Production equipment for composite smooth aluminum sleeve multilayer co-extrusion cable

A technology of multi-layer co-extrusion and production equipment, which is used in the manufacture of insulated cables, cables/conductors, and insulation of conductors/cables. The effect of small diameter, large elastic modulus and compact cable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

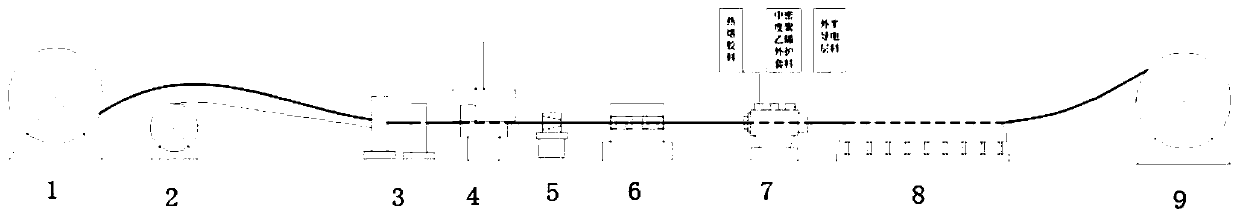

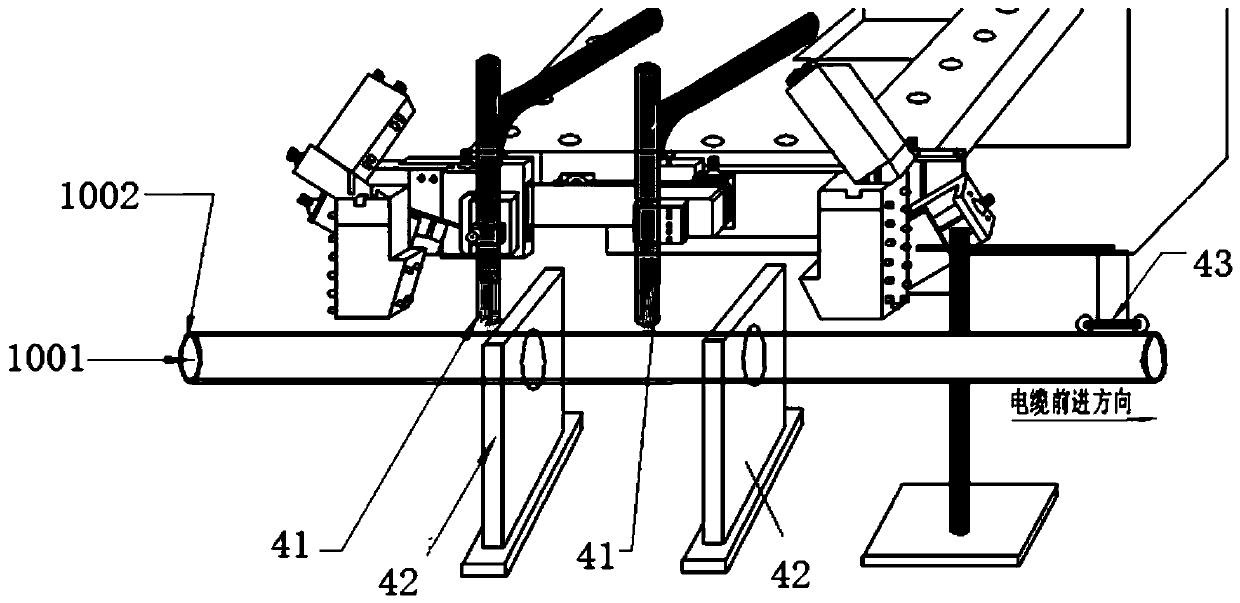

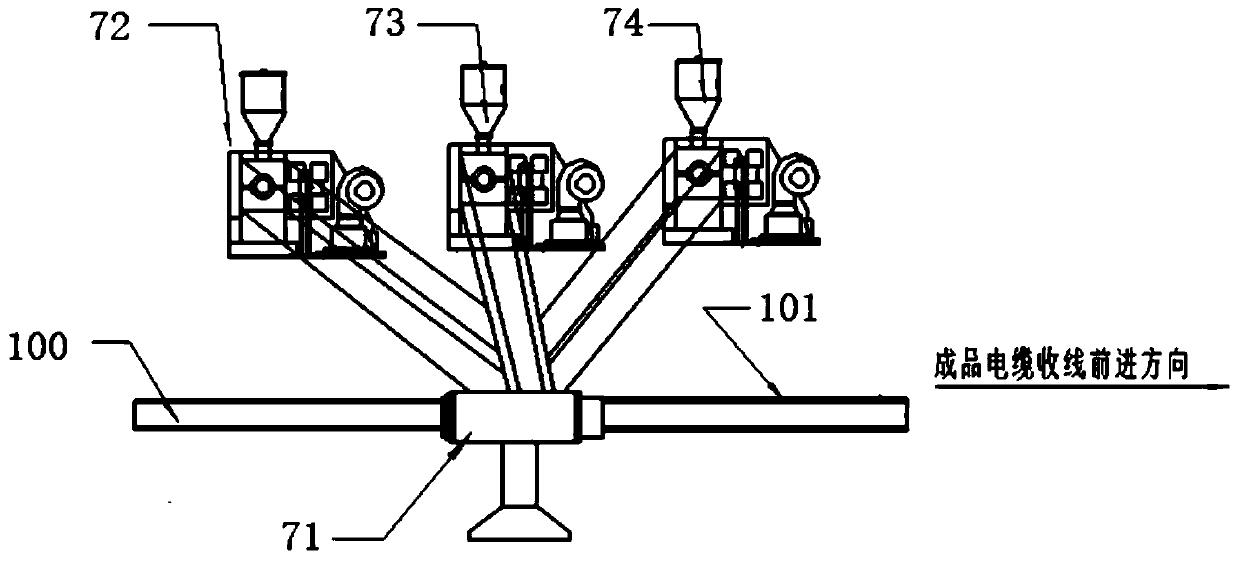

[0026] refer to Figure 1 to Figure 3 As shown, a composite smooth aluminum sheath cable sheath production equipment, including cable pay-off stand 1, aluminum strip pay-off stand 2, aluminum strip cladding device 3, double gun welding device 4, aluminum sheath drawing device 5, multiple Layer co-extrusion device 7, cooling water tank 8 and cable take-up device 9, a cable core disc is installed on the cable pay-off frame for releasing the cable core, and an aluminum tape reel is installed on the aluminum strip pay-off frame for use To release the aluminum strip, the aluminum strip coating device is used to wrap the aluminum strip on the outside of the cable core, the double-gun welding device is used to weld the aluminum strip and form an aluminum sheath, and the aluminum sheath pulling device is used to The aluminum sleeve is reduced in diameter, and the multi-layer co-extrusion device 7 includes a multi-layer co-extrusion head 71, a hot melt adhesive extruder 72, an outer sh...

Embodiment 2

[0040] A method for producing a composite smooth aluminum-sheathed cable sheath, which is produced by using the production equipment for a composite smooth aluminum-sheathed cable sheath described in Embodiment 1. The production process is as follows:

[0041] S1: Release the cable core on the cable core reel on the cable pay-off rack, and after the aluminum tape is released from the aluminum tape reel on the aluminum tape pay-off rack, wrap the aluminum tape on the outside of the cable core by the aluminum tape covering device;

[0042] S2: The double-gun welding device welds the aluminum strip and forms an aluminum sleeve;

[0043] S3: The diameter of the aluminum sleeve is reduced by the aluminum sleeve drawing device;

[0044] S4: Laminate the aluminum sleeve with hot melt adhesive, outer sheath and outer conductive layer through a multi-layer co-extrusion head;

[0045] S5: cooling and forming the cable through the cooling water tank after composite molding;

[0046] S6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com