Four eccentric butterfly valve and design method

A design method and four-eccentric technology, applied in the direction of lifting valves, valve devices, mechanical equipment, etc., can solve the problems of large extrusion angle between dynamic and static sealing surfaces, inability to withstand pressure, and inability to seal, so as to achieve good sealing effect and increase flow rate , the effect of reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

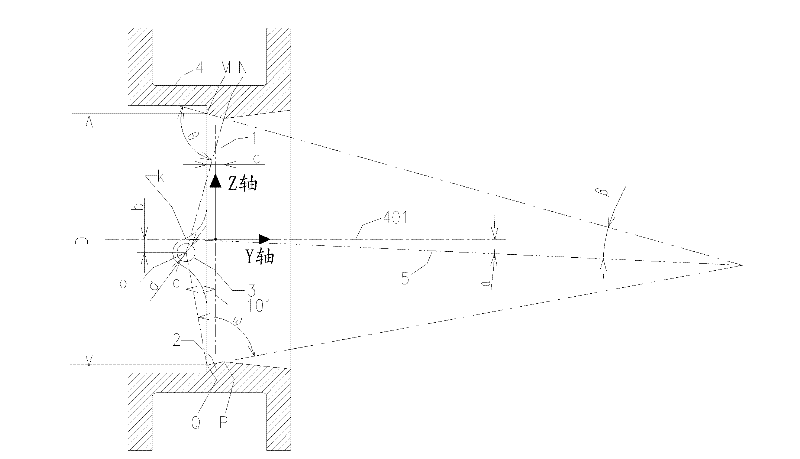

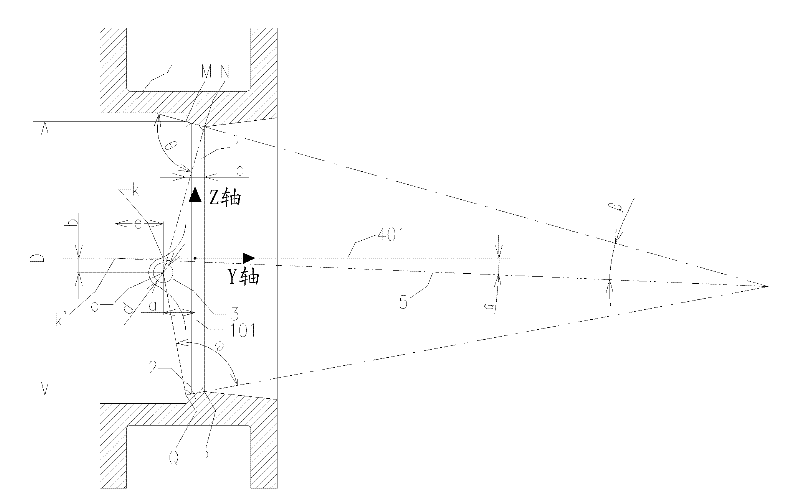

[0049] Assuming that the diameter of the four-eccentric butterfly valve is D=600, c=50mm and d=90mm are obtained according to the force analysis, and a≈50mm is obtained according to a=(c+d) / 2-c / 3. Take θ=ω=90°, take c / 3≈17mm as the chamfering parameter (that is, the remaining thickness of the valve plate 1 at the chamfering is about 17mm), use computer modeling and find out b through experiments min ≈6mm, using w1+w2-w3 as the objective function, find that when b=8mm, the value of w1+w2-w3 can roughly approach 0, at this time b=0.013D. The design of the valve plate 1 is thus completed. At this time, the fourth eccentric distance e=75.84mm, the third eccentric angle α=6.72°, and the half-cone angle β=16.34° can be obtained as the processing parameters of the valve plate 1 and the valve seat 2. The verification of the interference check in the three-dimensional design software shows that the dynamic and static sealing surfaces of the beveled conical eccentric butterfly valve do...

Embodiment 2

[0051]On the basis of Example 1, keep the values of parameters a, c, d, θ, ω unchanged, but continue to increase the value of parameter b, when b=45mm, the value of the objective function w1+w2-w3 is approximately At the upper limit of the acceptable range, b≈0.08D at this time. In this way, the fourth eccentricity e=131.33 mm, the third eccentricity α=3°, and the half cone angle β=9° can be obtained. The verification of the interference check in the three-dimensional design software shows that the dynamic and static sealing surfaces of the beveled conical eccentric butterfly valve do not interfere at all.

Embodiment 3

[0053] On the basis of Example 1, the values of parameters a, b, c, d, θ, ω are kept constant, and the chamfering parameter is c / 5=10mm (that is, the remaining thickness of the valve plate 1 at the chamfering place is about 10mm) , because the remaining thickness of the valve plate 1 at the chamfer is smaller than that of Example 1, and the dynamic and static sealing surfaces are closer to a "line seal", so the sealing effect is better. The verification of the interference check in the three-dimensional design software shows that the dynamic and static sealing surfaces of the beveled conical eccentric butterfly valve do not interfere at all.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com