A belt type compression release device for transmission shaft

A release device and transmission shaft technology, which is applied in the application field of aerospace technology, can solve problems such as no reports on the pressing and releasing device of a dual-axis solar wing drive mechanism, and achieve the effect of improving product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

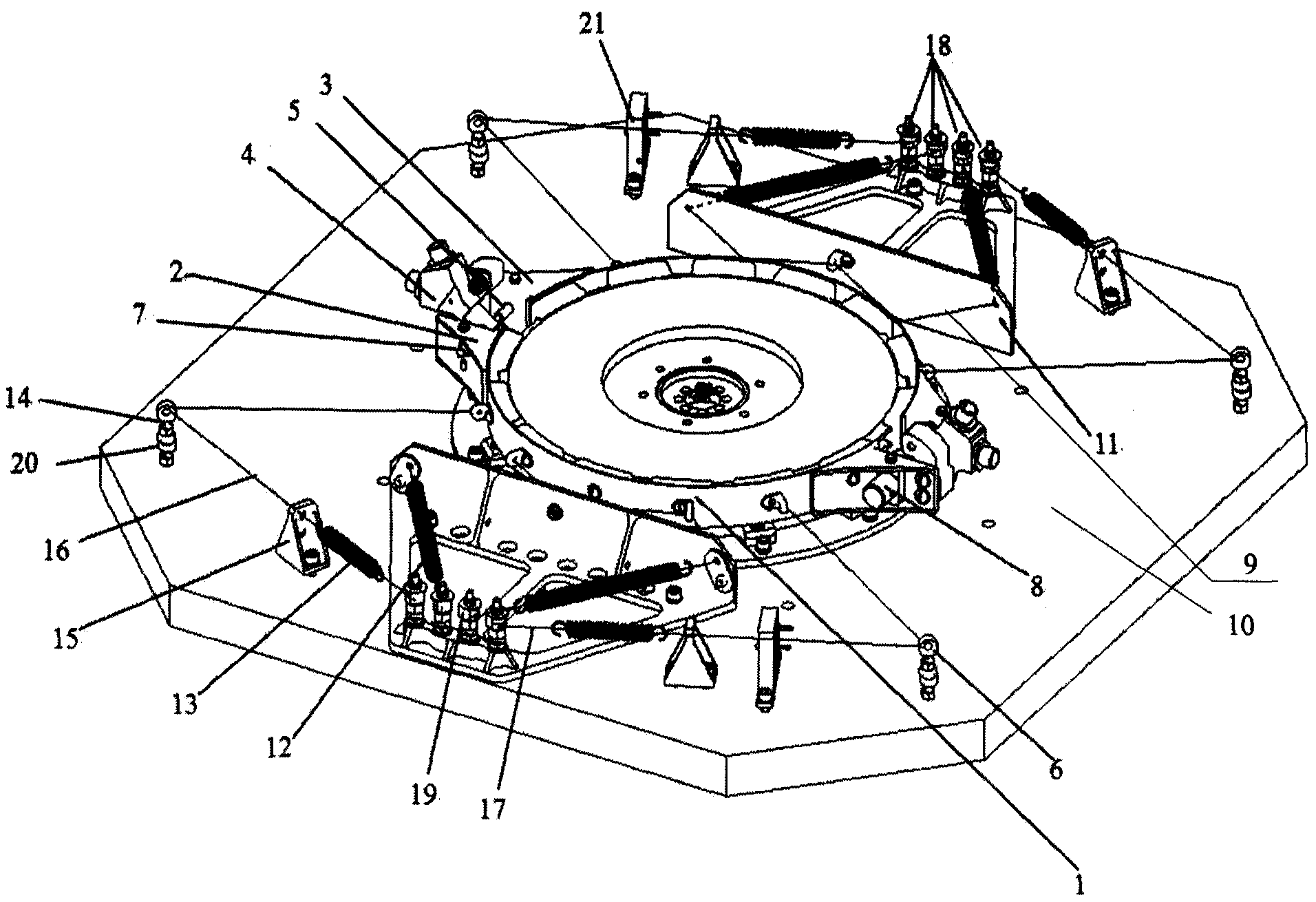

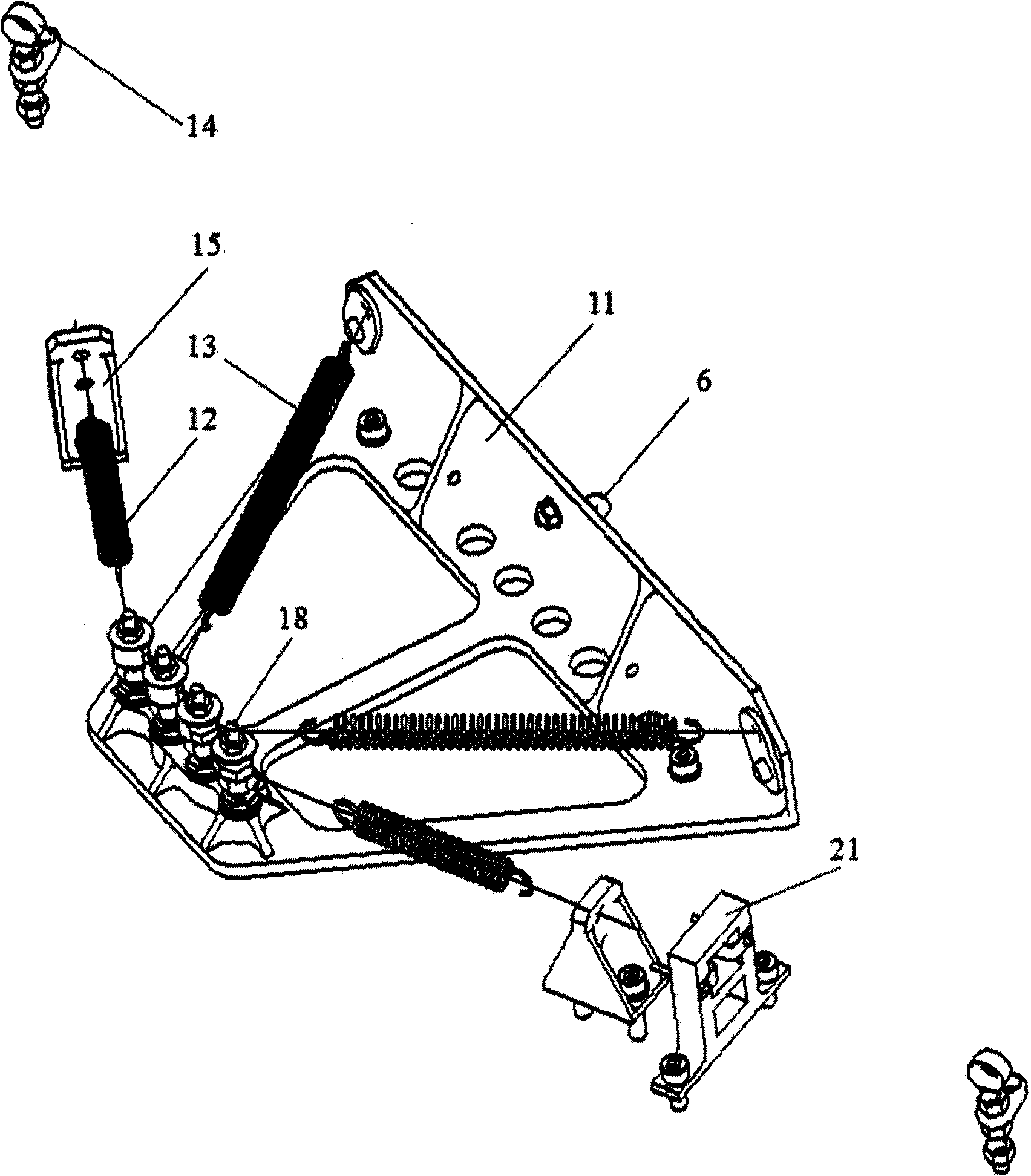

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the compression release device of the present invention includes a strap assembly and a storage assembly. Wherein the strap assembly is composed of two separated straps 1 connected by the left strap connector 2 and the right strap connector 3 at both ends; the separated strap 1 is connected with the left strap connector 2 and the right strap connector 3 by spot welding. Considering the unlocking reliability in the design, it is designed into two sections, which are connected into a circular ring through a titanium alloy pull rod 5 with a nut. Clamped to withstand various loads in flight. The manufacturing material of the separation tape 1 is a titanium alloy strip, which has good forming processability, small internal stress after forming, high modulus of elasticity, and easy to achieve the required pre-tightening force.

[0025] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com