Permanent Magnet Direct Control Valve and Its Application

A control valve, direct technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of unreliable work, difficult to adjust flow, high process cost, and achieve light operation, easy promotion and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

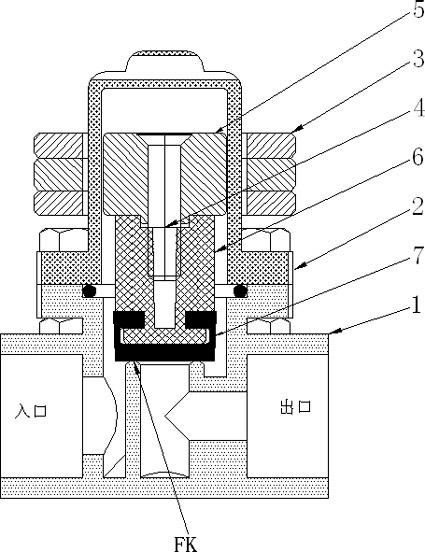

[0019] Embodiment one: according to figure 1 As shown, the valve seat 1 and the valve cover 2 are connected to form a statically closed valve body, a permanent magnet assembly 3 is provided outside the valve body, and only a valve plug assembly 4 is provided inside the valve, and an armature 5 is at one end of the valve plug assembly 4 , the middle is the extension rod 6, the other end is connected with the rubber valve plate 7, the rubber valve plate 7 is close to the valve port FK and closes the valve with the help of fluid pressure, when the permanent magnet assembly 3 moves upward, the valve plug assembly 4 follows upward The displacement opens the valve, and different displacements correspond to different flow rates.

Embodiment 2

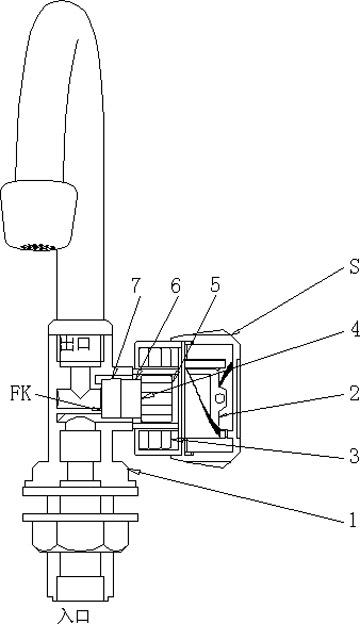

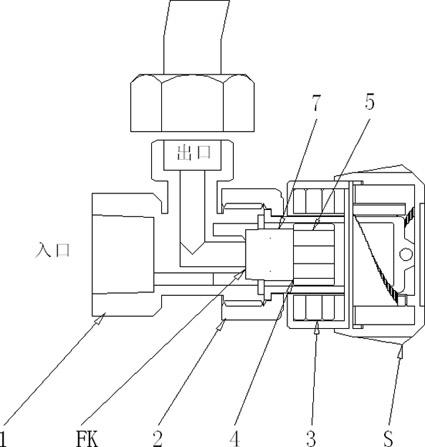

[0020] Embodiment two: according to figure 2 , image 3 As shown, the permanent magnet assembly 3 is installed in the handle S, which becomes the permanent magnet to directly control the faucet, or the permanent magnet to directly control the triangle valve. The method adopted in this embodiment is: radially fix a garden pin on the top of the valve cover 2 , the two ends or one end of the garden pin are inserted in the helical groove with several stair steps in the handle 6, when the handle 6 is rotated forward and reverse, the handle 6 will move the permanent magnet assembly 3 left and right, The valve plug assembly 4 in the valve also moves left and right to close and open the valve, and several stagnation steps correspond to different flow rates. image 3 The valve plug assembly 4 shown is only composed of an armature 5 and a valve plate 7 .

Embodiment 3

[0021] Embodiment three: according to Figure 4 As shown, the permanent magnet assembly 3 is connected with the floating ball F, which becomes the permanent magnet to directly control the liquid level valve. When the liquid level rises, the floating ball F can generate buoyancy to push the permanent magnet assembly 3 upward until the valve is closed. The gravity of the upper float F opens the valve when the liquid level drops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com