Two-way sealing butterfly valve

A two-way sealing and butterfly valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of reduced pipeline flow rate, high cost, narrow application range of butterfly valve, etc., and achieve the effect of increasing the sealing specific pressure and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

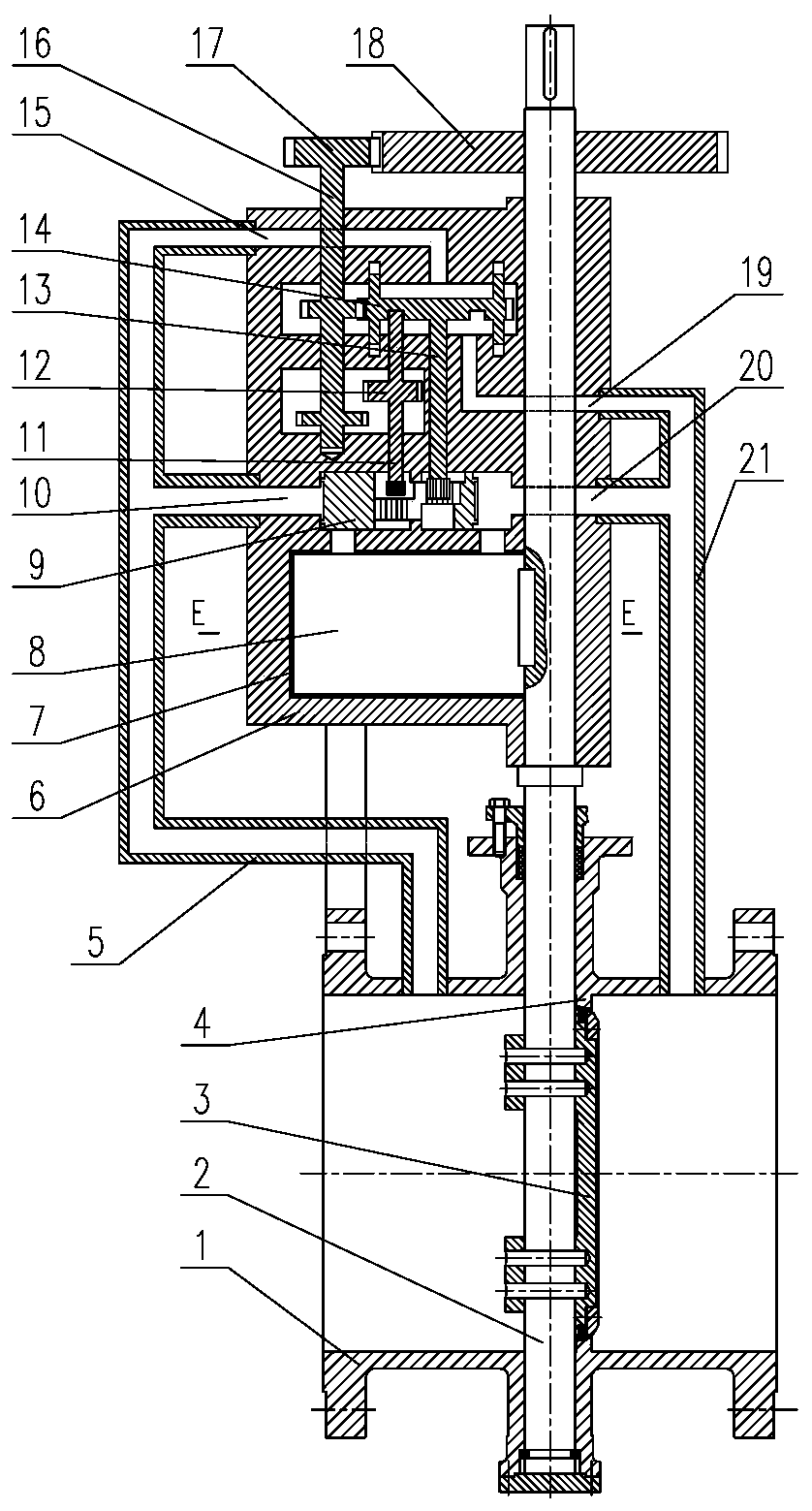

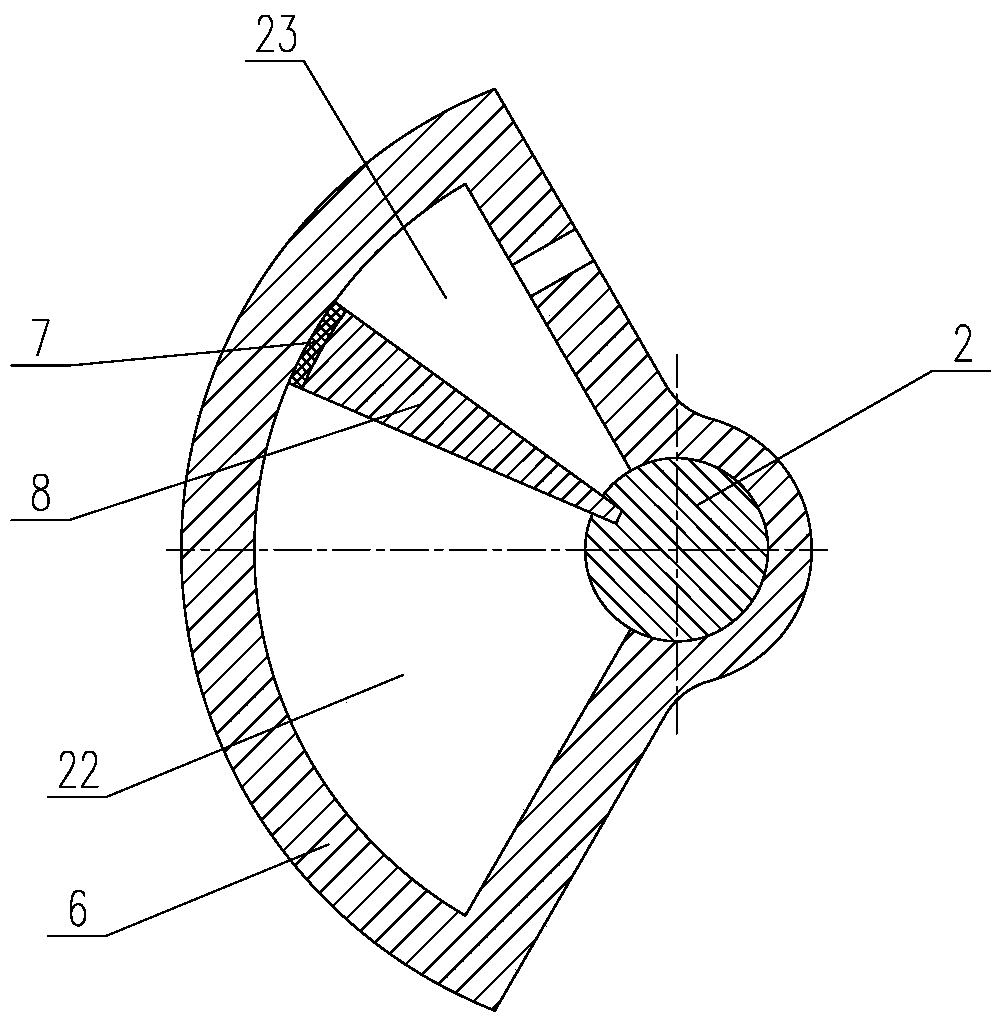

[0011] according to figure 1 , 2 It can be seen that this bidirectional sealing butterfly valve includes: valve body 1, valve stem 2, butterfly plate 3 and valve seat 4, the valve seat 4 is fixedly installed in the inner cavity of the valve body 1, and the inner surface of the valve seat 4 is provided with a seat seal On the surface, the butterfly plate 3 is installed in the inner cavity of the valve body 1, and the outer surface of the butterfly plate 3 is provided with a butterfly plate sealing surface that can form a seal with the sealing surface of the valve seat. The lower end of the valve stem 2 extends downward into the inner cavity of the valve body 1 and is The butterfly plate 3 forms a fixed connection. When the butterfly plate 3 cooperates with the valve seat 2 to form a closed valve, the butterfly plate 3 isolates the inner cavity of the valve body 1 to form a left cavity and a right cavity. The control mechanism, the left inlet connecting pipe 5 and the right inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com