Pump-gas boosting internal combustion engine

A technology for internal combustion engines and pumping gas, applied to combustion engines, mechanical equipment, engine components, etc., can solve the problems of large oil ring elasticity, high probability of burning engine oil, and large axial height of pistons, so as to reduce pumping gas consumption and increase Effective power, the effect of increasing the scavenging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

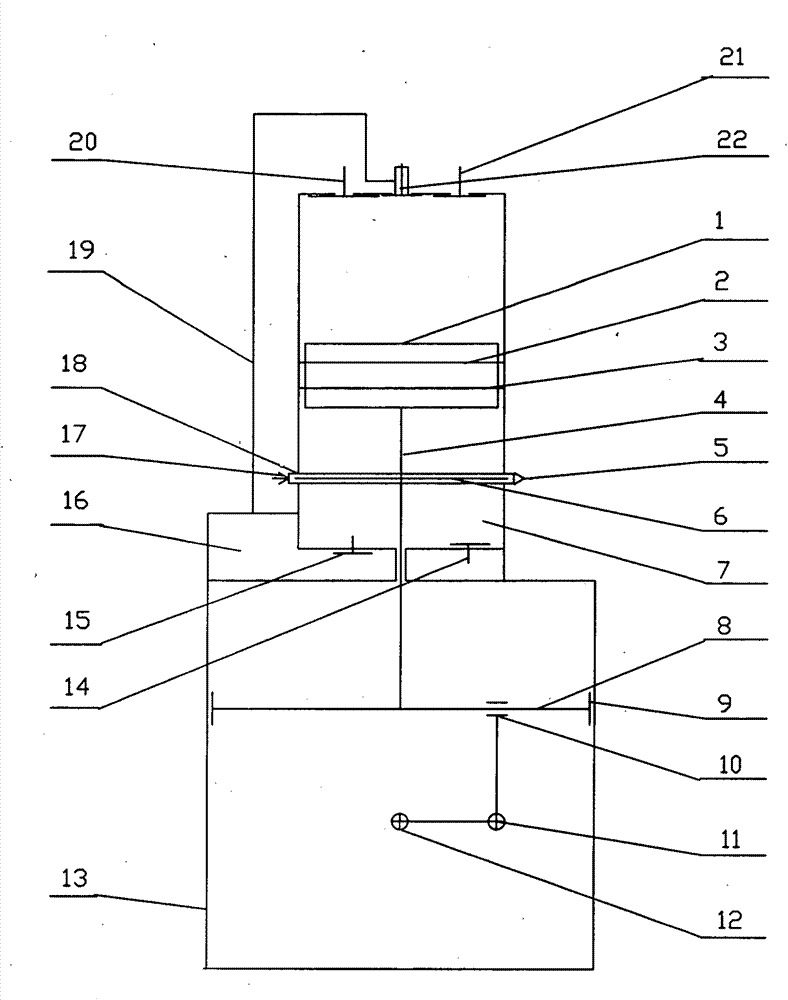

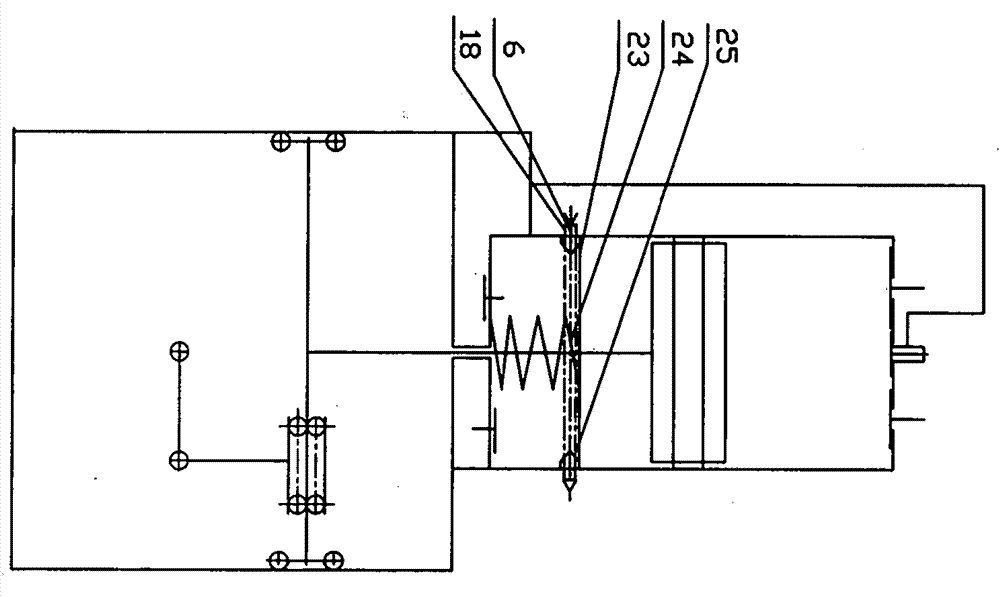

[0038] Such as figure 1 Shown is the first embodiment of the present invention, which has a piston crank slider mechanism, a cylinder liner internal circulation lubrication system and a pump air booster system.

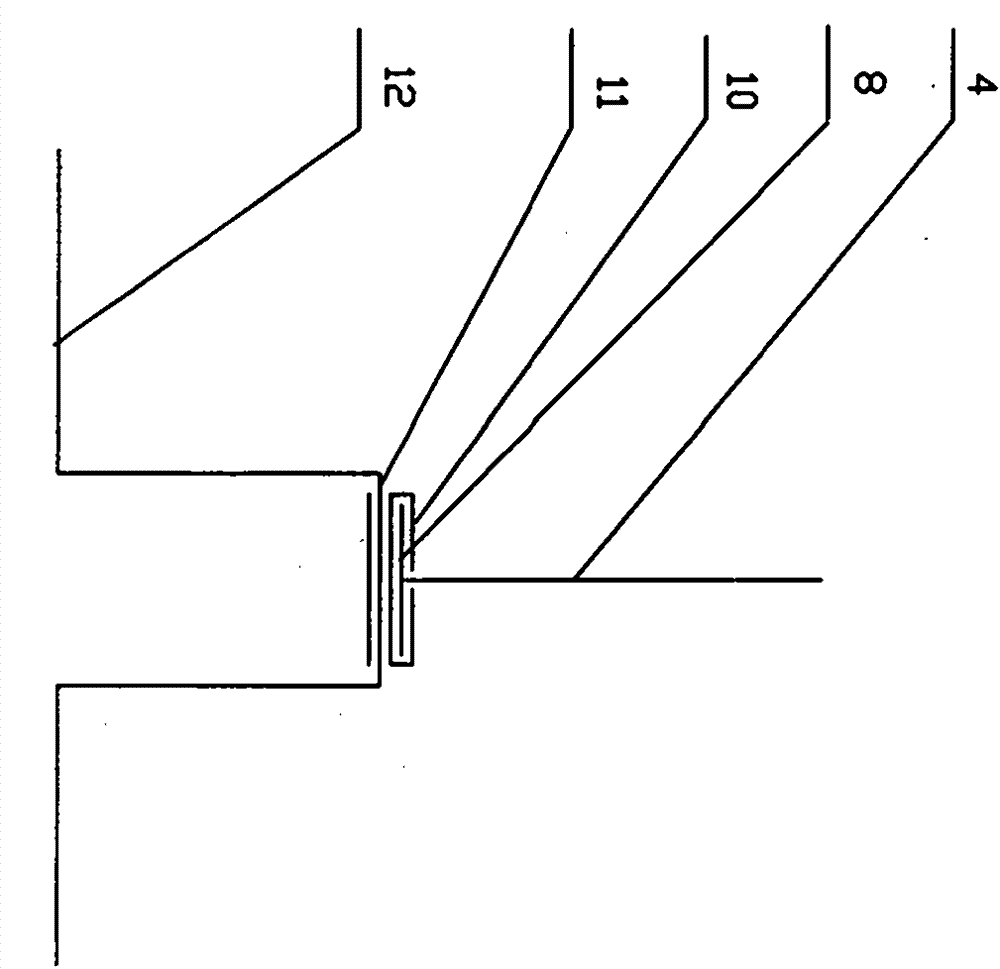

[0039] Piston crank slider mechanism is made up of piston 1, piston rod 4, slide rail 8, slide sled 9, slide block 10 and crankshaft 12. The piston 1 is integrated with the slide rail 8 through the piston rod 4 passing through the pump air chamber. Such as figure 1 , figure 2As shown, on the one hand, the upper part of the slider 10 is slidably connected with the slide rail 8 in the form of a clasp, and on the other hand, the slider is connected in rotation with the crank pin 11 of the crankshaft 12 . The piston-crank-slider mechanism formed under the above-mentioned connection state has three kinds of motion forms, that is, the piston 1, the piston rod 4, the slide rail 8, and the slide 9 do reciprocating linear motion up and down, and the slider 10 moves left an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com