Stop valve with non-rotating valve rod

A globe valve and valve stem technology, applied in the field of globe valves, can solve the problems of poor valve sealing performance, easy wear and tear of the sealing device, short service life, etc., and achieve the effect of ensuring the integrity of the sealing, prolonging the service life of the valve, and reducing the torsional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

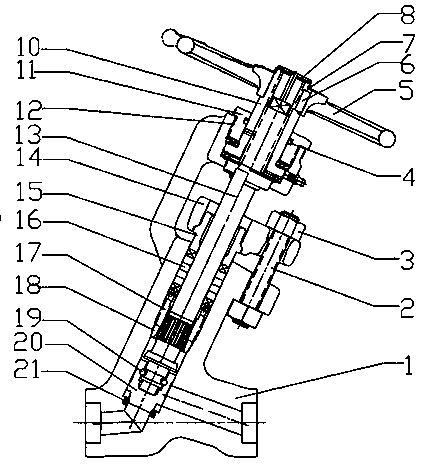

[0018] Such as figure 1 Shown: a globe valve with non-rotating valve stem, including valve body 1, handwheel 5, valve stem 13, valve stem bushing 11, valve stem nut 10, packing 16, spline bushing 17, back seat 18, Support frame 19, valve core 20 and sealing device 21. A valve stem 13 is arranged inside the valve body 1 , and a valve core 20 is arranged below the valve stem 13 . There is a sealing device 21 between the valve core 20 and the valve body 1 . The top of the valve stem 12 extends out of the valve body 1 and is connected with the valve stem nut 10 . The valve stem nut 10 is connected to the valve body 1 through a valve stem bushing 11 . The valve stem bushing 11 is fixed on the upper end of the valve body 1 . Filling 16 is filled between the valve stem 13 and the valve body 1 . The handwheel 5 is fixed on the upper end of the stem nut 10 . The end of the valve stem 1 is provided with a spline bushing 17 , a back seat 18 and a support frame 19 .

[0019] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com