Low-torque and two-way zero leakage all-metal sealing butterfly valve

An all-metal, zero-leakage technology, applied in two-way zero-leakage all-metal sealed disc valve, low torque field, can solve the problems of thick valve plate structure, poor sealing, large flow resistance, etc., to achieve reliable two-way sealing performance and fast closing speed , the effect of large flow coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

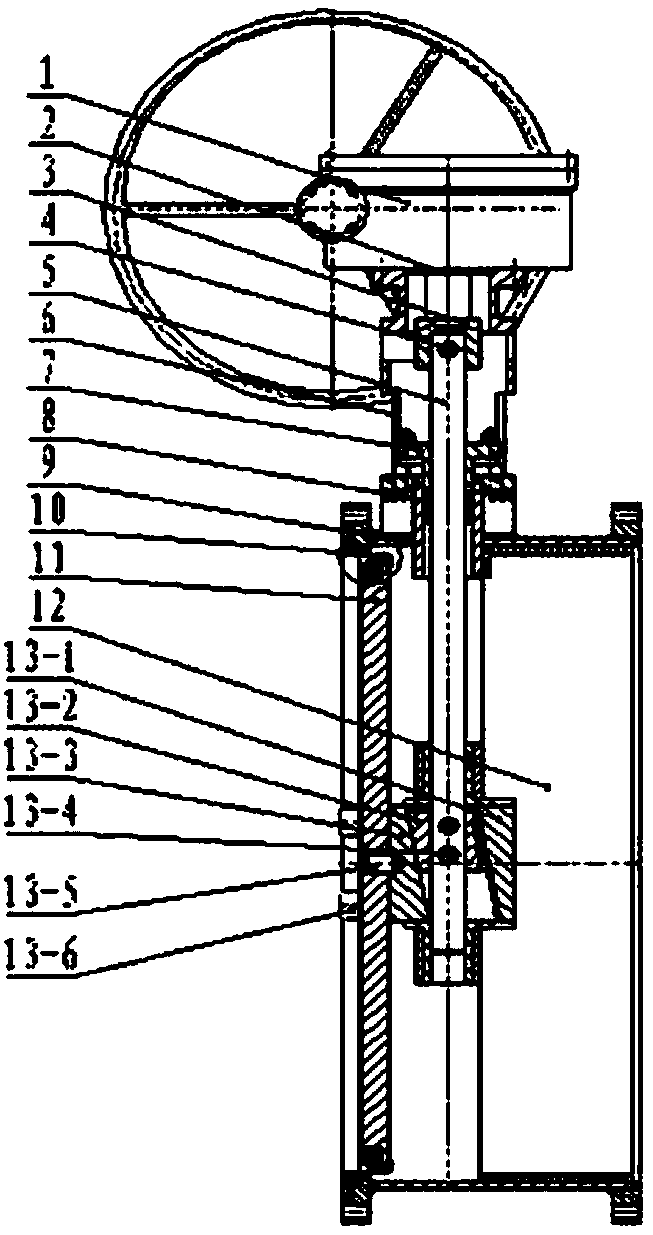

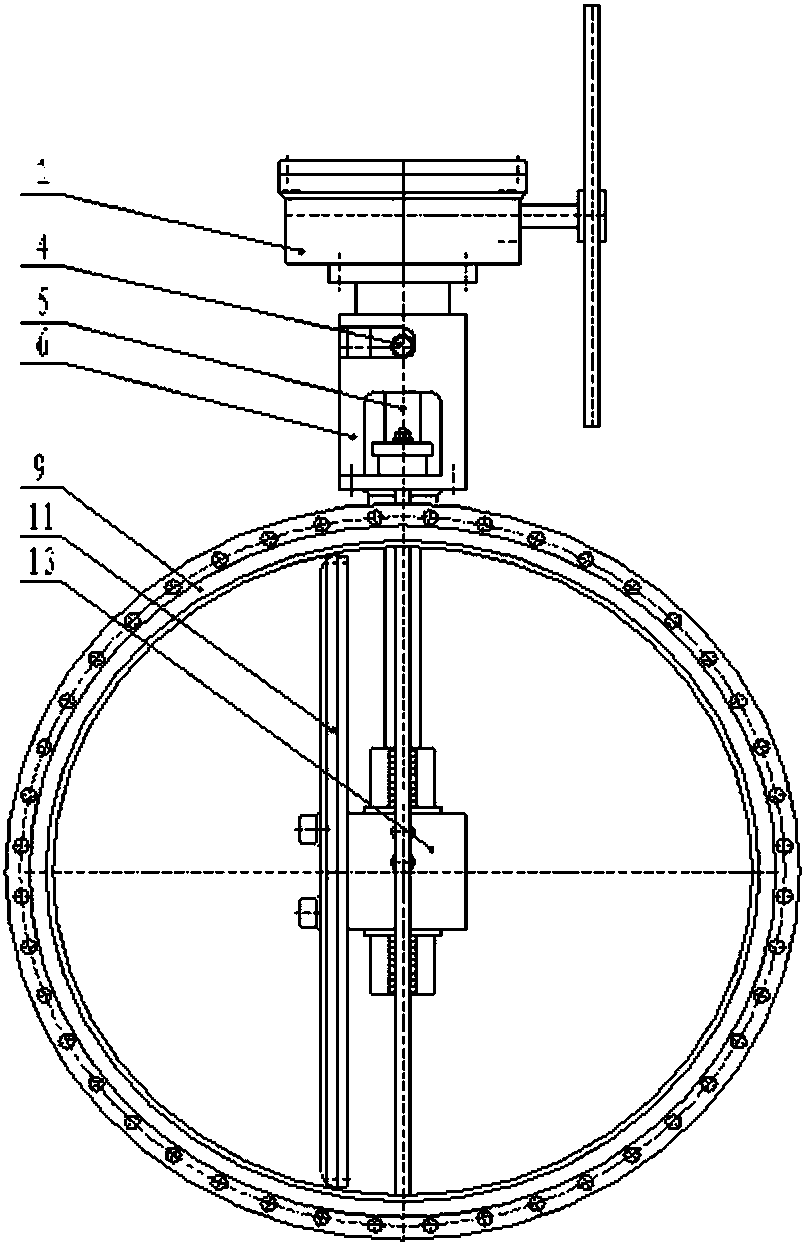

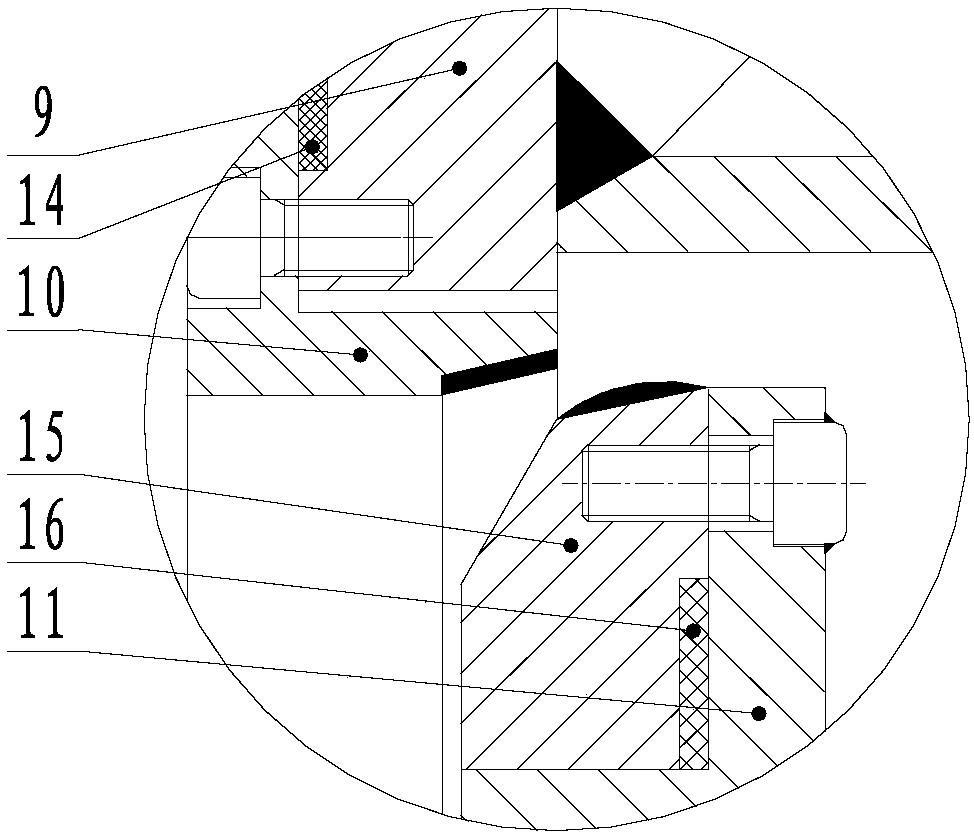

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a high-pressure water pump outlet control valve according to the present invention includes an actuator 1, a threaded sleeve 2, a screw 3, a connecting shaft 4, a valve stem 5, a bracket 6, a packing gland 7, a valve stem packing 8, Valve body 9, valve seat 10, butterfly plate 11, reinforcing rib 12, wedge split sliding assembly 13, valve seat sealing packing 14, all-metal sealing ring 15, butterfly plate sealing packing 16, needle roller bearing 17, roller 18; The mechanism 1 is installed on the bracket 6, and the inside of the actuator 1 is equipped with a threaded sleeve 2, a screw 3, and a connecting shaft 4. Needle bearings 17 and rolling wheels 18 are installed at both ends of the connecting shaft 4, and the screw rod 3 is connected to the connecting shaft 4 and The valve stem 5 is connected and fixed, the bracket 6 is processed with vertical grooves and horizontal grooves, and the scroll wheel 18 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com