Micro-turbine for turbine generator and air guide structure size calculation method thereof

A technology of turbine generator and wind guide structure, which is applied in the direction of wind power generators, calculations, engines, etc., which is consistent with the wind direction, can solve the problems of not being able to fully expand the air volume, not being able to make full use of wind energy, and the height of the turbine blades being low. The effect of increasing power, increasing power, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

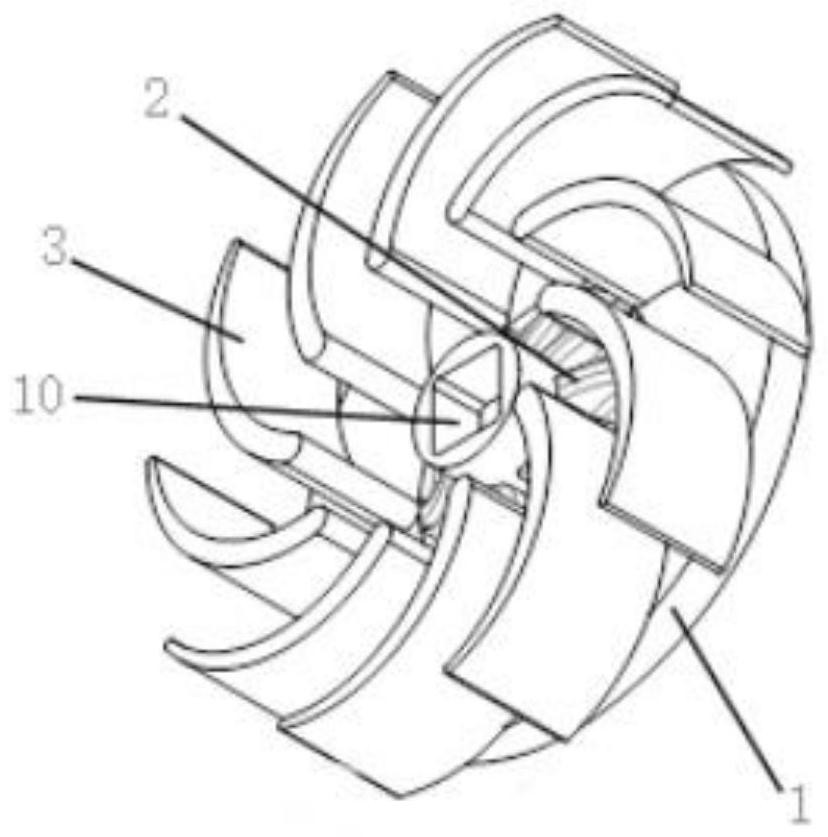

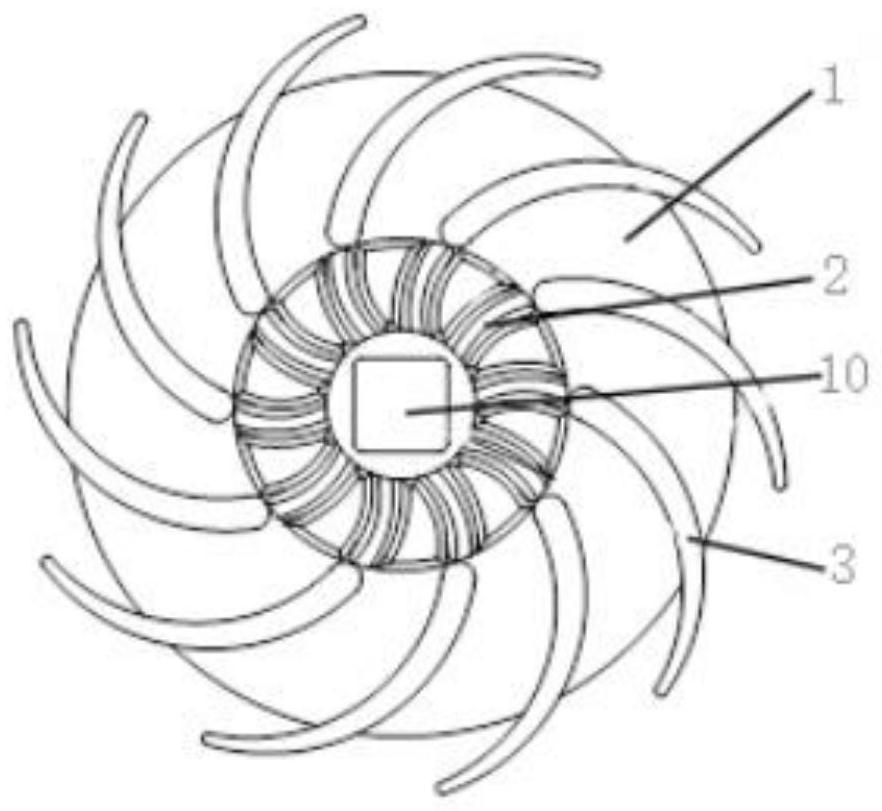

[0109] The micro-turbine for the turbo generator, the wind guide structure 2 is arranged inside the bottom support platform 1, the described wind guide structure 2 is a plurality of curved reinforcing ribs, and the wind blade 3 is arranged outside the bottom support platform 1, so The wind guide structure 2 and the wind blade 3 transition smoothly; the wind guide structure 2 is evenly distributed along the circumference of the bottom support platform 1, and the wind blade 3 is evenly distributed along the circumference of the bottom support platform 1; The upper end of the wind structure 2 is provided with rounded corners to reduce the amount of reflected air, and the start-up wind speed is lower, which can reduce the start-up wind speed by more than 3m / s. In addition, the wind guide structure 2 and the wind blade 3 smoothly transition, and the direction of the wind is dredged, reducing The wind resistance increases the wind force rushing towards the wind blade 3, thereby reduc...

Embodiment 2

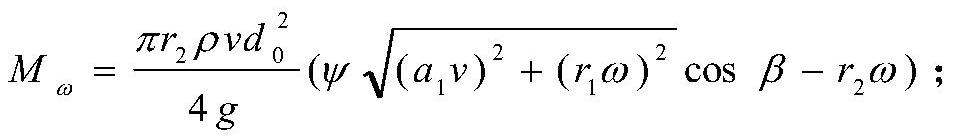

[0111] The method for calculating the size of the wind guide structure of the micro-turbine used in the turbogenerator can be seen from the comprehensive analysis of the above formulas, in order to increase the output voltage of the turbogenerator, the E d 、X aq value, reduce the internal resistance value r of the turbine generator. But E d 、X aq The value is related to the frequency of the turbine generator, the number of winding turns and the no-load effective flux factor. These factors are directly proportional to the output frequency of the turbine generator. Therefore, increasing the speed of the turbine generator is the most effective way to increase the output voltage of the turbine generator. However, when the speed of the turbine generator increases to a certain level, the output voltage of the turbine generator will not increase linearly, but tends to be flat due to the increase of the armature reaction and the hysteresis loss of the magnetic circuit. Based on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com