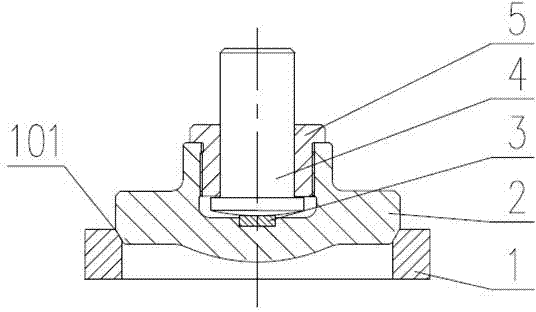

Anti-impact stop valve sealing structure

A technology of sealing structure and globe valve, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of short service life, deformation of sealing surface, etc., and achieve the effect of ensuring sealing performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

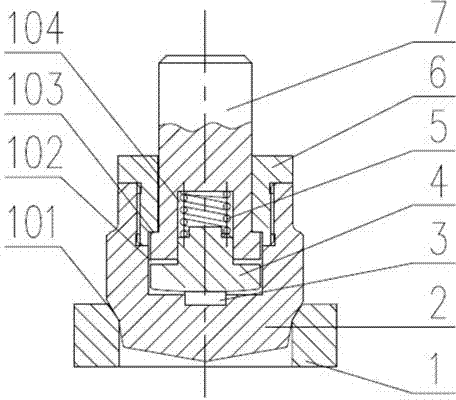

[0019] Please refer to the accompanying drawings for a further description of the present invention.

[0020] Such as figure 2 As shown, the present invention provides a sealing structure of an anti-shock stop valve, including a valve seat 1, a valve disc 2, a wear-resistant gasket 3, a buffer cover 4, a lock nut 5, a spring 6, a valve stem 7, and a valve disc 2 Installed on the valve seat 1, the contact surface of the valve disc 2 and the valve seat 1 forms a sealing surface 101, a concave hole 102 is arranged in the valve disc 2, and a wear-resistant gasket 3 is installed at the bottom of the concave hole 102, and the wear-resistant gasket 3 A buffer cover 4 is installed on the top, and a spring 6 is placed on the top of the buffer cover 4. A spring 6 is in close contact with the inner hole 104 indented at the bottom of the valve stem 7. The end of the valve stem 7 is provided with a boss 103, and the lock nut 5 is in contact with the valve. After the petal 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com