Bearing structure for vehicle pedal device and flanged bushing

A technology of bearing parts and pedals, applied in the direction of rotating bearings, bearings, road vehicles, etc., can solve problems such as abnormal noise, loosening or tilting of support parts, and achieve high support rigidity, restrain loosening, and improve durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

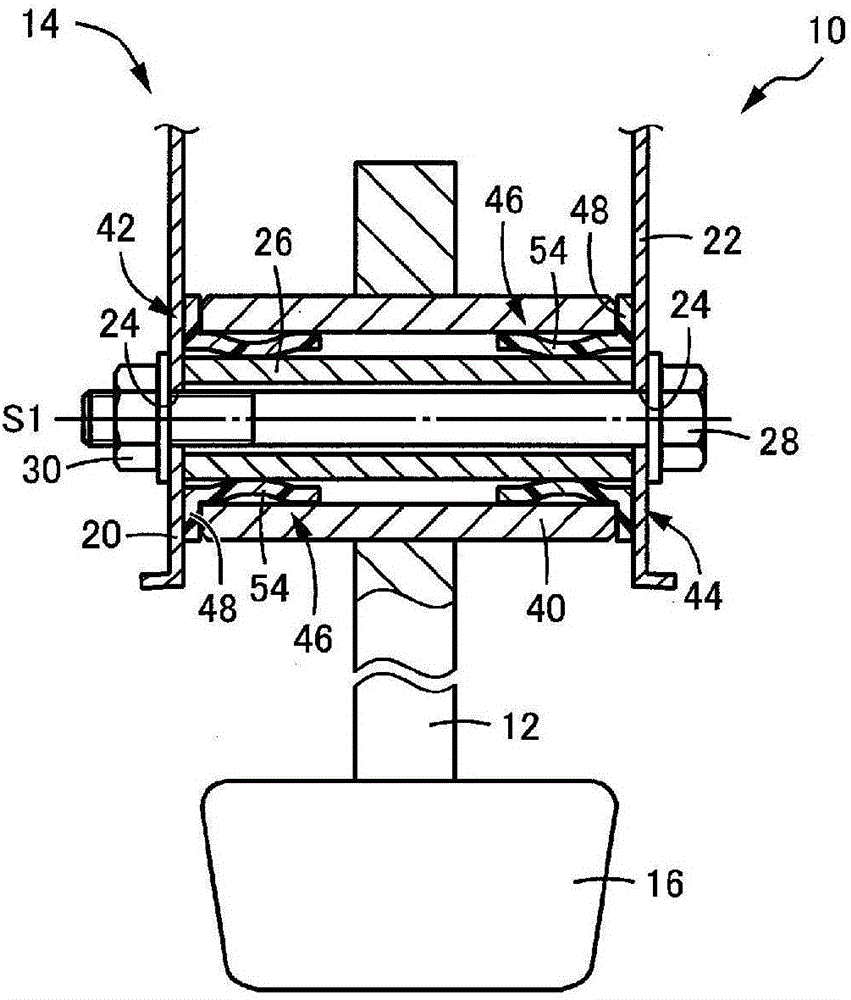

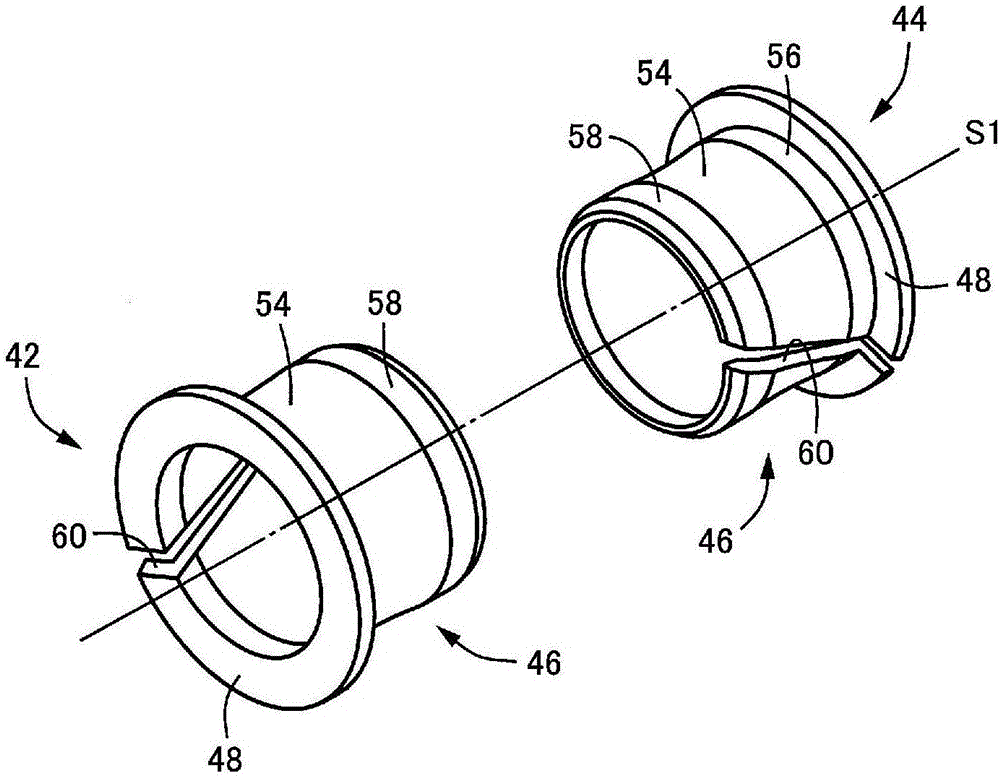

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the following examples, except Figure 4 with Figure 5 , the drawings are appropriately simplified or modified for the sake of explanation, and the dimensional ratios, shapes, etc. of each part are not necessarily drawn accurately. for Figure 4 with Figure 5 , for easy understanding, the dimensional ratios and shapes close to the real ones are described.

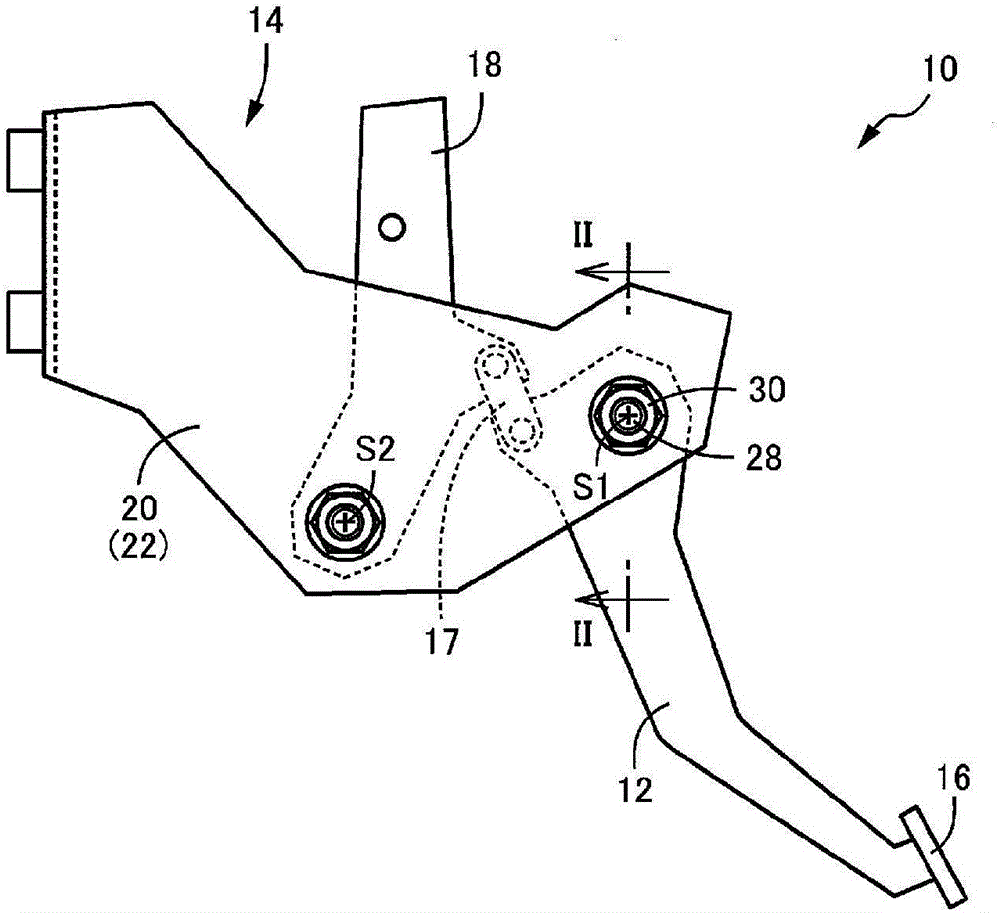

[0037] figure 1 It is a left side view showing a brake pedal device 10 for a service brake of a vehicle using the present invention, figure 2 yes figure 1 The enlarged cross-sectional view of the II-II arrow in . This brake pedal device 10 has a brake pedal 12 which is supported at an upper end by a pedal bracket 14 so as to be rotatable about a substantially horizontal support axis S1 and which is integrally attached to a lower end of the brake pedal 12 . There is a tread part 16 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com