Clamping butterfly valve body

A clamp butterfly valve and valve body technology, which is applied to the valve details, valve device, valve shell structure, etc., can solve the problems of butterfly valve body and valve plate assembly difficulties, excessive valve operating torque, valve plate wear, etc., to achieve High bi-directional pressure bearing capacity, good sealing performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

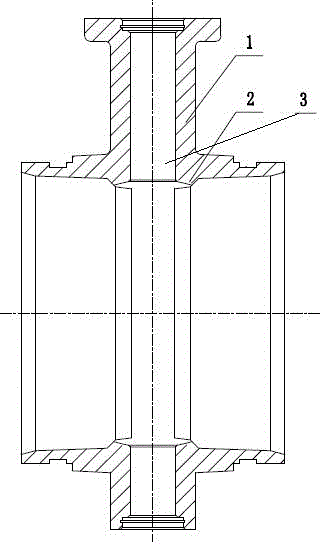

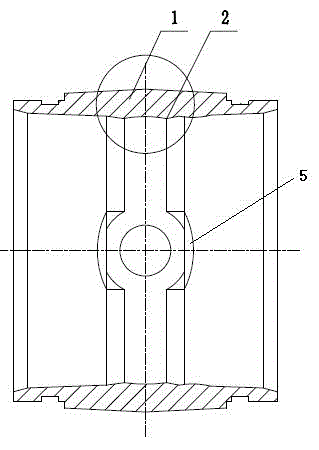

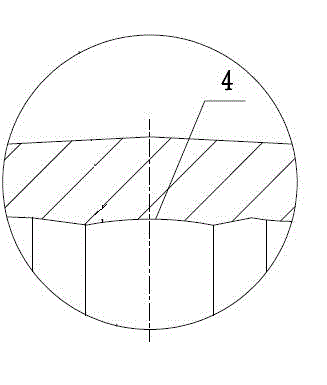

[0012] Such as Figure 1-3 As shown, the valve body 1 inner chamber of the present invention is respectively provided with shaft holes 3 of the valve column up and down. An arc-shaped sealing surface 4 is formed around the two bosses, and a widened boss 5 is provided at the position where the arc-shaped sealing surface intersects with the shaft hole of the valve column.

[0013] In the clamp butterfly valve body of the present invention, since both sides of the inner peripheral surface where the inner cavity of the valve body fits with the valve plate are made into bosses and processed into arc surfaces, when assembling, the valve plate is installed in the arc with special valve plate assembly In the type sealing band, the rotation makes the end of the valve body match the end of the valve plate, making the assembly easier and more convenient. The widened boss se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com