Patents

Literature

92results about How to "Zero leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

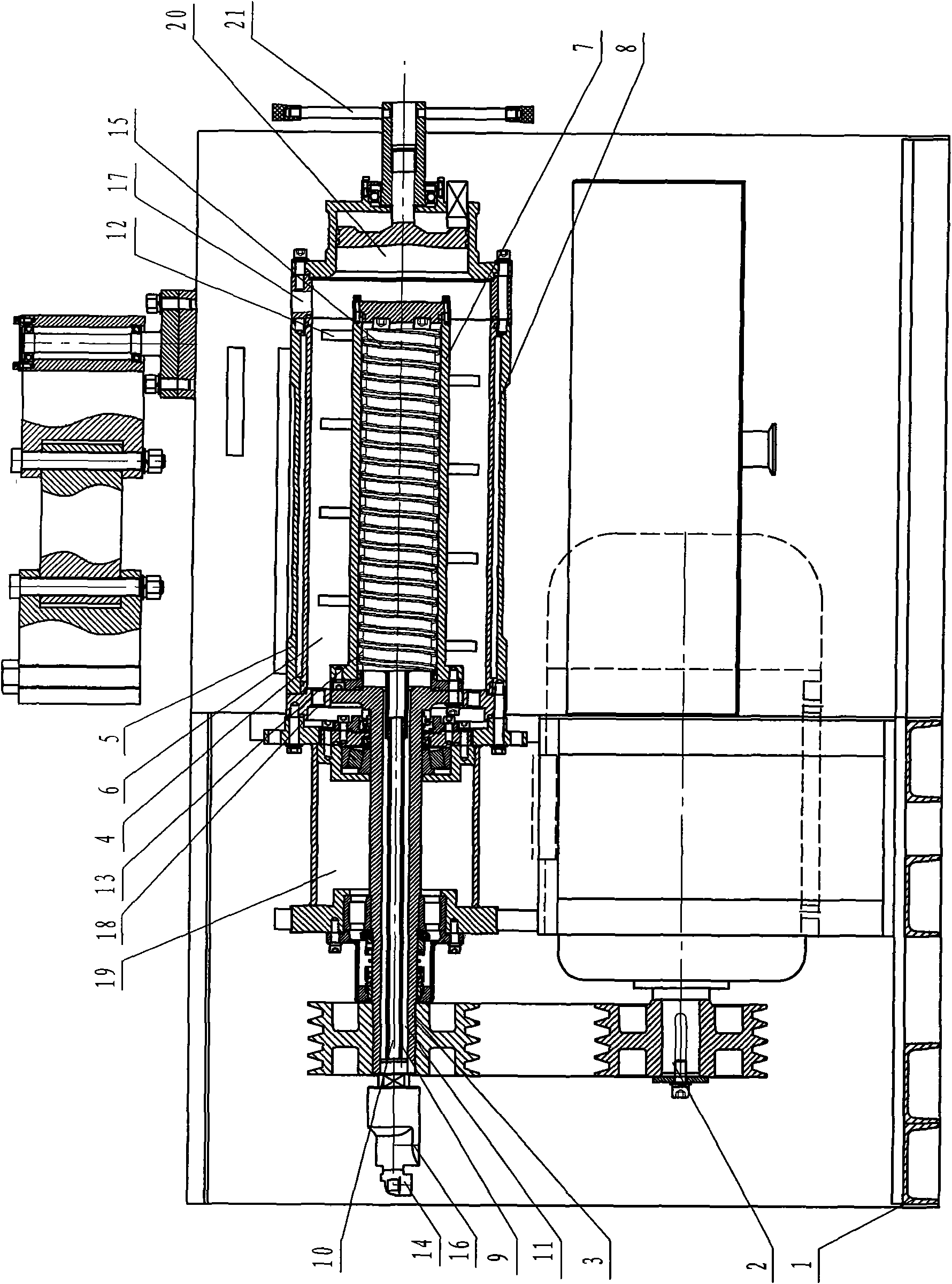

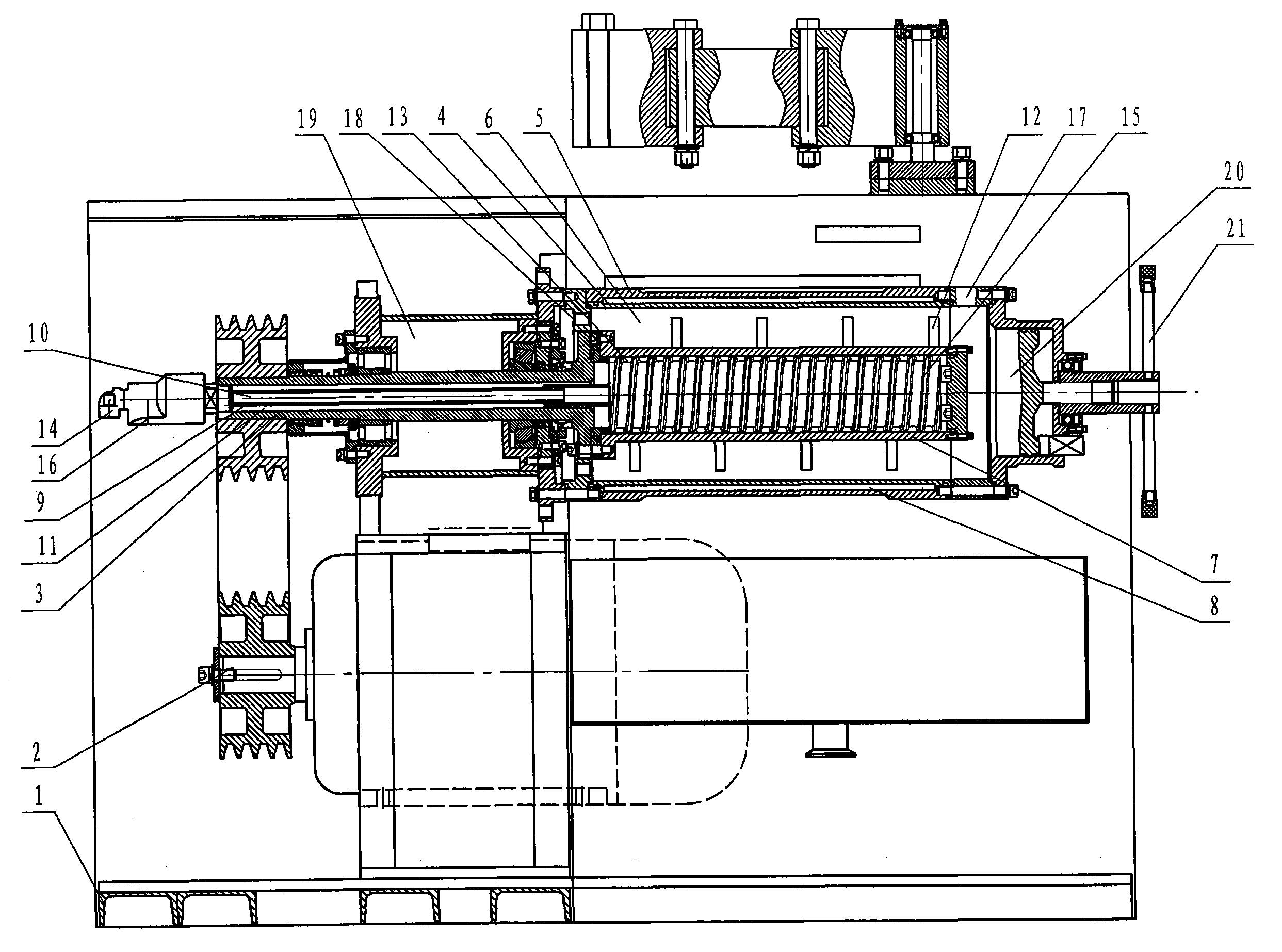

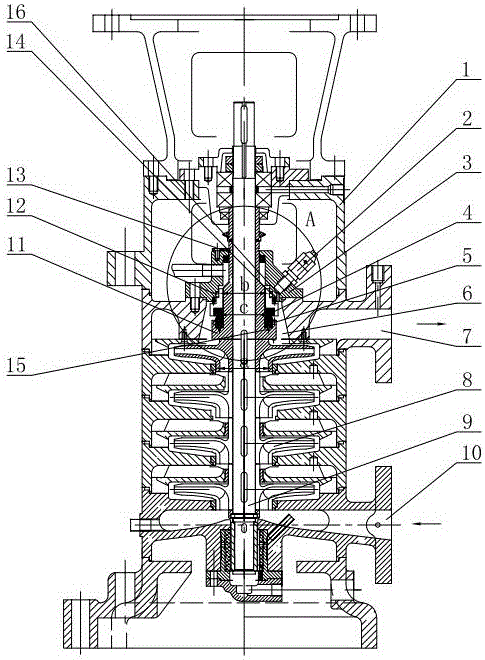

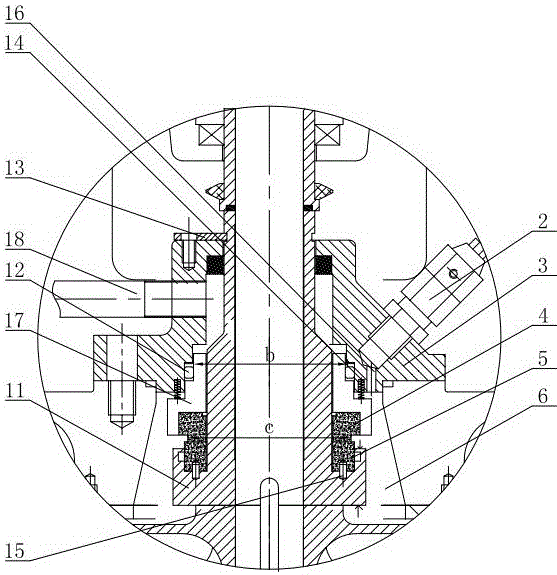

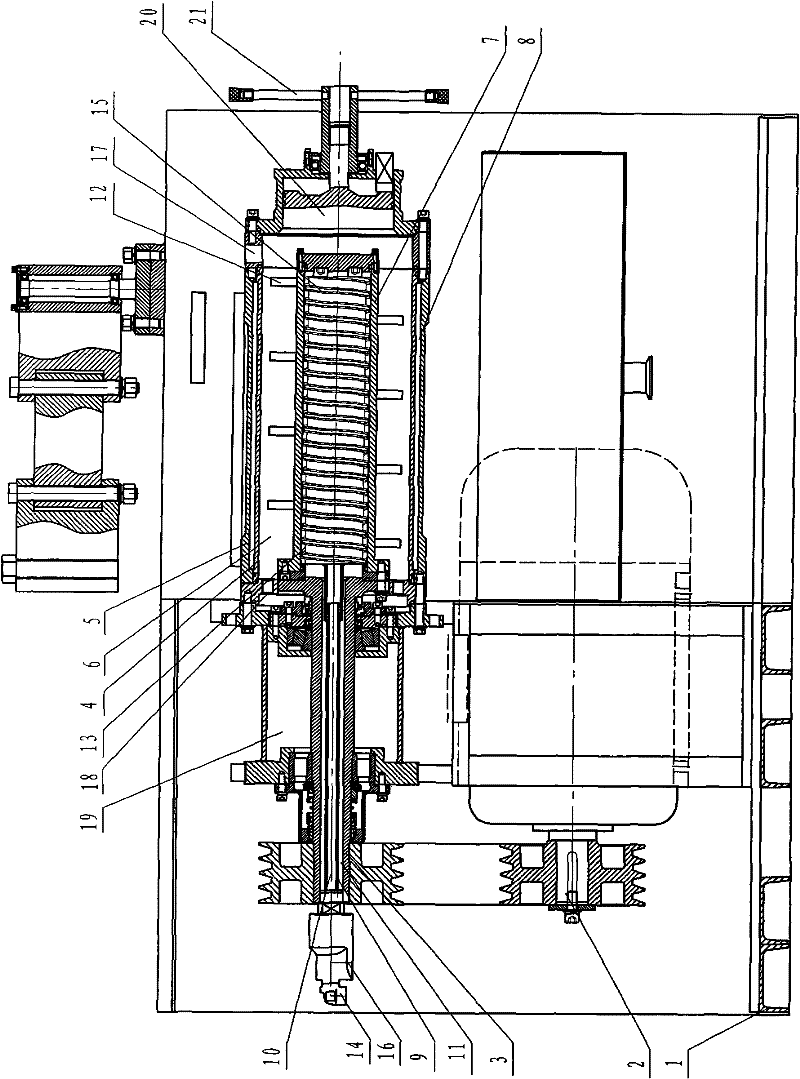

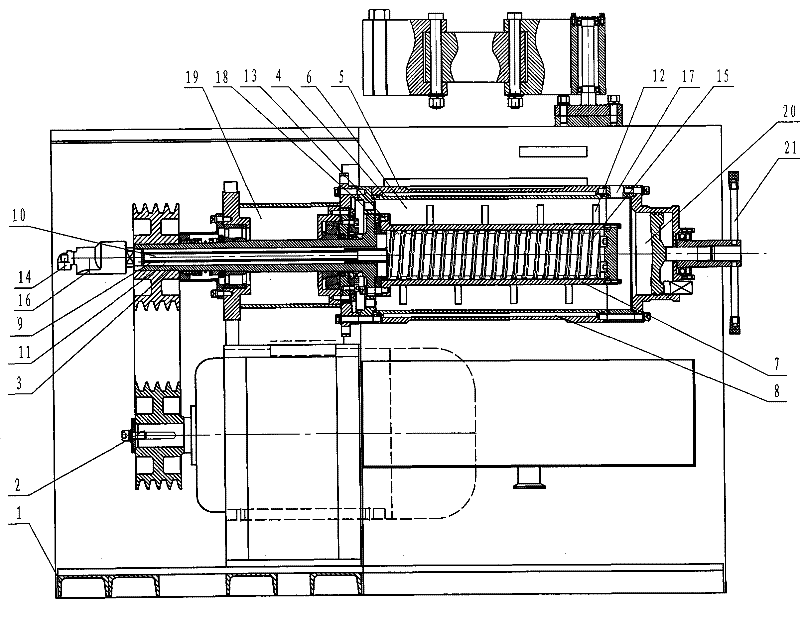

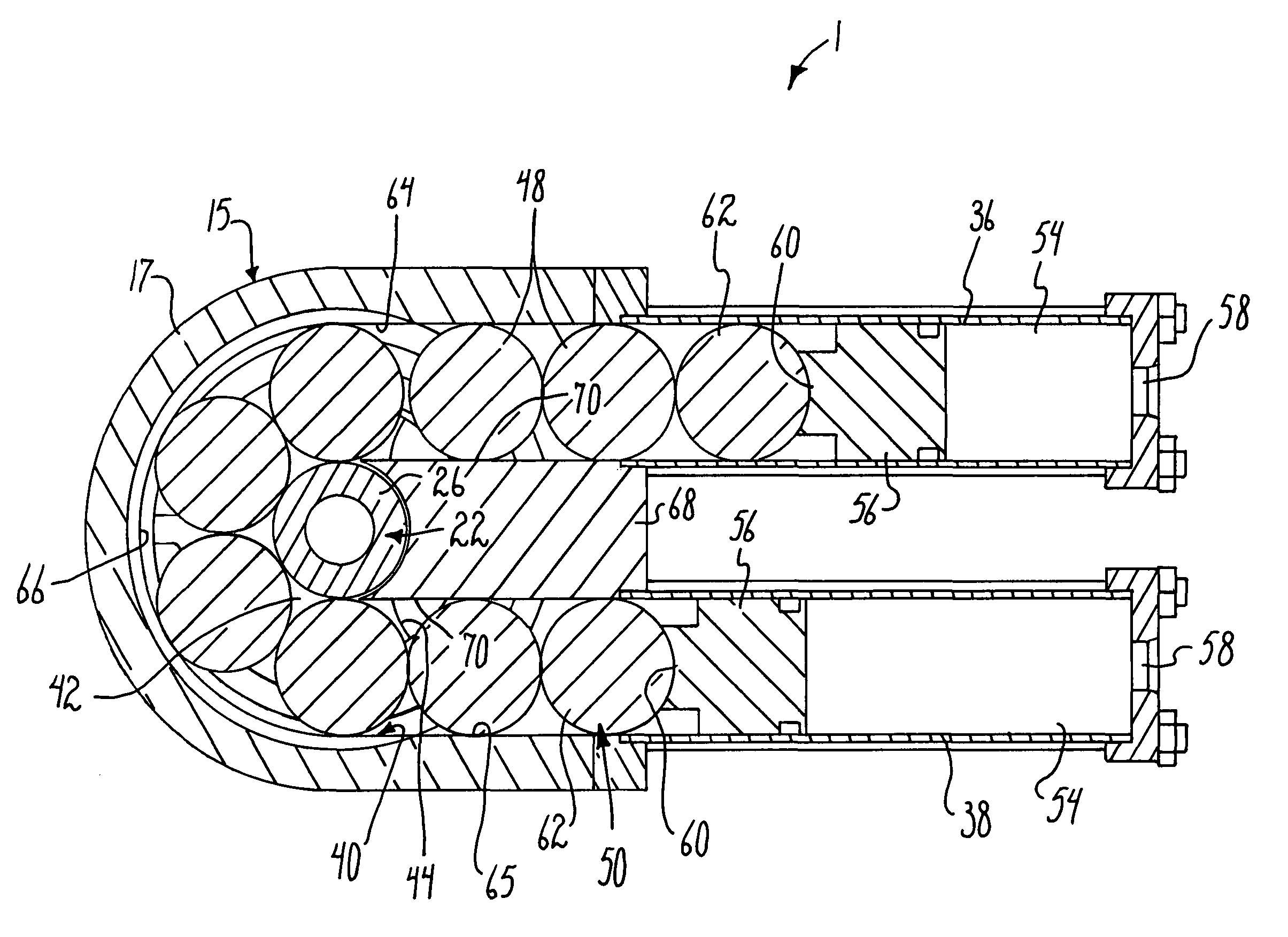

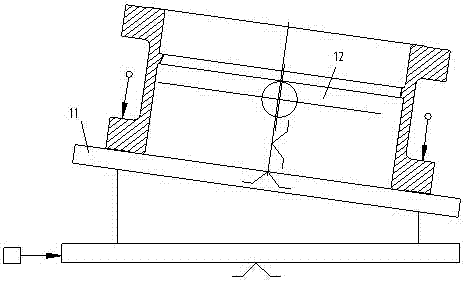

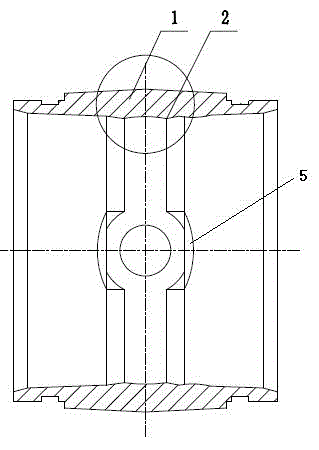

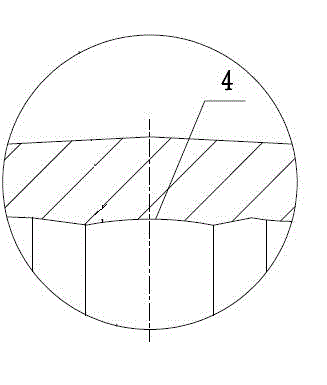

Horizontal sand mill

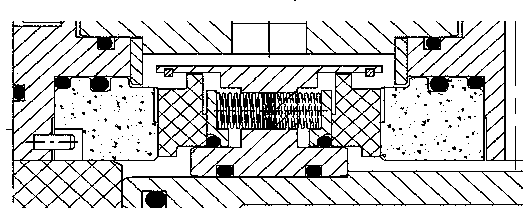

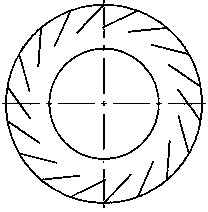

The invention discloses a horizontal sand mill which comprises a base, a motor, a main shaft and a grinding cylinder. The motor is fixed on the base, the main shaft is hollow and is connected with the motor through a belt pulley, cooling oil chambers are fixedly arranged around the main shaft, a cooling water flowing passage is intermediately formed, a plurality of grinding rods are fixedly arranged around the outer wall of a grinding inner sleeve, a cooling water pipe is arranged in the grinding inner sleeve, a U-shaped spiral water channel is fixedly arranged around the outer wall of the cooling water pipe, and a feeding hole and a discharging hole are arranged on a grinding outer sleeve. In the mill, both-end-surface mechanical sealing is adopted and a sealing ring is arranged at the joint of a bearing and a shaft. By adopting the technical scheme of the invention, the defects caused by overhigh temperature generated when a traditional horizontal sand mill runs are effectively overcome, the sand mill is stable and reliable to run, and the production quality and the operation efficiency are greatly improved.

Owner:安徽索维机电设备制造有限公司

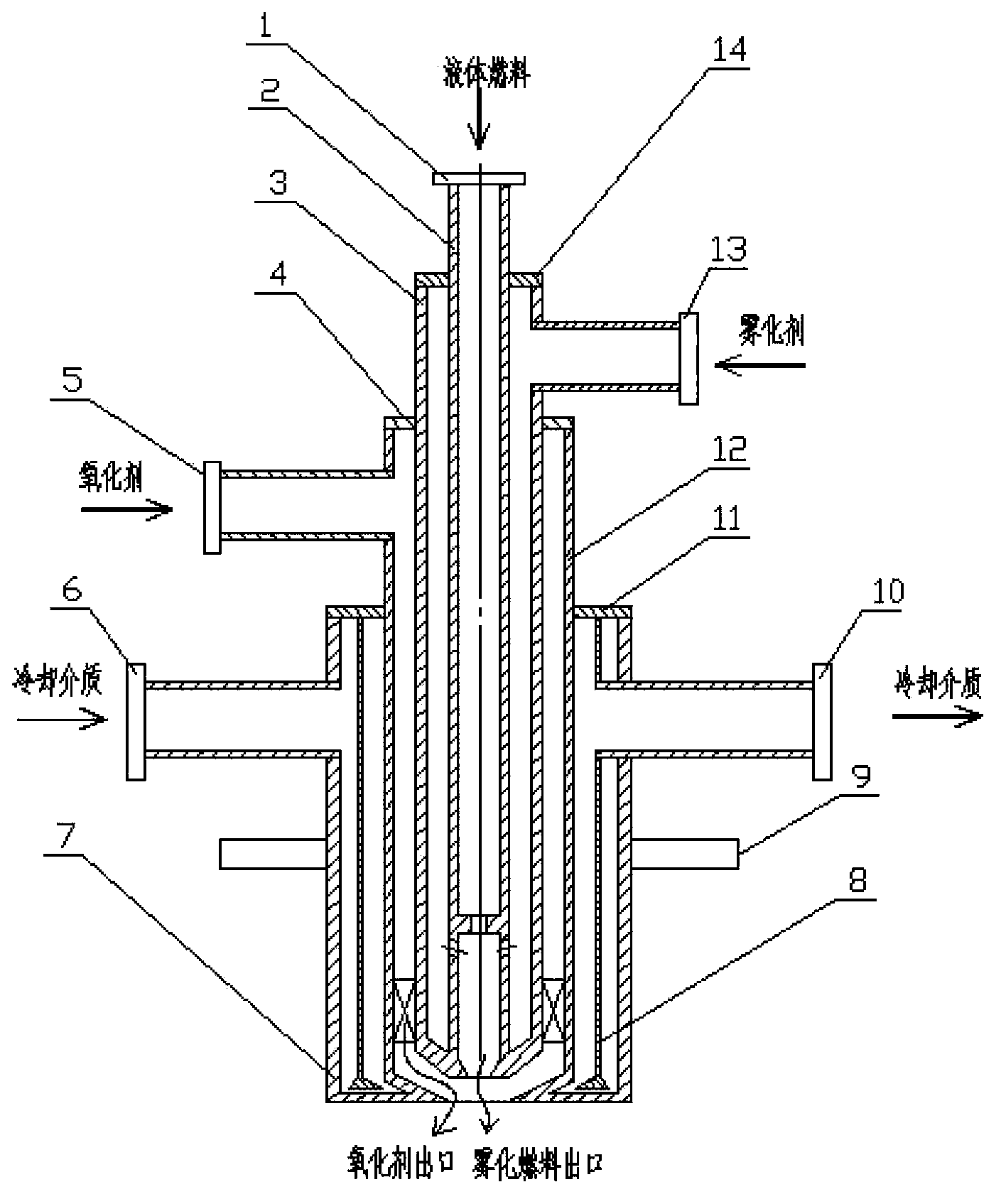

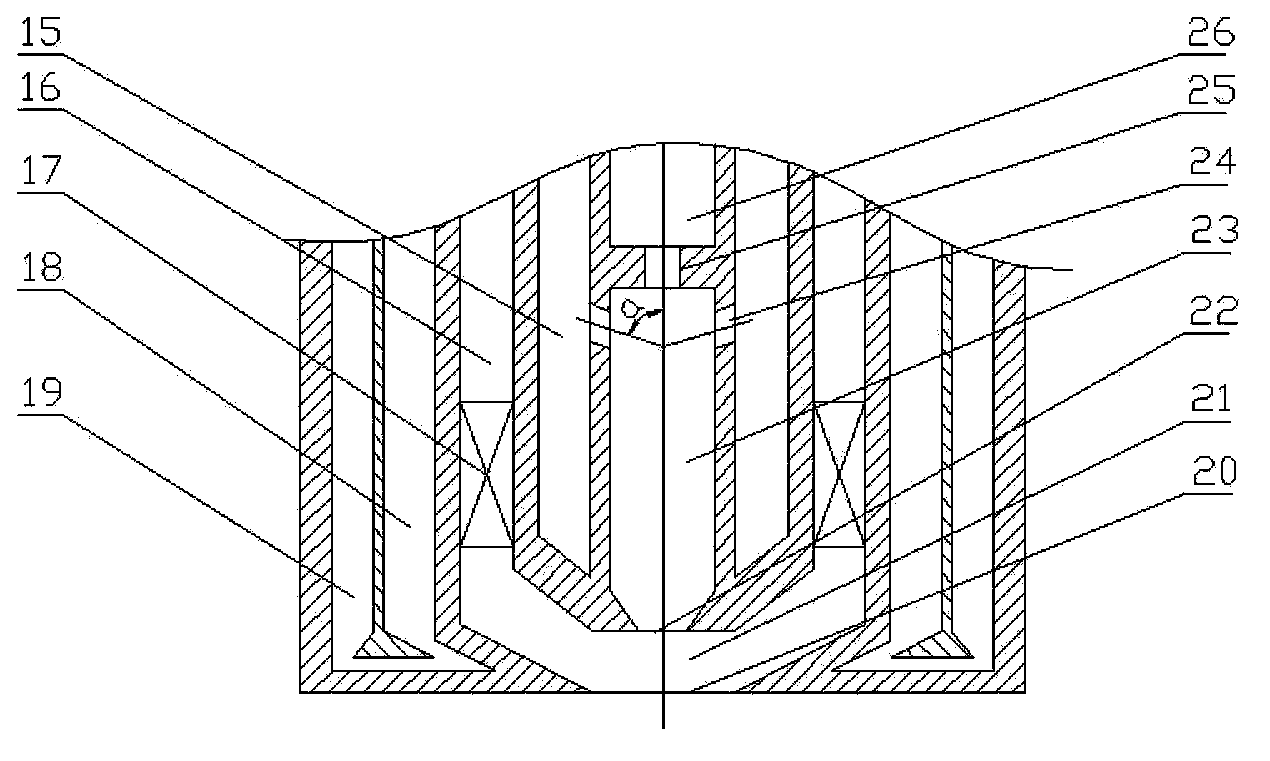

Variable-pressure and variable-working-condition oil burning nozzle

ActiveCN103822207AExtended service lifeImprove anti-ablation performanceBurnersFurnace temperatureEngineering

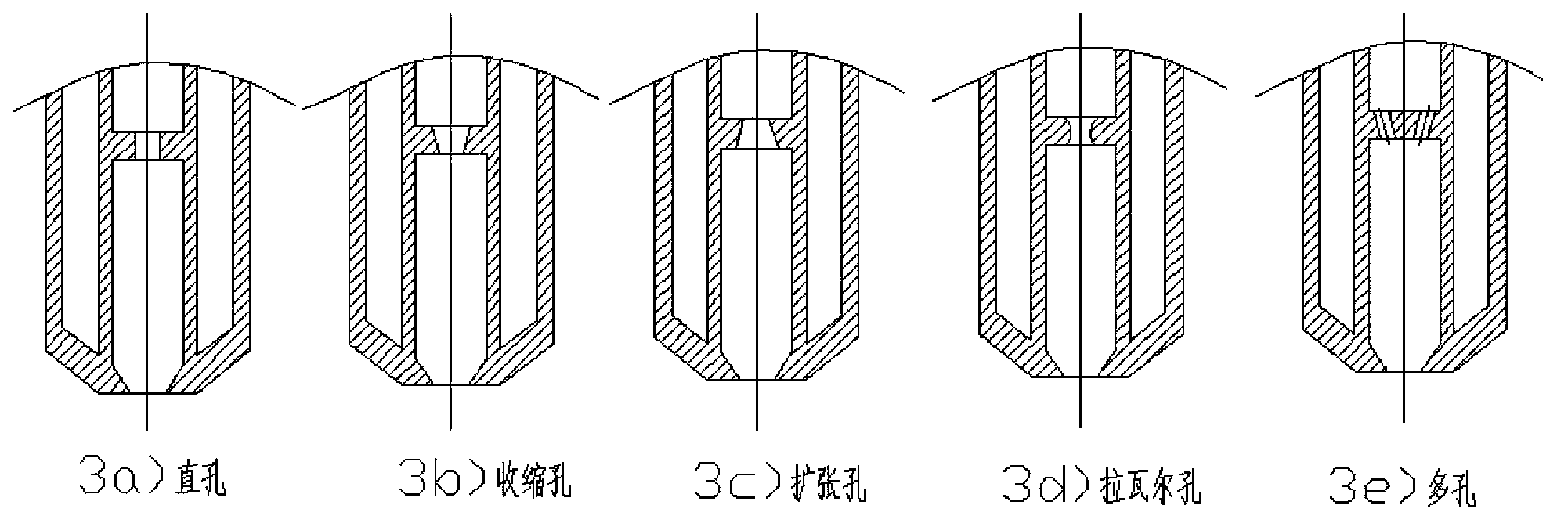

The invention provides a variable-pressure and variable-working-condition oil burning nozzle. The variable-pressure and variable-working-condition oil burning nozzle is a technical burning nozzle which is adapt to high-pressure environments, applicable to coal gasifiers, provided with igniting and burning capabilities in an operation process with random fixed pressure, variable pressure and continuous variable working conditions in a pressure range of 0-2.0MPaG, and used for igniting the coal gasifiers. The burning nozzle comprises body sleeves and a premix jet flow head. The body sleeves are in coaxial arrangement and include a liquid fuel outer sleeve, an atomizing agent outer sleeve and an oxidizing agent outer sleeve sequentially from inside to outside, and an annular space between each two sleeves form a medium passage. The premix jet flow head comprises inner and outer contraction type sonic or subsonic nozzles and two-level atomizing and mixing chambers and capable of realizing efficient atomizing and mixing of fuels and oxidizing agents and stable ignition and combustion. A double-layer closed annular passage cooling structure is arranged on the outermost layers of the head and the body of the burning nozzle, the burning nozzle is hermetically connected with a coal gasifier body through a mounting flange, and tightness and ablation avoidance of the burning nozzle under the furnace pressure of 0-8MPaG and at the furnace temperature of 1200-1700DEG C can be guaranteed.

Owner:CHANGZHENG ENG

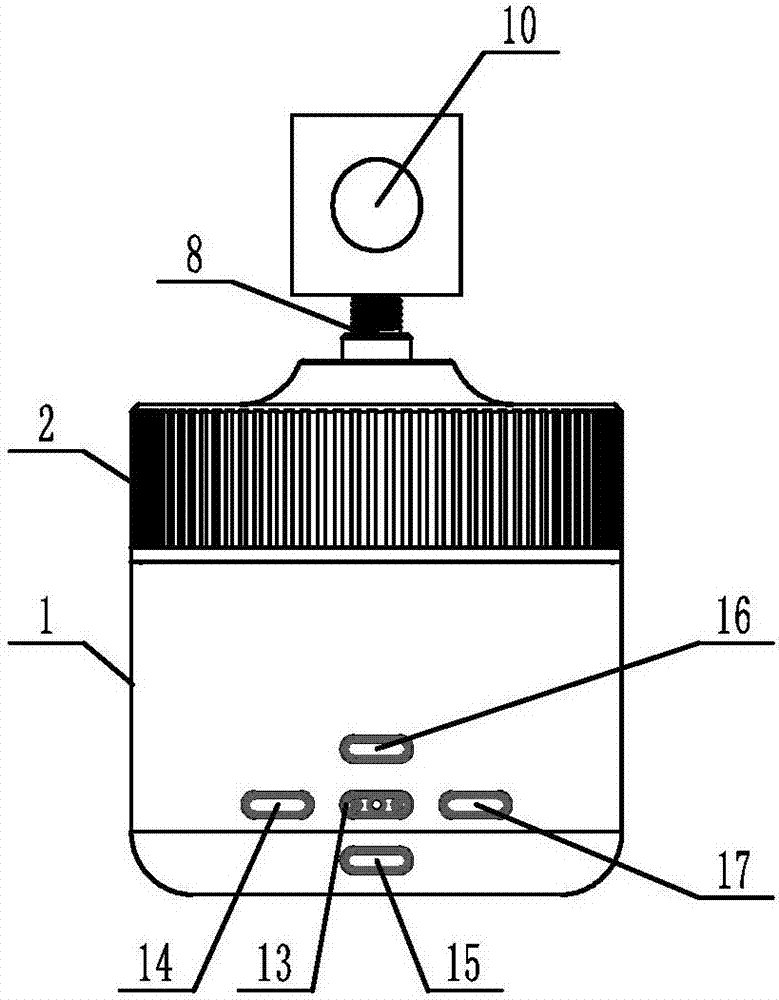

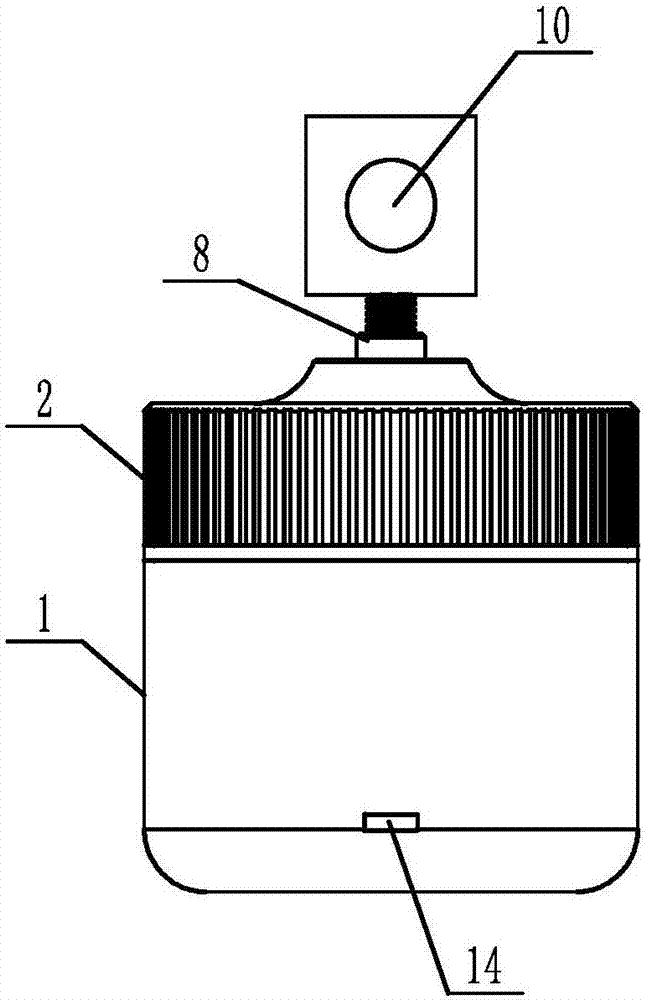

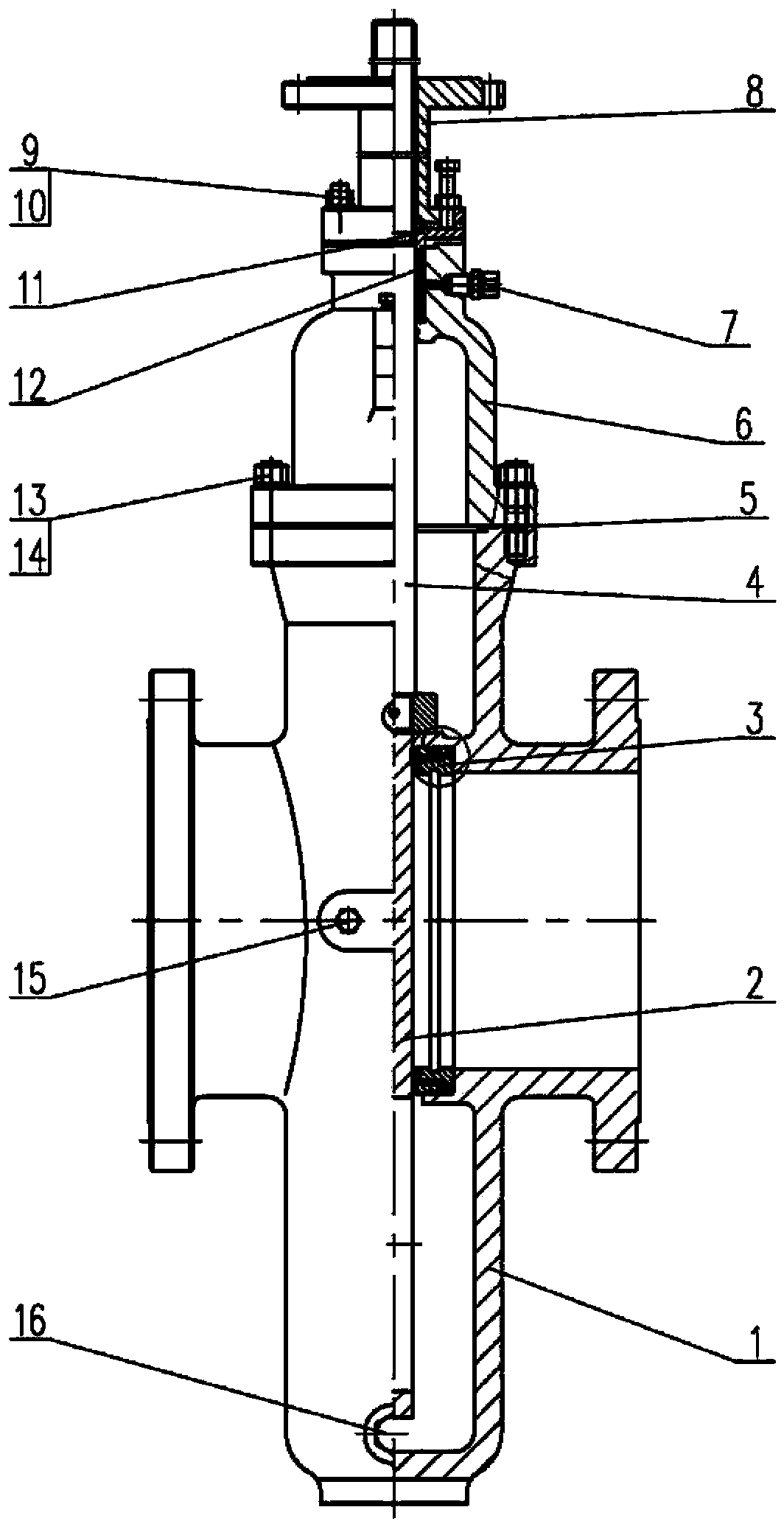

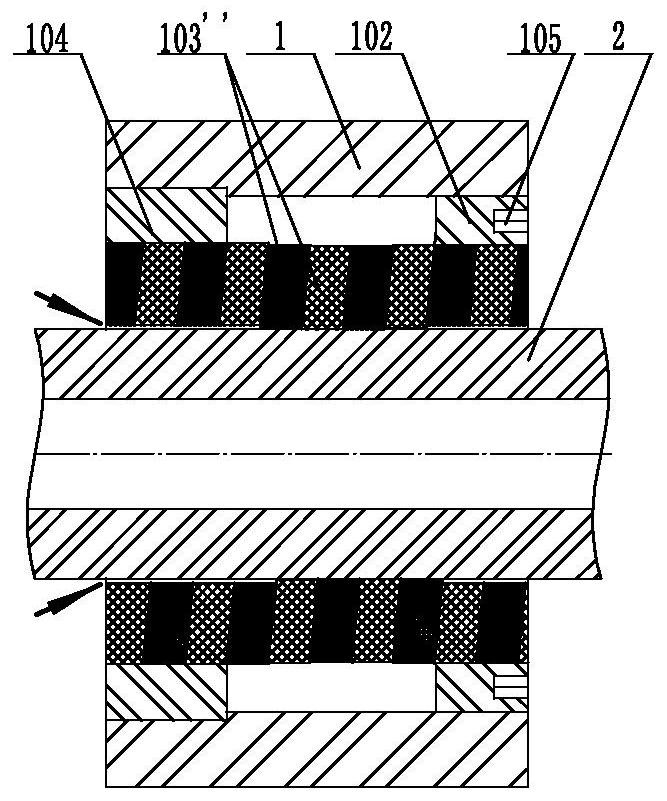

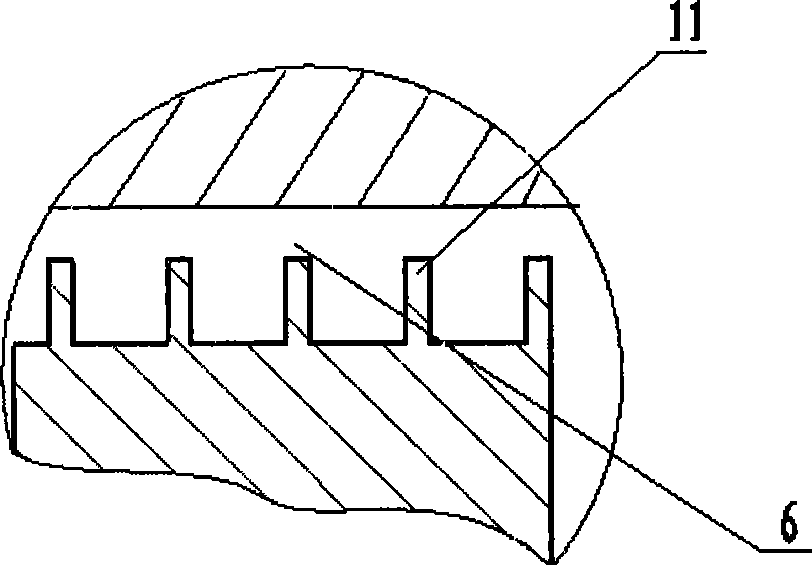

Magnetic powder and magnetic liquid combined sealing device

ActiveCN110939739AZero leakageFulfil requirementsEngine sealsBearing componentsMagnetic liquidsMechanical engineering

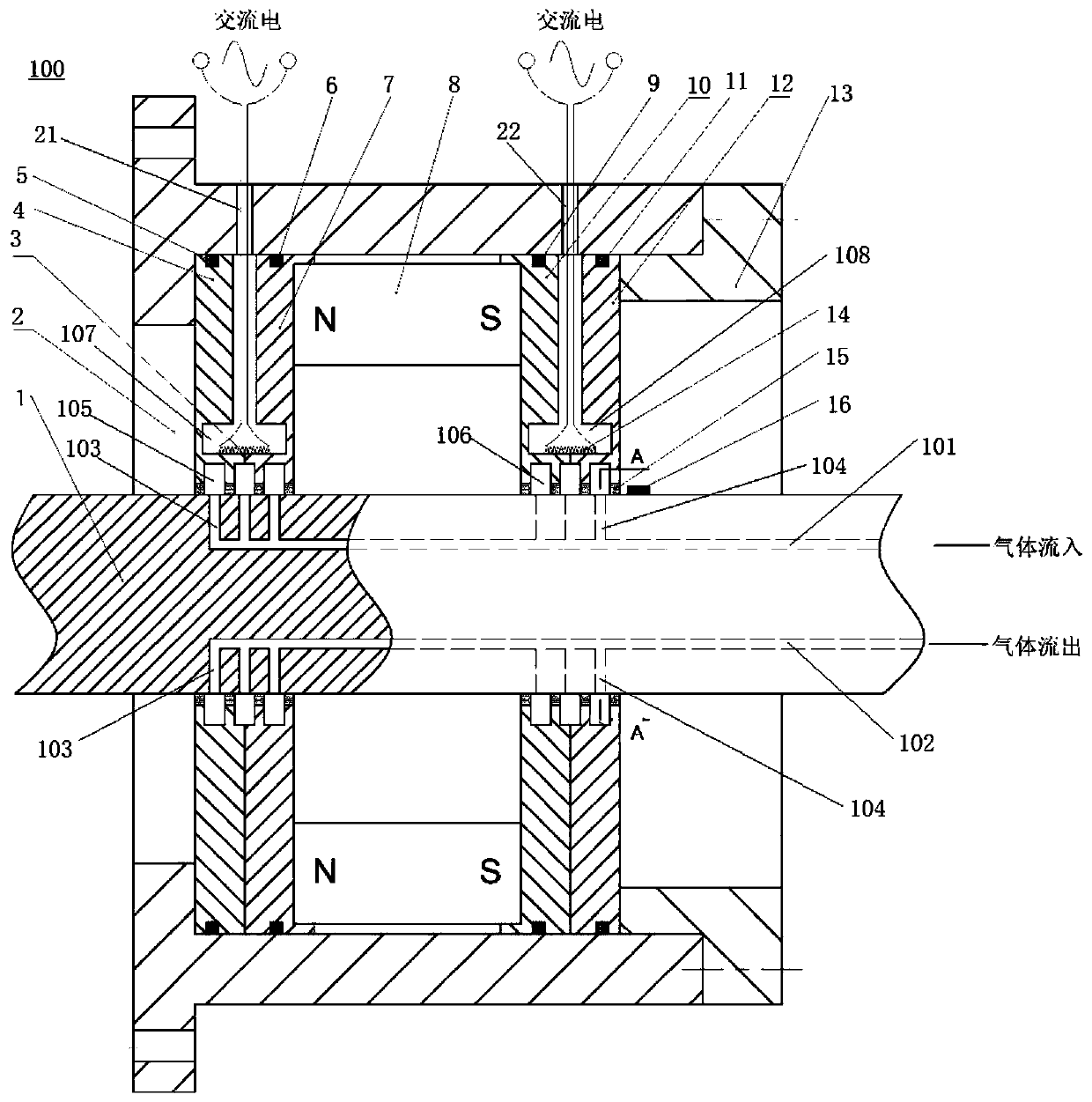

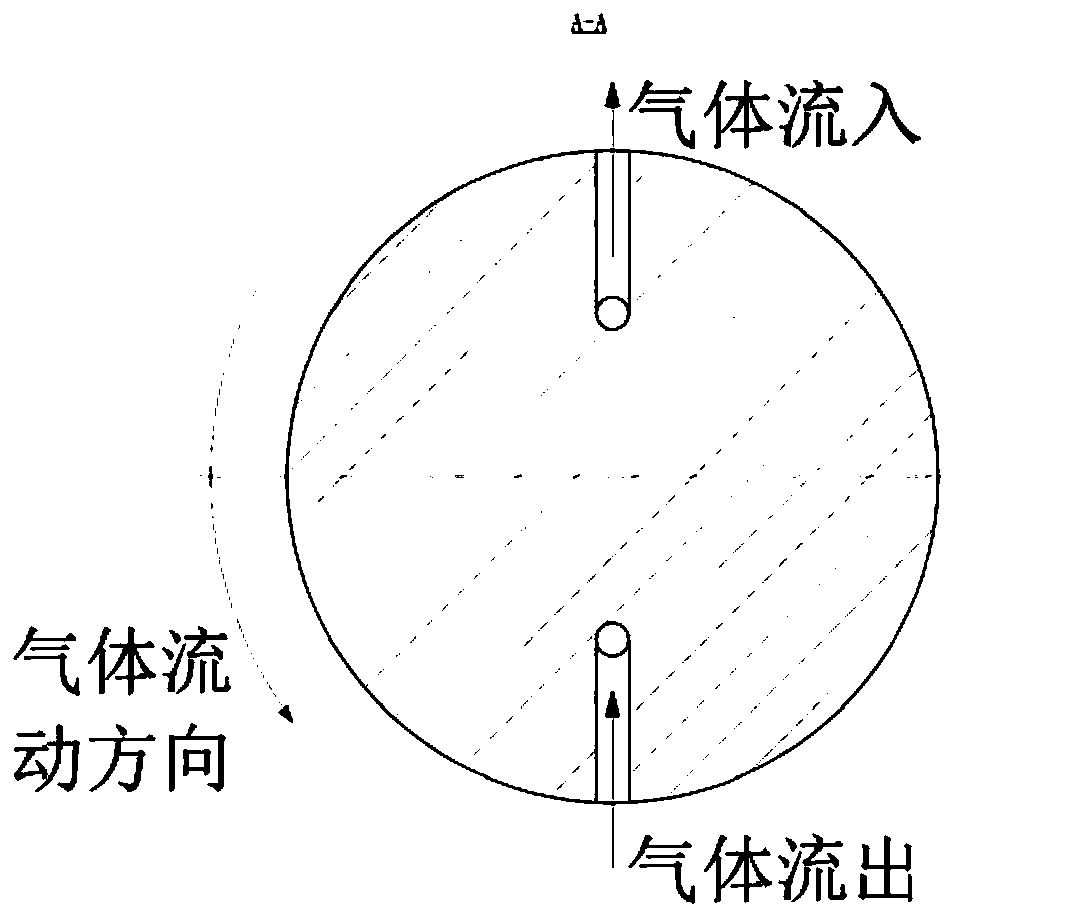

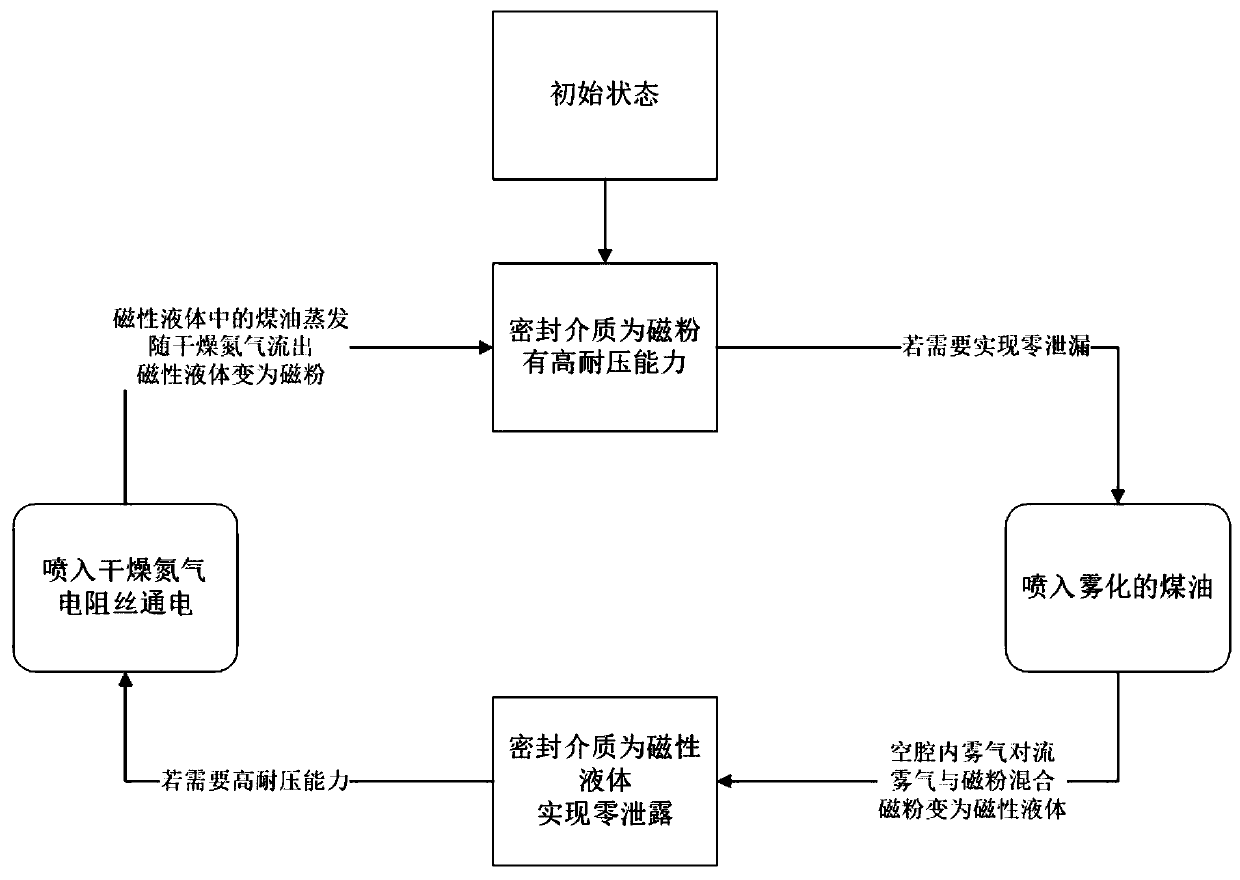

The invention discloses a magnetic powder and magnetic liquid combined sealing device, which comprises a shell, a rotating shaft, a first pole shoe, a second pole shoe, a permanent magnet, an end cover and a temperature sensor, wherein an accommodation cavity is formed in the shell; the rotating shaft is rotatably arranged in the accommodating cavity, and a first blind hole, a second blind hole, afirst via hole and a second via hole are formed in the rotating shaft; the first pole shoe is arranged on the outer side of the rotating shaft, a plurality of first pole teeth are arranged on the inner circumferential wall of the first pole shoe, and magnetic powder is arranged between the tooth top surface of each first pole tooth and the outer circumferential surface of the rotating shaft; thesecond pole shoe is arranged on the outer side of the rotating shaft in a sleeving mode, a plurality of second pole teeth are arranged on the inner circumferential wall of the second pole shoe, and magnetic powder is arranged between the tooth top surface of each second pole tooth and the outer circumferential surface of the rotating shaft; the permanent magnet sleeves the rotating shaft and is positioned between the first pole shoe and the second pole shoe; the end cover is positioned on one side, far away from the first pole shoe, of the second pole shoe; and the temperature sensor is arranged on the rotating shaft. According to the magnetic powder and magnetic liquid combined sealing device, the requirements for zero leakage and high pressure resistance can be met.

Owner:TSINGHUA UNIV

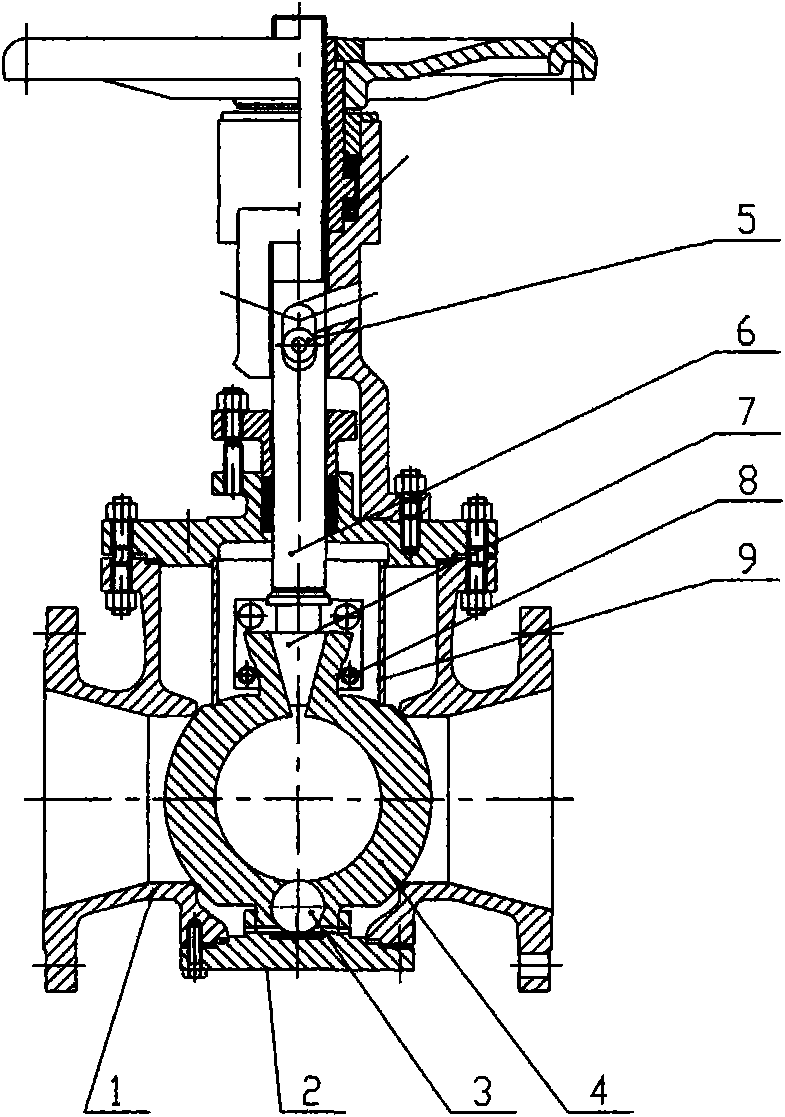

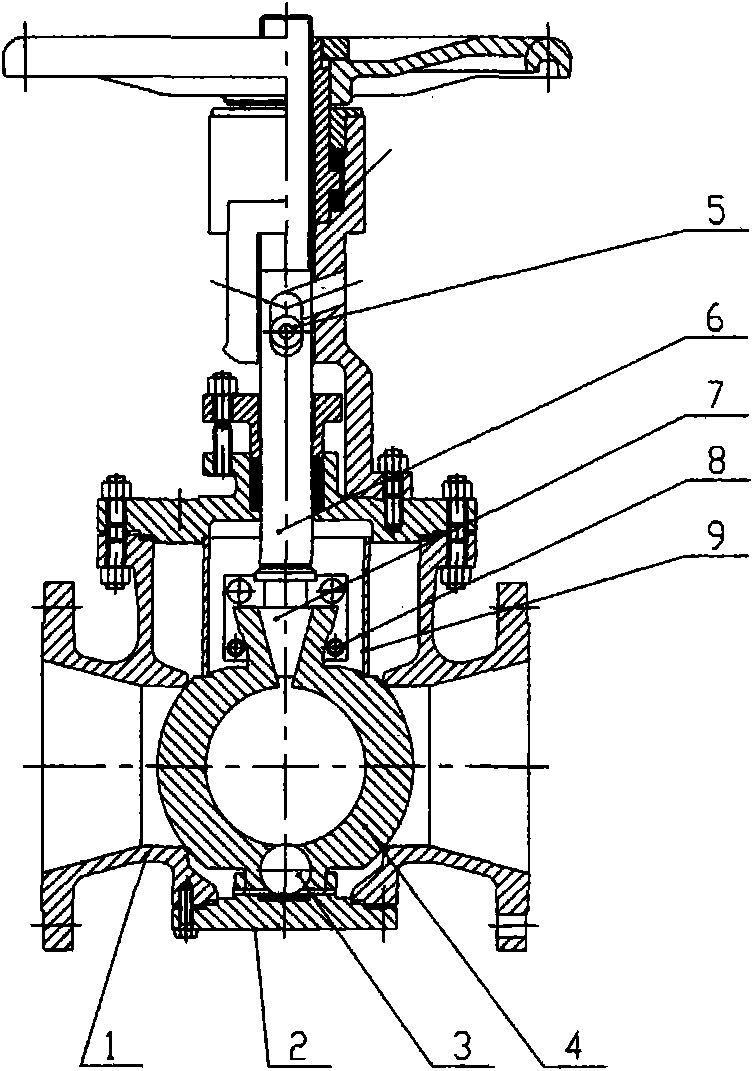

Expanding type two-way hard sealed spherical valve

InactiveCN101893111AEnergy savingSave resources and costsPlug valvesValve housingsBall valveEngineering

The invention relates to an expanding type two-way hard sealed spherical valve which comprises two hemispheres, a wedge body, a valve body, a valve cover, a valve rod, a supporting shaft, a roller, a positioner and the like, wherein the two hemispheres form a combined sphere; a positioning shaft is arranged at the lower end of the combined sphere, the supporting shaft is arranged in the middle of the sphere body of the combined sphere, and the supporting shaft is in a round shape; a Z-shaped groove is arranged at the middle part of the valve rod, the roller is fixed in the ''Z''-shaped groove to be used for the positioning of the lifting and rotation of the valve rod, the wedge body in the shape of a gate plate is arranged at the connecting part of the lower end of the valve rod and the upper end of the valve body, and the sphere body is combined together through the positioner; the valve rod is connected with the wedge body for connecting the sphere body and is installed in an inclination angle of 10-16 degrees, so that the sphere body can not be closely expanded; and an expanded ball clack is tightly stuck on the valve seat for sealing to form a hard-to-hard two-way seal on the valve seat. The upper sealed structure achieves zero leakage, and the structure capable of regulating flow achieves cleaning and sealing functions. The invention saves resources and cost and has convenient installation and use.

Owner:张雄飞

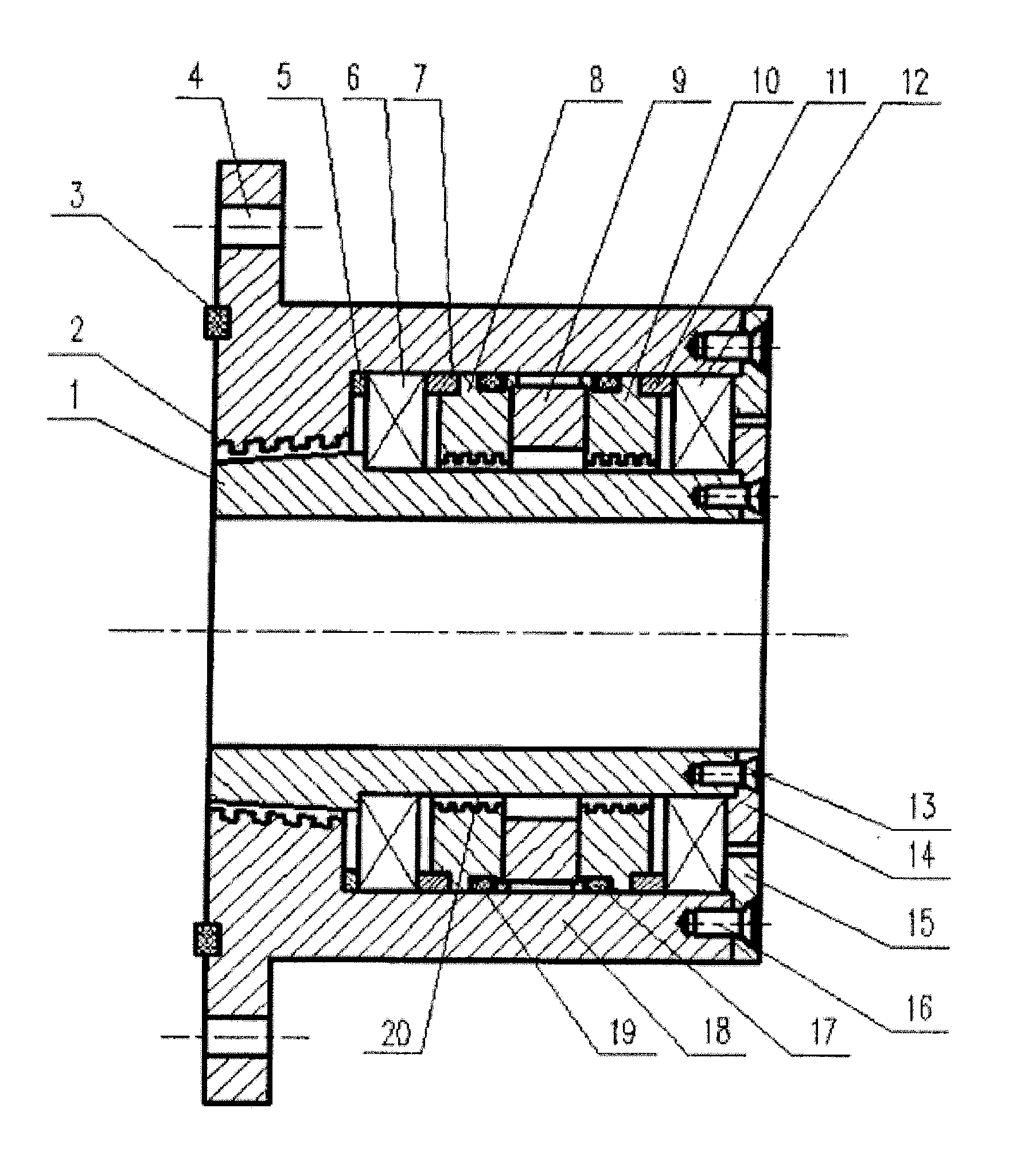

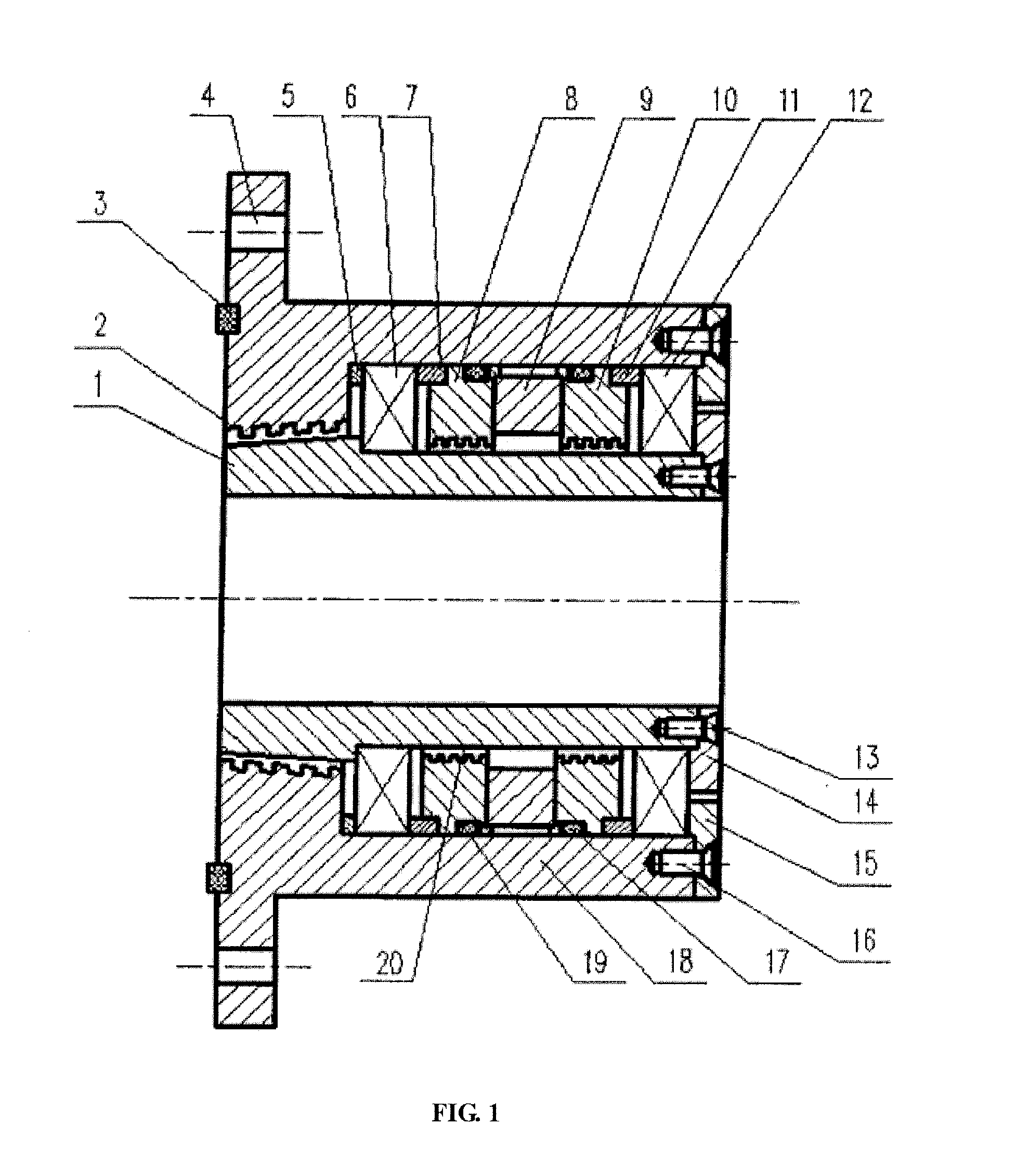

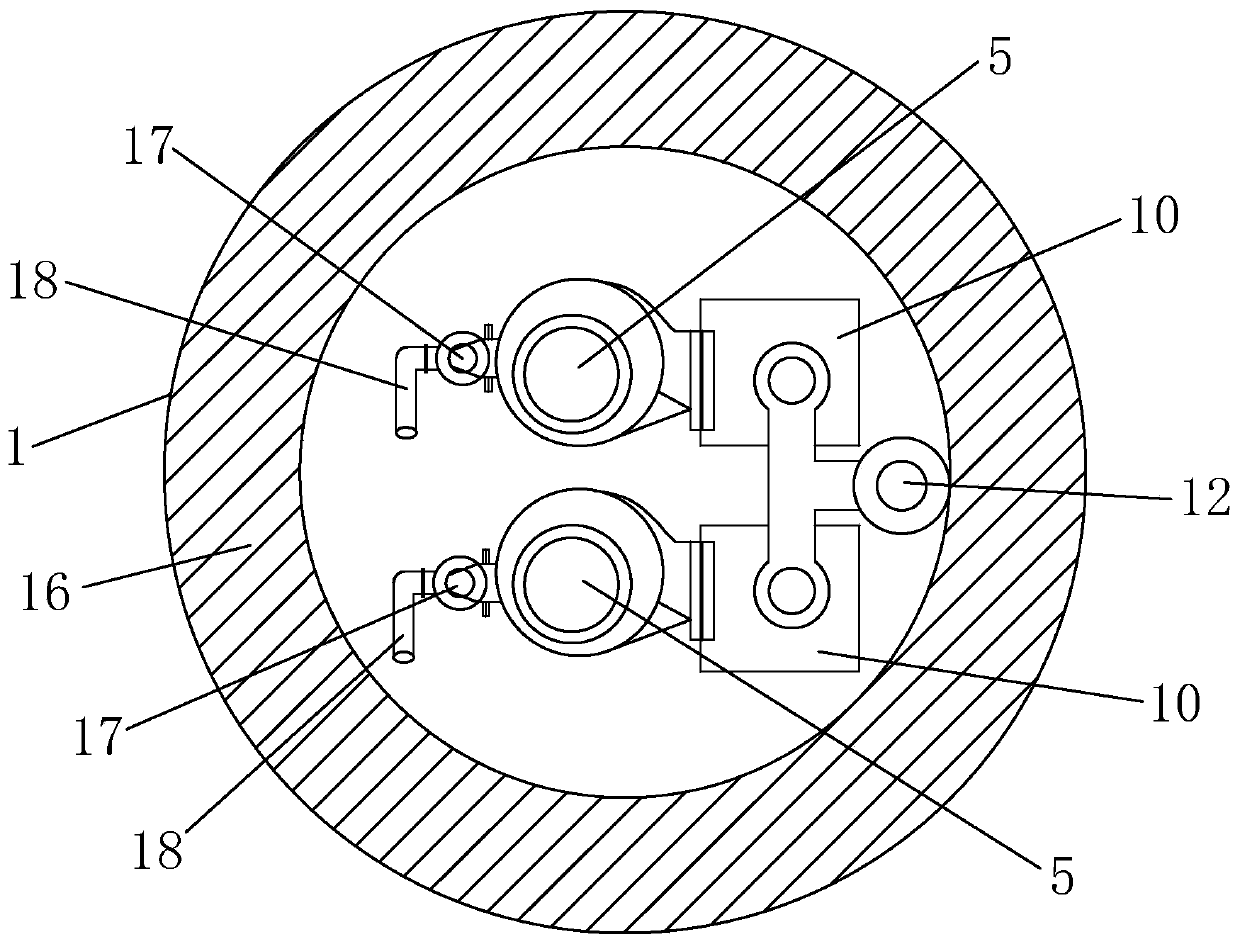

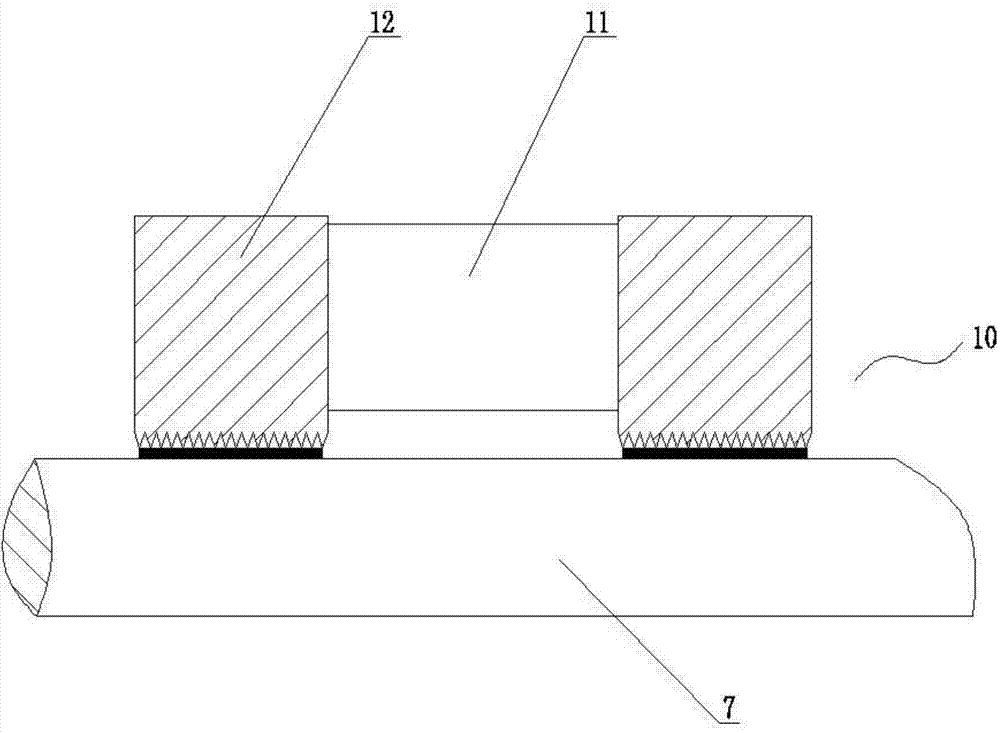

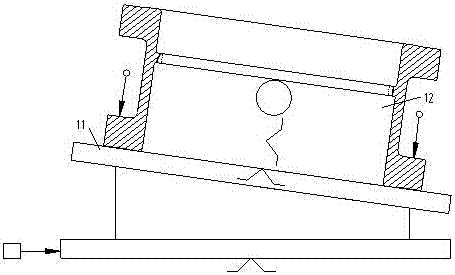

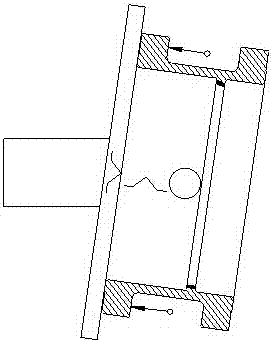

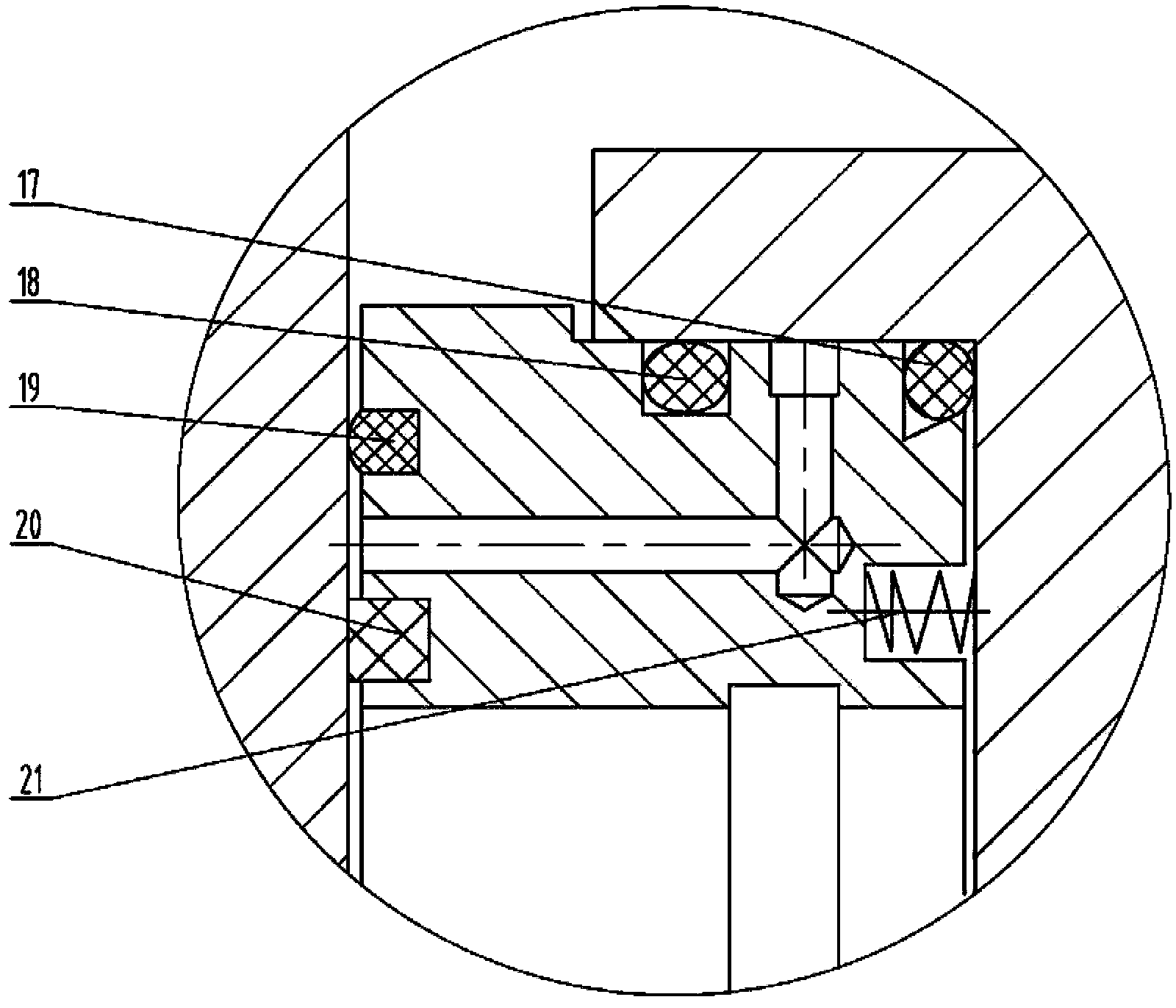

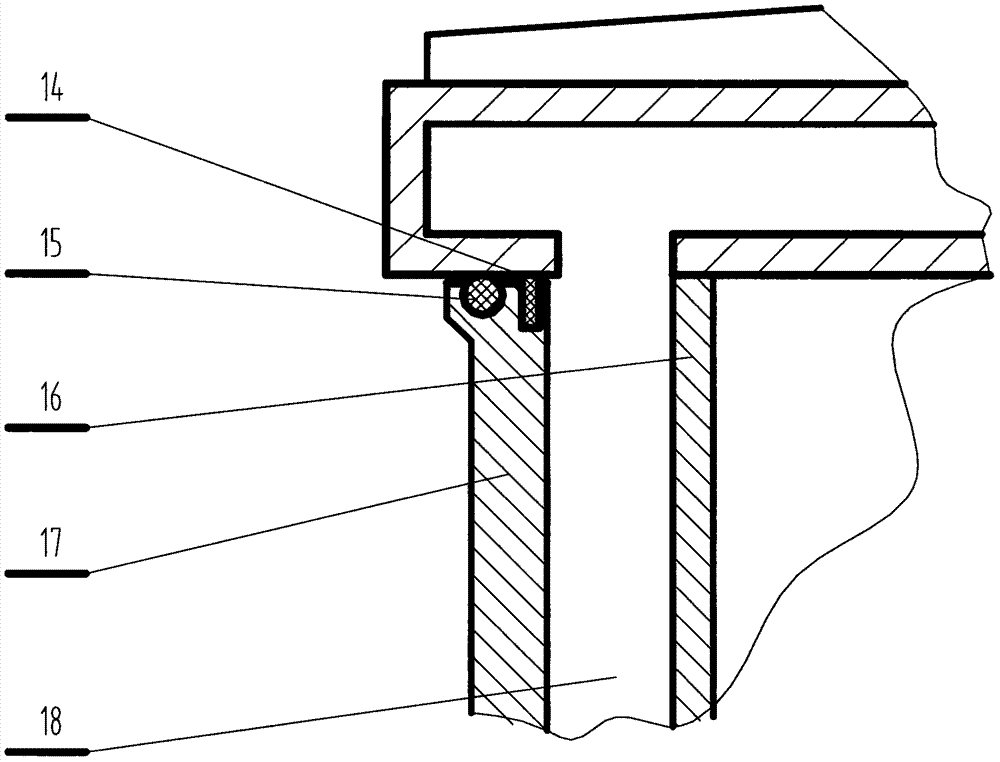

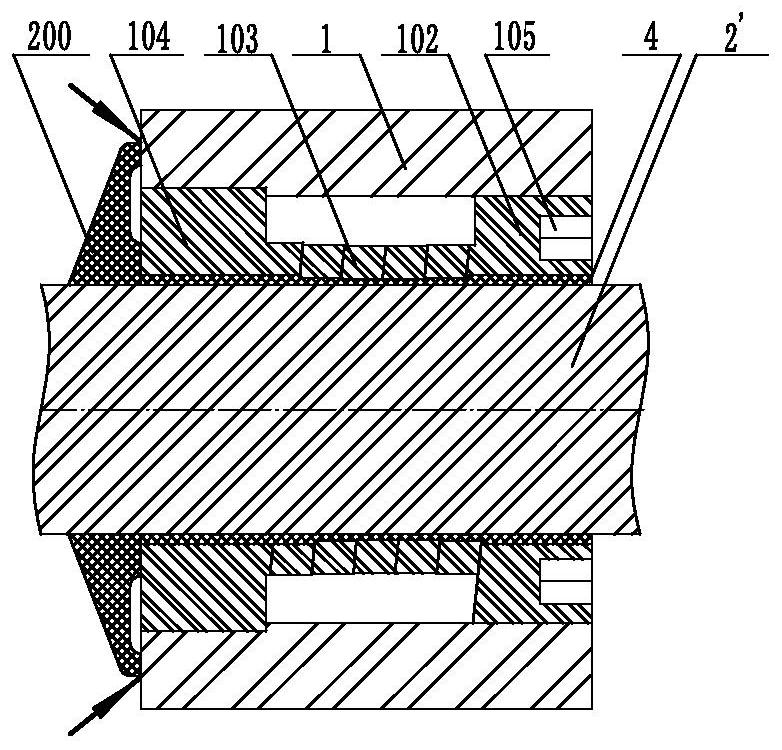

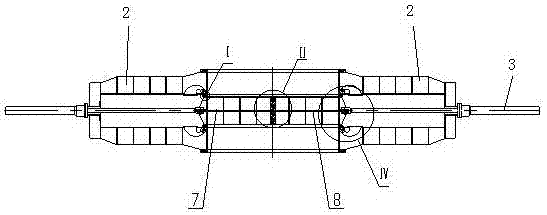

Combined sealing device for a rotary shaft

A combined sealing device for a rotary shaft, in which the combined sealing device comprises the ring (5), the left bearing (6), the left septum magnetic ring (7), a magnetic fluid sealing assembly, the right septum magnetic ring (11), and the right bearing (12) which are arranged inside a housing (18) in series, after the magnetic fluid is injected into the pole teeth of pole pieces in the magnetic fluid sealing assembly, the shaft housing is loaded into the inner hole of the above-mentioned parts, then the second end cover (15) is fixed on a housing by screw nails (16) to press the outer ring of the right bearing tightly, after that, the first end cover (14) is fixed on the shaft housing (1) by screw nails (13) to press the inner ring of right bearing tightly, so that a magnetic fluid seal is device is achieved, the left end external surface of the shaft housing is the conical surface, and the left end inner hole of the housing is the taper hole which has the same taper as the left end of shaft housing and in which spiral groove is processed, the left end external conical surface of the shaft housing coordinates with the left end spiral groove of the housing provided in the taper hole, so that a conical spiral seal is achieved. This device has the advantages such as a long service life, a reliable seal, and no pollution.

Owner:BEIJING JIAOTONG UNIV

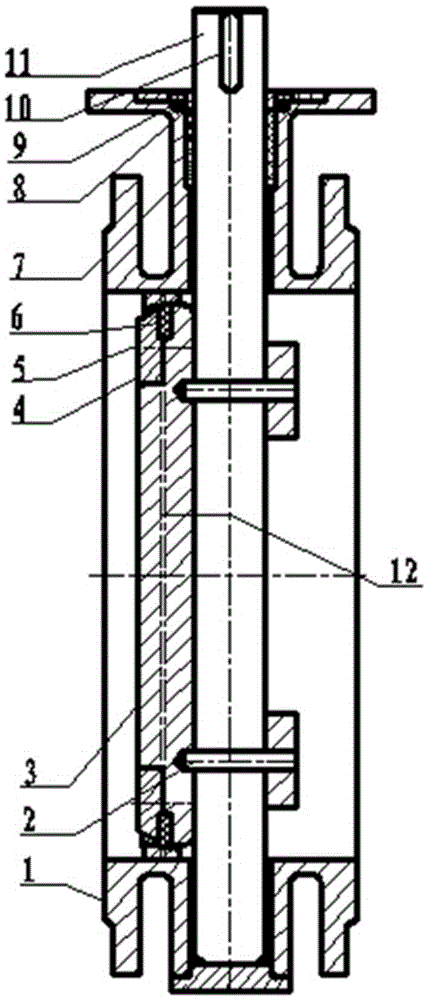

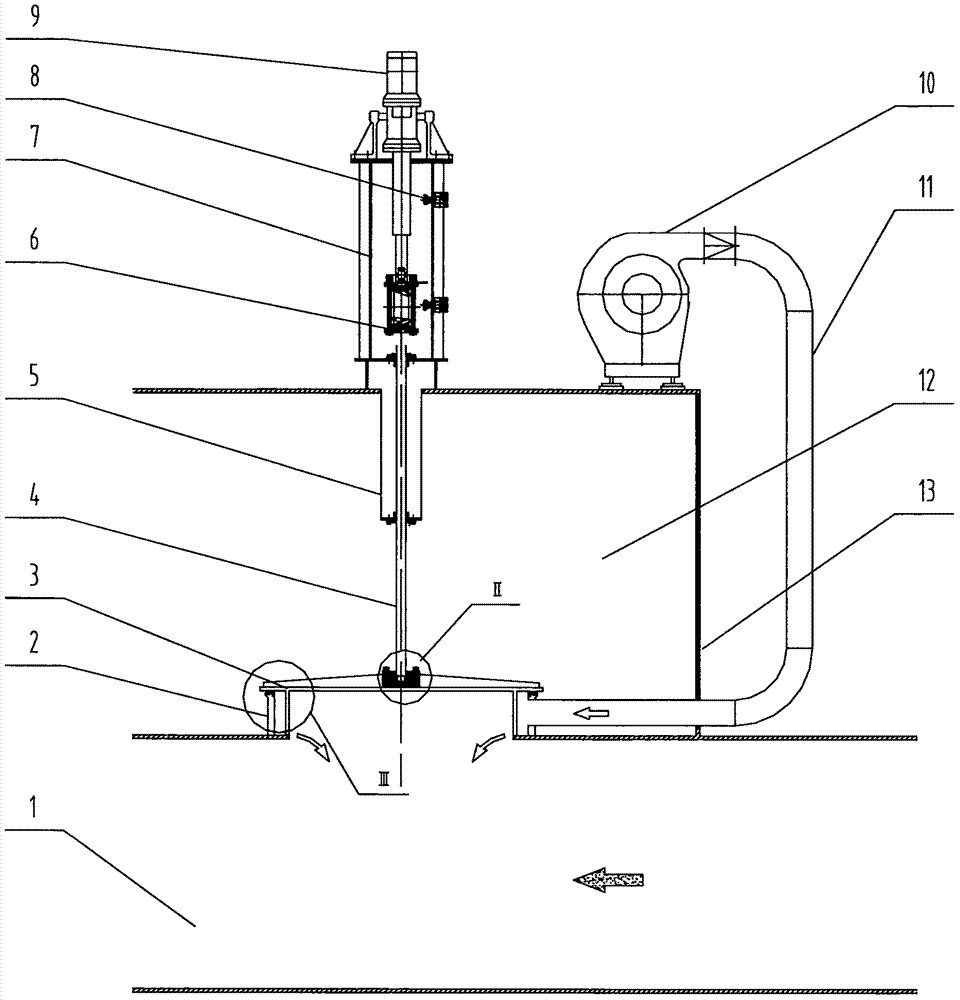

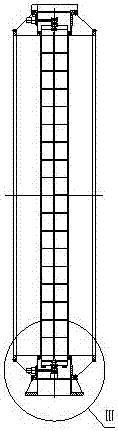

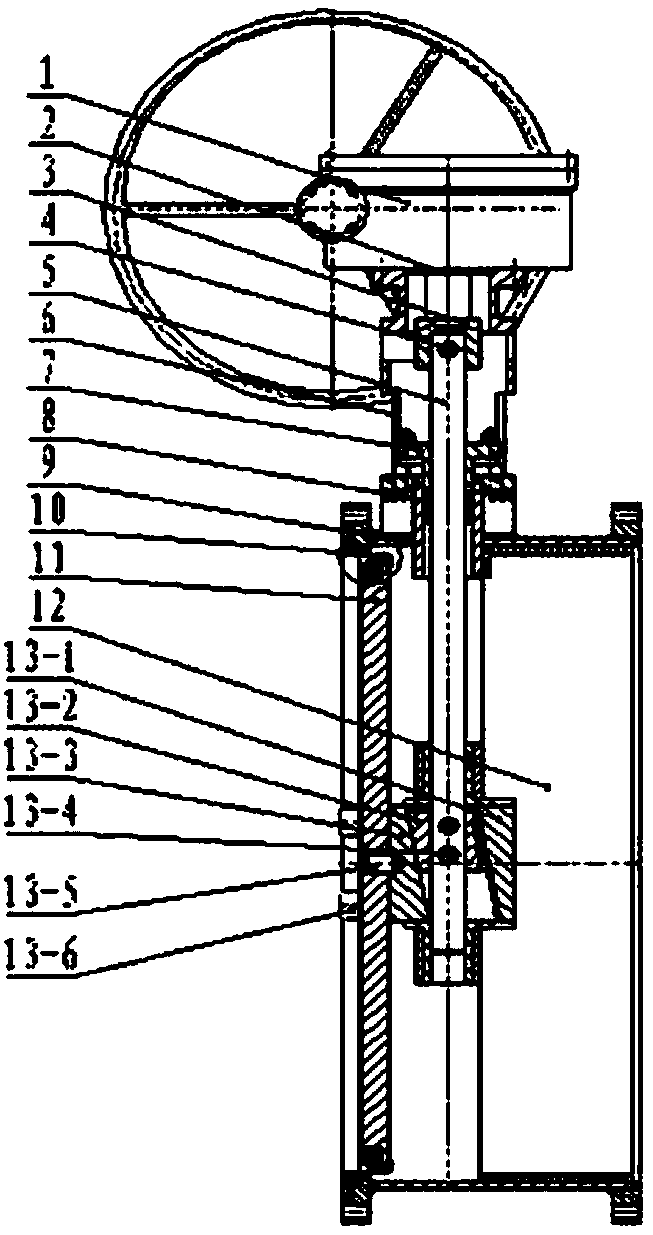

Novel vertical multistage pump

ActiveCN106015012ACompact structureReasonable structurePump componentsRadial flow pumpsImpellerHigh pressure

The invention discloses a novel vertical multistage pump. The novel vertical multistage pump comprises a pump body shell; a pump shaft is mounted in the pump body shell, and is provided with multiple impellers; a half-integrated mechanical seal is mounted on the pump shaft at the tops of the impellers, and includes a machine seal shaft sleeve; the machine seal shaft sleeve is provided with a clamping groove; a movable ring is embedded in the clamping groove; the machine seal shaft sleeve is coated with a static ring base on the outer peripheral surface on the movable ring, and is provided with a groove in the bottom; a static ring is tightly matched and embedded in the groove, and is tightly bonded with a friction surface of the movable ring; two steps are arranged on the outer peripheral surface of the static ring base, and are respectively a large step and a small step; the large step is connected with a machine seal gland through multiple small springs; meanwhile, the small step is sealed with the machine seal gland through a sealing ring; a high-pressure cavity is betwen the outer side of the half-integrated mechanical seal and the inner wall surface of the pump body shell; an input port is in the lower part of one end of the pump body shell; and an output port is in the upper part of one end of the pump body shell, and is communicated with an outlet of the final-stage impeller. The novel vertical multistage pump is excellent in reliability and long in service life.

Owner:无锡艾比德泵业有限公司

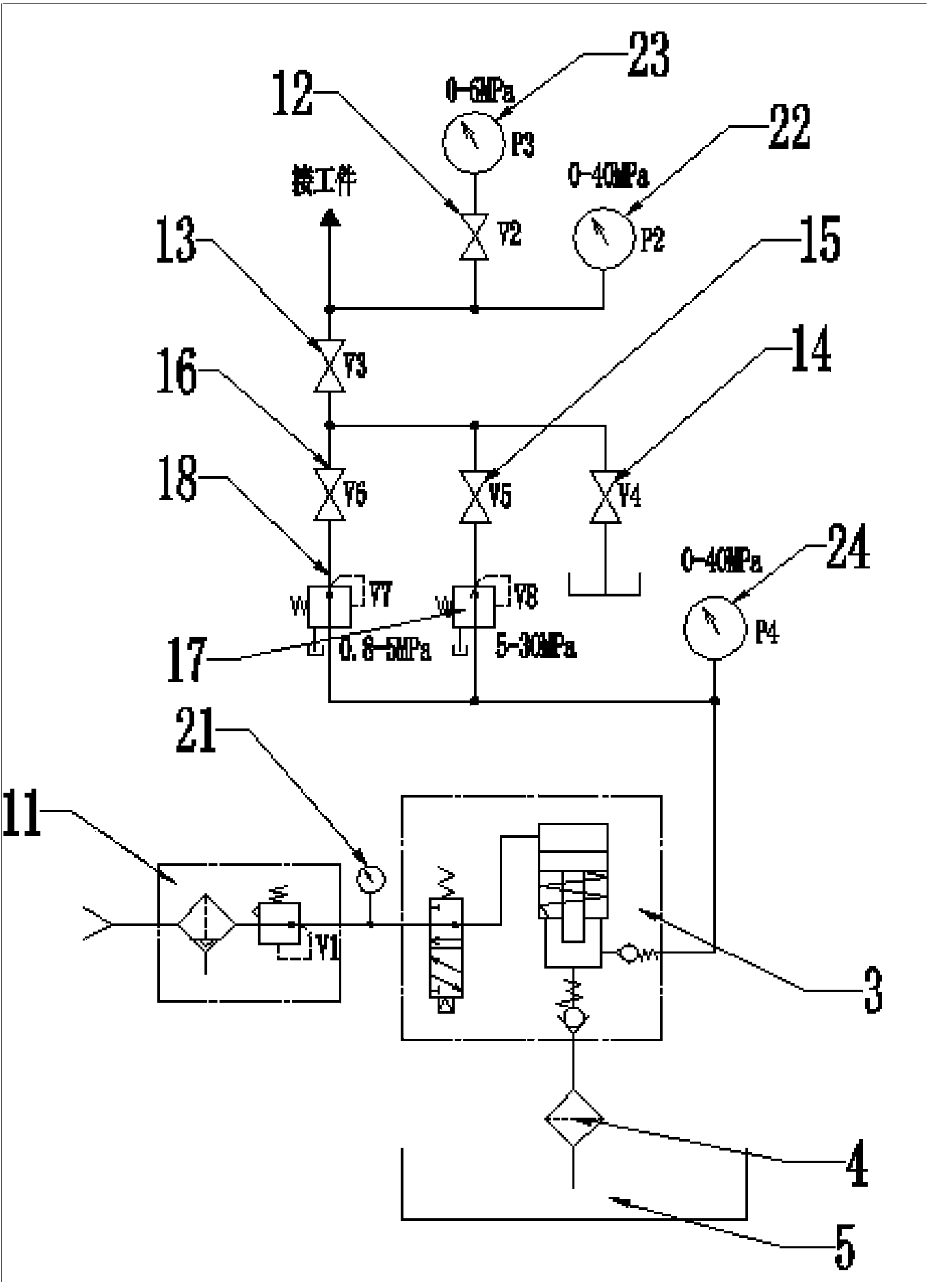

Kerosene sealing test system with gas-liquid boosting pump

InactiveCN103645015AReduce volumeReduce energy consumptionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateKeroseneSystem pressure

The invention discloses a kerosene sealing test system with a gas-liquid boosting pump, which comprises a gas source pressure regulating valve, wherein the gas source pressure regulating valve and the gas-liquid boosting pump are provided with a gas source pressure meter therebetween, the gas-liquid boosting pump is connected with an oil tank through an oil absorbing filter, the output end of the gas-liquid boosting pump is connected to a system pressure meter, a high-pressure reducing valve and a low-pressure reducing valve, the high-pressure reducing valve is connected to a high-pressure reducing valve outlet stop valve, the low-pressure reducing valve is connected to a low-pressure reducing valve outlet stop valve, the output ends of the high-pressure reducing valve outlet stop valve and the low-pressure reducing valve outlet stop valve are connected to an unloading valve and a pressure maintaining test valve, the pressure maintaining test valve is connected to a workpiece, a low-pressure test pressure meter and a low-pressure test pressure meter switching valve, and the low-pressure test pressure meter switching valve is connected to a high-pressure test pressure meter. The kerosene sealing test system with the gas-liquid boosting pump has the advantages of small size, no power supply, low power consumption, zero leakage, explosion prevention, safety, reliability, simple operation and the like.

Owner:DALIAN REALLY TECH

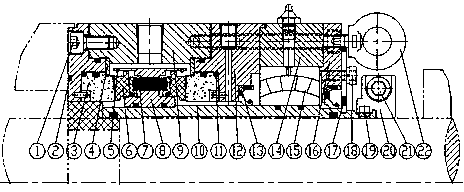

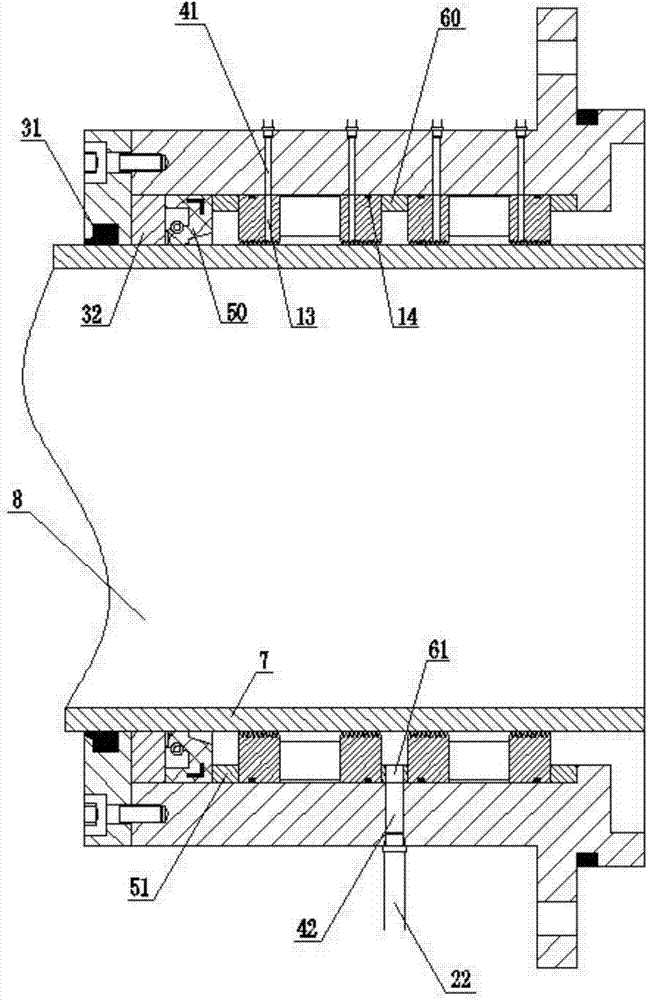

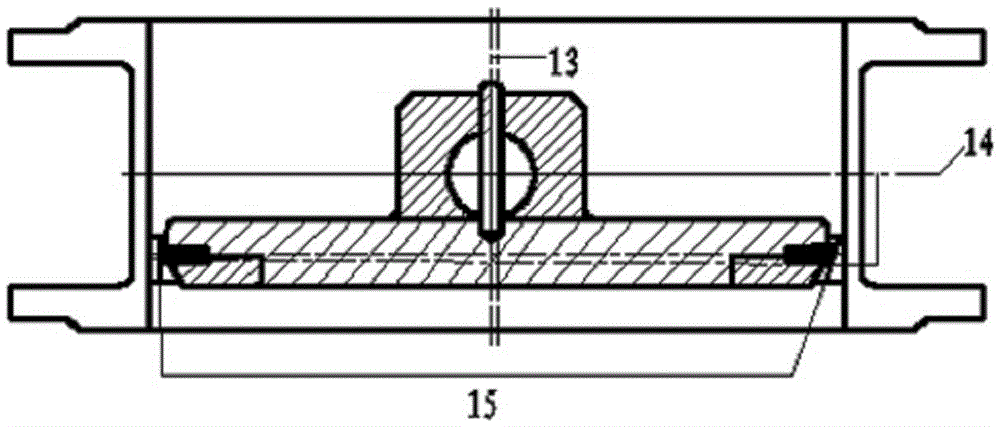

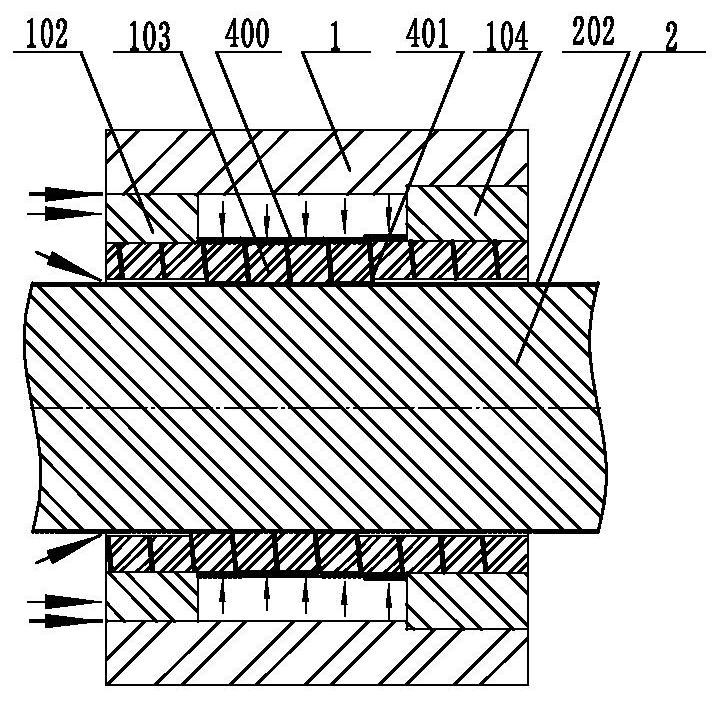

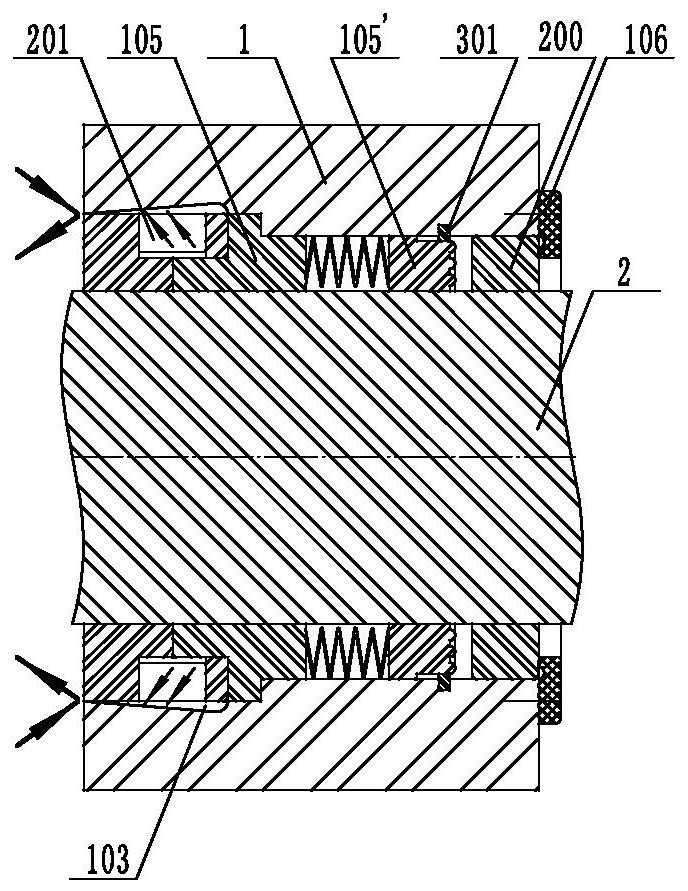

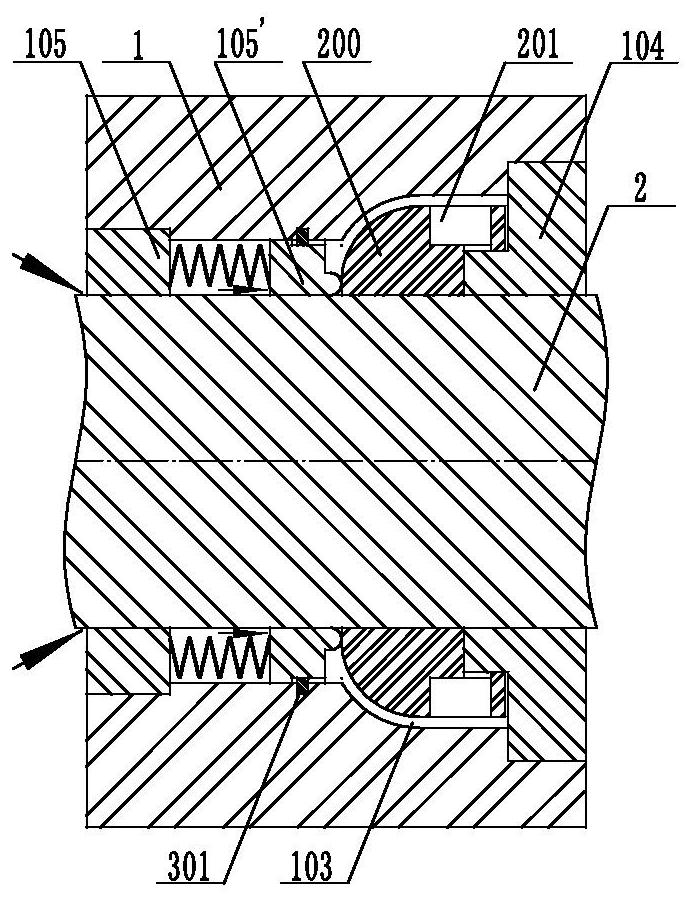

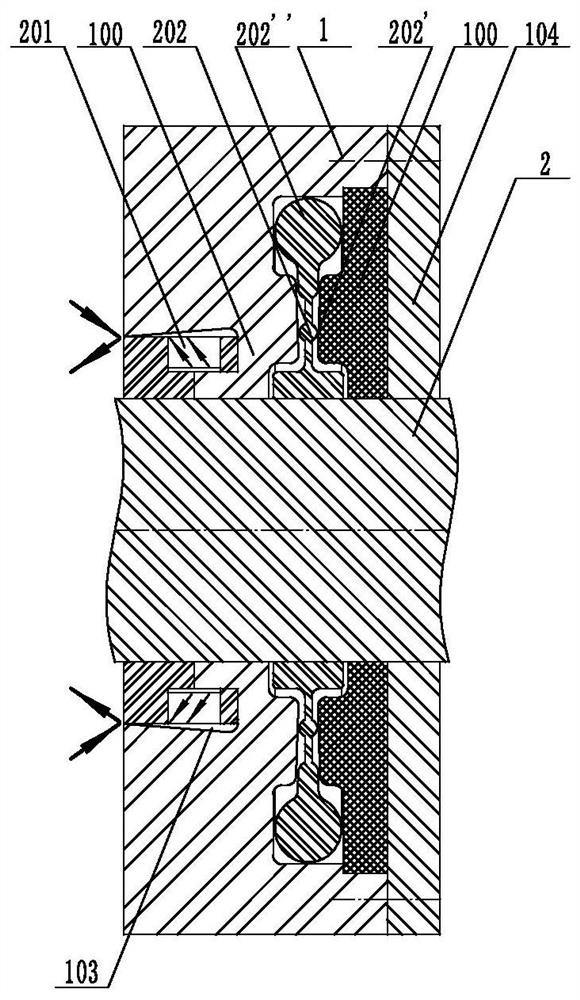

Double mechanical sealing method and double mechanical sealing device for kettle gas films

The invention discloses a double mechanical sealing method and a double mechanical sealing device for kettle gas films, and belongs to the field of machine manufacture. The double mechanical sealing device mainly comprises a shaft sleeve, a moving-ring seat, a stationary ring, a stationary-ring press plate, a moving ring, a bearing, a stationary-ring seat, an auxiliary seal and the like. The double mechanical sealing method is characterized in that a back-to-back rotating double-end-face structure is adopted for sealing to realize non-contact operation, and a fluid dynamic-pressure groove is formed in the end face of the seal stationary ring; high-pressure isolating gas is injected between two sealing structures, and a spring is not affected by solid particles and impurities in media as not contacting with the media; the stationary ring which is supported by two O-shaped rings and is positioned by the press plate can bear back pressure; a cartridge structure is adopted. The double mechanical sealing method and the double mechanical sealing device have the advantages that an auxiliary system is simple in structure and can ensure technological media to be prevented from pollution, leakage and overflow of sealed media can be completely avoided, and no environmental pollution is caused; through the cartridge structure, accuracy, convenience and rapidness in overall mounting are realized, and demounting is facilitated. The device is applicable to various blenders, reactors, dryers, reaction kettles, polymerizers and the like in the fields of petroleum, chemical engineering, pharmacy, rubber, oil refining and the like.

Owner:DONGYING HISCIEN SEALING TECH

Underwater photographing equipment

InactiveCN107991831AZero leakageImprove waterproof functionExposure controlCamera body detailsMagnetEngineering

The invention discloses underwater photographing equipment. The underwater photographing equipment includes a driving transmission case, a driven transmission case and a waterproof camera which are sequentially connected, and further includes a second magnet disposed in the driven transmission case, and a power supply, a motor and a first magnet which are sequentially connected and disposed in thedriving transmission case, wherein the driving transmission case is of a fully-sealed structure, a driven shaft is connected with the driven transmission case through a waterproof sealed bearing, thedriving transmission case is also provided with a charging port connected with the power supply, and the waterproof grade of the charging port is IP68. The underwater photographing equipment can achieve magnetic coupling between the first magnet and the second magnet so that force and torque can be transmitted without direct contact between a driving shaft and the driven shaft, can convert a dynamic seal of the driving transmission case into a static seal to achieve zero leakage, has enhanced waterproof functions, and is very suitable for underwater work.

Owner:INNOPLAY LTD

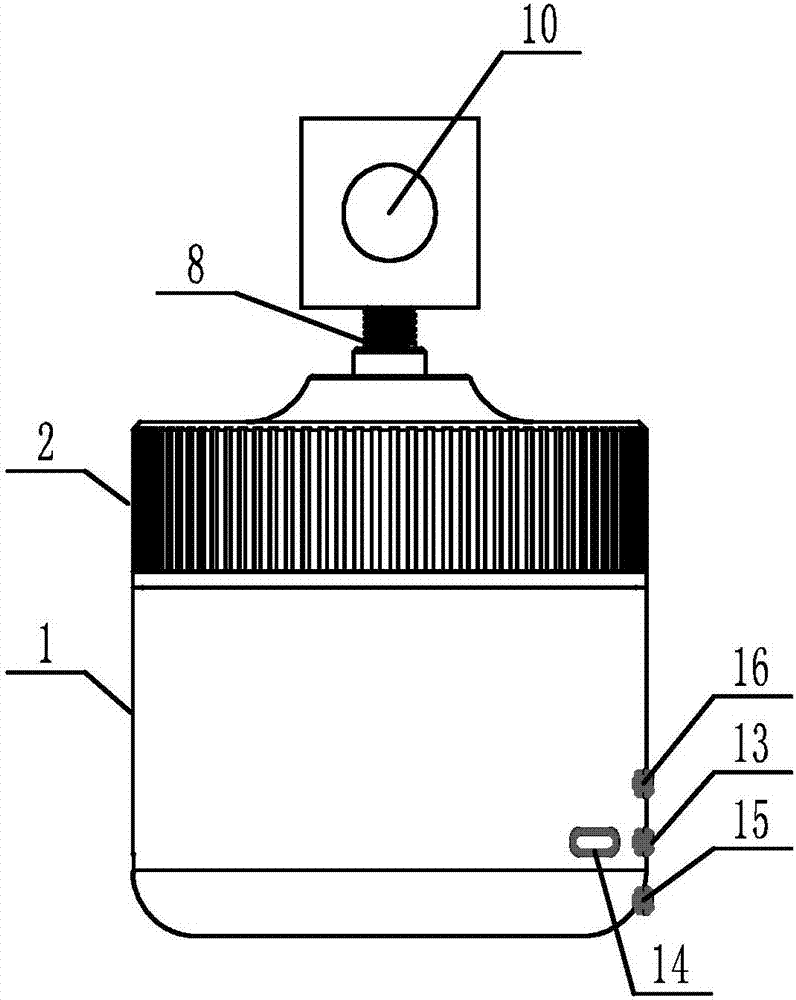

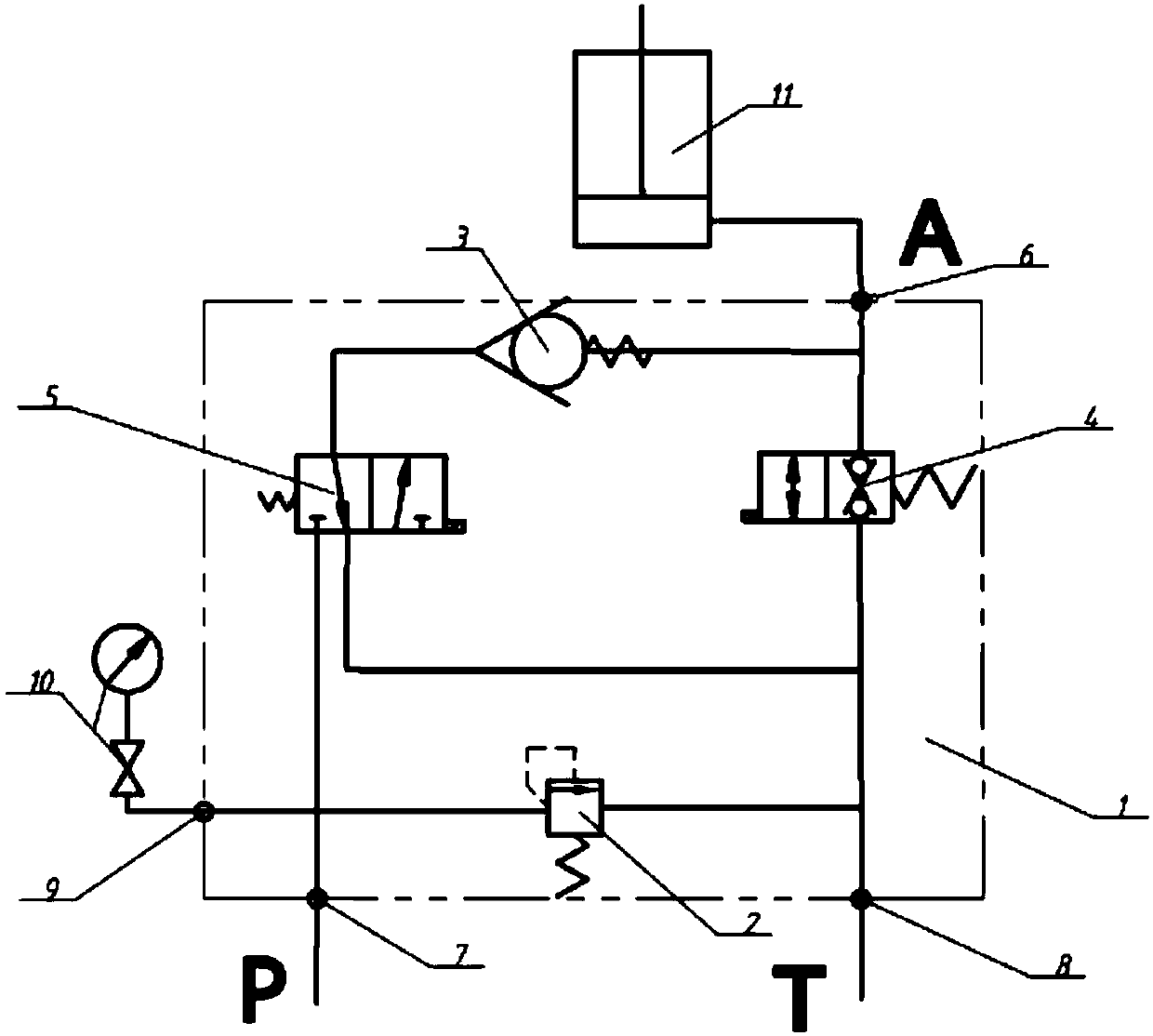

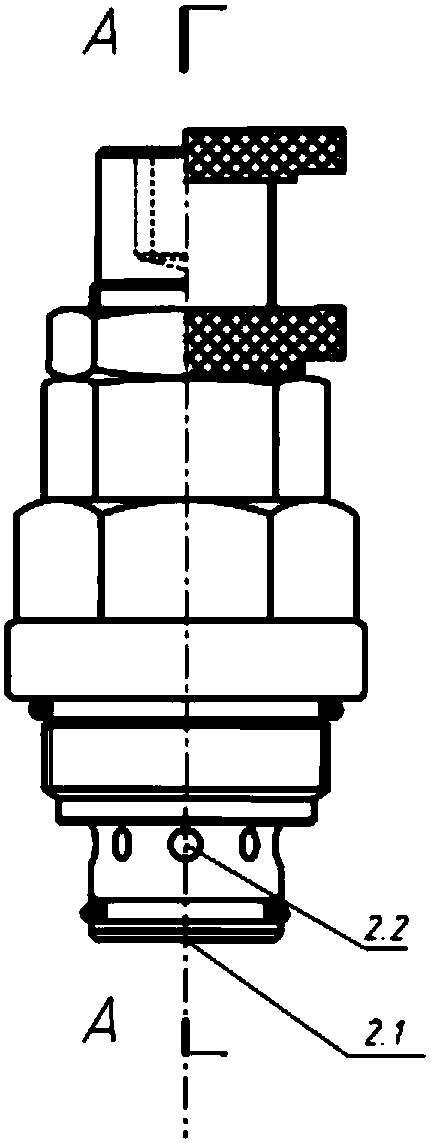

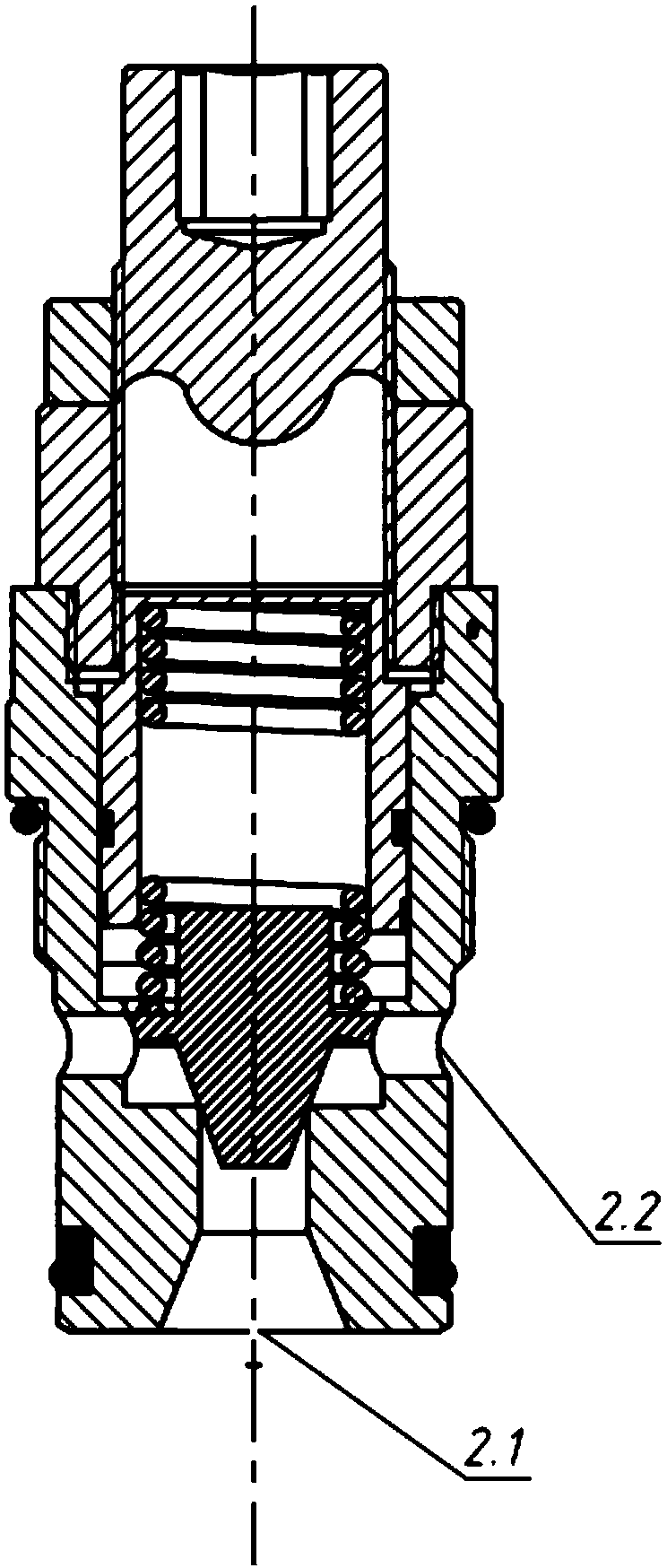

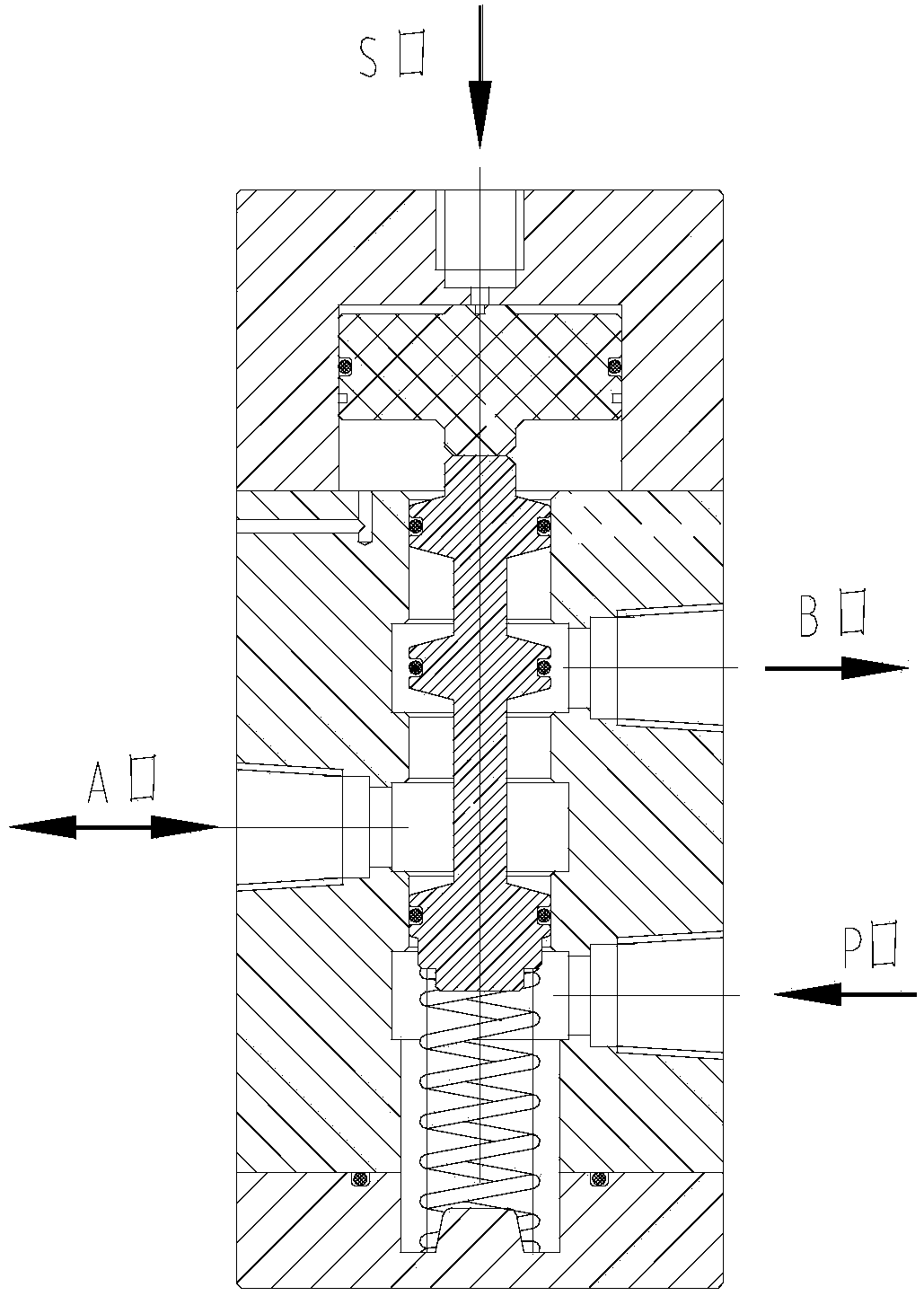

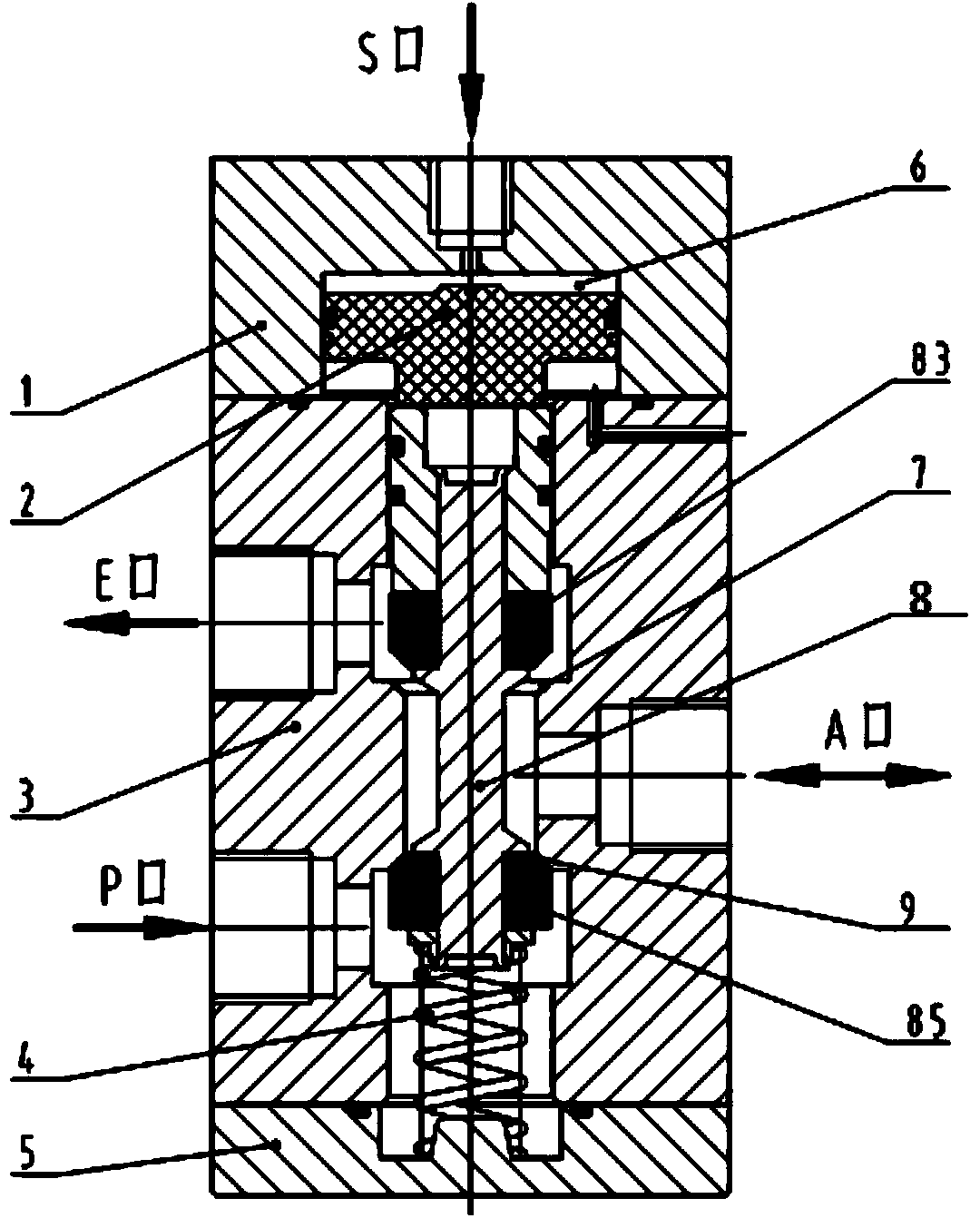

Control valve for electro-hydraulic suspension systems of small-and medium-horsepower tractors

PendingCN107642514ACompact structureEasy to controlFluid-pressure actuator testingAgricultural machinesHydraulic cylinderFuel tank

The invention belongs to the field of electro-hydraulic suspension systems and discloses a control valve for electro-hydraulic suspension systems of small-and medium-horsepower tractors. The control valve comprises a valve body, an overflow valve, a check valve, a two-position two-way electromagnetic valve, a two-position three-way electromagnetic valve, an oil outlet A, an oil inlet P, an oil return port T and a pressure testing oil port, and the overflow valve, the check valve, the two-position two-way electromagnetic valve, the two-position three-way electromagnetic valve, the oil outlet A,the oil inlet P, the oil return port T and the pressure testing oil port are mounted on the valve body through insertion. The valve body is internally provided with oil passages communicated with valve part oil ways, the oil inlet port P is connected with an oil cylinder, the pressure testing oil port is connected with a pressure meter and a switch, the oil outlet A is connected with a hydrauliccylinder, and the oil return port T is connected with an oil tank. The control valve has advantages of cost saving, compact structure, high response speed, convenience in connection with external oilways and hydraulic cylinders and convenience in electronic control.

Owner:NANJING AGRICULTURAL UNIVERSITY

Floating disc edge sealing device of floating-roof oil tank

The invention provides a floating disc edge sealing device of a floating-roof oil tank. The floating disc edge sealing device comprises a plurality of sealing sliding plates, sealing films and supporting strips. The sealing sliding plates are composed of upper segments and lower segments and sequentially arranged on the outer side of a floating disc in the peripheral direction of the floating disc so as to form a ring shape, the upper segments of the sealing sliding plates are bent towards the tank wall of the floating-roof oil tank, the top ends of the upper ends of the sealing sliding plates are connected with the edge of the floating disc, the lower segments of the sealing sliding plates are attached to the tank wall of the floating-roof oil tank, and the bottom ends of the lower segments of the sealing sliding plates are soaked into oil stored in the floating-roof oil tank. The sealing films are laid on the inner side faces of the sealing sliding plates. The supporting strips are located below the sealing films and used for supporting the sealing films so as to make the sealing films to be attached to the inner side faces of the sealing sliding plates, and the top ends of the supporting strips are connected with the edge of the floating disc. By means of the technical scheme, the floating disc edge sealing device has the advantages that active sealing performance is achieved, the compensation range is wide, and the sealing ability is high.

Owner:BEIJING SANYI NENGHUAN ENG TECH CO LTD

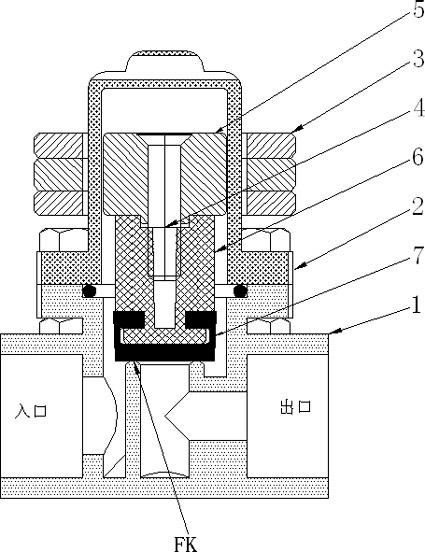

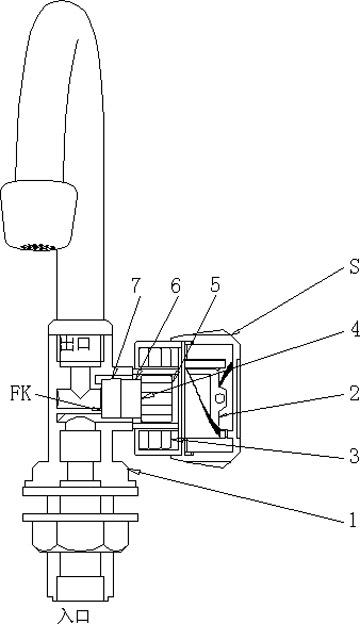

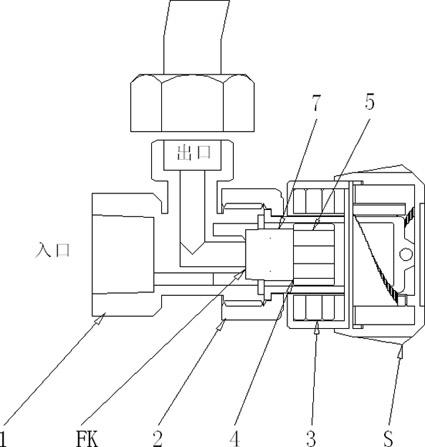

Permanent Magnet Direct Control Valve and Its Application

InactiveCN102278521AGenerate securitySimple structureOperating means/releasing devices for valvesEngineeringControl valves

A permanent magnet direct control valve, comprising: a valve seat (1), a valve cover (2), a permanent magnet assembly (3), and a valve plug assembly (4) which is only installed in the valve, and the valve plug assembly (4 ) is used to directly close or open the valve port (FK). Application of permanent magnet direct control valve: The inlet, outlet and magnetic control position of the permanent magnet direct control valve can be selected arbitrarily, and the permanent magnet assembly (3) can be dragged in different ways to form a new product with different functions and excellent performance. The advantages of the permanent magnet direct control valve and its application of the present invention are: the permanent magnet direct control valve has simple structure, low cost, no wearing parts, zero leakage, brisk operation, high reliability and long life, and its application is very wide. Various functional products such as faucets, triangle valves, liquid level valves, foot valves, and fuel guns are easy to promote, and people are willing to accept them. A large number of such products will produce significant savings and low-carbon effects.

Owner:钟逍虎

Horizontal sand mill

ActiveCN101972691BSolve dry skinPrevent solvent evaporationGrain treatmentsWater flowEnd face mechanical seal

The invention discloses a horizontal sand mill which comprises a base, a motor, a main shaft and a grinding cylinder. The motor is fixed on the base, the main shaft is hollow and is connected with the motor through a belt pulley, cooling oil chambers are fixedly arranged around the main shaft, a cooling water flowing passage is intermediately formed, a plurality of grinding rods are fixedly arranged around the outer wall of a grinding inner sleeve, a cooling water pipe is arranged in the grinding inner sleeve, a U-shaped spiral water channel is fixedly arranged around the outer wall of the cooling water pipe, and a feeding hole and a discharging hole are arranged on a grinding outer sleeve. In the mill, both-end-surface mechanical sealing is adopted and a sealing ring is arranged at the joint of a bearing and a shaft. By adopting the technical scheme of the invention, the defects caused by overhigh temperature generated when a traditional horizontal sand mill runs are effectively overcome, the sand mill is stable and reliable to run, and the production quality and the operation efficiency are greatly improved.

Owner:安徽维盛智能装备有限公司

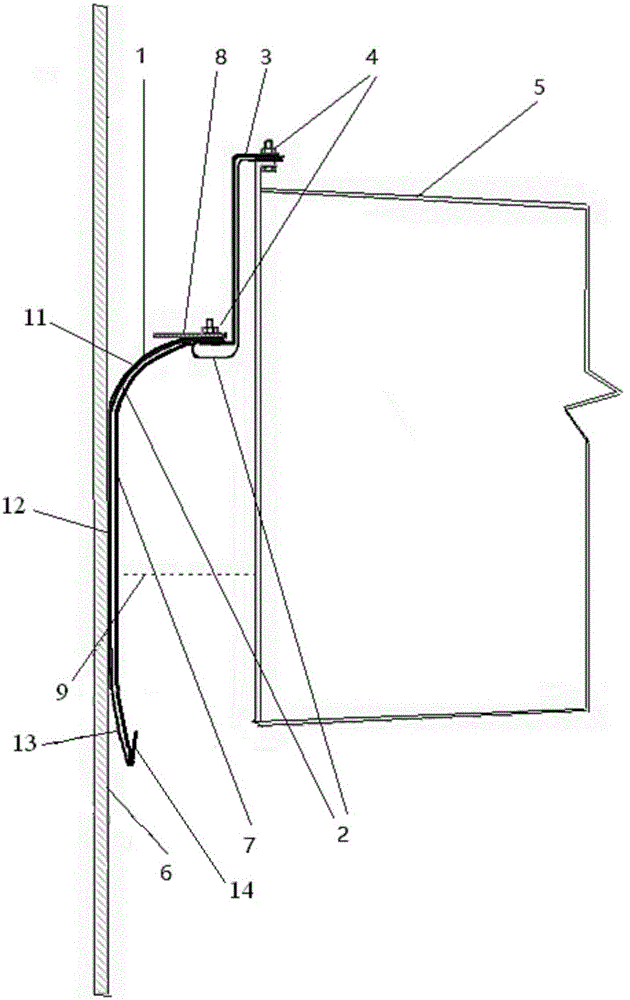

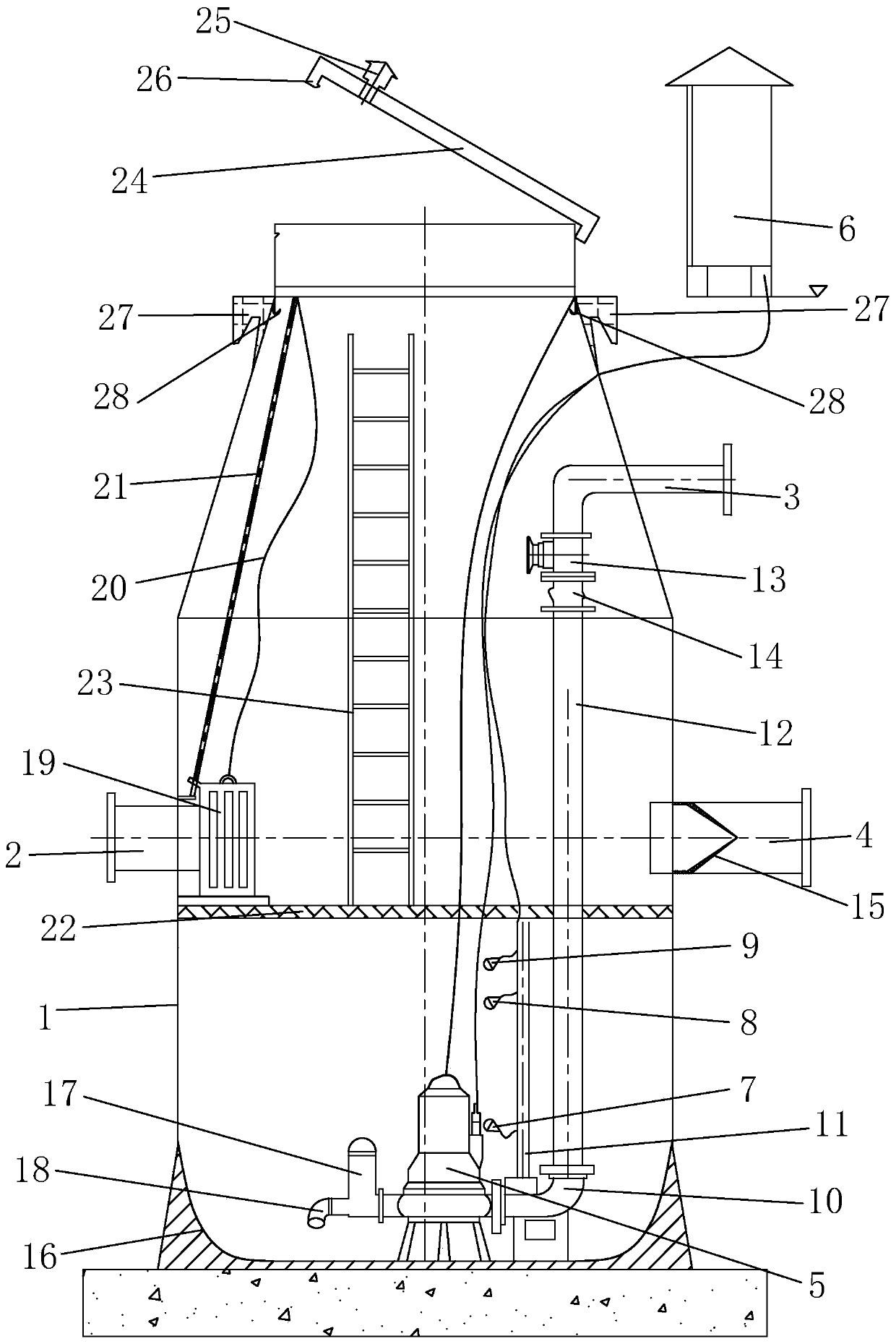

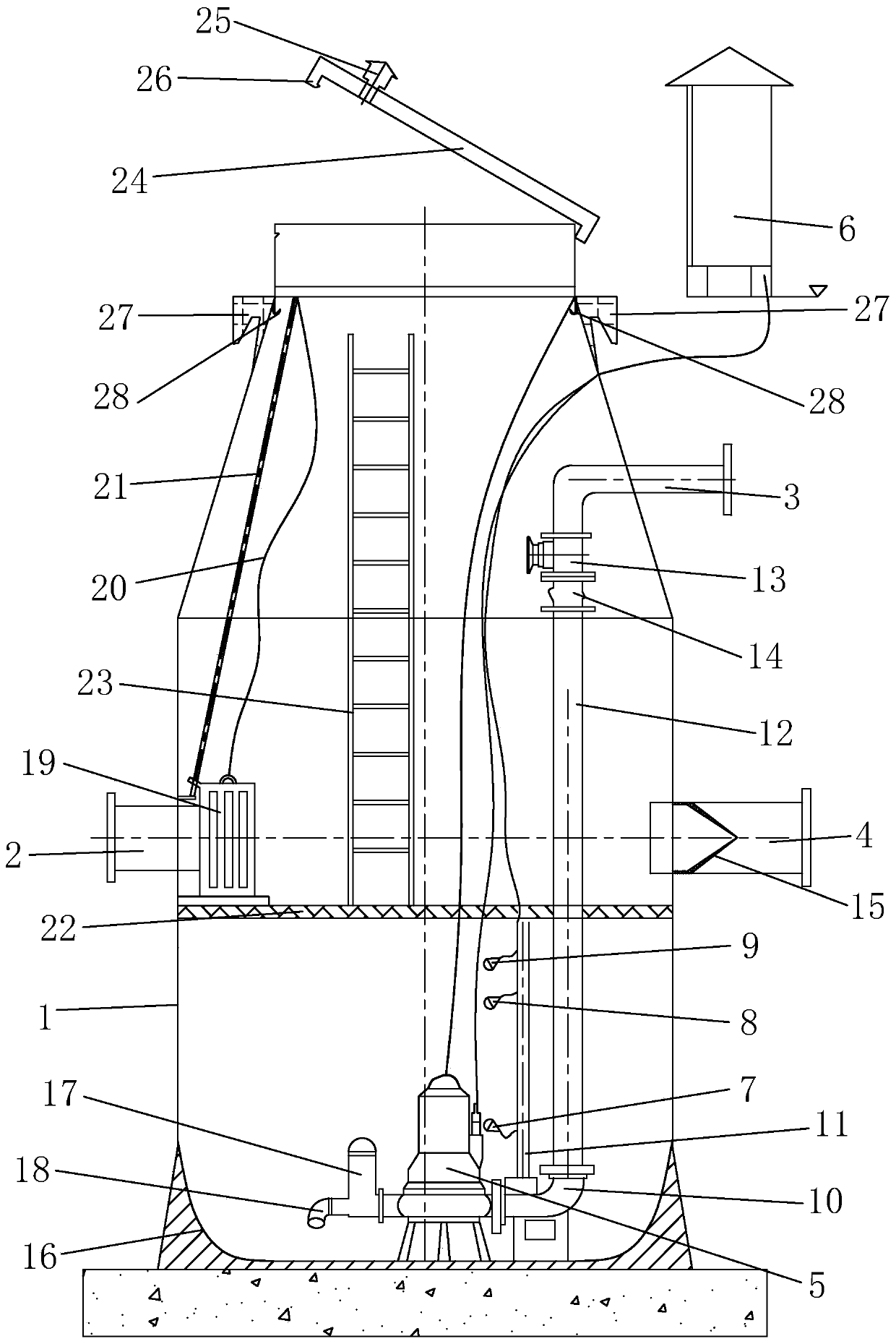

Prefabricated intelligent rainwater and sewage separation well

PendingCN110016956AAchieve dischargeWith automatic sludge removal functionSewerage structuresClimate change adaptationSewageEngineering

The invention discloses a prefabricated intelligent rainwater and sewage separation well, comprising a well body. The well body is provided with a water inlet, a sewage outlet, a rainwater overflow port and a submersible sewage pump, the sewage outlet communicates with the submersible sewage pump, and the submersible sewage pump is connected with a liquid level control switch. The bottom hole sewage collecting slope adopts the steepest descending line design, so that the sewage cleaning effect and efficiency are improved. By applying the prefabricated intelligent rainwater and sewage separation well, rainwater and sewage can be shunted, and the water level can be raised; even through the same water inlet pipe, sewage enters a sewage pipeline after passing through the separation well in sunny days, and clean rainwater obtained after automatic cleaning, initial discarding and secondary sedimentation is completed in rainy days flows into a rainwater pipeline.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

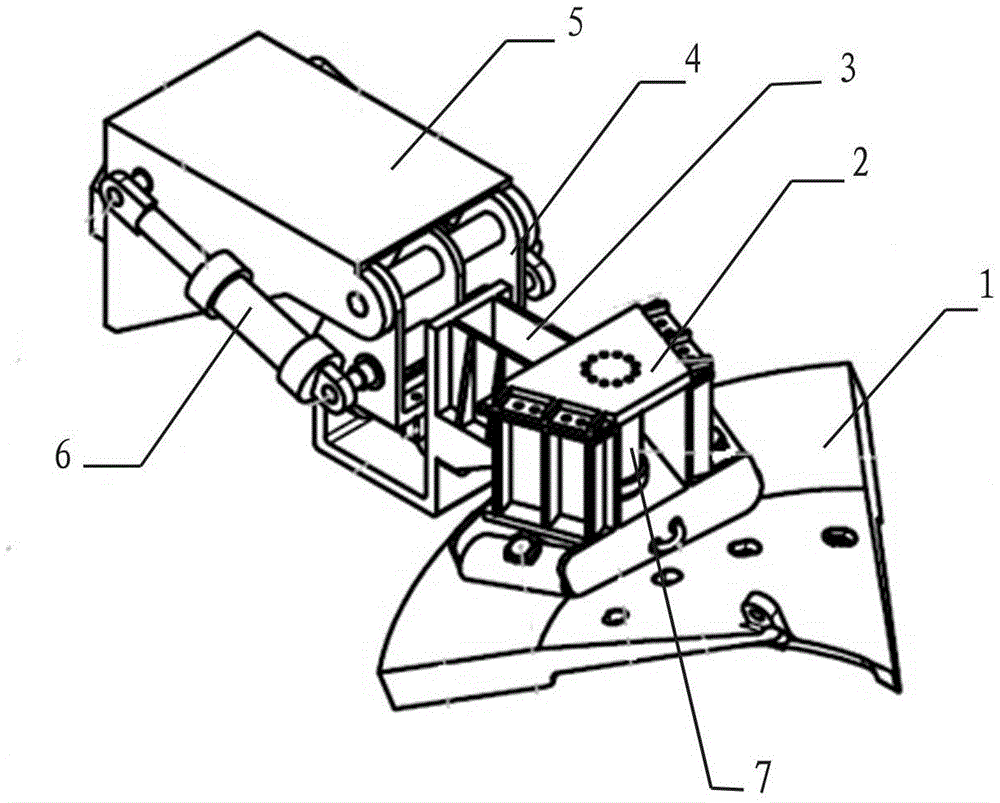

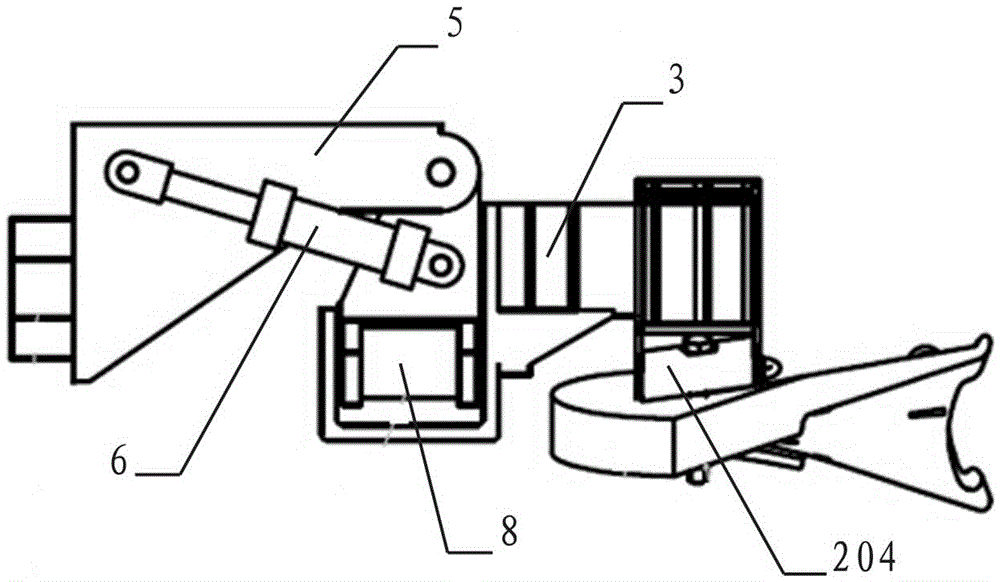

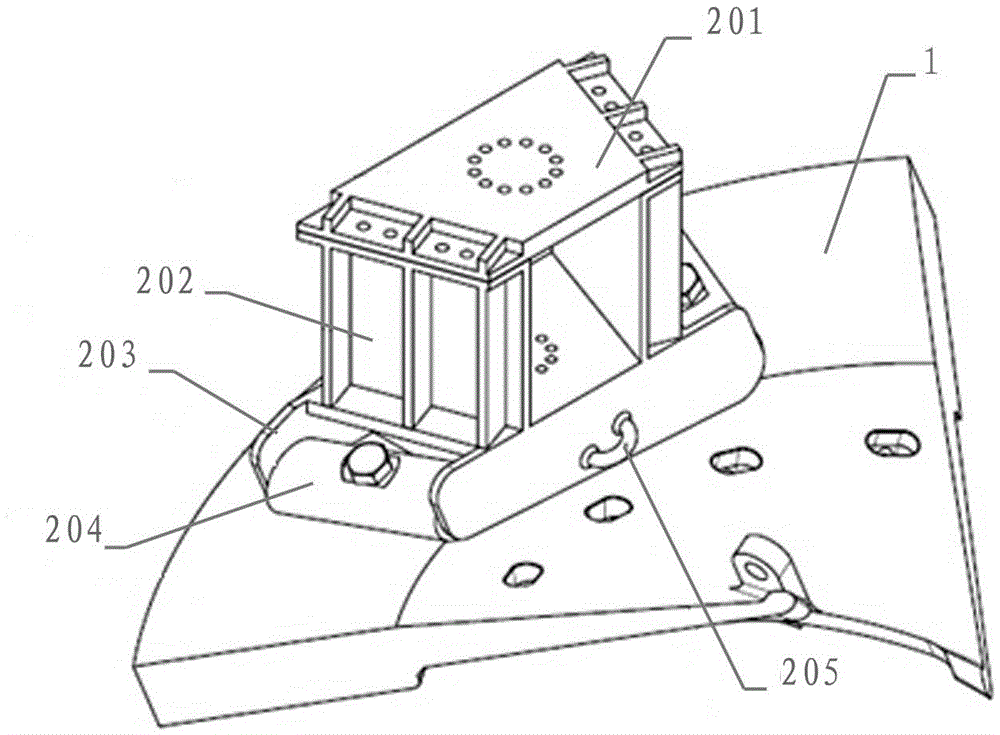

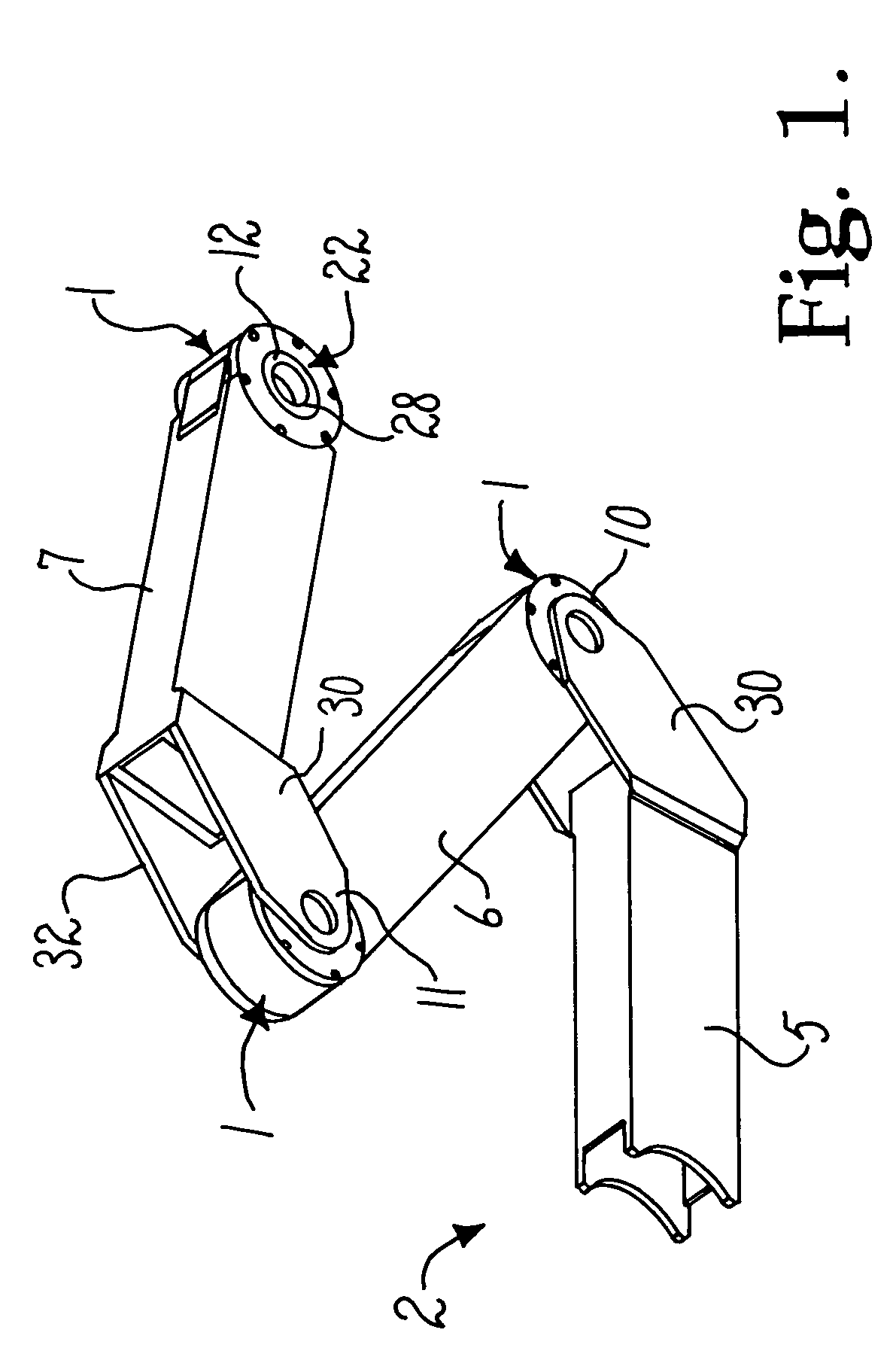

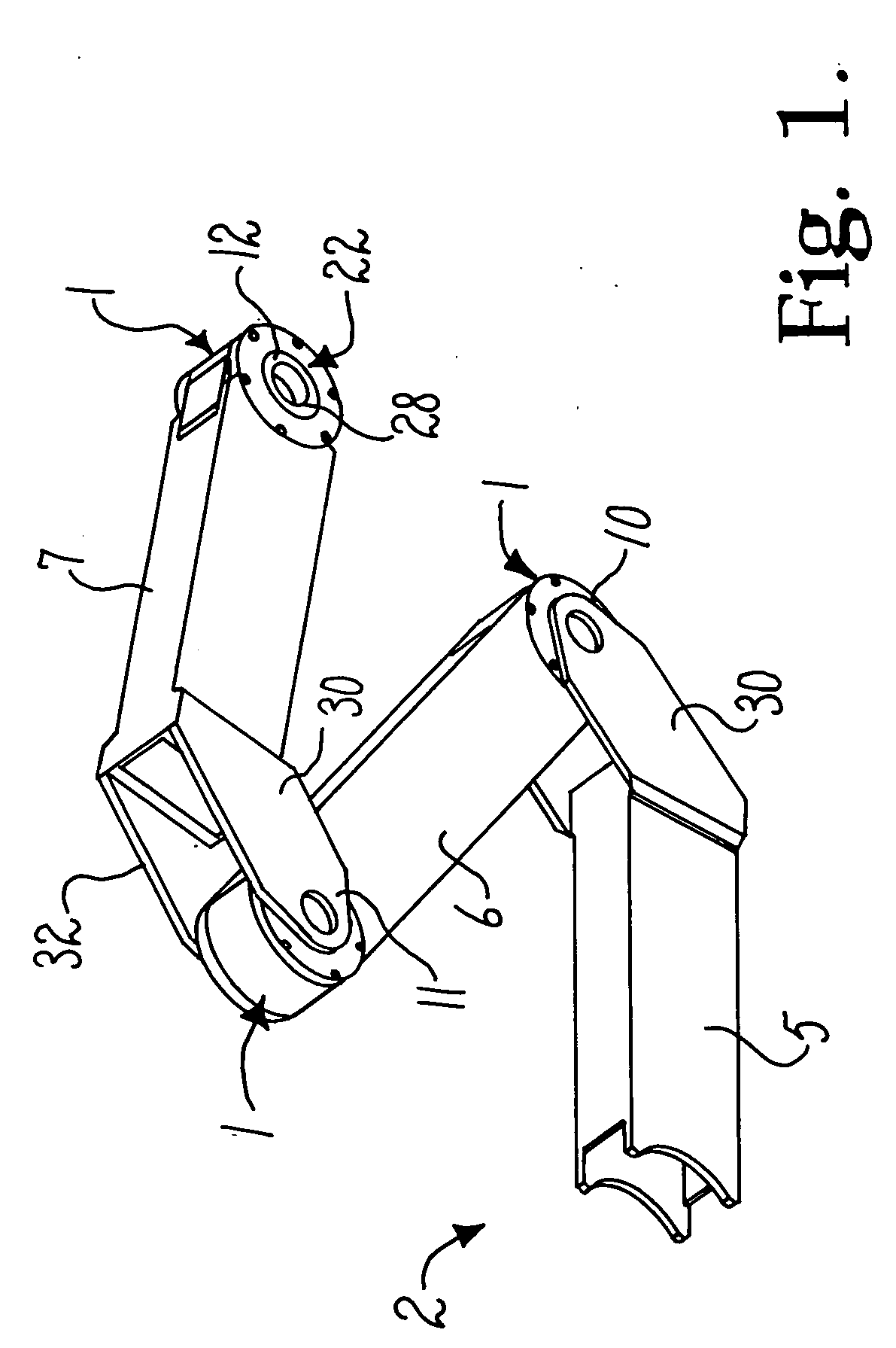

Mechanical arm used for replacing spiral liner plate

ActiveCN105643655AImprove mechanizationHigh degree of automationJointsWork holdersVertical planeRobot hand

The invention discloses a mechanical arm used for replacing a spiral liner plate. The mechanical arm comprises a linking tool, a pitching joint, a spiral curved surface attaching joint and an installation hole positioning joint. The spiral liner plate to be replaced is fixed to the linking tool. The pitching joint comprises a pitching connecting plate and a support, and the pitching action of the pitching joint is controlled by a drive mechanism arranged between the pitching connecting plate and the support. The spiral curved surface attaching joint comprises a tool connecting mechanism and a rotating mechanism I. The linking tool is connected to the tool connecting mechanism. The rotating mechanism I drives the linking tool to rotate. The installation hole positioning joint is composed of a rotating mechanism II arranged on the linking tool. The linking tool is driven to rotate in the horizontal plane. Pitching rotation, rotation in the horizontal plane and rotation in the vertical plane of the mechanical arm are completed through the coordination of the three joints, the posture of the spiral liner plate is adjusted gradually so that the spiral liner plate can be well attached to a spiral supporting plate of a vertical stirring mill and an installation hole can be positioned, and the mechanization and automation degree of replacing the spiral liner plate is greatly improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

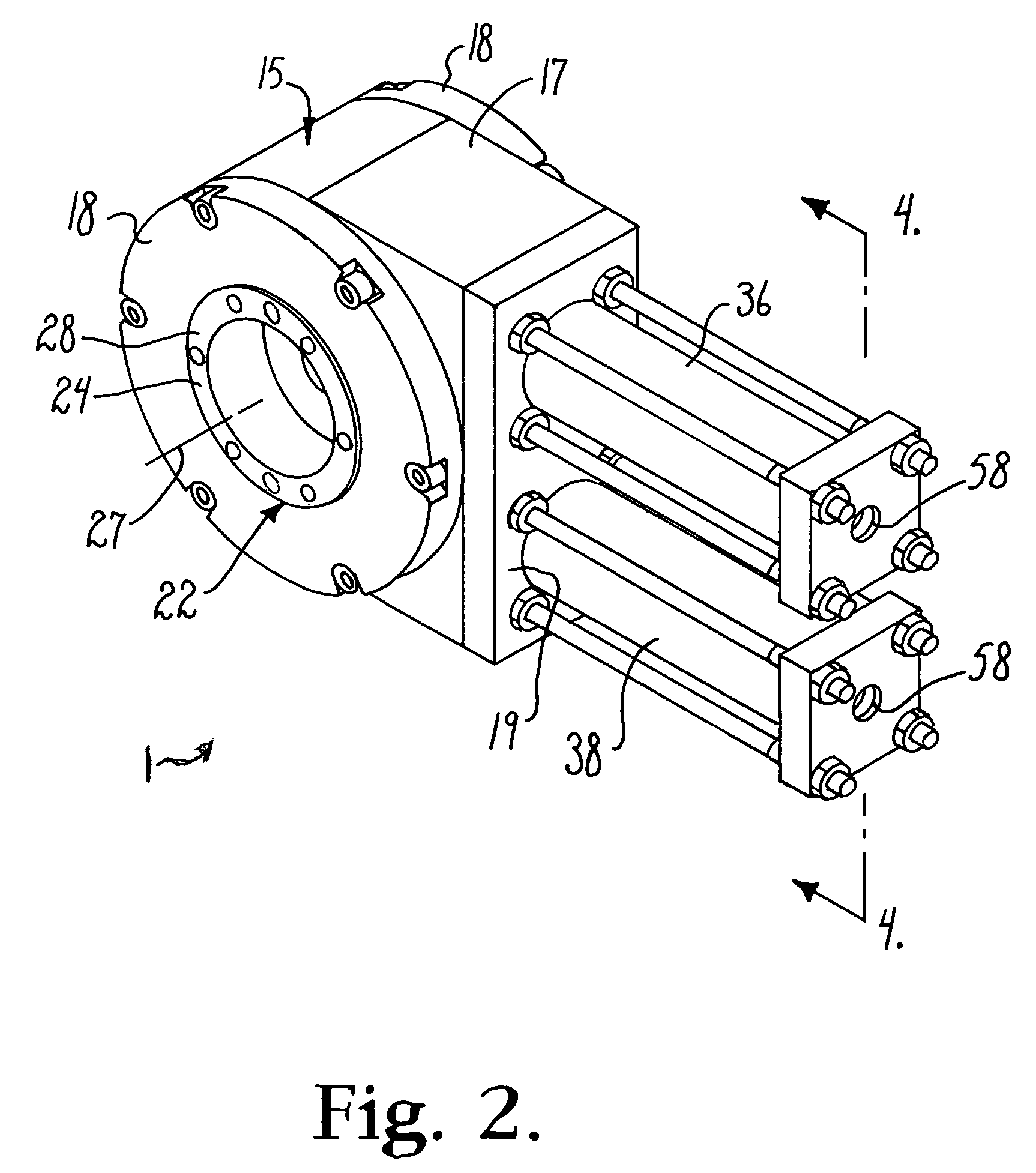

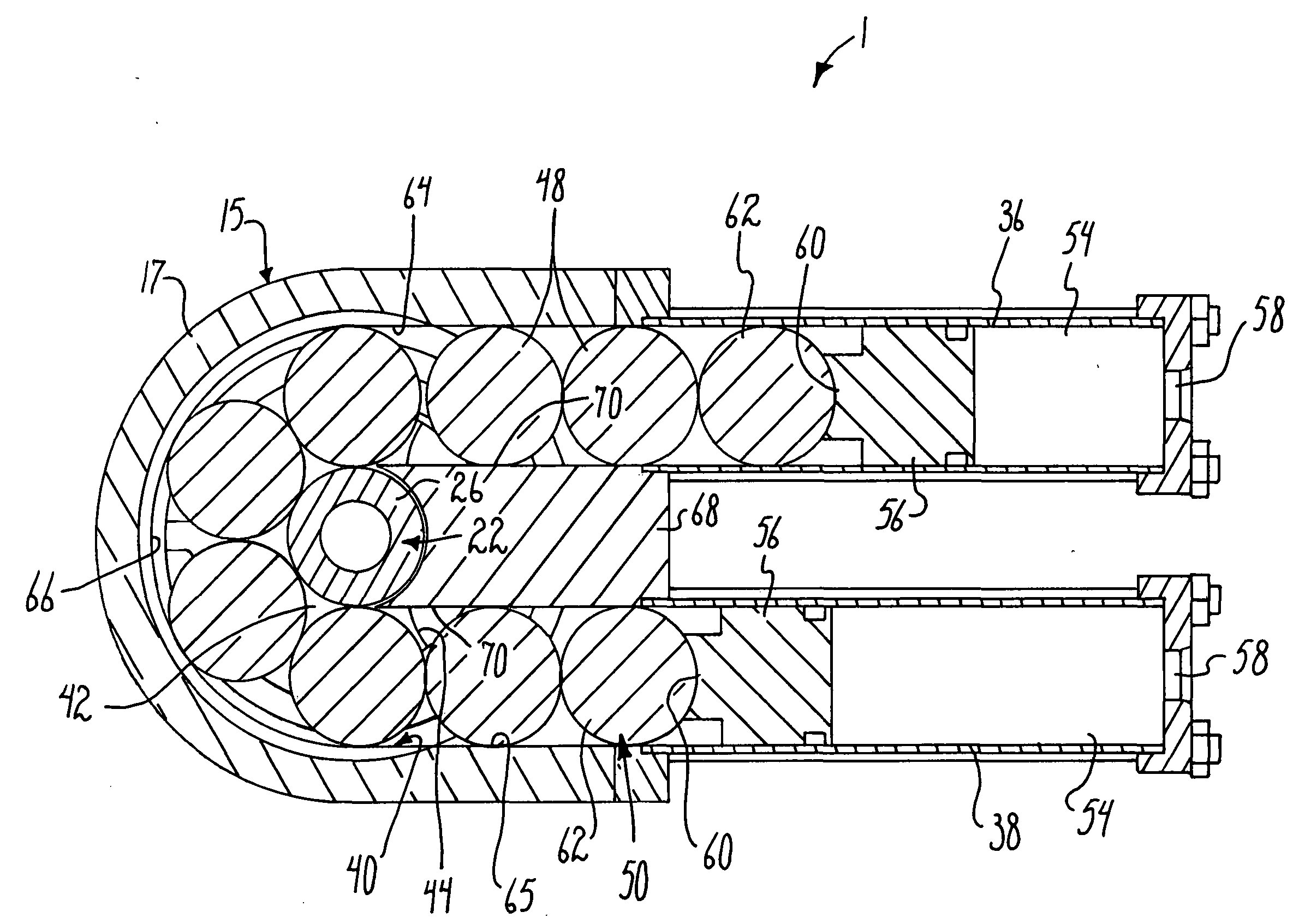

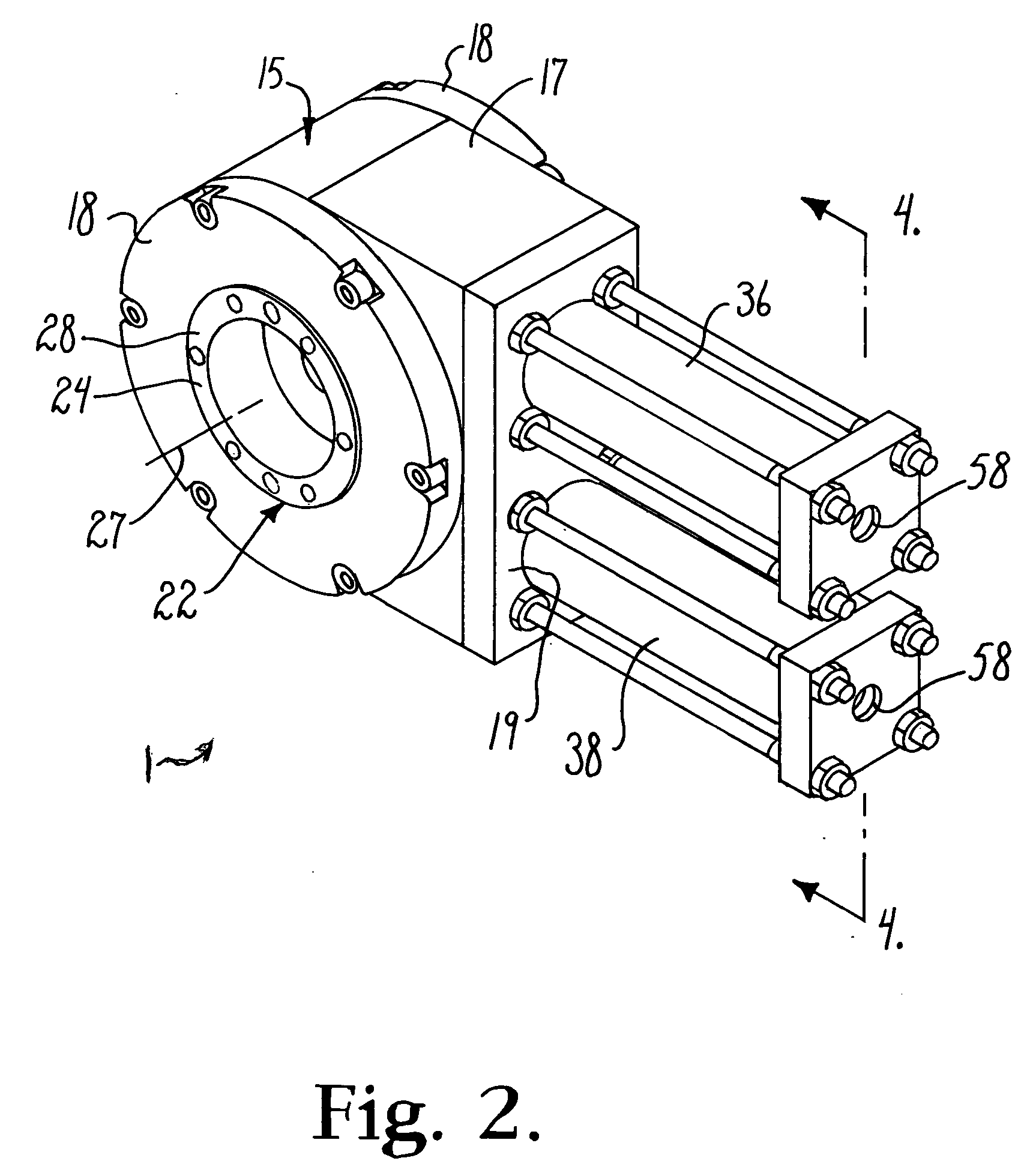

Ball and piston rotary actuator mechanism

A rotary actuator mechanism for applying torque to a shaft and comprising an actuator housing forming an actuator path that includes an actuator pinion rotatably supported in said housing and having said shaft secured thereto. The pinion having peripheral notches of a selected shape and positioned within the actuator path. The mechanism having a train of discrete actuator elements having opposite ends and positioned in the actuator path, each of the actuator elements being of said selected shape to enable reception in the peripheral notches, a plurality of the elements engaging the notches. The mechanism having at least one linear actuator supported by the housing and engaging one of the ends of the train of actuator elements, the linear actuator being selectively activated to push the train of discrete actuator elements through the actuator path to thereby serially engage the actuator elements with the notches of the pinion and thereby apply torque to the shaft.

Owner:KRAFT BRETT W

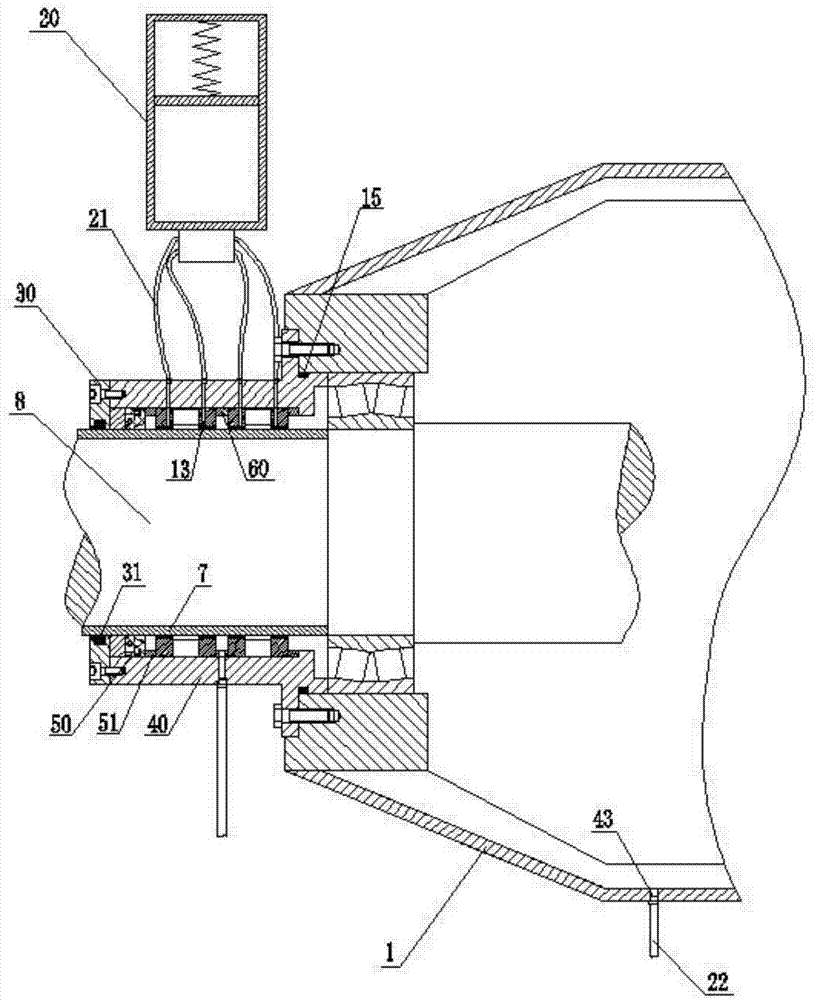

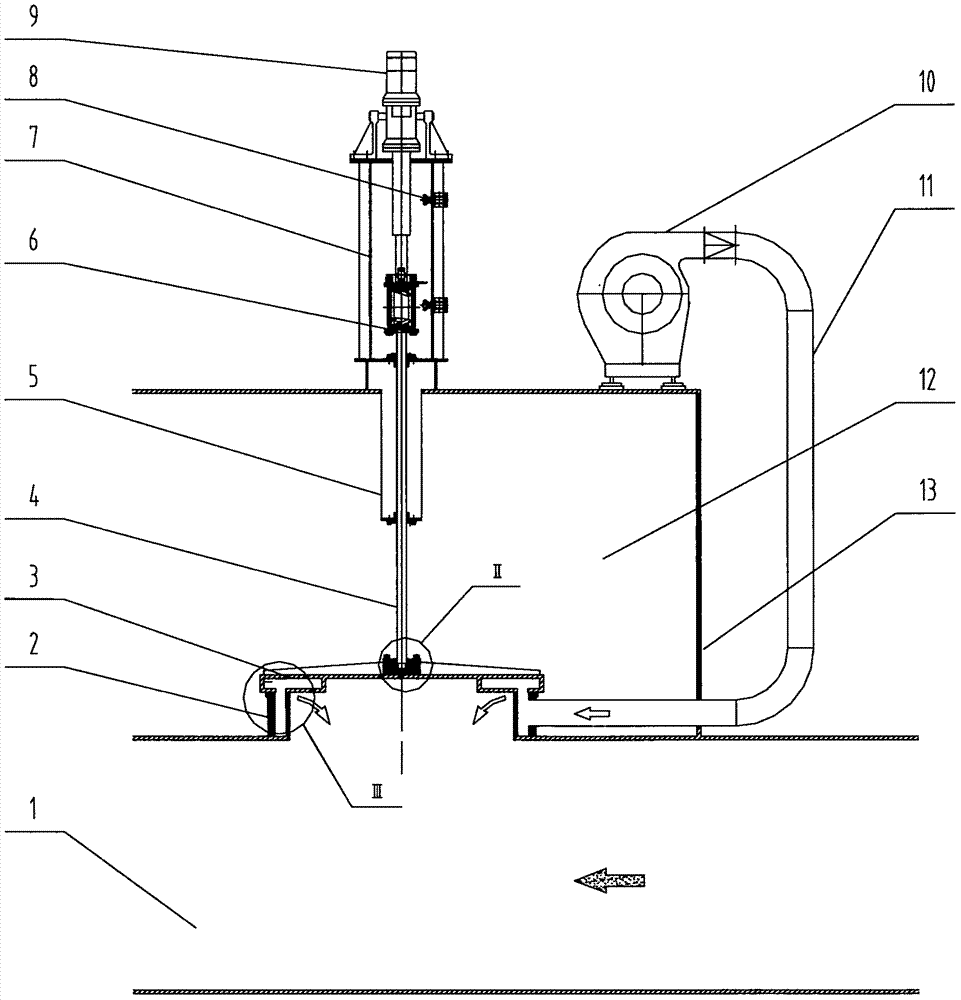

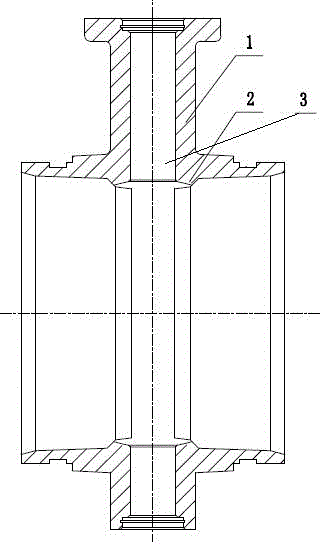

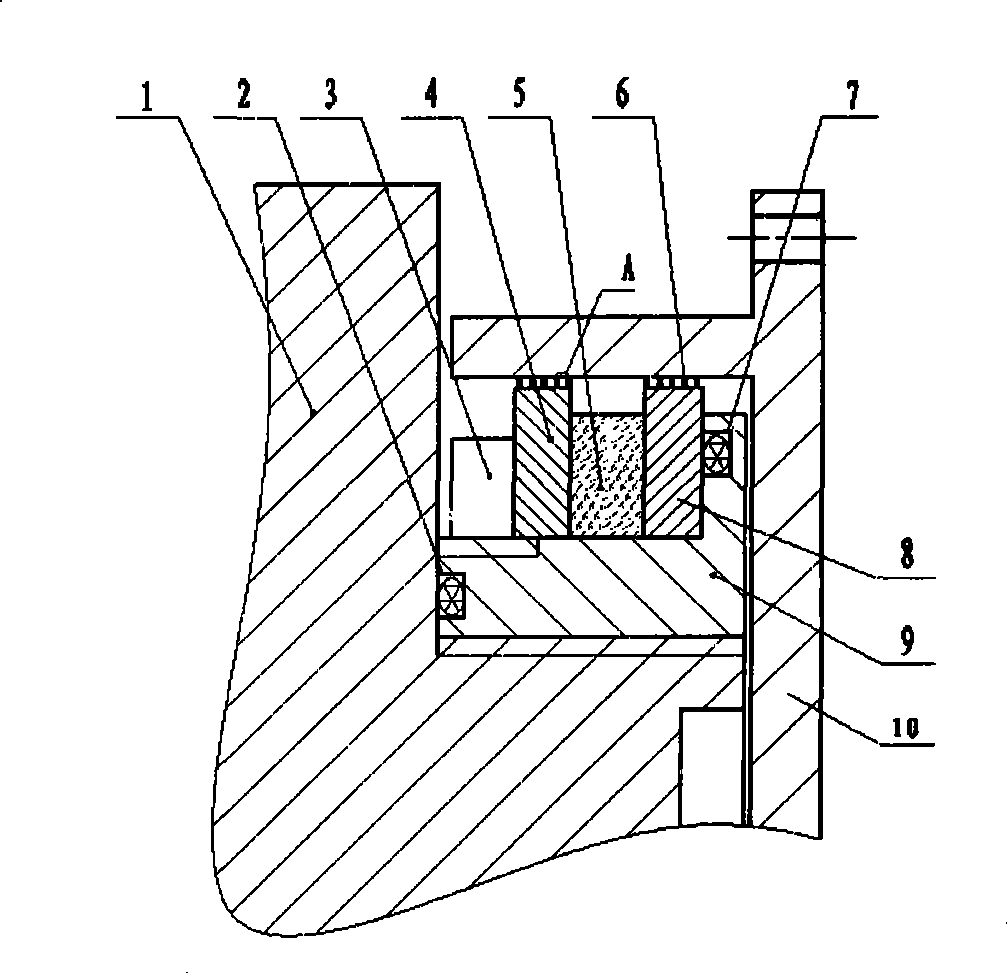

Impeller main shaft sealing device for ocean current energy power generation system

ActiveCN104763575AGood vibration and noise reductionImprove energy transfer efficiencyHydro energy generationMachines/enginesImpellerEngineering

The invention relates to an impeller main shaft sealing device for an ocean current energy power generation system. The sealing device comprises two magnetic fluid sealing pairs, magnetic fluid automatic compensating equipment, a shaft cover, a sealing housing, an inner packing framework oil seal, a wear-resisting sleeve and gas-filling equipment, wherein the shaft cover and the sealing housing are fixed together through a bolt. The sealing housing is of a sleeve type structure; the inner packing framework oil seal, and the two magnetic fluid sealing pairs are of circular-ring type structures; the inner packing framework oil seal and the two magnetic fluid sealing pairs are arranged on the inner surface of the sealing housing in sequence; four first liquid filing holes and a first gas filling hole are formed in the sealing housing; a second gas filling hole is formed in a cabin housing. The magnetic fluid automatic compensating equipment is communicated with the first liquid filling hole; the gas filling equipment is communicated with the first gas filling holes and the second gas filling hole. The sealing device adopts a magnetic fluid sealing technology to realize two-way sealing of the impeller main shaft, and adopts a mode of filling gas with certain pressure to gradually balance the external seawater pressure, so that the magnetic fluid sealing reliability is guaranteed.

Owner:ZHEJIANG UNIV

Hard alloy composite sealing structure and preparing technology thereof

InactiveCN107269859AReach frictionZero frictionLift valveValve member-seat contactsMachine partsAlloy composite

The invention relates to a hard alloy composite sealing structure and a preparing technology thereof. The hard alloy composite sealing structure comprises a valve seat machining part and a sealing ring machining part. In the valve seat machining part, a casting is fixedly arranged on a valve seat machining clamp inclining by 4-15 degrees, and after the sealing face thickness of 4-8 mm is reserved, a sealing face of the valve seat is roughly turned, and surfacing of a first hard alloy layer is conducted on the sealing face of the valve seat; and in the sealing ring machining part, a sealing ring blank is arranged on a sealing ring machining clamp of a lathe, and after the sealing face of the sealing ring is finely turned, surfacing of a second hard alloy layer is conducted on the sealing face of the sealing ring. According to the hard alloy composite sealing structure and the preparing technology thereof, the machining technology cost is low, the sealing precision is high, the product can achieve zero friction, zero leakage and both-way pressure bearing and achieves real high performance, a sealing pair is all metal, and once after closing is conducted in place, sealing is very reliable, and the application temperature range is wide.

Owner:SHANGHAI LEIFU VALVE MFG CO LTD

Dual soft sealing flat gate valve

InactiveCN103410996AIncrease elasticityImprove toughnessSlide valveValve housingsRubber ringValve seat

The invention relates to a dual soft sealing flat gate valve. The dual soft sealing flat gate valve comprises a valve body, a valve cover, a sealing gasket, a valve rod, a padding pressing plate, a gland box, a flashboard and valve seats. A medium passage is transversely and coaxially formed inside the valve body, the valve cover is longitudinally, coaxially and fixedly installed at the upper end of the valve body, the valve rod is longitudinally and coaxially installed in the middle of the valve cover, the gland box is coaxially installed between the valve cover and the valve rod at the lower end of the padding pressing plate in a pressing mode, the lower end of the valve rod stretches into the valve body, the flashboard is longitudinally, coaxially and fixedly installed at the lower end of the valve rod, the two parts, located on the two transverse sides of the flashboard, of the valve body are internally provided with the valve seats respectively and symmetrically in a pressing mode, two rectangular grooves are longitudinally formed in the valve seat contact face connected with the flashboard at intervals, an RPTFE rectangular sealing ring is embedded inside one rectangular groove close to the medium passage, and a rectangular rubber ring is installed inside the other rectangular groove. The dual soft sealing flat gate valve is simple in structure, scientific in design, reliable in sealing, easy to machine, low in sealing specific pressure, flexible in operation, long in service life and high in sealing reliability, torque is reduced, and the sealing performance is improved.

Owner:TIANJIN BAILIZHANFA GRP

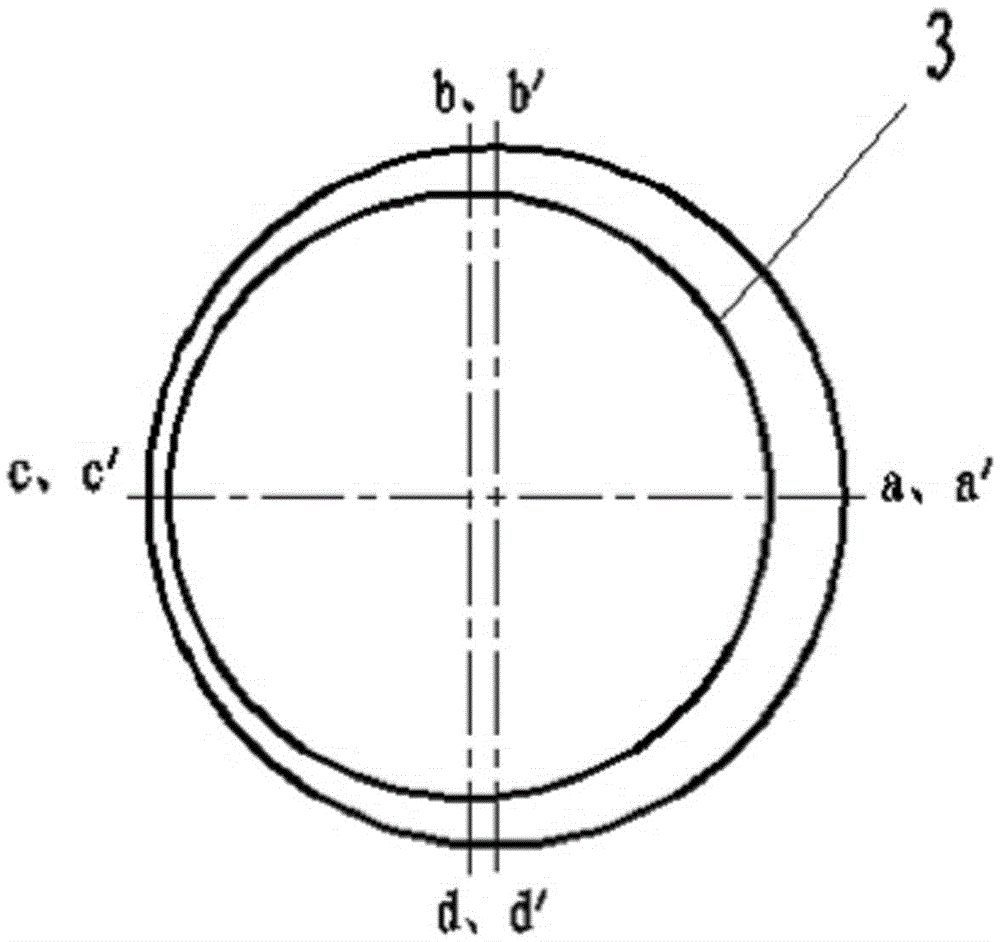

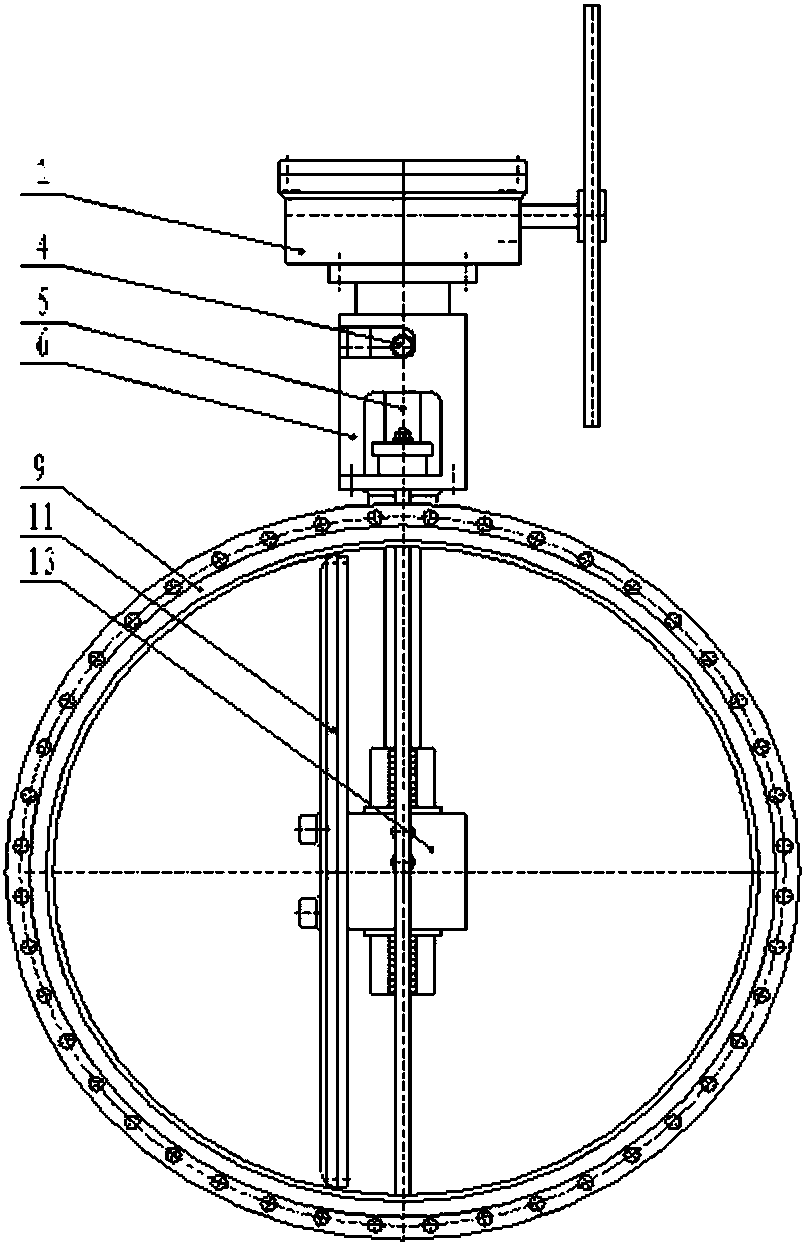

Four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve

The invention discloses a four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve which comprises a butterfly plate assembly consisting of a valve body, a valve shaft, a valve plate, a stack and a valve plate pressure ring, wherein the valve plate is arranged in the valve body and fixed on the valve shaft through a pin; a stuffing box is arranged on the upper part of the valve body; and a transmission mechanism is arranged on the stuffing box. The four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve is characterized in that the valve plate has a four-dimensional four-eccentric structure, wherein the valve plate of the four-dimensional four-eccentric structure is located with four surfaces of a valve base of the valve body, i.e., surfaces a, b, c and d of a diagonal-dimensional valve base and surfaces a', b', c' and d' of a valve plate diagonal-dimensional stack are correspondingly arranged together according to an assembly position so as to form a sealing structure; a sealing angle alpha of the assembled c-c' is 1 degree, and the degree is changeless, and is a designed angle. The four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve is reasonable in structure, wide in scope of application, long in service lifetime, free of leakage, relatively low in manufacturing cost, convenient in mounting, and high in qualified rate; and safety cost is greatly reduced.

Owner:黄一立

Positive-pressure air seal by-pass valve with single-layer valve plate

PendingCN107420558ASimple structureCompact structureDispersed particle filtrationLift valvePositive pressureEngineering

A positive-pressure air seal by-pass valve with a single-layer valve plate comprises the valve plate, an electric push rod for improving power and a high-pressure draught fan for assisting sealing, a guiding mechanism and a spring buffering mechanism. The valve plate is arranged in a dust containing air flue and a by-pass air flue, is of a single-layer structure and is provided with a valve plate bottom plate and a vertically-bulging annular side wall. A valve opening is provided with a valve opening bottom plate and a vertically-bulging annular valve opening body. The valve plate makes contact with the corresponding valve opening to form a relatively-closed valve chamber. The high-pressure draught fan communicates with the valve chamber formed by the valve plate and the valve opening. The positive-pressure air seal by-pass valve with the single-layer valve plate has the advantages that the structure is simple, compact and capable of achieving zero leakage, operation is stable and reliable, operation and maintenance are easy and convenient, and the applicability is high.

Owner:DATANG ENVIRONMENT IND GRP

Ball and piston rotary actuator mechanism

ActiveUS20110094325A1Strict controlMove preciselyProgramme-controlled manipulatorJointsPinionRotary actuator

A rotary actuator mechanism for applying torque to a shaft and comprising an actuator housing forming an actuator path that includes an actuator pinion rotatably supported in said housing and having said shaft secured thereto. The pinion having peripheral notches of a selected shape and positioned within the actuator path. The mechanism having a train of discrete actuator elements having opposite ends and positioned in the actuator path, each of the actuator elements being of said selected shape to enable reception in the peripheral notches, a plurality of the elements engaging the notches. The mechanism having at least one linear actuator supported by the housing and engaging one of the ends of the train of actuator elements, the linear actuator being selectively activated to push the train of discrete actuator elements through the actuator path to thereby serially engage the actuator elements with the notches of the pinion and thereby apply torque to the shaft.

Owner:KRAFT BRETT W

Composite seal-based spiral sheet sealing assembly

PendingCN113062984ASuitable for runout compensationThe overall structure is simple and reliableEngine sealsEngineeringClutch

The invention discloses a composite seal-based spiral sheet sealing assembly and belongs to pioneering inventions in the field of sealing. At least one spiral sheet sealing assembly is arranged in a sealed cabin to wrap a sealed part, each spiral sheet sealing assembly is sequentially provided with a shifting ring, a spiral sealing sheet and a fixing ring installed in the sealed cabin in the axial direction, and each spiral sealing sheet is axially and tightly attached and is radially and tightly attached to the sealing ring surface of the sealed part to form a sealing pair at the same time; or a spiral sheet sealing assembly and a corrugated pipe clutch are arranged in the sealed cabin to wrap a rotating shaft, a fixed end plate is arranged at one end of a corrugated pipe of the corrugated pipe clutch, a movable end plate is arranged at the other end of the corrugated pipe, the fixed end plate is tightly connected with the inner cavity of the sealed cabin, the movable end plate can axially move in the inner cavity of the sealed cabin, and when the relative pressure difference between two end surfaces of the movable end plate is greater than zero, the sealing end surface of the movable end plate and the sealing end surface of the corresponding sealing ring seat form a sealing pair. The assembly is simple and reliable in structure, wide in application, high in cost performance, zero in leakage, long in service life and convenient to maintain.

Owner:卢星霖

Clamping butterfly valve body

The invention discloses a clamping butterfly valve body. The upper part and the lower part of a cavity of the valve body are respectively provided with a rotating shaft hole of a valve column, two peripheral edges of the inner peripheral surface of the cavity of the valve body matched with a valve plate are provided with a boss respectively, the inner peripheral surface and the peripheral edges of the two bosses form an arc-shaped sealing surface, and crossing parts of the arc-shaped sealing surface and the rotating shaft holes of the valve column are provided with a widened boss. Since the two edges of the inner peripheral surface of the cavity of the valve body matched with the valve plate are provided with the bosses and are processed into the arc-shaped surface, the valve plate is assembled into an arc-shaped sealing strip via a special valve plate assembly tool during assembly and is then rotated until the end of the valve body is matched with the end of the valve plate, and the assembly is easier and more convenient. Due to sealing of the arc-shaped surface, the sealing surface is matched better.

Owner:杨元亭

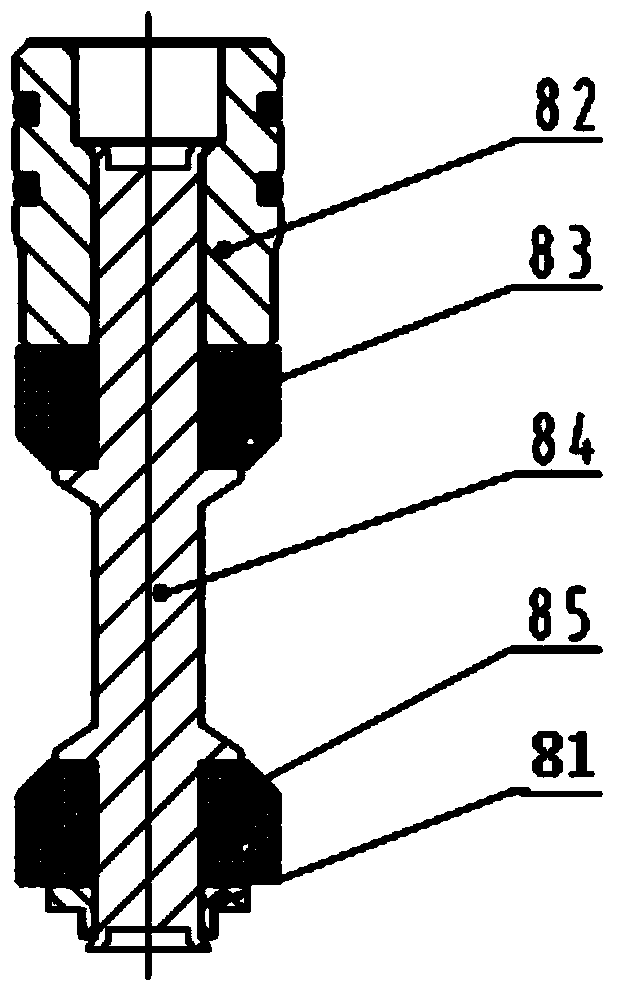

Novel three-way reversing valve

The invention relates to a novel three-way reversing valve. The novel three-way reversing valve is characterized by comprising a hollow reversing cavity (3), an air inlet, an air outlet and a reversing opening are respectively formed in the side face of the reversing cavity (3), the reversing opening is formed between the air inlet and the air outlet, a piston cavity (1) is formed in the top end of the reversing cavity (3), a signal inlet is formed in the piston cavity (1), a base (5) is arranged at the bottom end of the reversing cavity (3), a guide piston (82) is arranged in the reversing cavity (3), the top of the guide piston (82) is connected with a pneumatic piston (2), the pneumatic piston (2) is arranged in the piston cavity (1), and the outer wall of the pneumatic piston (2) and the inner wall of the piston cavity (1) are in gas seal. According to the reversing valve, a compressing structure of a metal valve base and V-type rubber is adopted by the sealing structure, and the defects that machining difficulty of a traditional structure is large, and after a sealing ring is abraded, air leakage is prone to happening are overcome.

Owner:WUZHONG INSTR

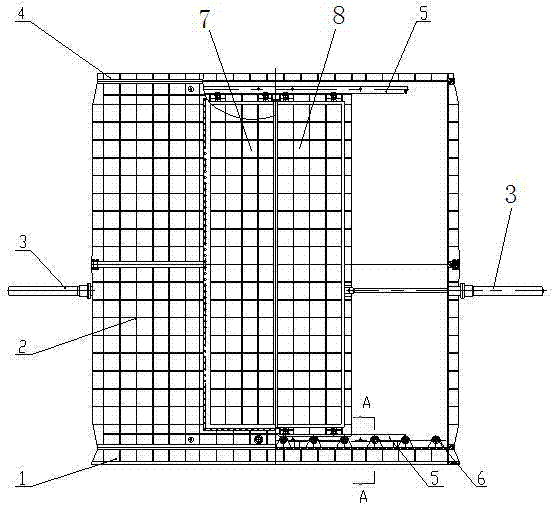

Middle open type translation double-sealed rectangular gate valve

The invention relates to a middle open type translation double-sealed rectangular gate valve. A right valve plate and a left valve plate which are opened or closed through rectangular frames are installed in a rectangular valve body, and the right and left valve plates are driven to move by a driving device installed on the valve body, and limited by shifting forks at the tops and bottoms of the right and left valve plates and limit rollers; and flow channel compensation is performed by virtue of a flow channel compensation device installed on the edge of an inner cavity of the valve body and flow channel compensation pieces connected to the flow compensation device, while a front sealing ring and a rear sealing ring of the inner cavity of the valve body as well as the front and rear sealing rings in the closure position of the right and left valve plates constitute bidirectional sealing. The rectangular gate valve provided by the invention is a valve with large size and zero leakage, the flow channel clearance is smaller than 5 mm, and the valve is applicable for working conditions of high flow rate and strong vibration.

Owner:HUBEI HONGCHENG GENERAL MACHINERY

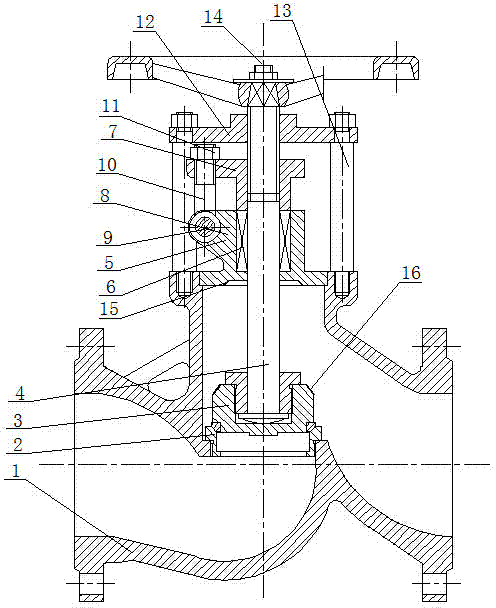

Integrated stop valve

The invention discloses an integrated stop valve, relating to the field of a valve and comprising a valve body; a valve seat is installed in the center of the valve body; a valve clack is arranged on the valve seat in a matching manner; the upper end of the valve clack is connected with a valve rod; the stop valve is characterized in that a stuffing box is arranged on the valve rod in a penetrating manner; a cavity matched with the lower end of the stuffing box is formed in the center of the upper side of the valve body; the lower end of the stuffing box is arranged in the cavity in the center of the upper side of the valve body in the matching manner and is connected in a sealing manner; a stuffing is arranged in the stuffing box and is compressed by a stuffing box gland; the valve rod above the stuffing box gland is in threaded connection with a nut seat; the nut seat is connected with the valve body by fastening via an upright post; the upper end of the valve rod is connected with a hand wheel. According to the integrated stop valve disclosed by the invention, a valve cover connected with the upper end of the valve body is omitted, no leak point exists and the sealing effect is improved.

Owner:NANTONG TIANYUAN VALVE MFG

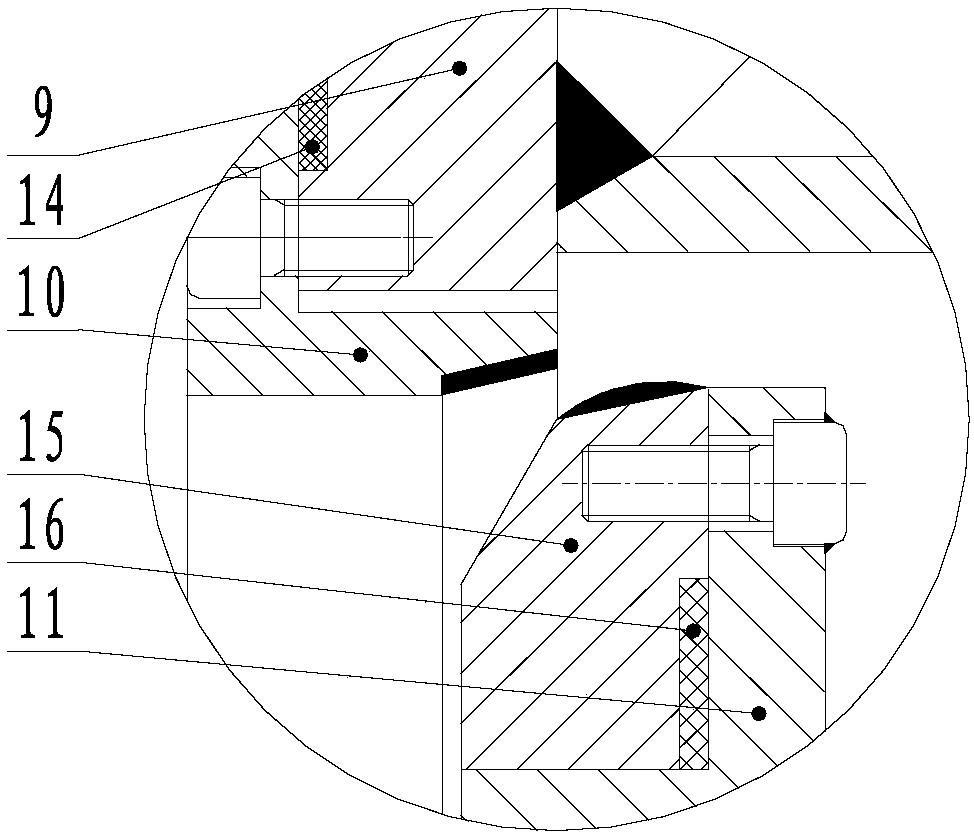

Low-torque and two-way zero leakage all-metal sealing butterfly valve

InactiveCN108105401ASmall operating torqueClose fastLift valveValve housingsNeedle roller bearingValve opening

The invention relates to a low-torque and two-way zero leakage all-metal sealing butterfly valve. According to the technical scheme, the low-torque and two-way zero leakage all-metal sealing butterflyvalve comprises an actuating mechanism, a thread sleeve, a lead screw, a connecting shaft, a valve rod, a bracket, a packing gland, a valve rod packing, a valve body, a valve seat, a butterfly plate,a reinforcing rib, a wedge splitting sliding component, a valve seat sealing filler, an all-metal sealing ring, a butterfly plate sealing filler, needle roller bearings and rollers. The low-torque and two-way zero leakage all-metal sealing butterfly valve adopts metal hard sealing and active sealing, sealing specific pressure is high, and zero leakage and two-way sealing are achieved; wear-proof,temperature-resistant and corrosion-resistant alloy materials are overlayed on the sealing surfaces of the valve seat and the butterfly plate, so that the service life is long; in the valve opening and closing processes, the sealing surfaces are not in contact, no friction is caused, operating torque is little, and the closing speed is high; the valve seat and the butterfly plate are of detachable structures, and are simple in structure, convenient in overhaul and low in maintenance cost; and the valve plate is relatively thin, so that the flow resistance is little, the discharge coefficientis high, and the scope of application is wide.

Owner:樊东升

Zero-leakage non-friction composite seal for rotating shaft

PendingCN113175530AReduce function consumptionFrictionlessEngine sealsInterengaging clutchesThermodynamicsEngineering

The invention discloses a zero-leakage non-friction composite seal for a rotating shaft, belongs to pioneering invention in the field of sealing, and mainly relates to two directions of sealing of rotating machinery and sealing of tail shafts of naval vessels and ships. A confrontation type and dredging type mode is adopted to avoid flowing of a medium in the rotating process, and dynamic sealing is achieved; a corrugated pipe clutch and / or a flywheel clutch are / is adopted to cut off the infiltration pressure after the rotating shaft stops rotating, and when the relative pressure difference is larger than or equal to zero, the sealing end face of a movable end plate and the sealing end face of a corresponding sealing ring seat form a sealing pair, and static sealing is achieved; main internal components are free of friction and abrasion, the maintenance cost is eliminated or greatly reduced, the fault risk is reduced, the working efficiency is improved, and the service life is greatly prolonged; and the zero-leakage non-friction composite seal for the rotating shaft is safe and reliable, is shock-proof and shock-absorbing, is wide in application range, and adapts to radial runout of the rotating shaft.

Owner:卢星霖

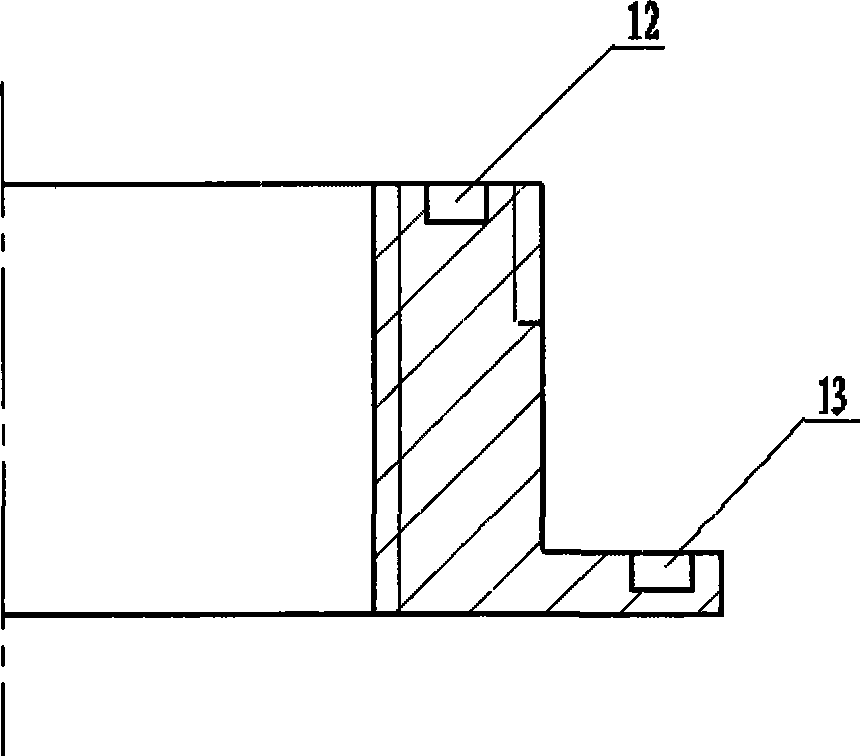

Seal structure for tank periscopic lens

The invention discloses a tank panoramic mirror sealing structure, relating to a magnetic liquid sealing structure, which respectively arranges a first O-shaped ring (2) and a second O-shaped ring (7) into two annular slots (12, 13) of a non-magnetic sleeve (9); mounting a right polar boot (8), a permanent magnet (5) and a left polar boot (4) from the small end of the non-magnetic sleeve (9); using a nut (3) to connect the screw of the small end of the non-magnetic sleeve (9) to lock the three elements on the non-magnetic sleeve (9), connecting the non-magnetic sleeve (9) and an direction shaft (1) via screws; sheathing an upper adverse head (10) on the right polar boot (8) and the left polar boot (4) and forming a sealing clearance (6); filling magnetic liquid into the sealing clearance (6) to form a tank panoramic mirror sealing structure. The tank panoramic mirror sealing structure has low resistance moment, simple installment, high reliability, long service life and the ability for realizing zero leakage.

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com