Self-adaptive intelligent pipeline robot and intermittent circulation driving method

A technology of intelligent pipes and robots, applied in the direction of electric energy management, pipe components, special pipes, etc., to achieve the effect of improving the degree of intelligence and work efficiency, automatically adapting to pipe diameter changes, and simplifying the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described in detail below with reference to the accompanying drawings and examples, but the present invention is not limited to the following embodiments.

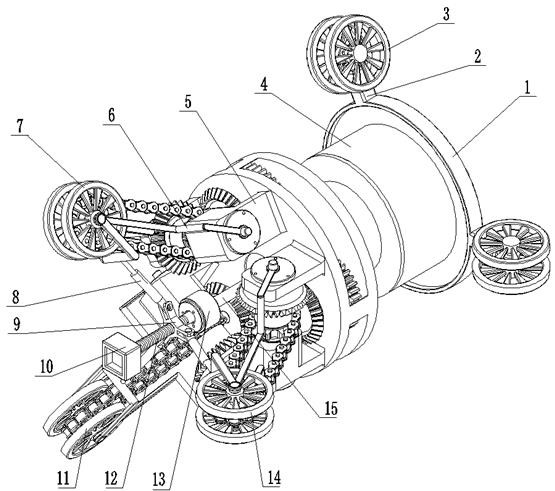

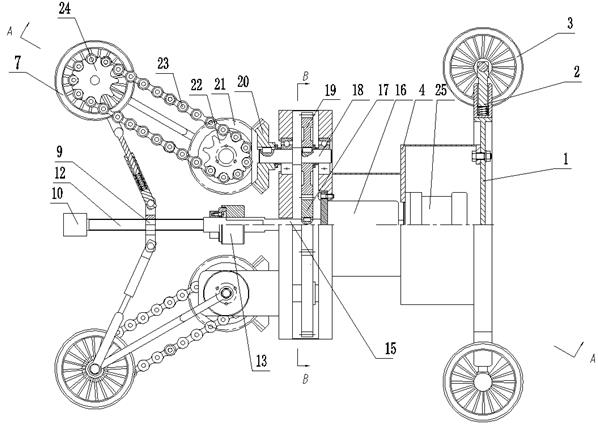

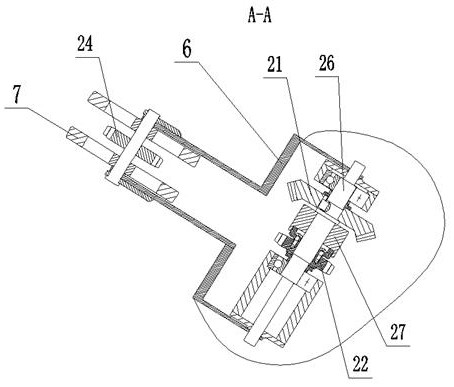

[0018] exist Figures 1 to 5In the present embodiment, the base 1 of the adaptive intelligent pipeline robot is provided with a mounting frame 4 and a drive motor 25, the drive motor 25 is located in the mounting frame 4, and the drive motor 25 is connected with the main drive shaft 15 through the reducer 16. The main drive shaft The end of 15 is connected to the variable diameter adjusting screw 12 with the nut 9 through the first electromagnetic clutch 13, and the end of the variable diameter adjusting screw 12 is installed with an intelligent detection sensing unit 10, and three fixed on the front side of the mounting frame 4. Drive wheel frame I, drive wheel frame II, and drive wheel frame III are hinged on the support 5 distributed at 120°, respectively, and drive wheels are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com