Non-merging cervical vertebra intercalated disc prosthesis and assembly method thereof

A cervical intervertebral disc, non-fusion technology, applied in the direction of spinal implants, etc., can solve the problems of low polymer strength, limit the service life of the prosthesis, and poor wear resistance, and achieve good fatigue resistance, simple structure, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

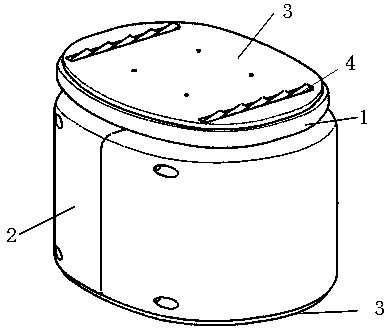

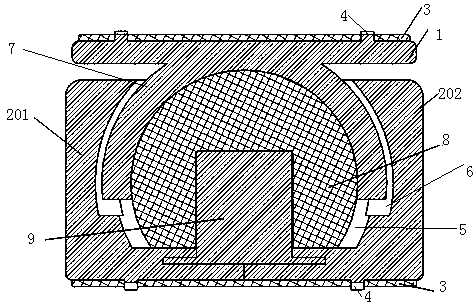

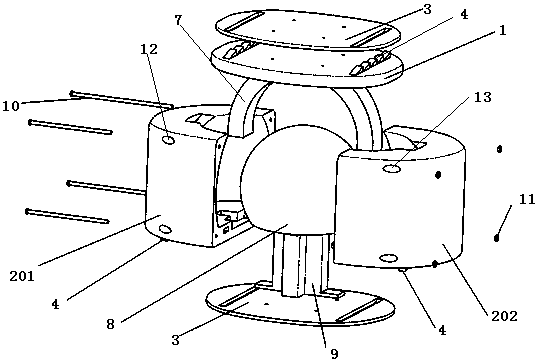

[0030] like Figure 1-8 As shown, a non-fused cervical intervertebral disc prosthesis includes an upper endplate and a lower endplate made of cobalt-chromium-molybdenum alloy material. The lower endplate is a shell with an unclosed upper end, and a spherical cavity is arranged in the shell , the spherical cavity is provided with a spherical nucleus made of metal rubber. The spherical nucleus is wrapped in the spherical cavity to prevent the spherical nucleus from prolapse. The lower end of the nucleus is sleeved on the guide rail. The lower surface of the spherical nucleus is a horizontal plane. The diameter of the horizontal plane is smaller than the diameter of the spherical nucleus. The cross-shaped chute is matched with the cross-shaped guide rail. There is a gap of 1mm between the cross chute and the cross-shaped guide rail. The upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com