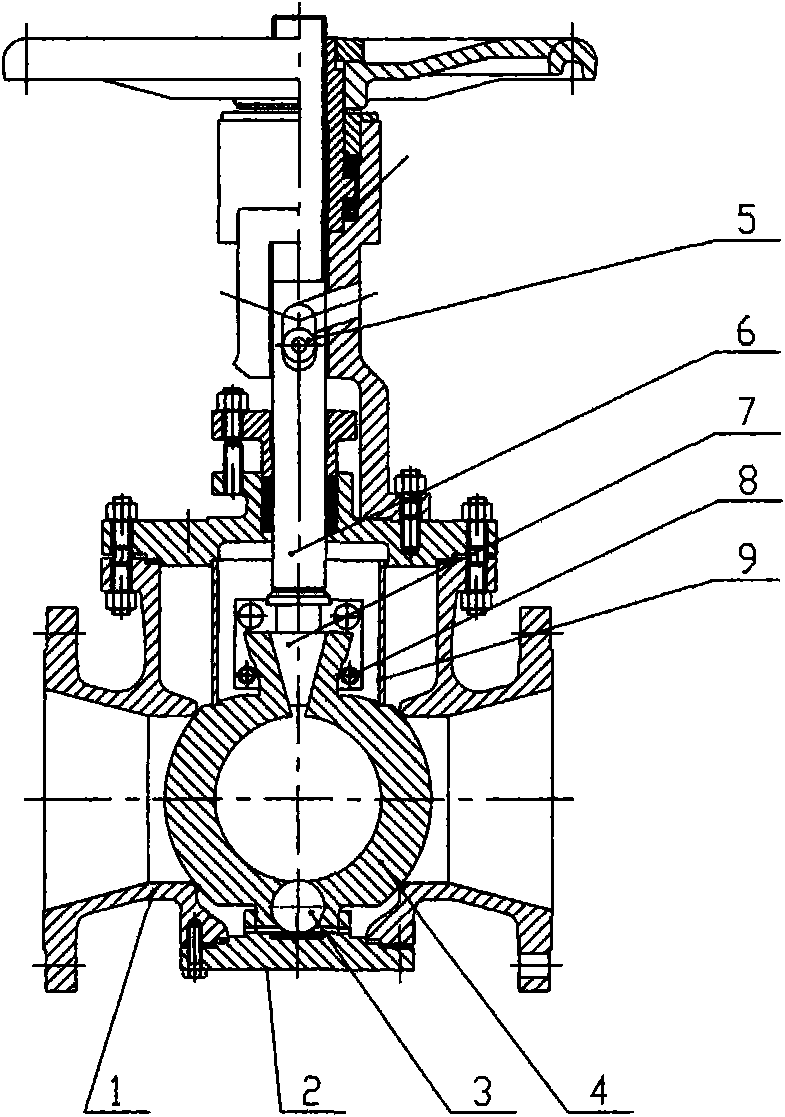

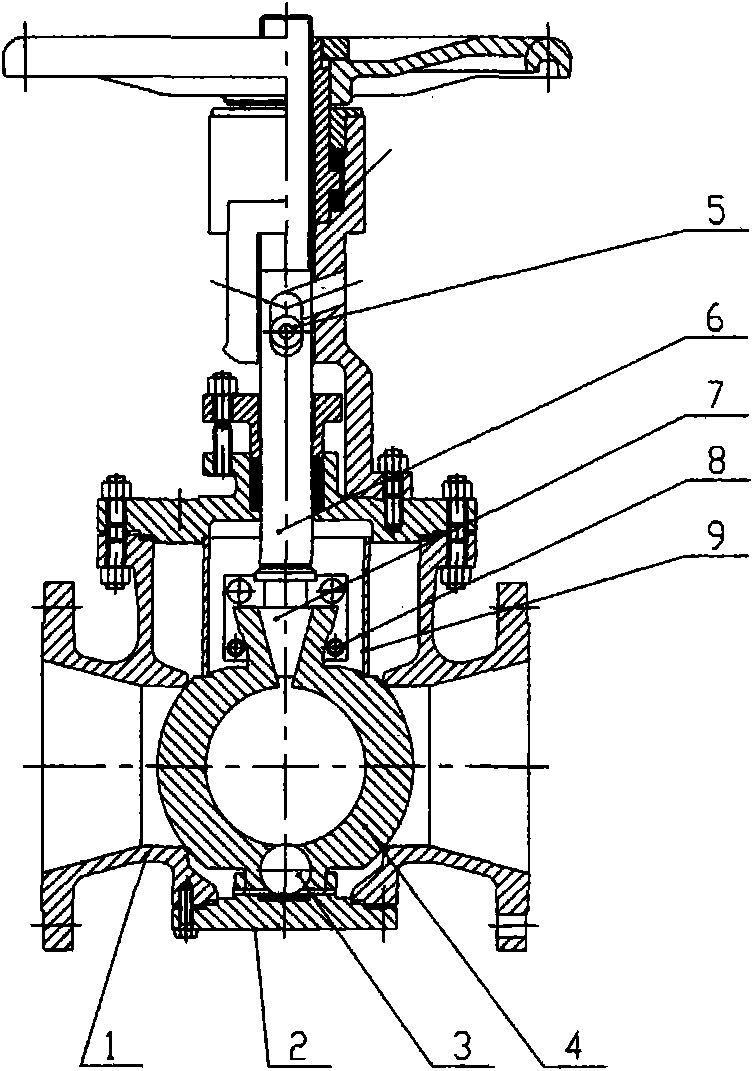

Expanding type two-way hard sealed spherical valve

A hard sealing, ball valve technology, applied in the field of pipeline control valves, can solve the problems of increased dead life, easy wear and tear of metal sealing pairs, high temperature deformation, etc., and achieves the effect of saving resources and costs, convenient installation and use, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A braced two-way hard-sealed ball valve is composed of two hemispheres, a wedge, a support shaft, a roller and a locator. The two hemispheres form a combined ball. The lower end of the combined ball is provided with a positioning shaft. There is a support shaft (3), and the support shaft (3) adopts a circular body design, so that the ball (4) can be stretched and closed flexibly, even under the working conditions that are prone to fouling and slagging, it does not affect the stability of the ball (4) Stretch and close; there is a roller (5) in the middle of the valve stem (6), which is fixed in the "Z" groove, and is used for the lifting and rotation of the valve stem (6). The joint at the upper end of the valve body (6) is a gate-shaped wedge (7), and the ball (4) is combined by a locator (8); when the handwheel is rotated counterclockwise and the valve stem (6) is lifted , the positioner (8) closes the combined ball, and at the same time the valve rod (6) drives the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com