Safe and easily-controlled high-transparency and low-haze sulfone polymer and preparation method thereof

A polymer and easy-to-control technology, applied in the field of high temperature resistant transparent thermoplastic engineering plastic sulfone polymer and its composition or composite material, special engineering plastics, and can solve the problems of difficult to control stable polymerization molecular weight, complex preparation process, high energy consumption, etc. , to achieve the effect of easy recycling and reuse, simple post-processing process, and safe production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

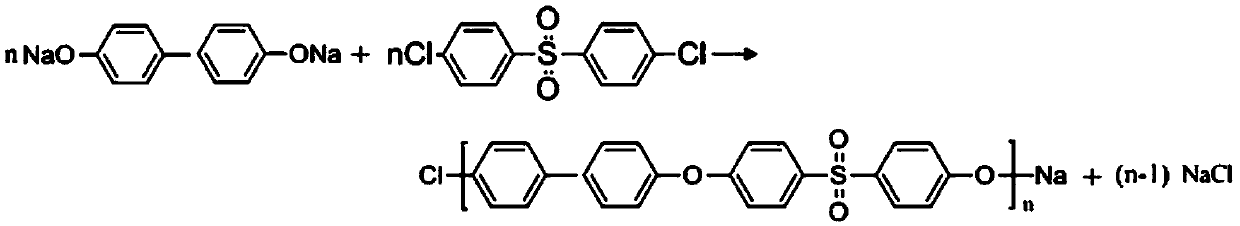

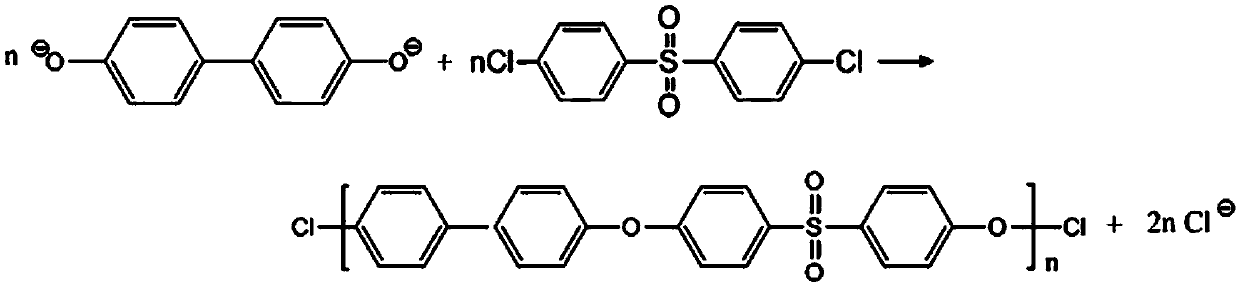

Method used

Image

Examples

Embodiment 1

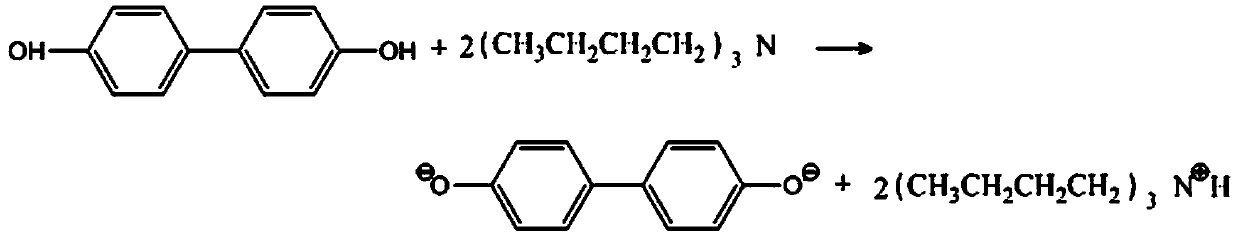

[0049] Embodiment 1: mass or mass concentration

[0050] In the reaction device equipped with a thermometer, a nitrogen pipe, a condensing separator, and an agitator, 125.13g (0.5mol) of 4,4'-dihydroxybiphenyl and 147.17g (0.5125mol) of ) 4,4'-dichlorodiphenyl sulfone, then add 426g of solvent, stir and heat up to 80°C to dissolve the monomer until the solution is transparent, add 97.31g (0.525mol) catalyst organic base tri-n-butylamine solution, continue to stir gradually Raise the temperature to 230°C to start the polymerization reaction, keep the temperature for 3 hours until the torque of the stirring motor remains unchanged, indicating that the viscosity in the reaction system is basically constant, stop stirring and heating to obtain the reaction polymer material, and slowly pour the reaction polymer material into 1% NaOH aqueous solution During the reaction, the mixed solution of white strip solid and water phase is obtained after cooling, and the white strip solid obta...

Embodiment 2

[0064] In the following examples, except for the following explanations, the rest of the unexplained parts are the same as in Example 1. That is, the method is the same as in Example 1, except that the reaction raw material is replaced with 125.15g (0.5mol) 4,4'-dihydroxydiphenyl sulfone (bisphenol S), and the polymerization temperature is in the range of 210°C-230°C to obtain polyphenylene Sulfone polymer PPSU material. The performance characterization comparison data is shown in Table 1 below.

Embodiment 3

[0068] The method is the same as in Example 1, except that 4,4'-dihydroxydiphenyl sulfone (bisphenol S) is replaced by 114.14g (0.5mol) 2,2-bis(4-hydroxyphenyl)propane (bisphenol A) , the polymerization temperature is in the range of 180°C-200°C to obtain the polysulfone polymer PSU material. The performance characterization comparison data is shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com