Variable-pressure and variable-working-condition oil burning nozzle

A technology of changing working conditions and oxidants, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of poor safety of on-site operators, restrictions on high-pressure coal gasification technology, and long processing time for flameout accidents, so as to shorten the processing time, The effect of shortening the ignition time and improving the adaptability to load changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described below in conjunction with the accompanying drawings of the present invention.

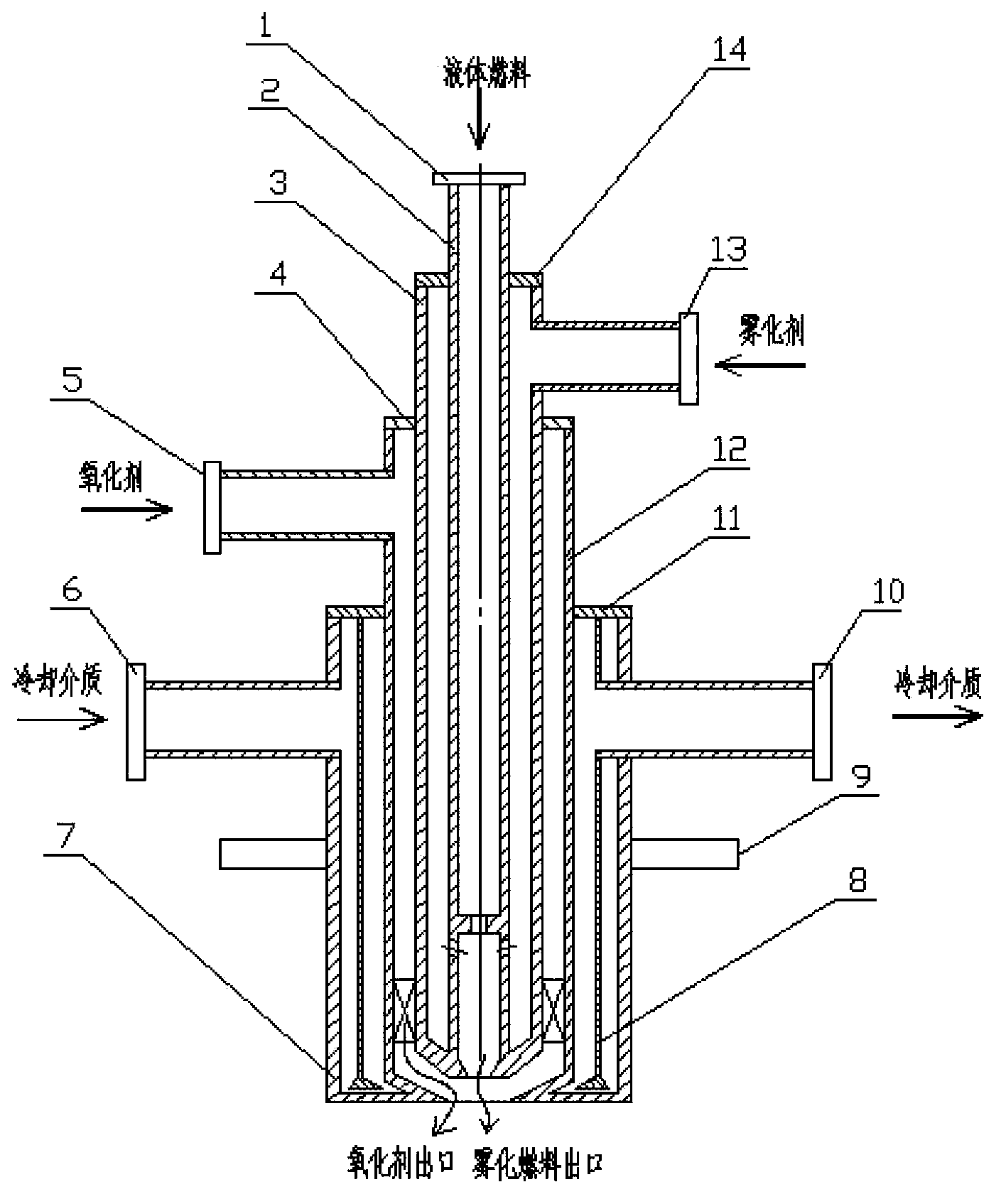

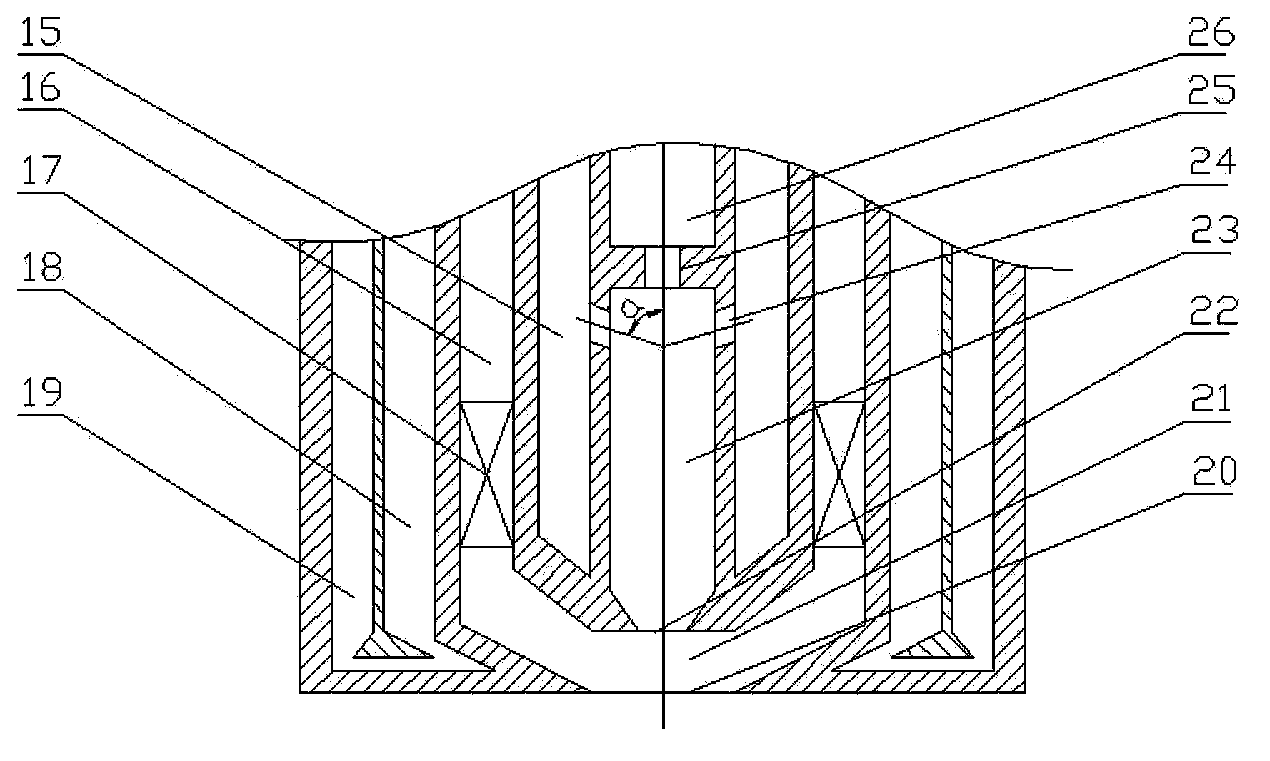

[0041] see figure 1 and figure 2 , an oil burner with variable pressure and variable working conditions according to the present invention, including a burner body sleeve and a premixed jet head. The outermost layer of the body and head of the burner is provided with a cooling structure, and is sealed and connected with the gasifier body (not shown in the figure) through the installation flange 9 .

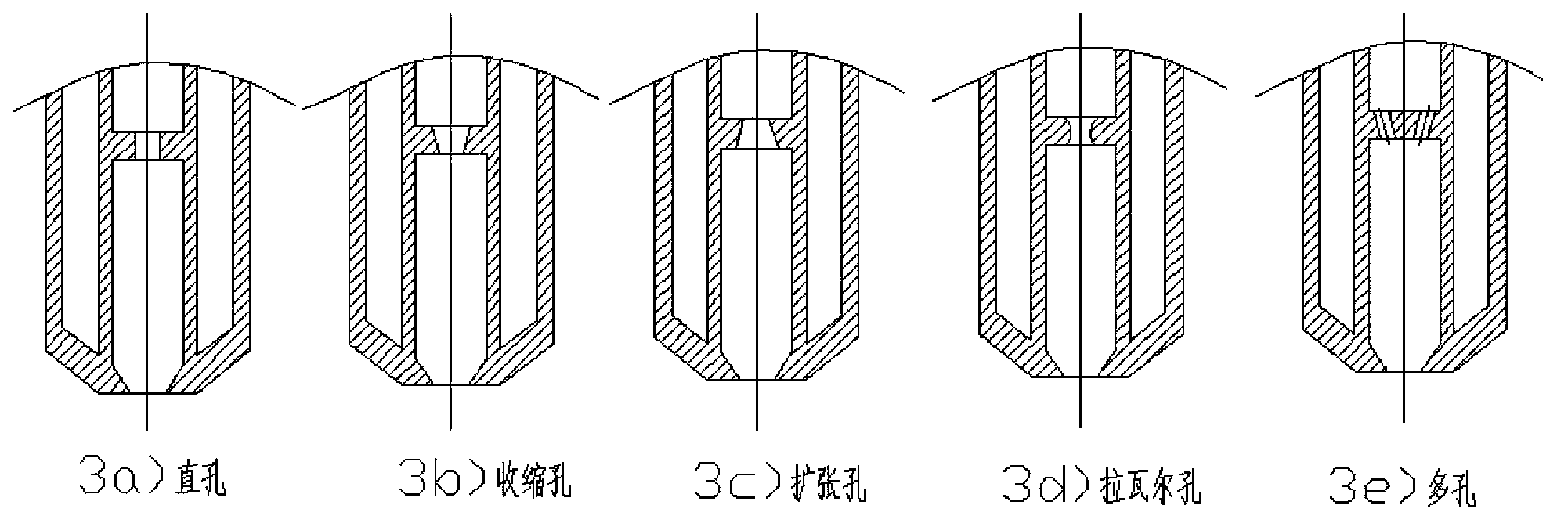

[0042]The body sleeves are coaxially arranged, and from the inside to the outside are the liquid fuel outer sleeve 2, the atomizing agent outer sleeve 3, and the oxidizer outer sleeve 12. The annular space between the casing and the casing forms various medium passages, wherein the passage formed by the innermost liquid fuel outer casing 2 itself is the liquid fuel passage 26, and the gap between the liquid fuel outer casing 2 and the atomizing agent ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com