Four-dimensional four-eccentric unidirectional and bidirectional sealing butterfly valve

A four-eccentric, four-dimensional technology, used in the field of sealing butterfly valves, can solve the problems of poor compensation effect and insufficient sealing, and achieve the effects of wide application range, long service life and enhanced sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

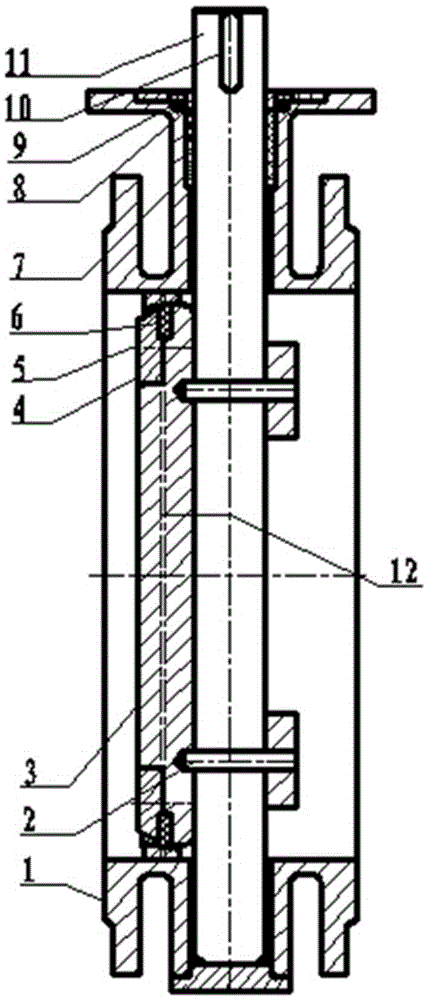

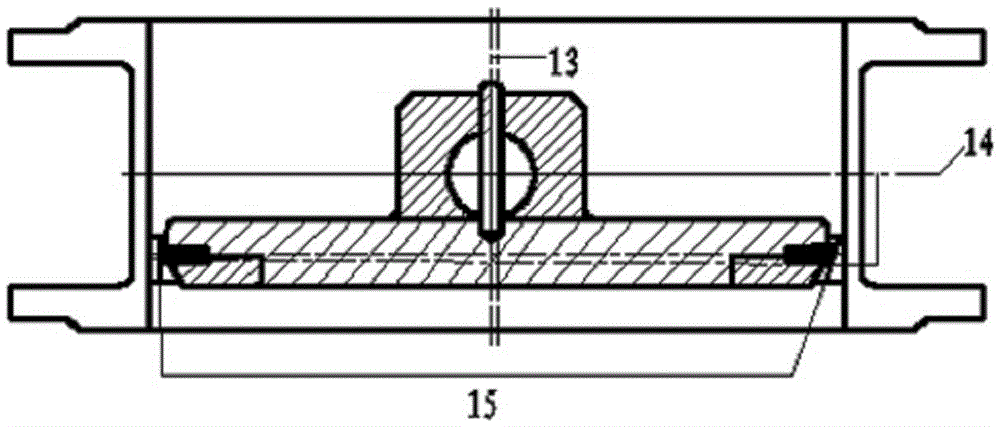

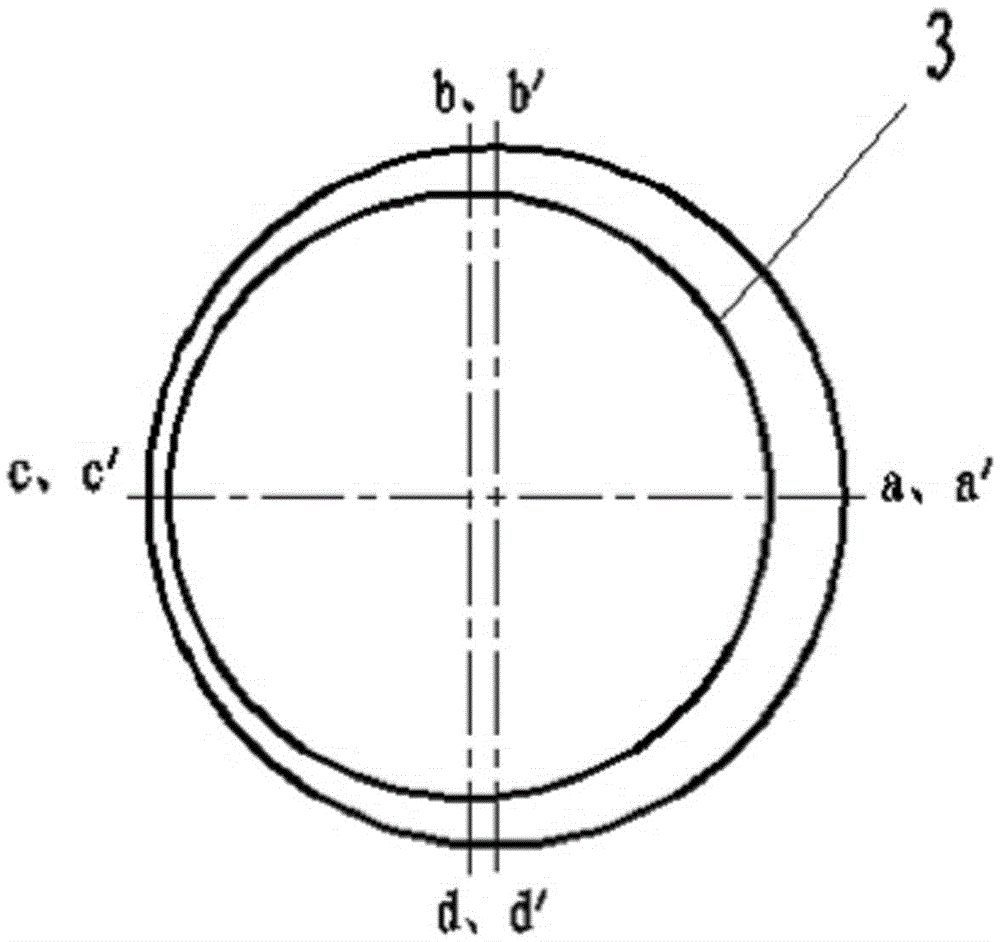

[0027] Such as figure 1 As shown, the present invention is a four-dimensional four-eccentric two-way sealed butterfly valve, which includes a butterfly plate combination consisting of a valve body 1, a valve shaft 11, a valve plate 3, laminations 6, and a valve plate retainer 4. The valve plate 3 is mounted on the valve Inside the body 1, the pin 2 is used to fix the valve shaft 11, and the stuffing box 7 is equipped with a transmission mechanism; the valve plate 3 is a four-dimensional four-eccentric structure, and the valve plate 3 of the four-dimensional four-eccentric structure is positioned on all sides of the valve seat of the valve body 1, that is The a, b, c, d surfaces of the oblique-dimensional valve seat and the four sides a', b', c', d' of the oblique-dimensional lamination of the valve plate are arranged together according to the combined position to form a sealing structure, see image 3 , to ensure the sealing stability and increase the sealing area. After the ...

Embodiment 2

[0032] Manufacture a four-dimensional four-eccentric two-way sealing butterfly valve of the present invention, its diameter is DN800, PN1.6MPa design principle see figure 1 , where the value of the first eccentricity is 78.85±0.1, the value of the second eccentricity is 73.75±0.1, the value of the third eccentricity is 22±0.1, and the value of the fourth eccentricity is 6.6±0.1, from image 3 Zhongkan’s 1-dimensional point a angle is 18°, 2-dimensional point b’s angle is 9°30′, and 3-dimensional point c’s angle α is 1° to further strengthen the function of the four-dimensional four-eccentric sealing butterfly valve; the 4-dimensional point d’s angle is 9°30′. When assembling, the valve plate 3, the lamination 6, and the valve plate pressure ring 4 are assembled and fixed with bolts 5 to form a butterfly plate assembly, and then the butterfly plate assembly and the valve shaft 11 are installed on the valve seat. The pin 2 forms the valve shaft and the valve plate as a whole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com