Positive-pressure air seal by-pass valve with single-layer valve plate

A bypass valve, single-layer valve technology, applied in the direction of lift valve, valve device, dispersed particle filtration, etc., can solve the problems of complex valve structure, complex process, poor practical effect, etc., to achieve simple operation and maintenance, stable and reliable operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This implementation case is carried out on the premise of the technical method. It should be understood that the implementation case is to illustrate the present invention, but the protection scope of the present invention is not limited to the following implementation case.

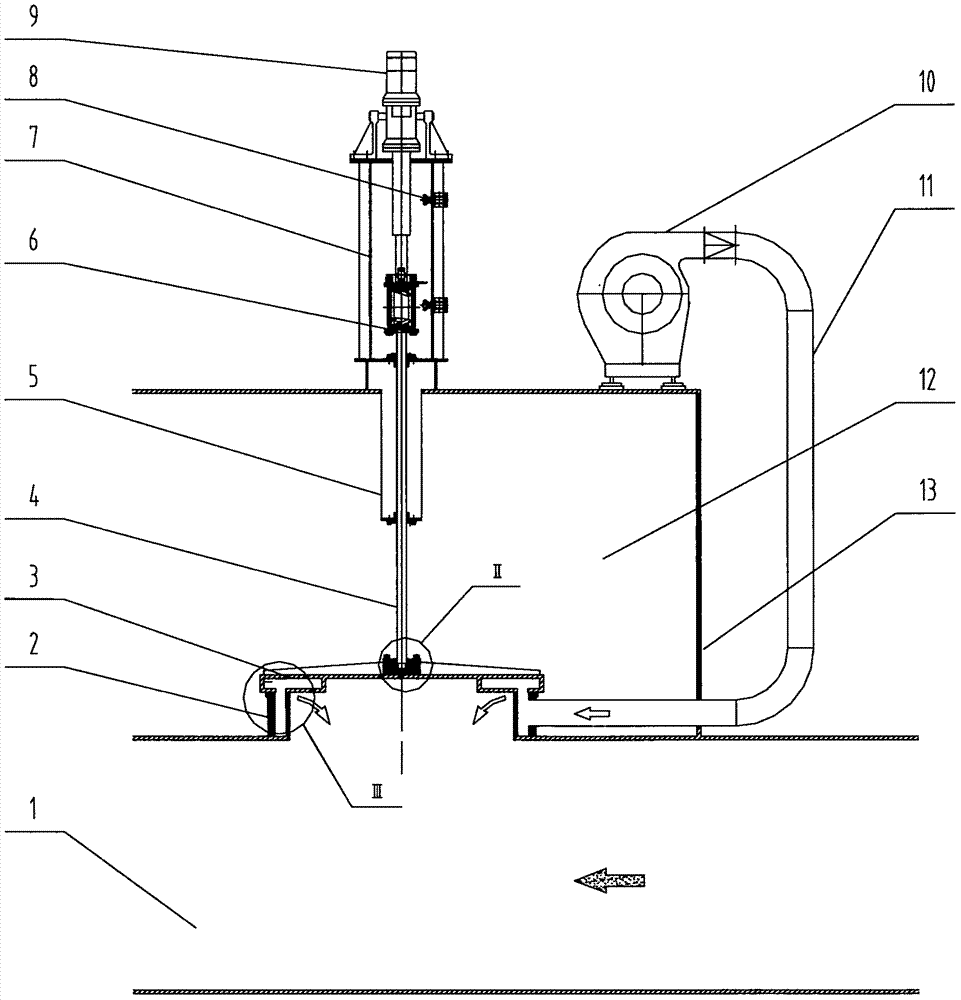

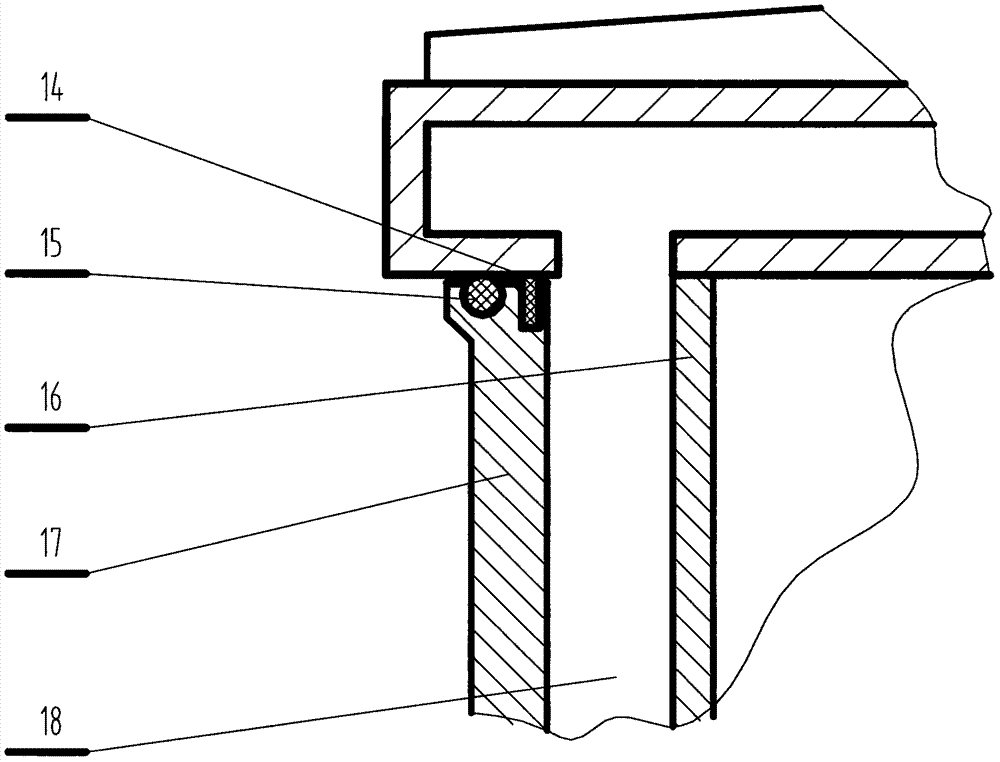

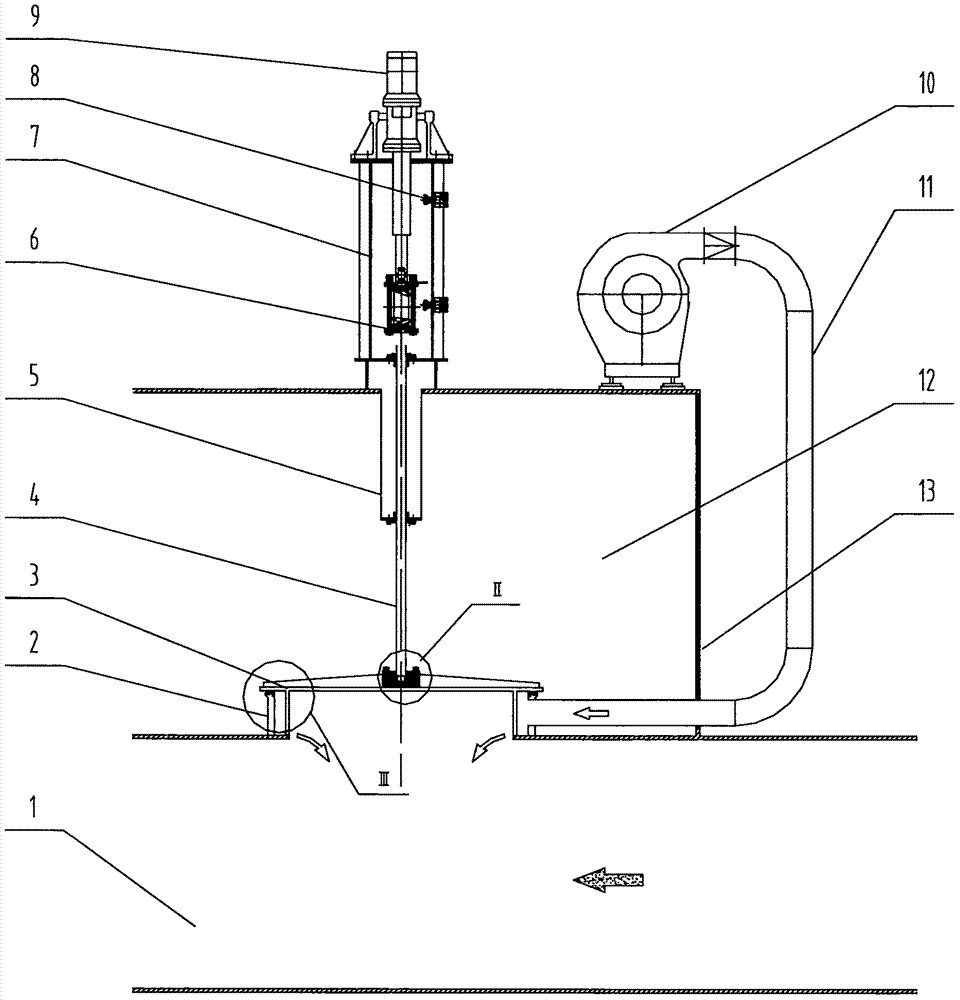

[0022] see Figure 3-Figure 7 Shown: a positive pressure air seal bypass valve, the bypass valve includes a valve plate 3, an electric push rod 9 for boosting power, a high-pressure centrifugal fan 10 for auxiliary sealing, a guide mechanism 5, and a spring buffer mechanism 6 , the valve plate 3 is set in the dust-containing air duct 1 and the bypass air duct 12, the valve plate 3 is a single-layer structure, and has a vertically protruding annular side wall 16b on the valve plate bottom plate 16a; the valve port 2 has The bottom plate 17a of the valve port and the annular valve por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com