Bending mode supersonic vibration auxiliary cutting device for precision or ultra-precision turning

A technology of ultrasonic vibration and cutting devices, applied in auxiliary devices, fluids using vibration, turning equipment, etc., to improve processing efficiency, ensure processing accuracy, and ensure rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

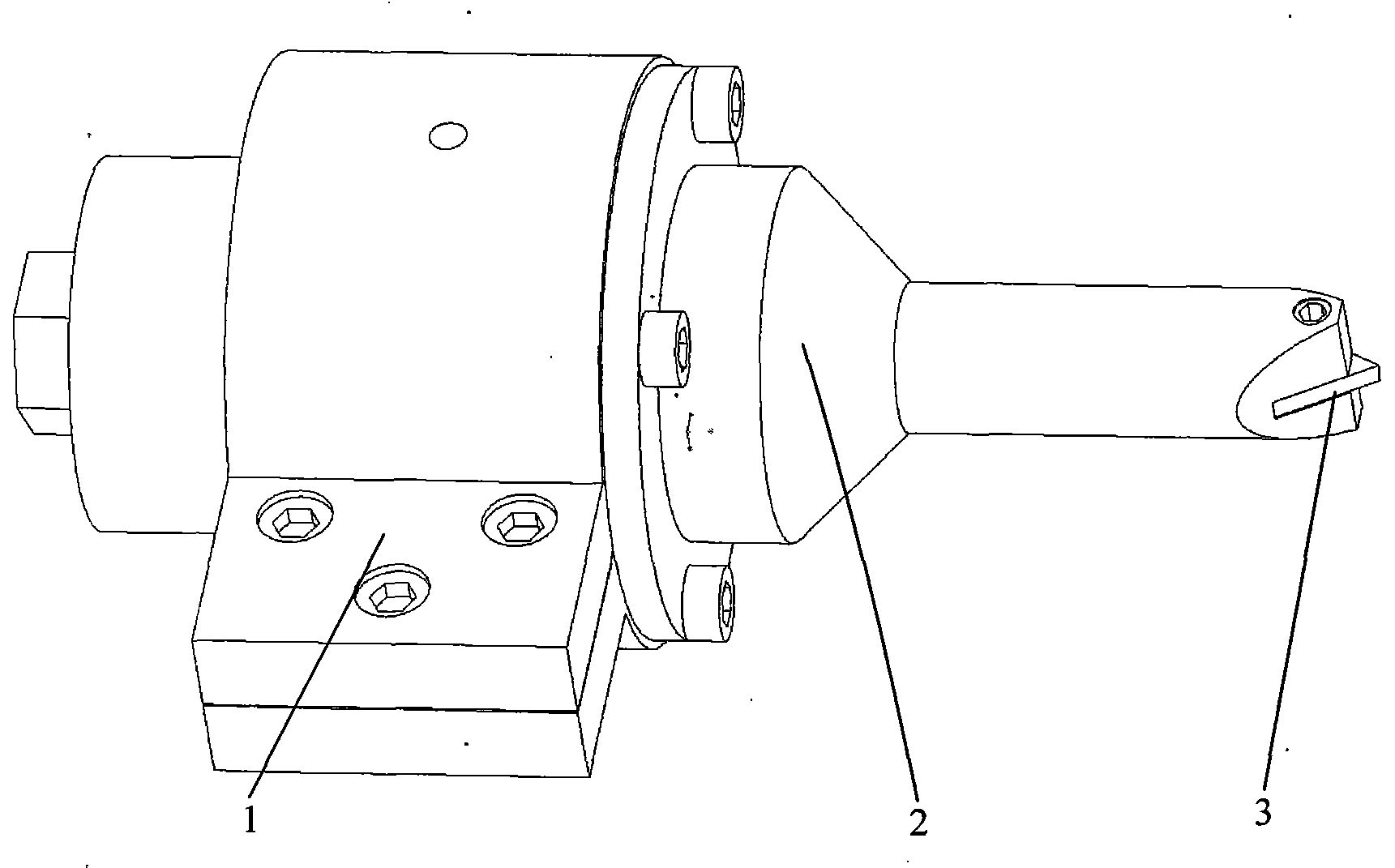

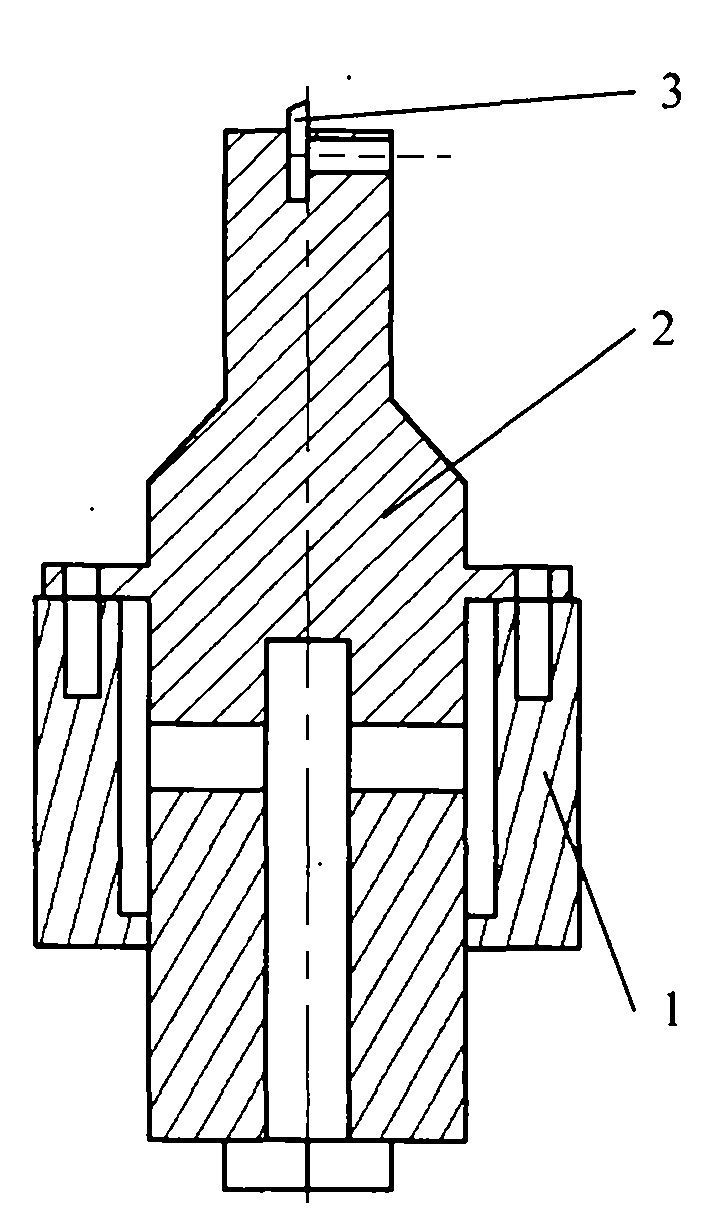

[0039] see figure 1 , Figure 1A , Figure 1B As shown, a bending mode ultrasonic vibration assisted cutting device for precision or ultra-precision turning of the present invention, the cutting device includes an ultrasonic vibration unit 2, a housing 1 set on the outer surface of the ultrasonic vibration unit 2 and a top through the front end of the housing 1. The threaded hole 216 and the knife groove 215 are installed on the cutter 3 on the output end of the ultrasonic vibration unit 2 .

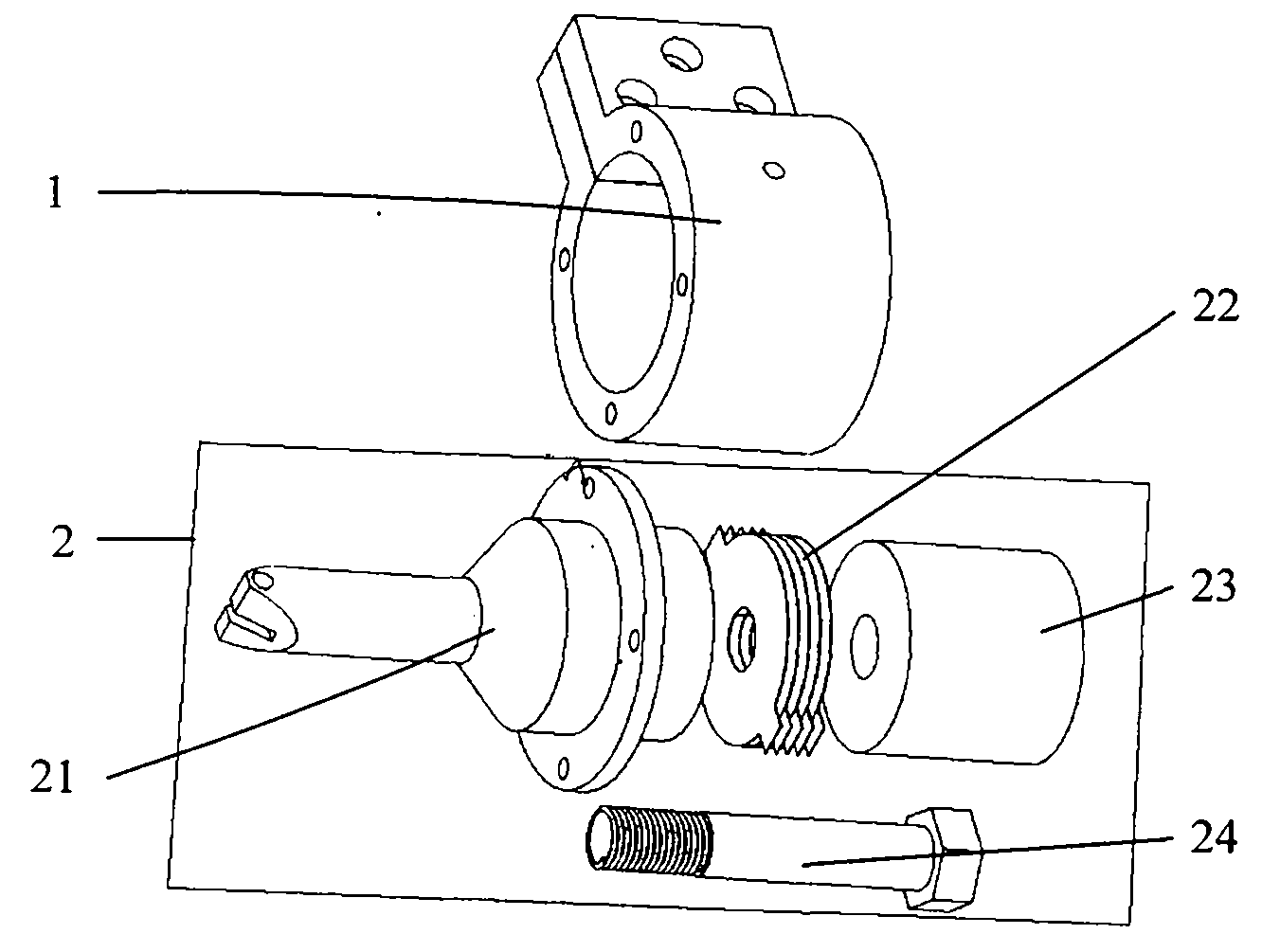

[0040] (1) Ultrasonic vibration unit 2

[0041] see Figure 1B As shown, the ultrasonic vibration unit 2 includes a flanged front cover 21, an excitation source 22, a rear cover 23 and fastening screws 24; the structure of the rear cover (23) is a hollow cylinder structure.

[0042] see figure 2 As shown, the flanged front cover 21 is a stepped shaft structure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com