and achieve good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

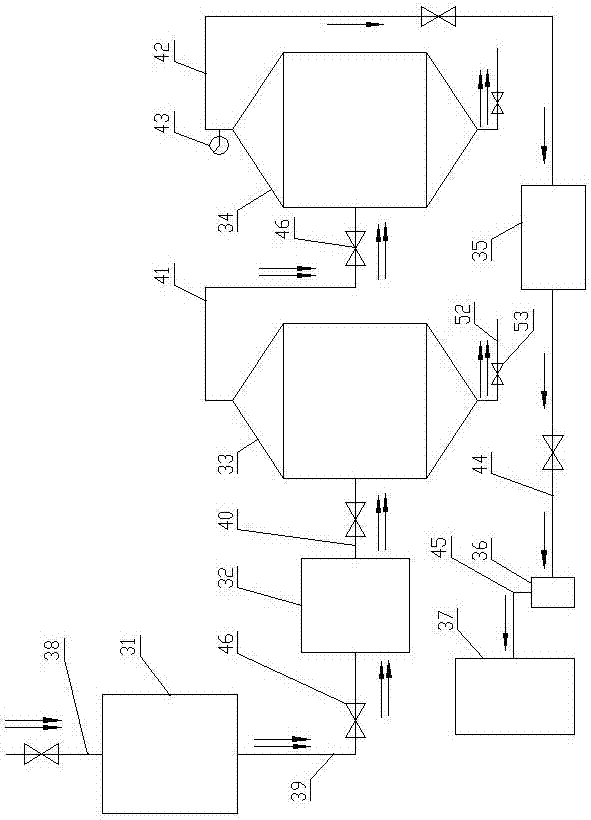

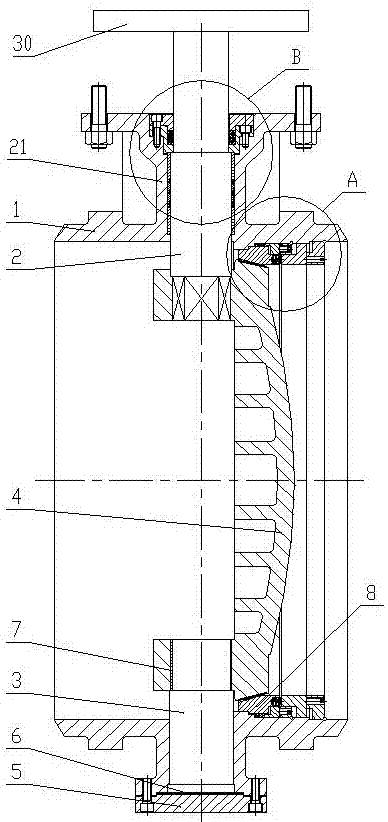

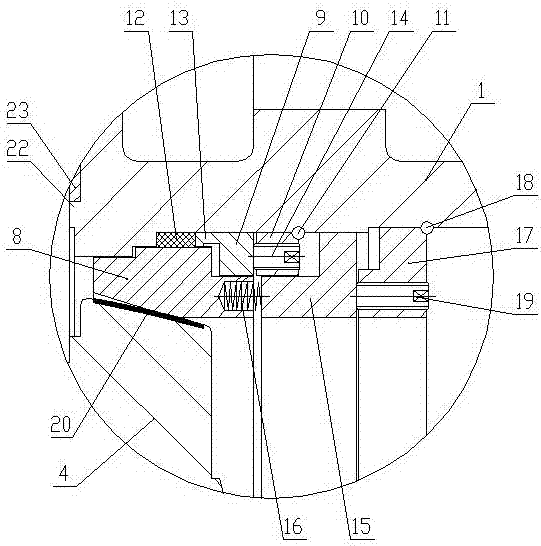

[0038] Such as Figure 1-Figure 6 As shown, the biomass boiler flue gas recycling system of the present invention includes an air preheater 31, a spray type dust removal and sulfur removal device 32, a primary flue gas static pressure box 33, a secondary flue gas static pressure box 34, a gas Dryer 35, air compressor 36 and high-pressure gas storage tank 37;

[0039] The flue gas outlet of the boiler is connected to the high-temperature gas inlet of the air preheater 31 through the first pipe 38, and the low-temperature gas outlet of the air preheater 31 is connected to the air inlet of the spray dedusting and desulfurizing device 32 through the second pipe 39 , the gas outlet of the spray dust removal and sulfur removal device 32 is connected to the middle part of the first-stage flue gas plenum 33 through the third pipe 40, and the top of the first-stage flue gas plenum 33 is connected to the second-stage flue gas through the fourth pipe 41. The middle part of the static pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com