Supporting disk for soldering tool clamp of micro-diameter thin-walled tube of heat exchanger

A technology of heat exchangers, disks, used in the field of aerospace science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

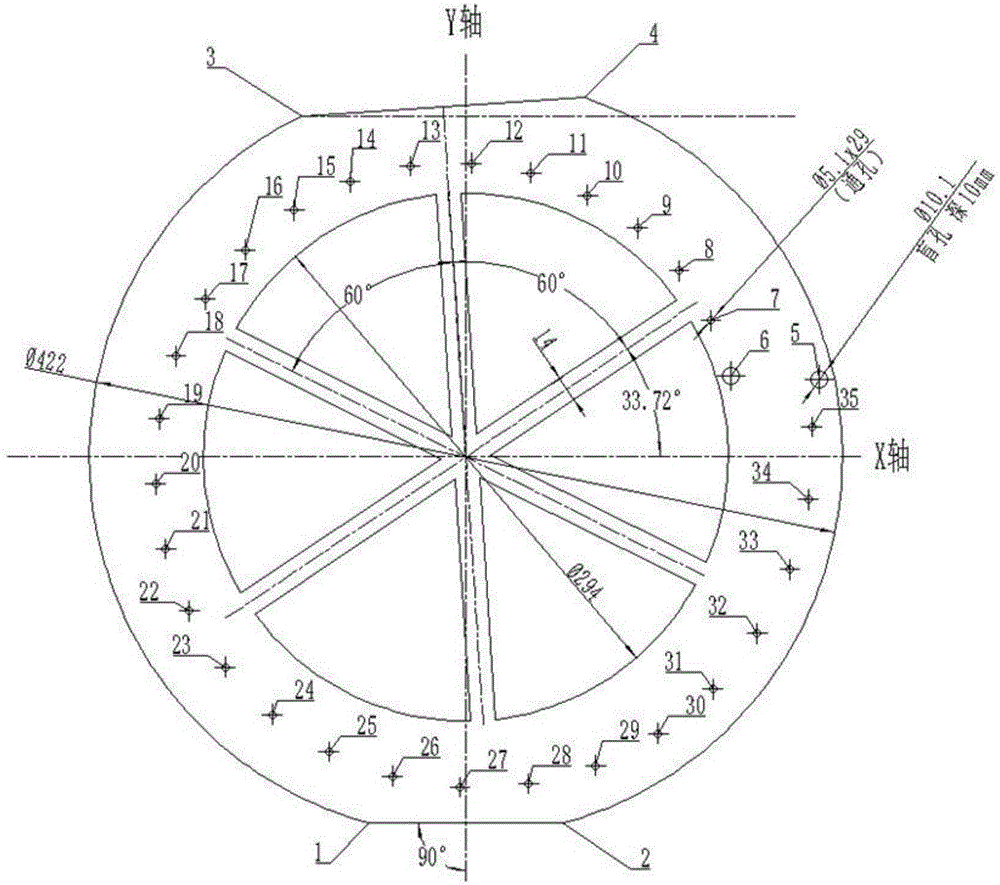

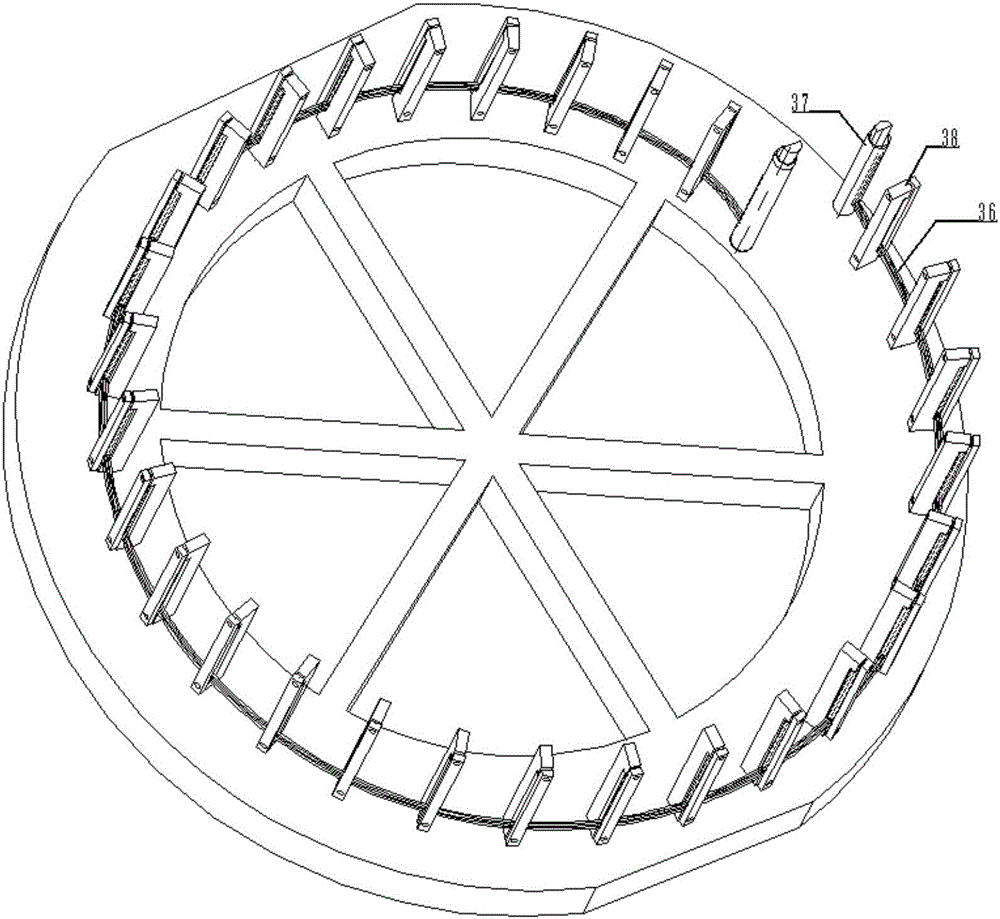

[0026] figure 1 It is a front view of the supporting disk of the present invention, which mainly includes blind holes 5, 6 for inserting diodes 37 for positioning, through holes 7-35 distributed in a spiral shape at equal intervals, and two holes for vertically supporting the disk. The positioning planes are the lower positioning plane 1-2 and the upper positioning plane 3-4. figure 2 It is the bottom view of the supporting disk of the present invention. image 3 is the isometric drawing of the support disc assembly.

[0027] When this supporting disc is working, it is first placed on the horizontal truss for installation. The first step is to insert 29 vertical fixing components 38 into the through holes 7-35 of the supporting disc, the vertical fixing components 38 can be rotated in this through hole to adjust the angle of installation, and the part of the vertical fixing component 38 protruding out of the disc With threads, the nuts are tightened when the final position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com