Forced seal valve with modular design and angular travel operation

A modular design, forced sealing technology, applied in valve devices, mechanical equipment, cocks including cut-off devices, etc. Valve seat sealing surface scouring and other problems, to reduce wear, save maintenance time, and improve the effect of sealing specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

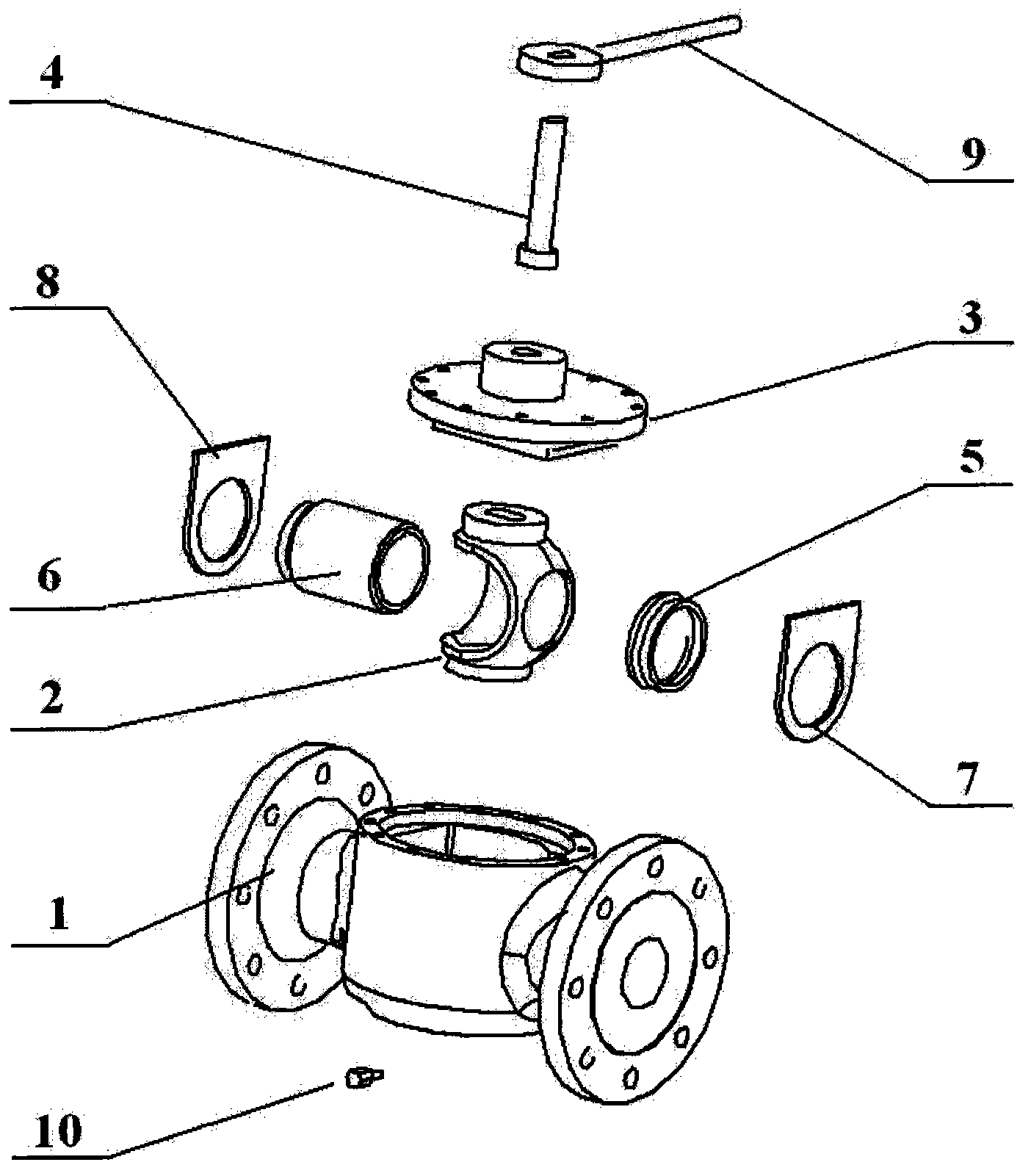

[0020] A forced seal valve with modular design and angular stroke operation, its main components include: valve body 1, opening and closing member 2, valve cover 3, valve stem 4, valve seat 5, guide tube 6, valve seat support plate 7, Guide tube support plate 8, operating mechanism 9, blowdown valve 10. Such as figure 1 shown.

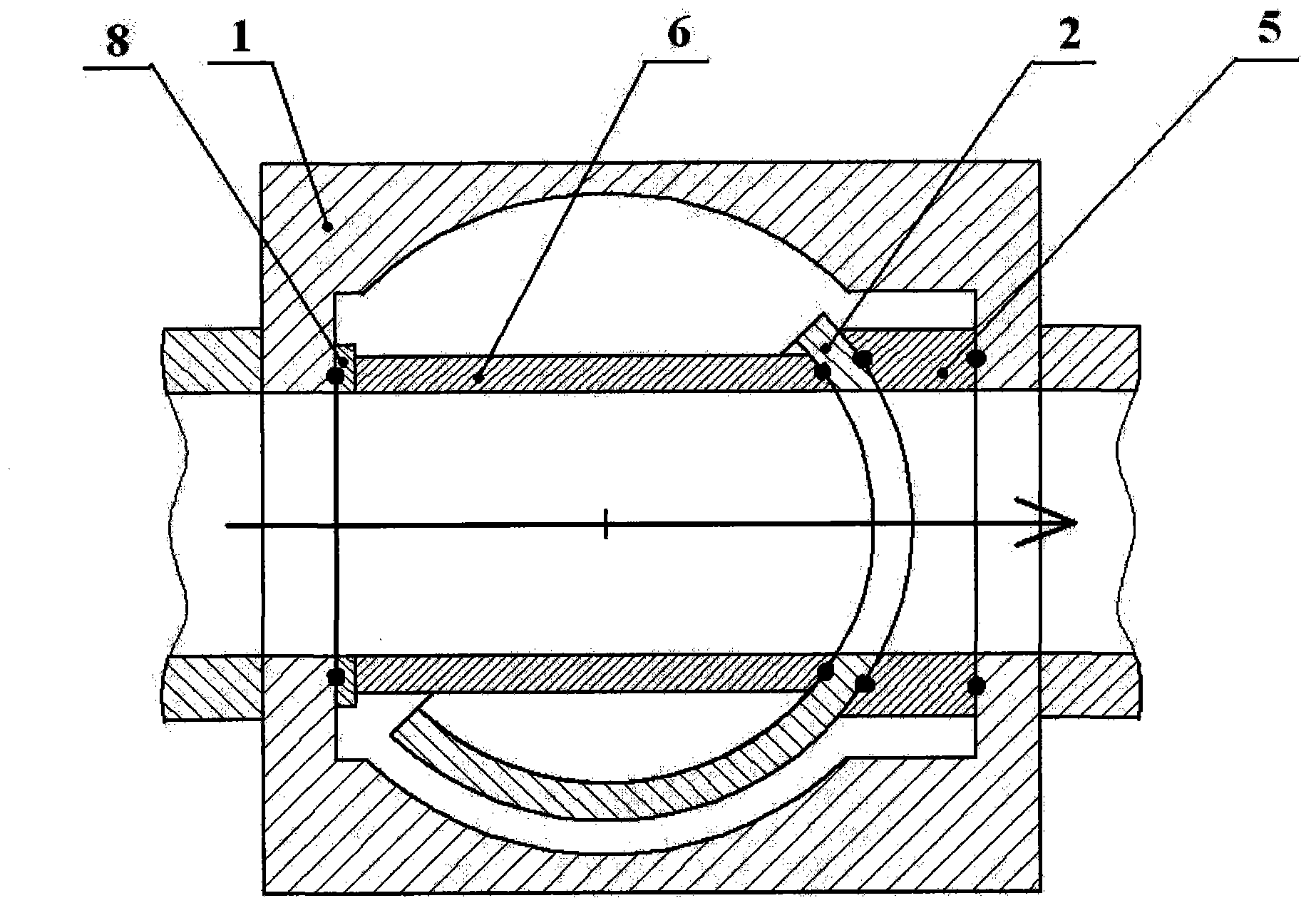

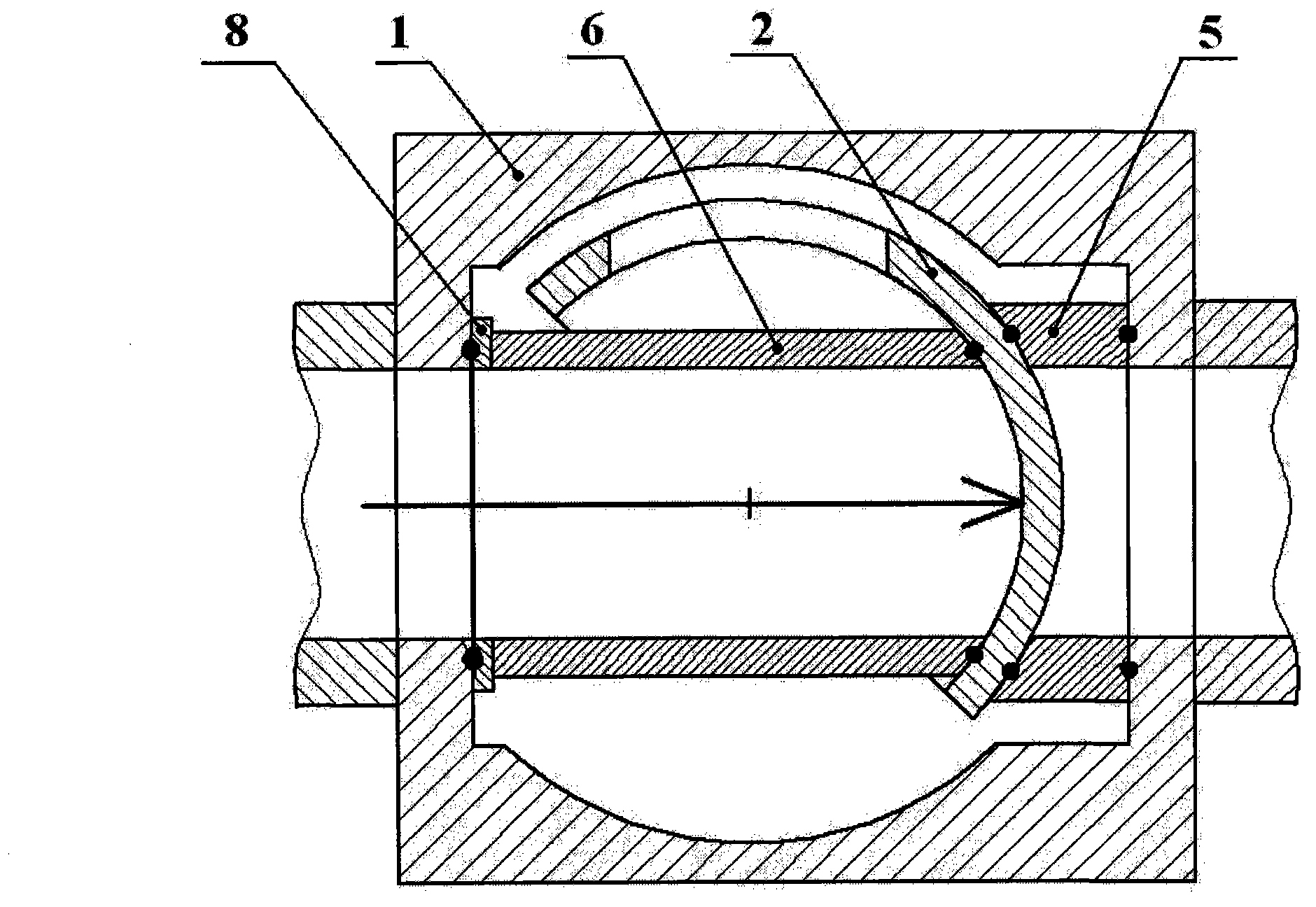

[0021] The opening and closing part 2 is connected with the valve stem 4, and the opening and closing part 2 is driven to rotate by rotating the valve stem 4 to change the relative relationship between the flow channel of the opening and closing part 2 and the diameter of the valve seat 5 to open and close the flow of the medium. Purpose. When the flow channel area of the opening and closing part 2 is connected with the diameter area of the valve seat 5 by 100%, the valve is in the fully open position; when the flow channel area of the opening and closing part 2 is isolated from the diameter area of the valve seat 5 by 100%, The valve is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com