Formula, preparation method of solid corrosion inhibitor and its using method

A corrosion inhibitor and solid technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of difficult to reach the bottom of the well, inconvenient operation, large dosage, etc., to increase crude oil production and anti-corrosion efficiency High and prolong oil recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

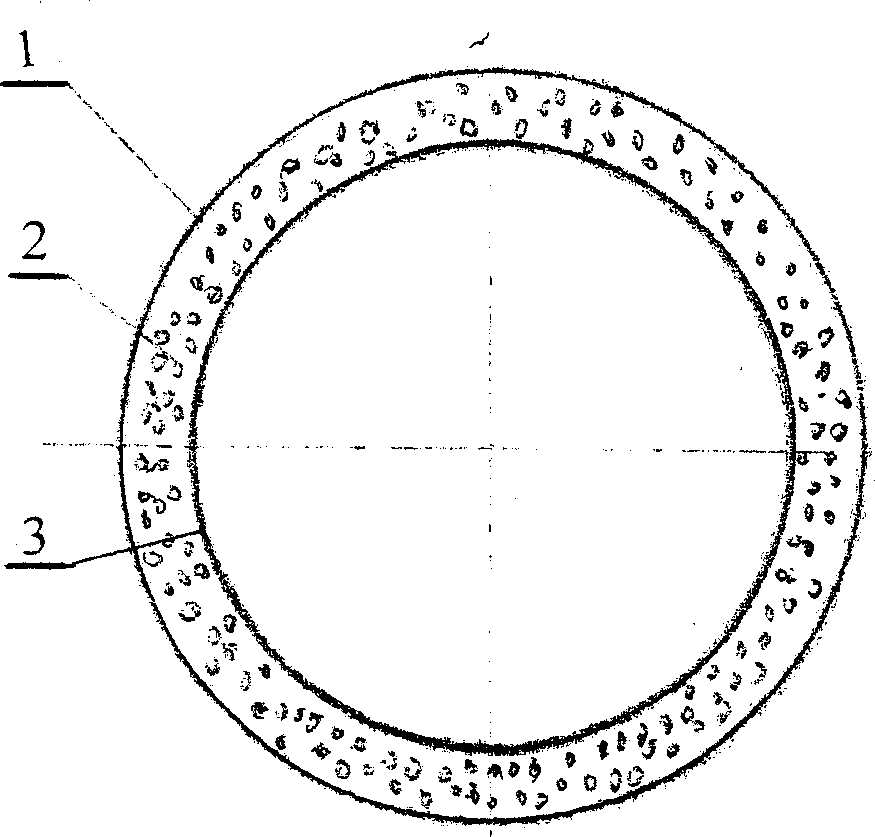

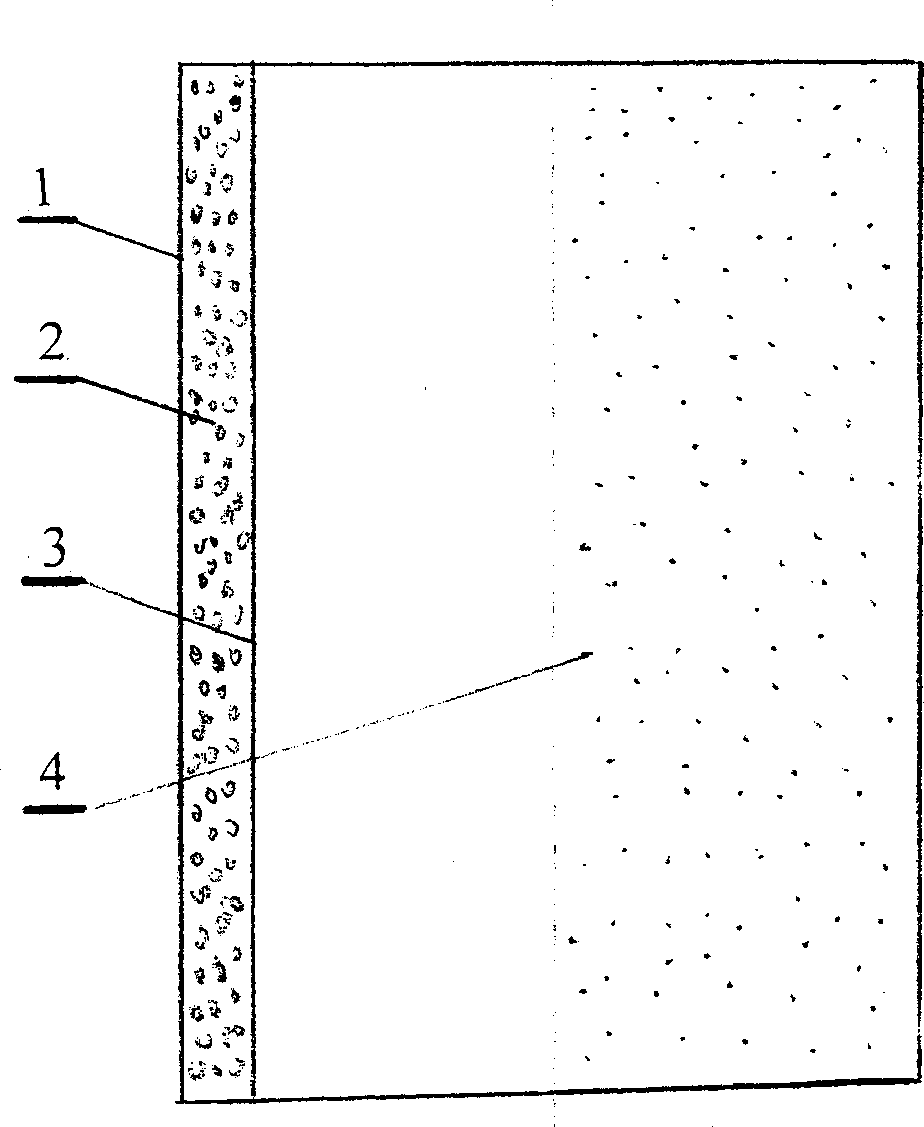

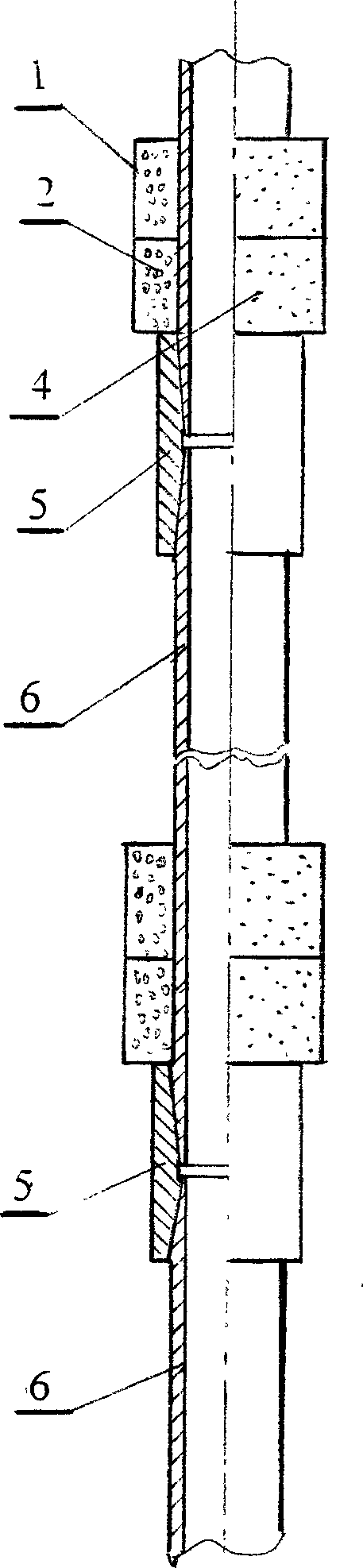

Image

Examples

Embodiment Construction

[0024] Formulation example, the solid corrosion inhibitor of the present invention is prepared from the following raw materials in weight ratio: a certain dibasic acid, 34%; diethylenetriamine, 12%; chloroacetic acid, 10%; dodecyl Sodium benzenesulfonate, 10%; Hexamethylenetetramine, 8%; Hydrolyzed polymaleic anhydride (HPMA), 8%; Polyepoxysuccinic acid, 8%; Epoxy resin, 4%; Polyamide resin, 4%.

[0025] The concrete preparation method embodiment of the present invention adopts the formula in the formula embodiment, comprises the following steps:

[0026] A. Synthesis of intermediates: Put a dibasic acid in a reaction tank, turn on the heater, and stir while heating. When the temperature reaches 150°C, add diethylenetriamine, and keep stirring, keep the temperature for 130 minutes, and heat up to 200°C, constant temperature reaction for 4 hours. Stop heating, after cooling to 80°C, add chloroacetic acid dropwise, react for 1.5 hours, and finally evaporate the solvent to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com