High-temperature-pressure-resistant double-direction rigidity seal rotary ball valve with pretension compensation movable valve seat

A hard-sealing, high-temperature-resistant technology, applied in valve details, valve device, valve shell structure, etc., can solve the problem that the rotary ball valve is only used for flanged valves, which is difficult to achieve, and achieves space-saving location, sealing ratio The effect of increased pressure and stable preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

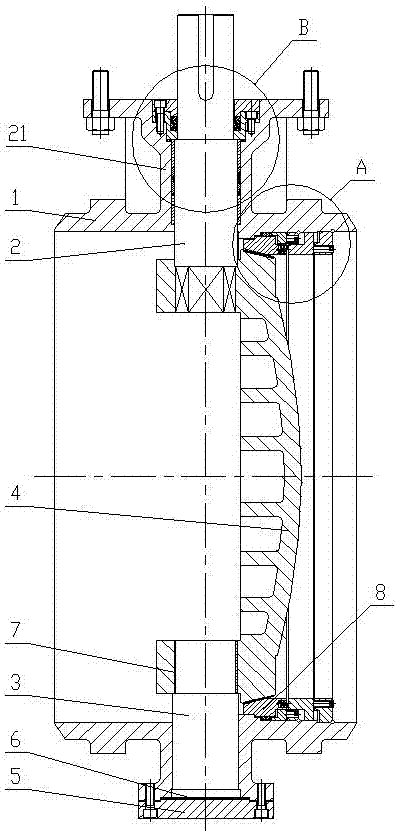

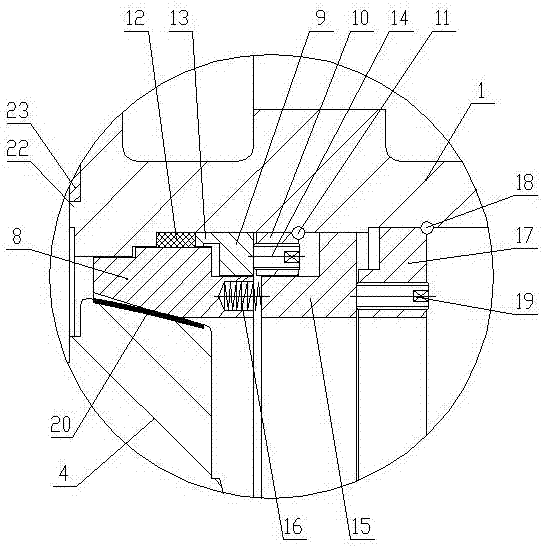

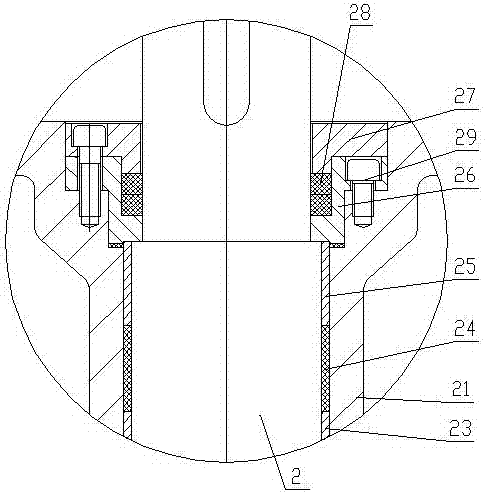

[0022] Such as figure 1 , figure 2 and image 3 As shown, a high temperature and high pressure resistant two-way hard-sealed ball valve with a preload compensation movable seat of the present invention includes a valve body 1, a valve stem 2, a ejector rod 3 and a valve disc 4, assuming that the center line of the valve body 1 is horizontal along the left and right sides. The direction is set, the valve stem 2 extends radially into the valve body 1 from top to bottom, the valve stem 2 and the valve body 1 rotate and are connected by a sealing assembly, and the ejector rod 3 extends along the valve body from bottom to top. 1 extends radially into the valve body 1, the ejector rod 3 is fixedly connected with the valve body 1, the lower end of the valve body 1 is provided with a bottom cover 5 and a sealing gasket 6 for sealing the ejector rod 3, the valve stem 2 and the ejector rod 3 The center line of the valve disc 4 is set in the valve body 1, the lower end of the valve st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com