Heat-insulating pipe

A technology of thermal insulation pipes and straight pipes, which is applied in the directions of thermal insulation, pipes, and protection pipes through thermal insulation, etc., can solve the problems of easy infiltration of rainwater and snow water, difficult to handle the joints of thermal insulation materials, and shortened service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

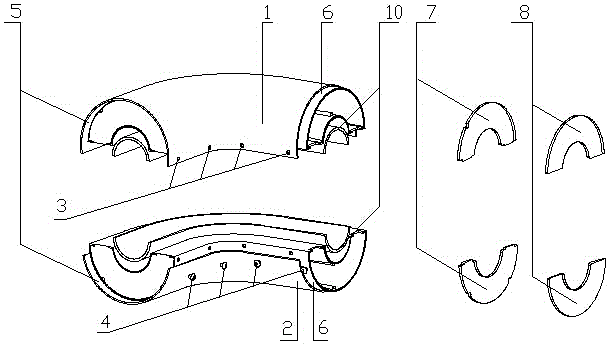

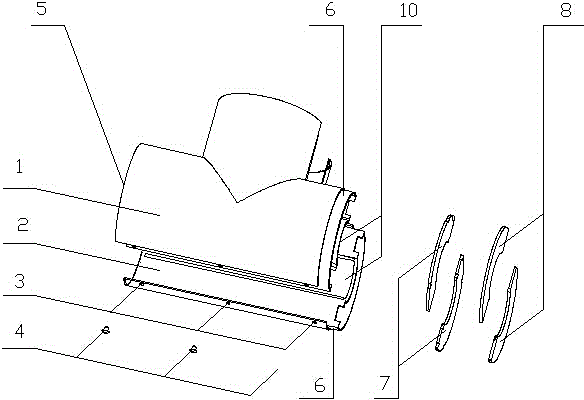

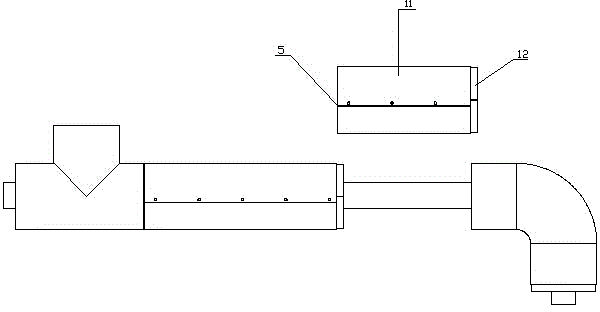

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0018] Such as Figure 1 to Figure 4 As shown, it is a kind of insulation pipe proposed by the present invention, including straight pipe, bent pipe, tee, and cut-off pipe. Straight pipes, bent pipes, tee pipes, and cut-off pipes are all single-section pipes formed by locking the upper shell 1 and the lower shell 2 with the same structure through a locking device. One end of the single-section pipe is provided with a round Hemming 5, the other end of the single-section pipe body is provided with a circular retraction platform 6, the upper shell 1 and the lower shell 2 are both set as hollow structures, and one end of the upper shell 1 and the lower shell 2 is set as an opening, The other ends are all set to be closed, and the opening ends of the upper casing 1 and the lower casing 2 are all equipped with a button cover 7 and a buffer cotton 8, and the button cover 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com