Mechanical arm used for replacing spiral liner plate

A manipulator and screw technology, applied in the field of manipulators, can solve the problems of inability to fit the screw lining, inconvenient on-site installation, large volume and weight, etc., and achieve the effects of easy adjustment, simple and compact structure, and large driving torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

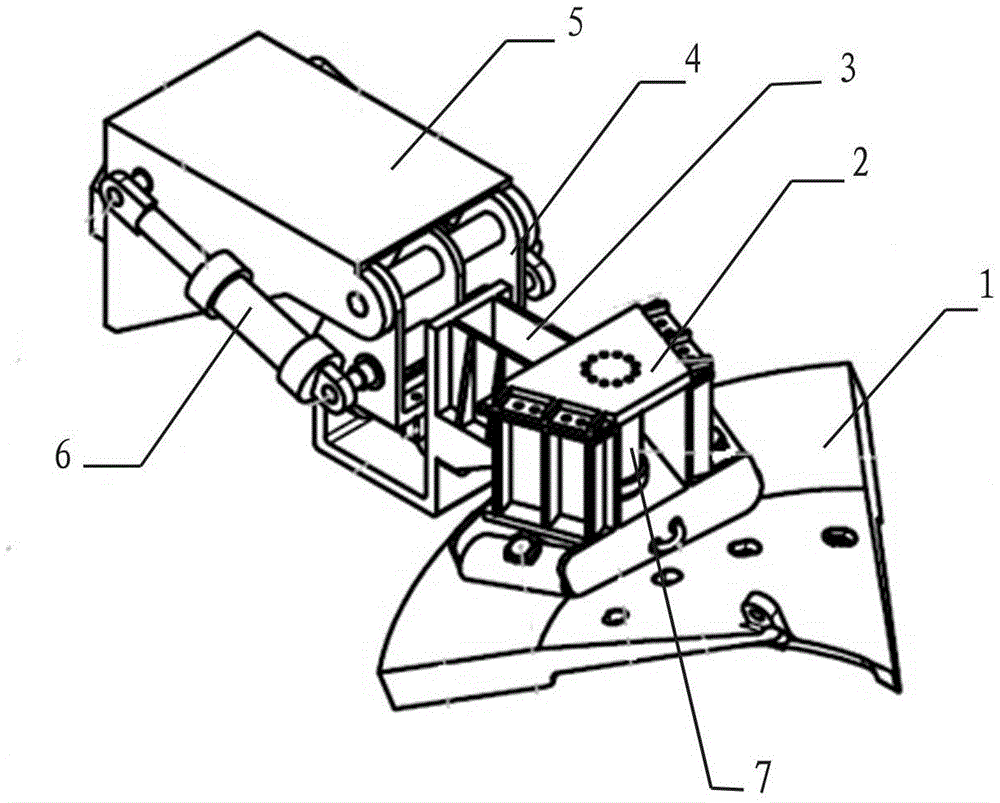

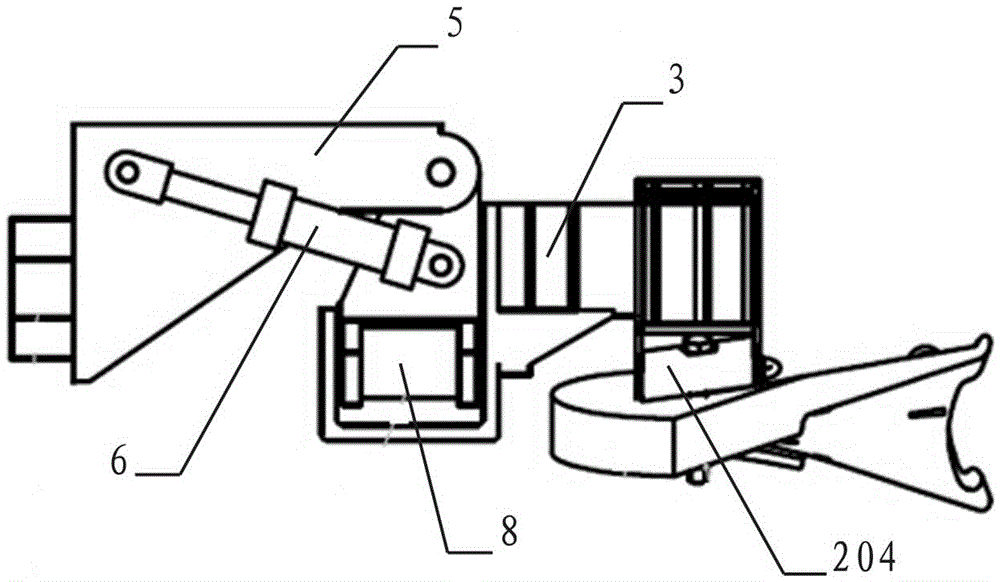

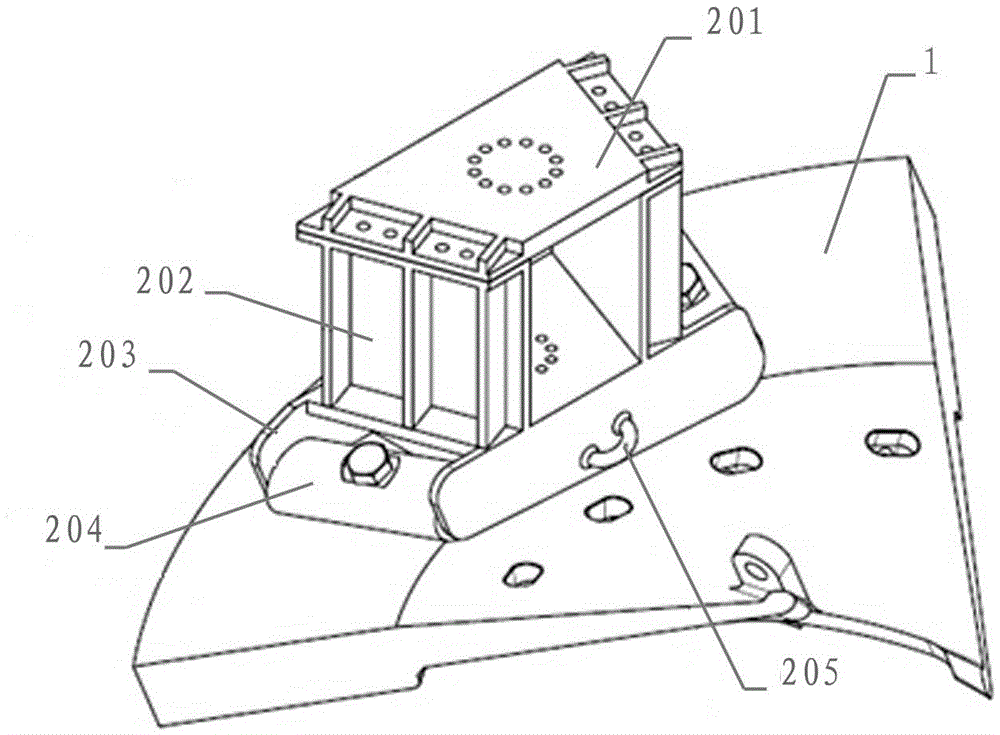

[0031] As shown in the figure, a manipulator for replacing the spiral liner is installed at the end of the mechanical arm of the liner replacement robot, including the connecting tool 2, the pitch joint, the joint for fitting the spiral surface and the positioning joint for the installation hole, to be replaced After the spiral liner 1 is put on the connecting tool 2, through the gradual adjustment and cooperation of each joint, the adjustment and positioning of the spiral liner 1 posture are realized, so that the spiral liner 1 can be connected with the spiral support plate of the vertical mixing mill Fit, and the installation hole of the spiral lining 1 is aligned with the installation hole of the spiral supporting plate, so as to realize the installation of the spiral lining 1.

[0032] In the above composition structure, the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com