Friction clutch

A technology of friction clutches and clutches, which is applied in the direction of friction clutches, clutches, mechanically driven clutches, etc., and can solve problems such as insufficient compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

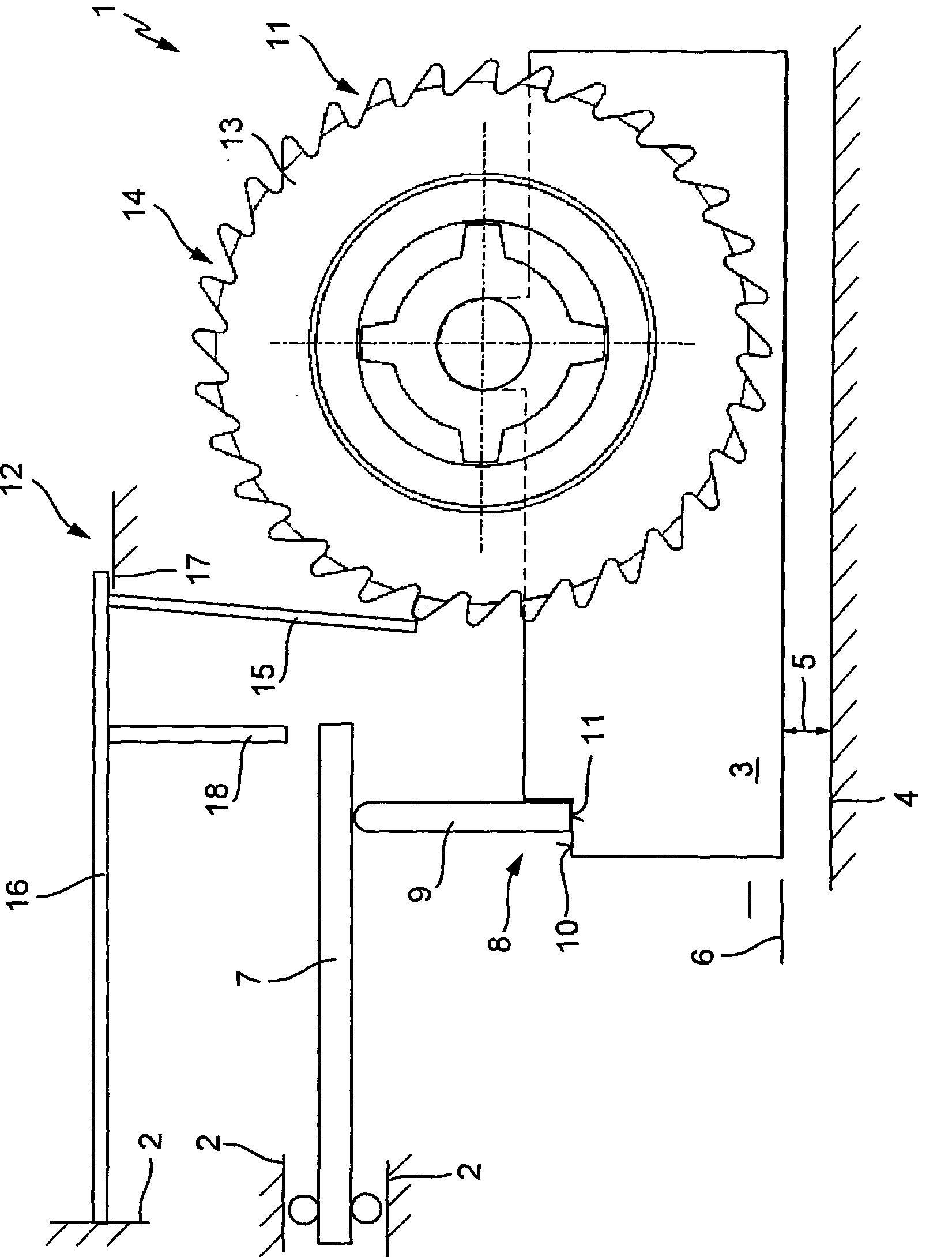

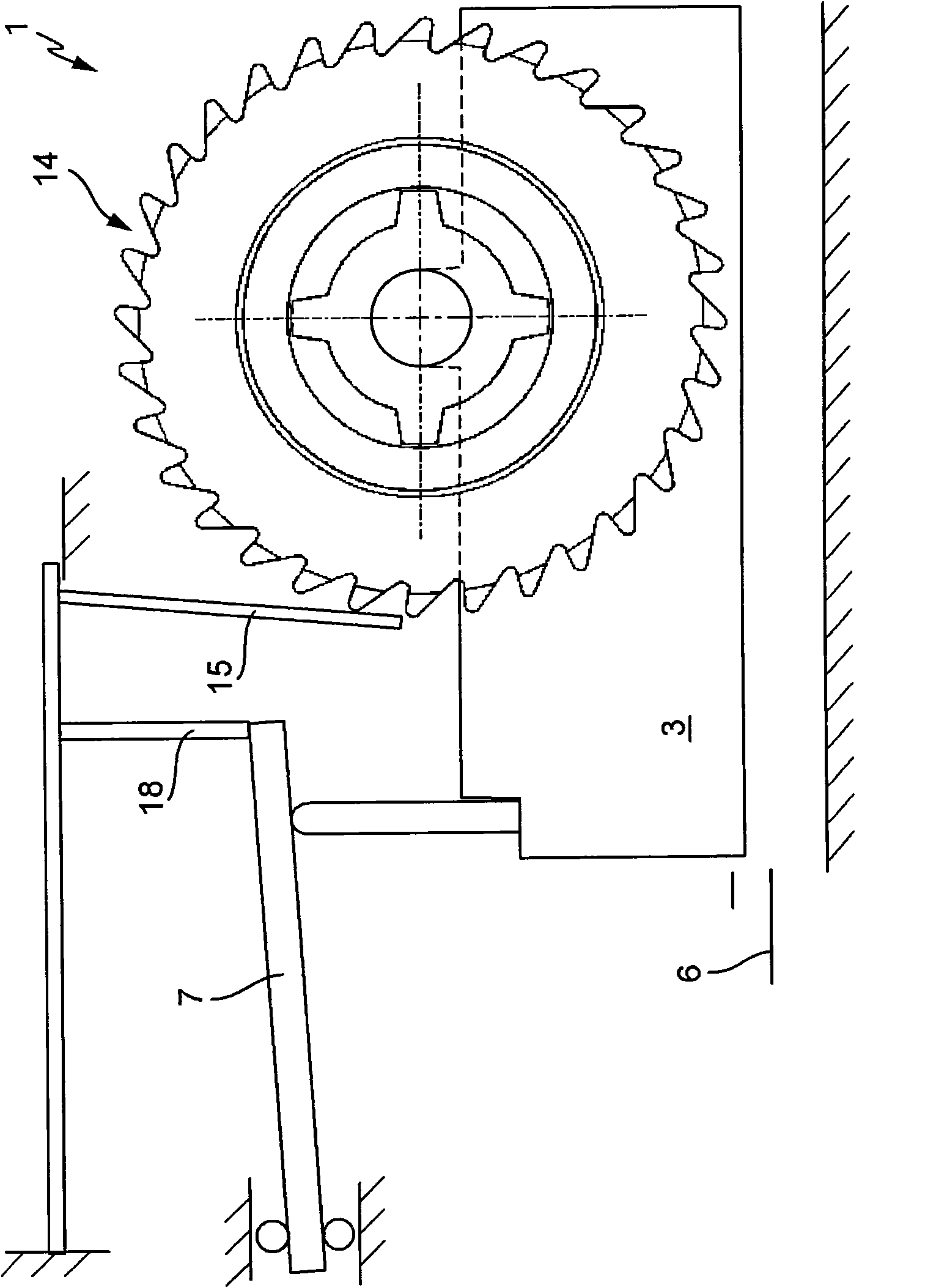

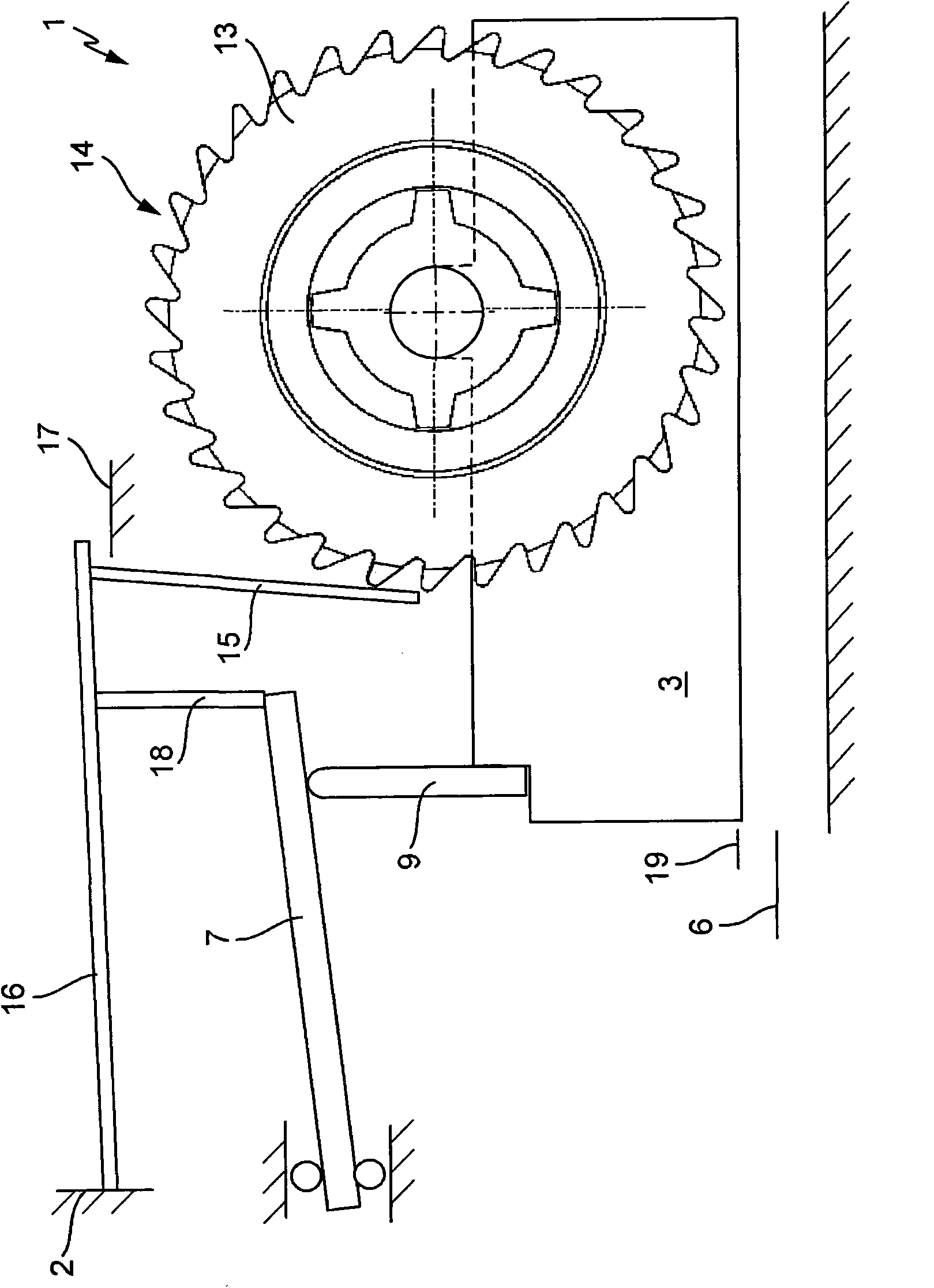

[0022] figure 1 The readjustment device 1 of the friction clutch in the closed state is schematically shown in a sectional view. The pressure plate 3 , which is non-rotatably connected to the clutch housing 2 and axially by means of an energy store, not shown, such as a leaf spring, is clamped at a distance 5 relative to a pressure plate 4 arranged fixedly to the housing. This distance corresponds to the thickness of the friction linings of the clutch disc (not shown) in the clamped state, which is represented by the operating point 6 . The pressure plate 3 is acted upon by a lever system 7 pivotably mounted on the clutch housing 2 with a pressure force whose magnitude is applied on the other side of the lever system with a disengaging system (not shown) for actuating the friction clutch. to measure. In the exemplary embodiment shown, this is a so-called press-on friction clutch with a double-arm lever system 7 , for example a disk spring, which is not loaded in the shown c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com