Oblique block-type elevating platform

A technology of lifting platforms and inclined blocks, which is applied in the direction of lifting frames and lifting devices, can solve the problems that the mechanism is difficult to bear large loads or alternating loads, the structure of the scissor lifting mechanism is complicated, and the requirements for manufacturing and processing precision are high, and it can achieve The effect of compact structure, simple structure and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

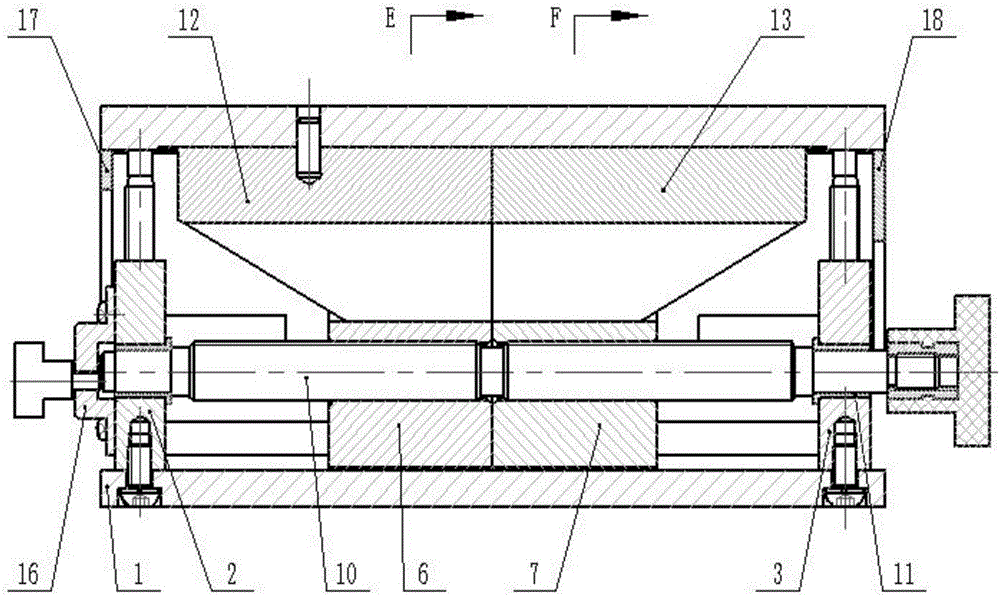

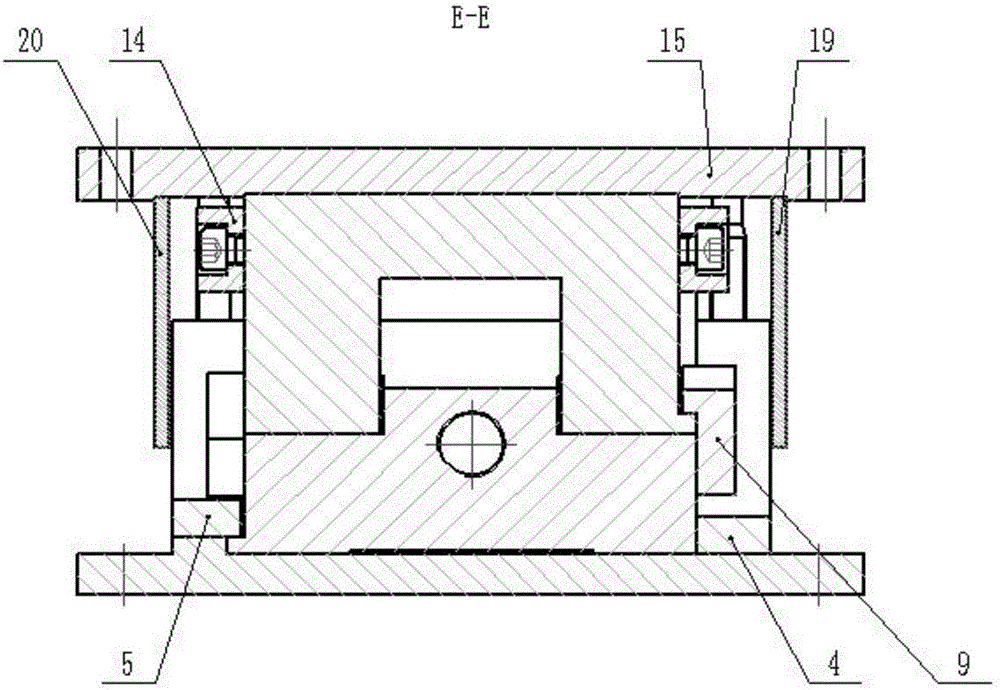

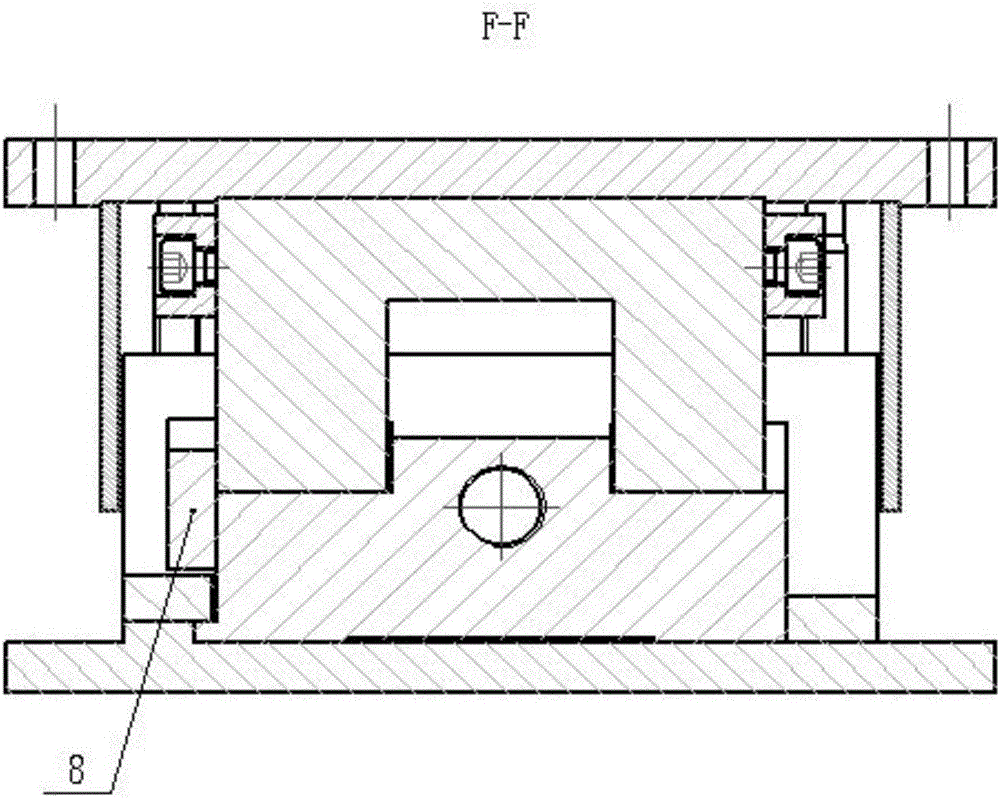

[0016] In conjunction with the accompanying drawings, an inclined block type lifting platform of the present invention includes a base plate 1, a left support plate 2, a right support plate 3, a lower baffle plate 4, a lower pressure plate 5, a left slider 6 and a right slider 7, the The left support plate 2, the right support plate 3, the lower baffle plate 4, and the lower pressure plate 5 are fixed on the upper surface of the base plate 1, wherein the left support plate 2 and the right support plate 3 are located at the left and right ends of the base plate 1, and the lower baffle plate 4, the lower plate Pressing plate 5 is respectively positioned at the front and back sides of base plate 1 and is parallel to each other, and lower baffle plate 4, lower pressing plate 5 and base plate 1 form chute, left slide block 6, right slide block 7 are set in the chute, described left slide block 6, Right slide block 7 can slide between left support plate 2, right support plate 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com