A three field of view switching mechanism for optical equipment

A technology of switching mechanism and optical equipment, applied in the directions of optics, optical components, installation, etc., can solve the problem that the positioning accuracy and repeated positioning accuracy cannot meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

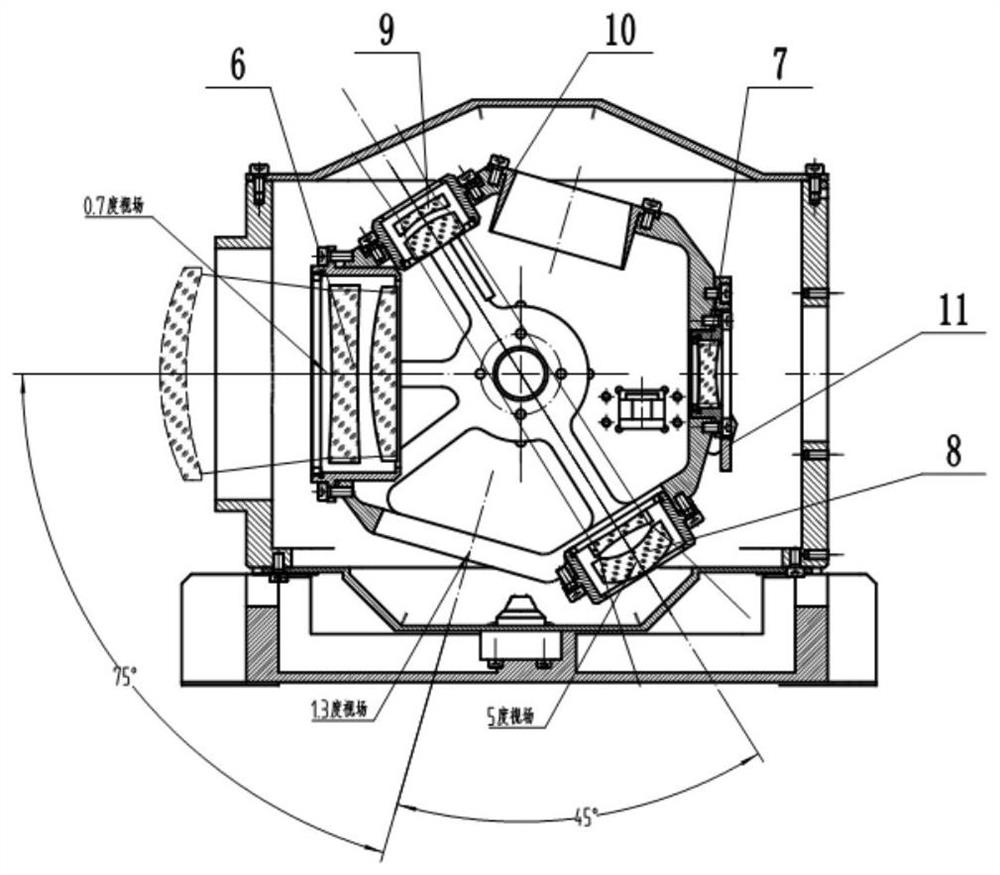

[0064] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

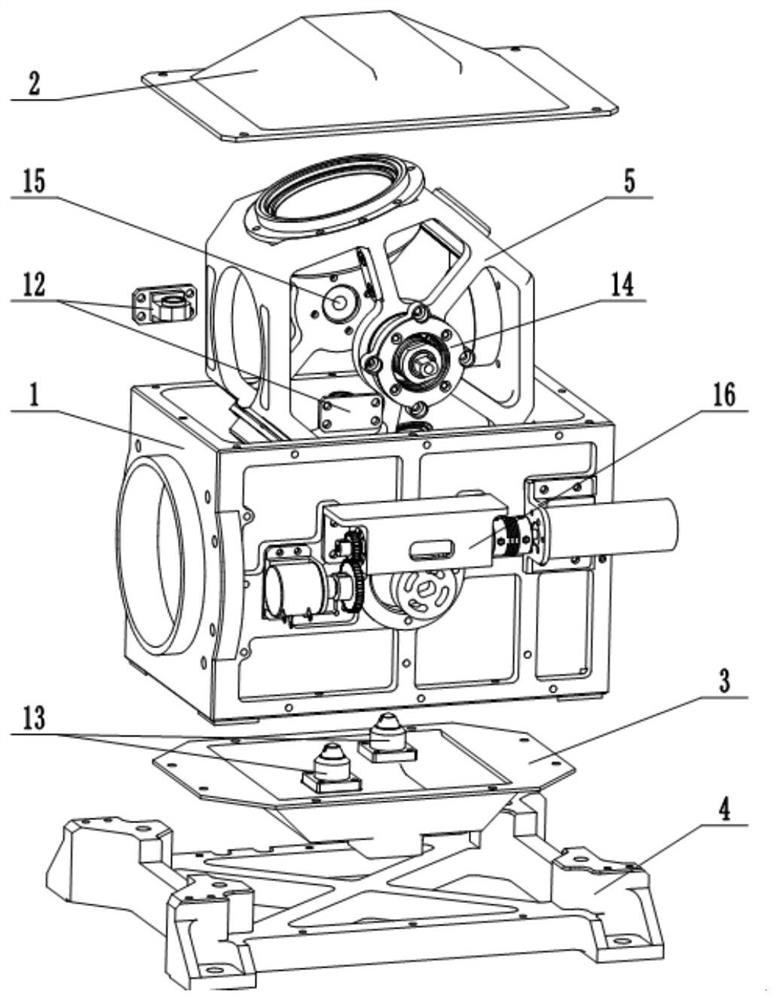

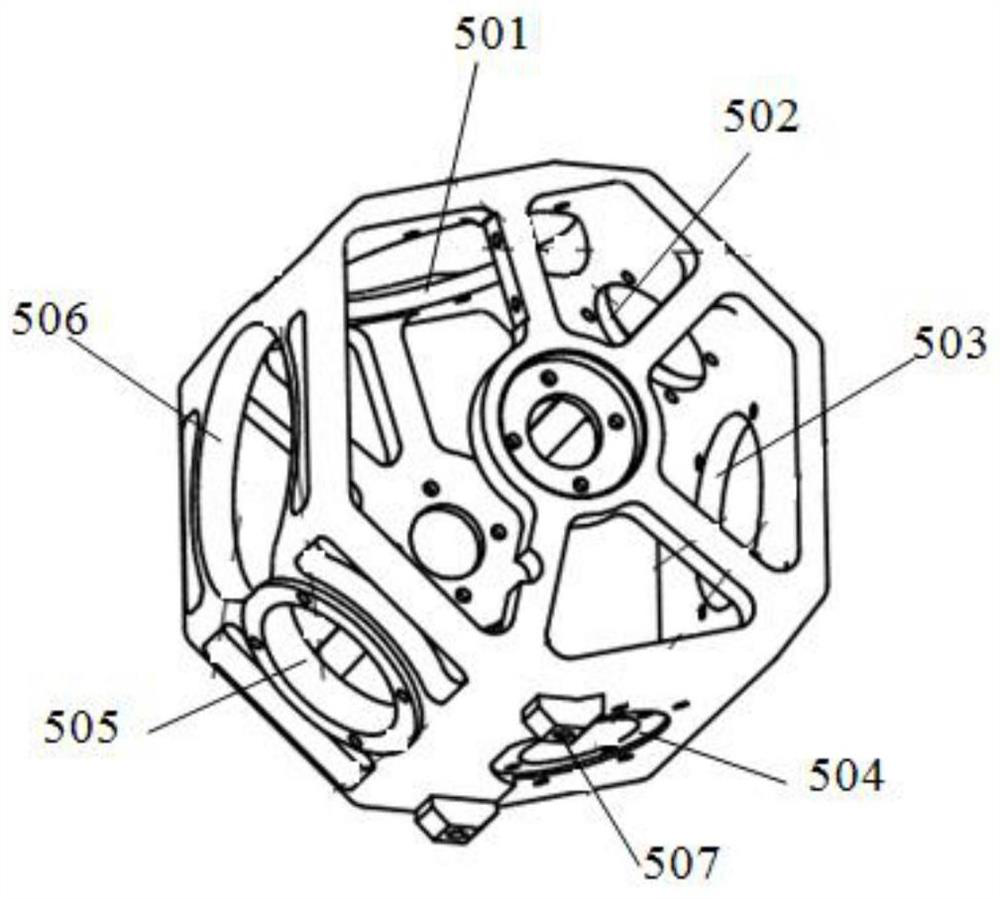

[0065] see figure 1 , the present invention is a three-field switching mechanism for optical equipment, including a main frame assembly, a rotating lens barrel assembly, a driving assembly 16 and a limit assembly.

[0066] The above-mentioned main frame assembly includes the main frame 1 . In this embodiment, for the sake of simple processing and cost saving, the main frame 1 preferably adopts a box structure, which is a rectangular frame, and its upper and lower sides are opened to facilitate the installation of the rotating lens barrel 5 . The main frame assembly in this embodiment also includes an upper cover plate 2 and a lower cover plate 3; the upper cover plate 2 and the lower cover plate 3 are respectively covered on the upper and lower surfaces of the main frame 1, are fixedly connected with the main frame 1, and surround into a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com