Bi-directional sealing elastic tri-eccentric butterfly valve

An elastic sealing and two-way sealing technology, which is applied in shaft sealing, lifting valves, valve details, etc., can solve the problems of uneven deformation, uneven force around the sealing ring, and difficult problems, so as to achieve small friction and torque, and reduce User cost, effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings.

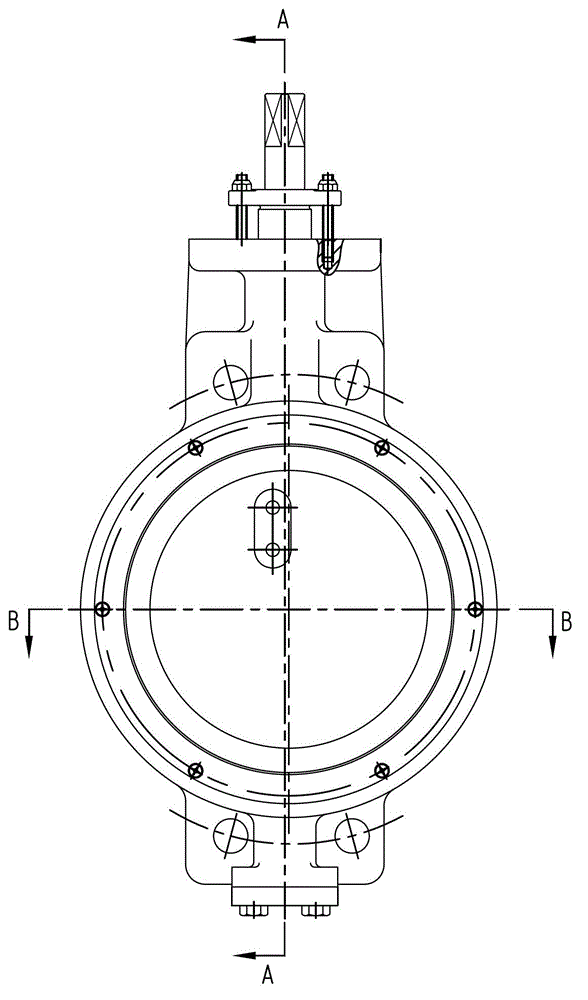

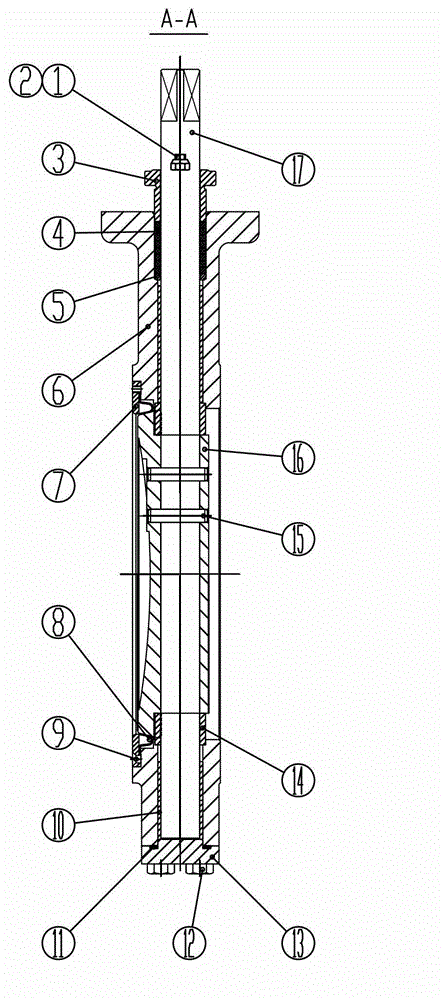

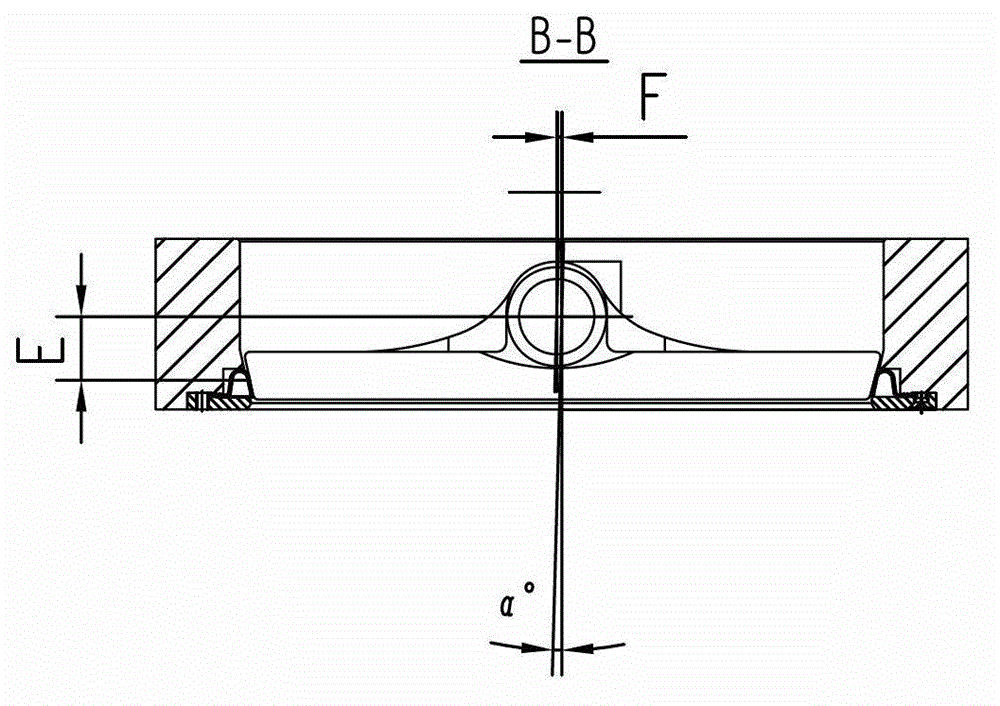

[0022] Such as Figure 1 to Figure 5 As shown, the two-way sealing elastic sealing triple eccentric sealing butterfly valve mainly includes lock nut 1, screw rod 2, packing gland 3, packing group 4, packing pad 5, valve body 6, pressure ring 7, elastic sealing ring 8, cross groove sink Head screw 9, bushing 10, wound gasket 11, hexagonal bolt 12, bottom flange 13, thrust ring 14, direct pin 15, valve plate 16, valve stem 17, non-metallic sealing ring 18, backing ring 19 and other components .

[0023] The thrust ring 14 is installed between the valve body 6 and the valve plate 16 . The valve plate 16 is installed in the valve body 6, aligned with the center of the shaft hole of the valve body 6, and positioned with the thrust ring 14 through the top and bottom of the back shaft housing. The valve plate 16 is connected and fixed with the valve rod 17 through the direct pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com