Micro arc surface reflector punching backplane

A mirror and backplane technology, applied in the field of solar energy utilization, can solve the problems of unfavorable reflective surface strength and accuracy guarantee, heavy weight, difficult-to-reflect mirror surface shape accuracy, etc., to prevent deformation from being relatively concentrated in distribution and to ensure integrity. , the effect of many processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

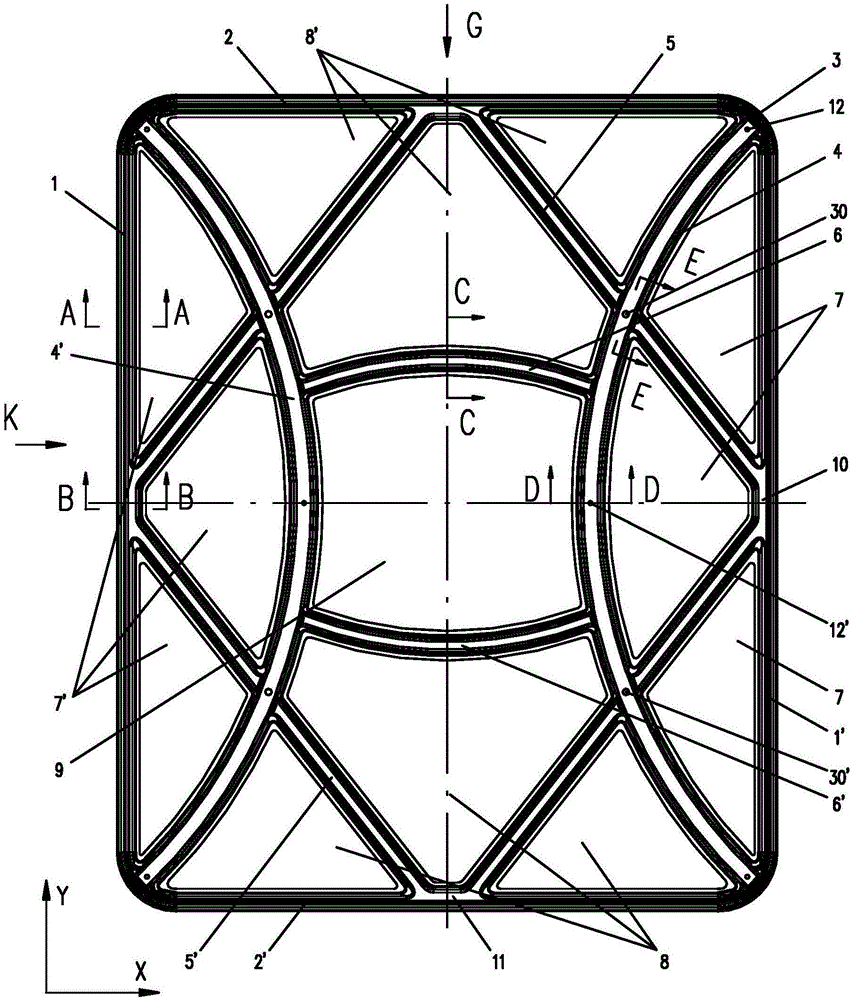

[0048] Taking the heliostat in the tower-type solar thermal power generation technology as an example, combined with the current mainstream rectangular heliostat mirror (or facet) shape, in order to make the technical solution and advantages of the present invention more clear, the following is combined with illustrations and implementation For example, the present invention is described in detail.

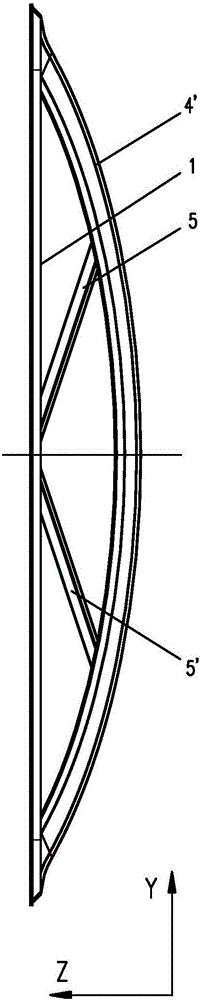

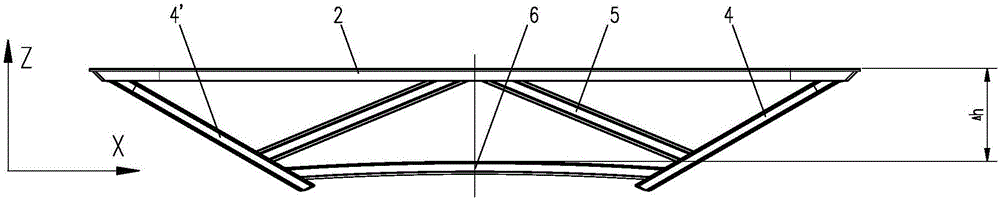

[0049] Such as figure 1 As shown, a micro-arc mirror stamping back plate, the back plate is punched and formed by cutting thin steel plate (stretched plate), on the overall frame structure of the back plate, each forming part inside the back plate Four inward inclined surfaces 7, 7', 8, 8' are formed, so that when the reflector body is bonded and fixed to the back plate, the spatial shape of the back plate forces the reflector to sag toward its center point, A slight elastic deformation is produced, so that the surface shape of the reflector produces a slight arc, and a certain d...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, the difference is that: when the ring-shaped forming part is a circular structure, it is preferable to refer to the actual arrangement of the arc-shaped forming part, the connecting arm and the reinforcing arm. Figure 9 As shown: the reinforcement arms 5, 5' are sequentially connected to four points evenly distributed on the circular ring-shaped forming part 1, forming a square; the arc-shaped forming parts 4, 4' are connected to the corresponding two adjacent reinforcement arms The arc midpoint on the annular forming part, the two arc forming parts 4, 4' are left and right symmetrical and symmetrical about the center of the circle; the connecting arms 6, 6' connect the two 1 / 4 positions on the two arc forming parts, The two connecting arms are symmetrical up and down and centered on the center of the circle.

Embodiment 3

[0059] This embodiment is basically the same as Embodiment 1, the difference is that when the ring-shaped forming part is an elliptical structure, the actual layout rules of the preferred arc-shaped forming part, connecting arm and reinforcing arm are referred to in reference Figure 10 As shown: the reinforcement arms 5, 5' are sequentially connected to four points evenly distributed on the elliptical ring-shaped forming part, that is, the intersection of the long and short axes and the ellipse, forming a rhombus; two arc-shaped forming parts 4, 4' The left and right symmetry and the center of the circle are symmetrical; the two connecting arms 6, 6' are symmetrical up and down and are symmetrical about the center of the circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com