Plug valve for high-pressure and high-frequency occasion

A high-pressure, high-frequency, plug valve technology, used in plugs, valve devices, engine components, etc. including cut-off devices, can solve problems such as seal failure, poor key force, inconvenient operation, etc., to reduce driving torque and friction. The effect of reduced force and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

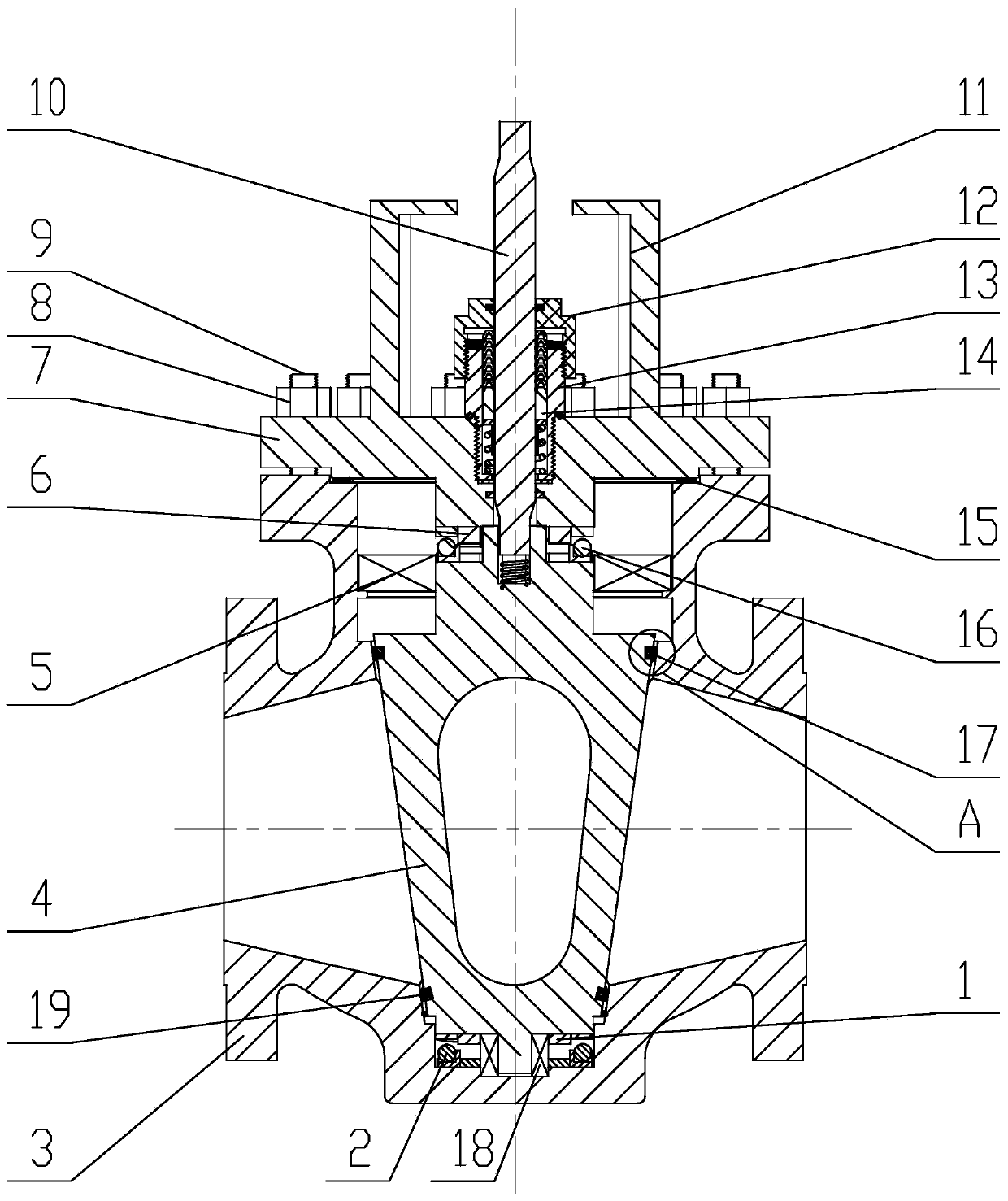

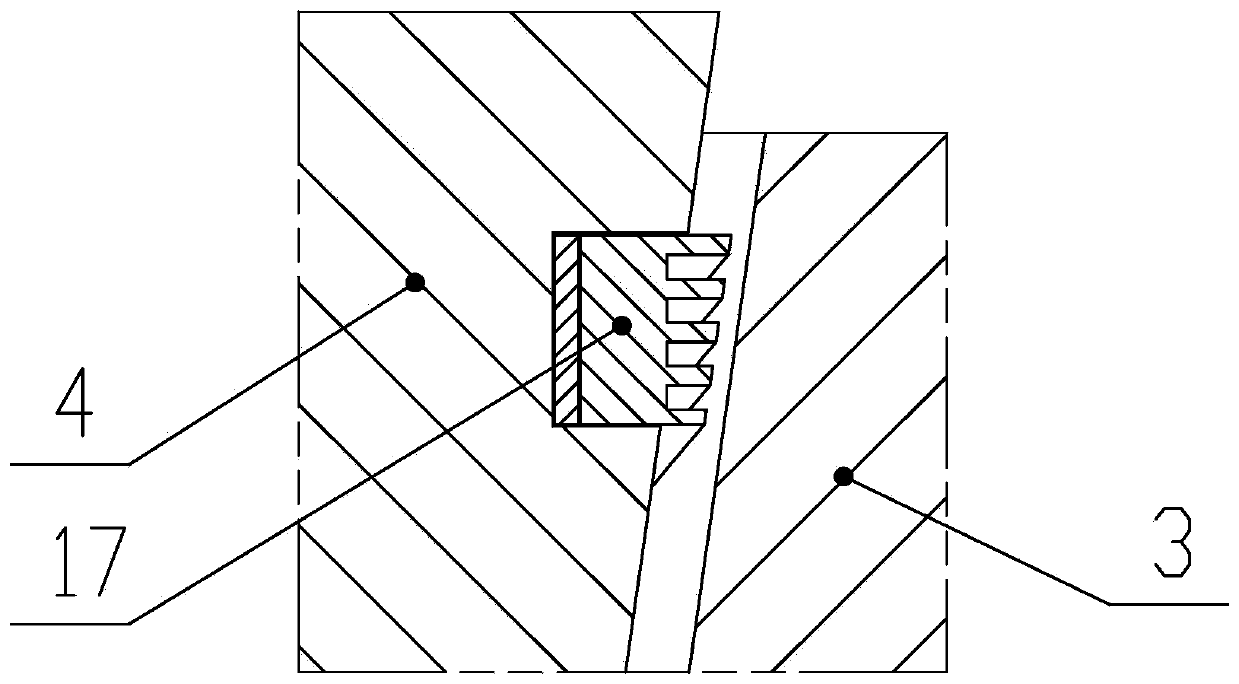

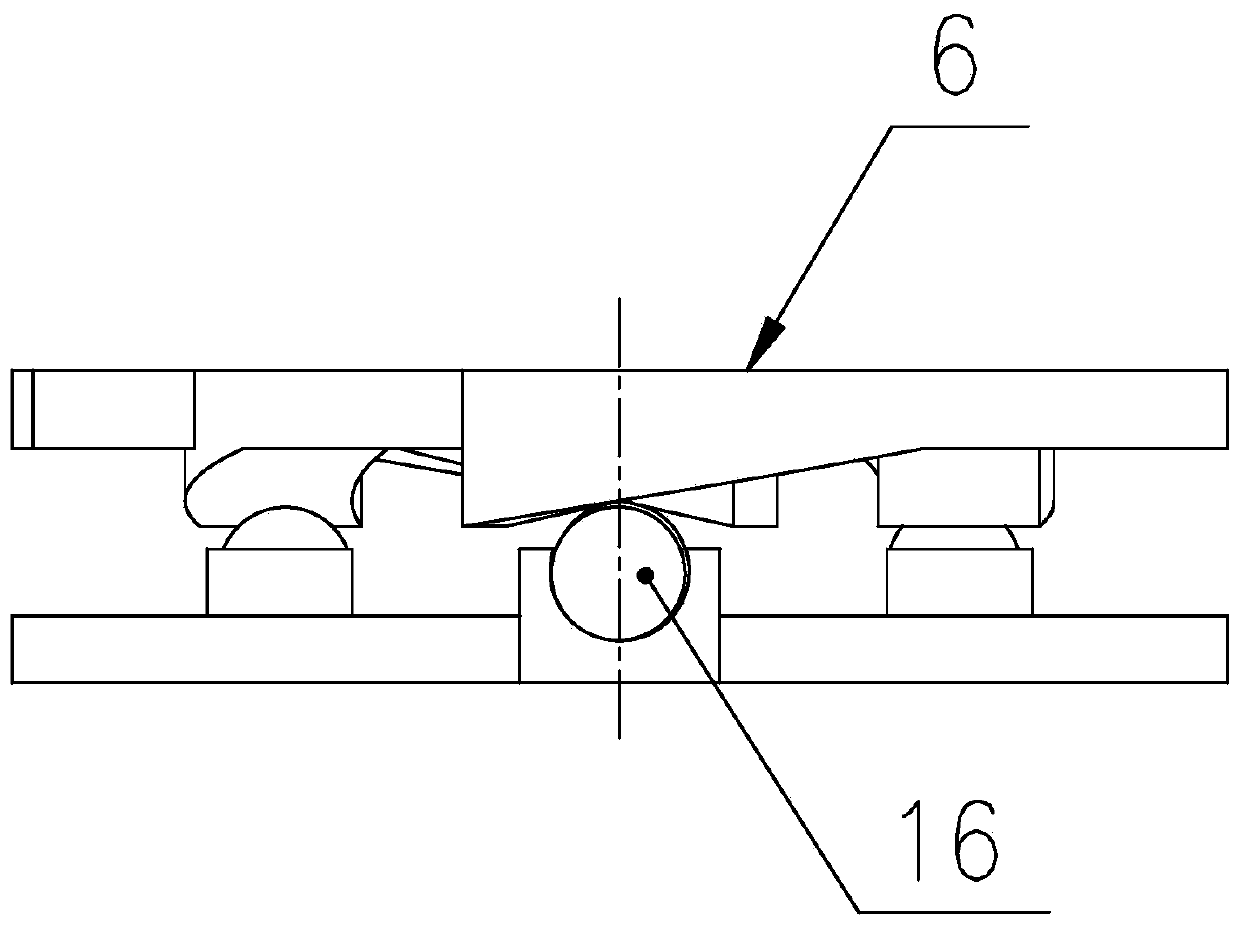

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0026] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the plug valve for high-pressure and high-frequency occasions includes a valve body 3, a valve cover 7 arranged on the valve body 3, a plug body 4 rotatably arranged in the valve cavity of the valve body 3, and the lower end of which passes through the valve cover. 7. The valve stem 10 coaxially connected with the cock body 4; it also includes a pressing structure arranged between the bottom of the valve cover 7 and the top of the cock body 4, a jacking structure arranged between the bottom of the cock body 4 and the bottom of the valve cavity, And a first sealing structure and a second sealing structure arranged on the outer wall of the cock body 4 and respectively located on both sides of the flow passage hole of the cock body 4;

[0027] The pressing structure inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com