Core barrel sealing structure capable of increasing sealing specific pressure

A technology of sealing structure and core barrel, which is applied to the extraction of undisturbed core devices, valve devices, earth-moving drilling, etc., can solve the problems of poor sealing performance of flap valves, low matching success rate, and large space occupation, and achieve reliable sealing performance. , The effect of high matching success rate and strong deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

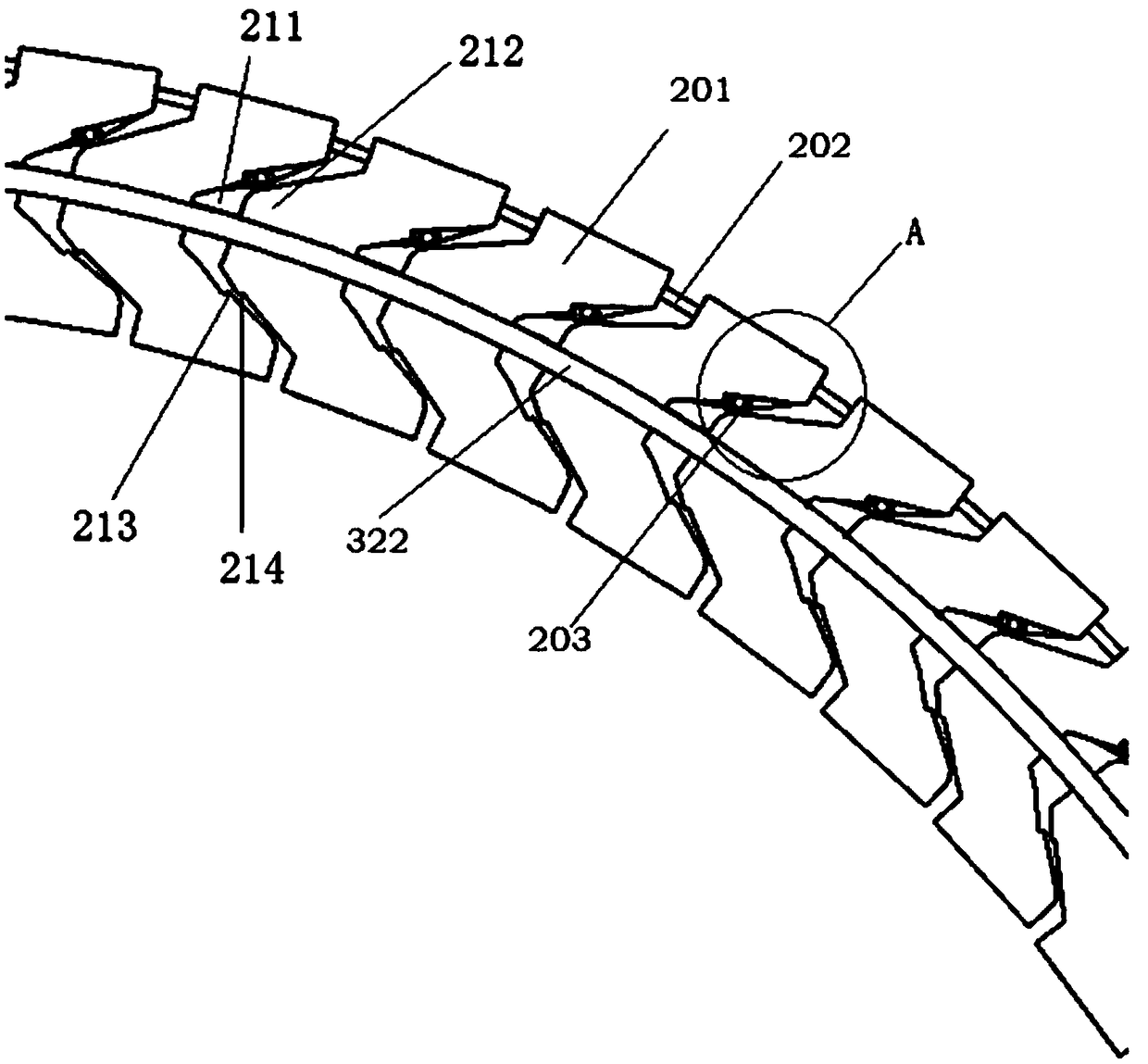

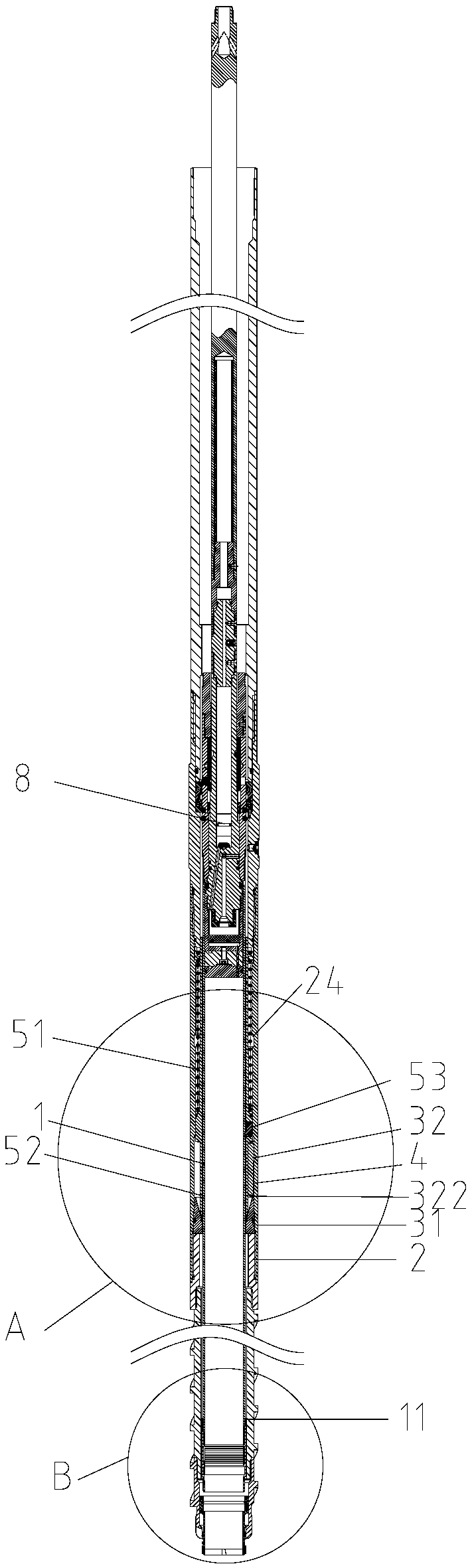

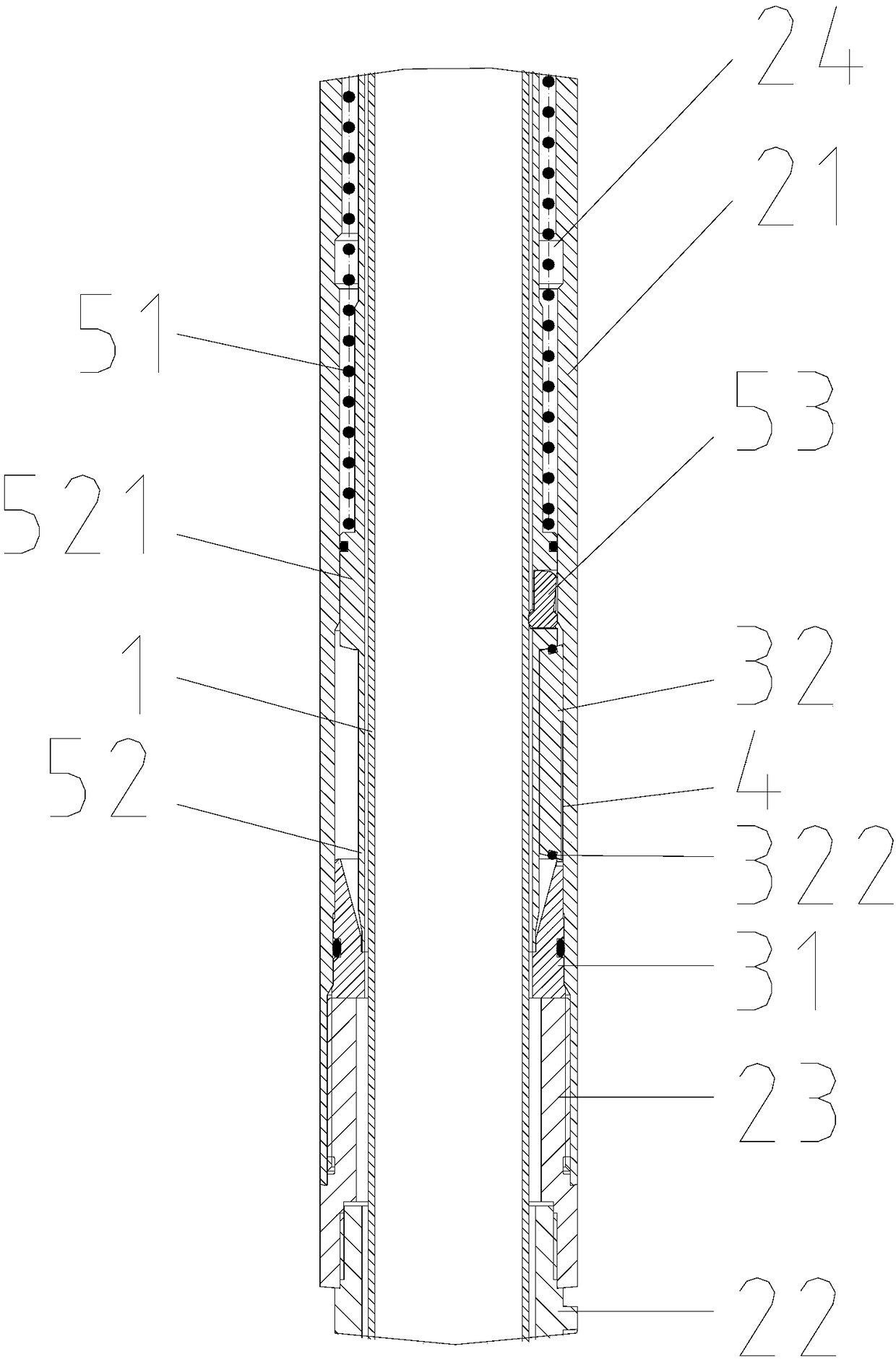

[0037] Such as figure 1 , 2 , 6, the core barrel sealing structure that can increase the sealing specific pressure disclosed by the present invention includes a core barrel 1, a drilling rig outer cylinder 2, a chain mail flap valve and a trigger mechanism, and the chain mail flap valve includes The valve seat 31 and the valve disc 32 of chain mail type, the valve seat 31 is coaxially installed on the inner wall of the outer cylinder 2 of the drilling rig, one end of the valve disc 32 is movably connected with the outer side wall of the upper end of the valve seat 31, and the top of the valve seat 31 is connected with the valve disc 32 Matching valve port sealing surface 311.

[0038] The trigger mechanism includes a trigger inner cylinder 52 and a trigger block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com