Preparation method of water-based coating integrating corrosion resistance and fireproofing

A water-based and coating technology, applied in anti-corrosion coatings, fire-proof coatings, epoxy resin coatings, etc., can solve the problem of heat transfer rate reduction, achieve the effects of reducing heat transfer rate, avoiding multiple brushing, and delaying the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

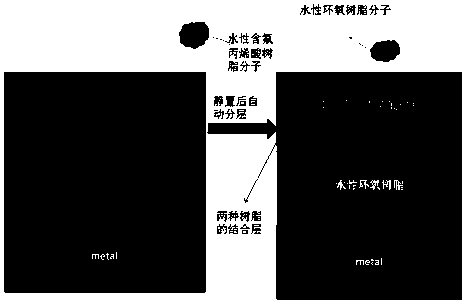

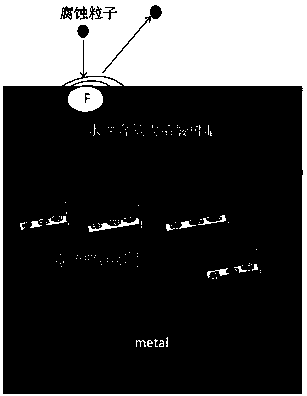

[0031] A method for preparing a water-based anti-corrosion and fire-proof integrated coating, the coating is composed of a water-based fluorine-containing acrylic resin and a modified water-based epoxy resin, and comprises the following preparation steps:

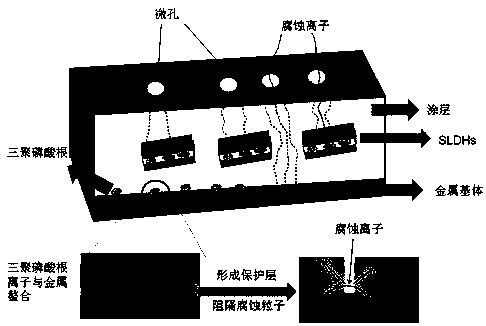

[0032] a. Weigh 500ml of deionized water, put it into a heating pot, heat to 100°C and boil for 3-5 times, put the boiled deionized water beaker into a water bath at 50-70°C for later use, and weigh 3-5g Magnesium nitrate and 3-5g of aluminum nitrate are put into a beaker, pour 30-60ml of boiled deionized water, and mechanically stir with a stirring speed of 100-200r / min and a stirring time of 5-10min. Add the mixed solution into constant pressure funnel A. Weigh 2-5g of sodium hydroxide and 5-10g of sodium tripolyphosphate into a beaker, and weigh 30-60ml of boiled deionized water. Use a disperser to stir the solution evenly, the dispersion speed is 20000-30000 / min, and the dispersion time is 5-10min. The resulting solut...

Embodiment 1

[0048] (1) Preparation of tripolyphosphate pillared hydrotalcite:

[0049] Weigh 500ml of deionized water and put it into a heating pot, heat to 100°C and boil for 3 times, put the beaker containing boiled deionized water into a water bath at 60°C for later use, weigh 3g of magnesium nitrate and 3g of aluminum nitrate into Pour 50ml of boiled deionized water into the beaker, and use mechanical stirring at a stirring speed of 100r / min for 5min. Add the mixed solution into constant pressure funnel A. Weigh 3 sodium hydroxide and 8 g sodium tripolyphosphate and pour them into a beaker, and weigh 50 ml boiled deionized water. Use a disperser to stir the solution evenly, the dispersion speed is 30000 / min, and the dispersion time is 10min. The resulting solution was added to constant pressure funnel B. Insert funnels A and B into the flasks, respectively. Add 80ml of boiled deionized water to the flask, put the flask into a water bath at 60°C, under the protection of a nitrogen ...

Embodiment 2

[0055] (1) Preparation of modified waterborne epoxy resin:

[0056] Weigh 500ml of deionized water and put it into a heating pot, heat to 100°C and boil for 3 times, put the beaker containing boiled deionized water into a water bath at 60°C for later use, weigh 3g of magnesium nitrate and 3g of aluminum nitrate into Pour 50ml of boiled deionized water into the beaker, and use mechanical stirring at a stirring speed of 100r / min for 5min. Add the mixed solution into constant pressure funnel A. Weigh 3 sodium hydroxide and 8 g sodium tripolyphosphate and pour them into a beaker, and weigh 50 ml boiled deionized water. Use a disperser to stir the solution evenly, the dispersion speed is 30000 / min, and the dispersion time is 10 minutes. The resulting solution was added to constant pressure funnel B. Insert funnels A and B into the flasks, respectively. Add 80ml of boiled deionized water to the flask, put the flask into a water bath at 60°C, under the protection of a nitrogen at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com