Patents

Literature

45results about How to "No emission issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

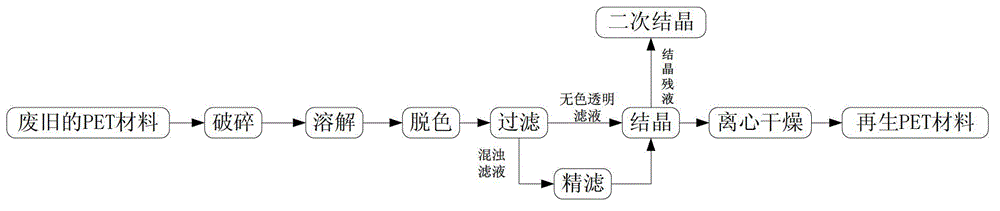

Process for recovering waste polyethylene glycol terephthalate (PET) material

The invention discloses a process for recovering a waste polyethylene glycol terephthalate (PET) material. The process is characterized by comprising the following steps of: crushing the waste PET material, dissolving the crushed PET material ion into an organic solvent to form a homogeneous solution; and adding an adsorbent into the homogeneous solution, discoloring and removing insoluble substances, and sequentially filtering and crystallizing to obtain the required crystallized PET material. According to the process for recovering the waste PET material, the recycled polyester intrinsic viscosity control technology, the crystallization technology and the impurity removal technology are realized, water is not required to be added in the whole process, the wastewater discharge is avoided, and the environmental pollution is reduced. The intrinsic viscosity of the recycled PET product reaches 0.77dL / g, the purity is 99.5 percent, and the recovered material reaches a novel level.

Owner:SHUYE ENVIRONMENTAL TECH CO LTD

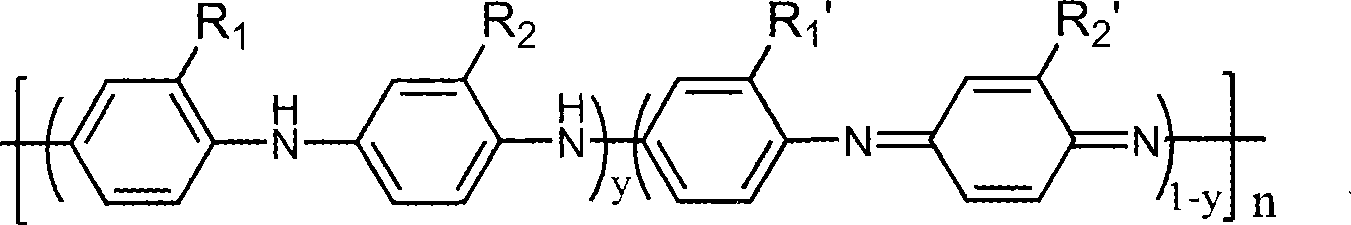

Ultraviolet-heat dual curing polyaniline anti-corrosive paint and preparation method thereof

ActiveCN101418146ANo emission issuesNo pollution problemAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletChromium

The invention provides an ultraviolet-thermal double curing polyaniline anti-corrosive coating and a preparation method thereof. In the coating, polyaniline is adopted as a main anti-corrosive material, and oligomer, a reactive diluent, polyurethane polylol, polyaniline, filler, light trigger and an auxiliary agent are used for preparing filtrate of the coating; and the filtrate and a polyurethane curing agent are stored respectively and uniformly mixed in proportion for use. The anti-corrosive paint has good anti-corrosive effect on different metals, not only can perform ultraviolet curing crosslinking but also can perform thermal curing crosslinking, well overcomes the defect of incomplete curing of an ultraviolet curing anti-corrosive paint, has the characteristics of resisting acid medium corrosion and alkali medium corrosion, is suitable to be used under the condition of a severe environment and particularly suitable for corrosion protection under the condition of a marine environment, does not contain heavy metals such as plumbum, chromium and zinc, and simultaneously does not contain any organic solvent in a formula. Therefore, the coating does not have the problem of environmental pollution during the production process and the use process, and is a completely environment-friendly coating.

Owner:中科应化(长春)科技有限公司

Waterless dyeing method of dispersed dye

The invention relates to a waterless dyeing method of dispersed dye, comprising: (1) taking an ionic liquid as a solvent where the dispersed dye is dissolved; (2) dyeing dacron according to an ionic liquid impregnating method and an ionic liquid hot melt pad dyeing method; and (3) recycling the ionic liquid and the dye by an alcohol or water distillation circulation method. The dyeing method and a formula are simple, and the operation is convenient; during dye bath, since no dyeing auxiliaries such as a dispersing agent and a high temperature leveling agent are needed, the problems of dyeing waste water caused by the dyeing auxiliaries themselves and the toxicity of a carrier are solved; and in addition, the ionic liquid in the residual dyeing liquid and the dye can be recycled.

Owner:DONGHUA UNIV

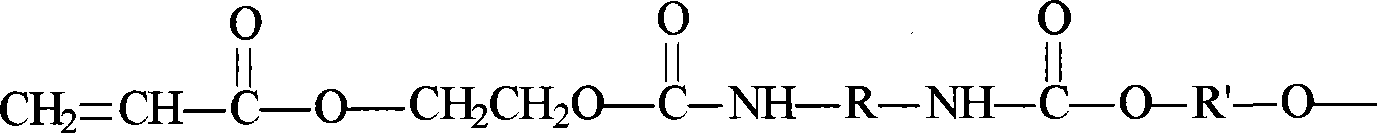

Method for preparing binder resin for water-based ink and application thereof

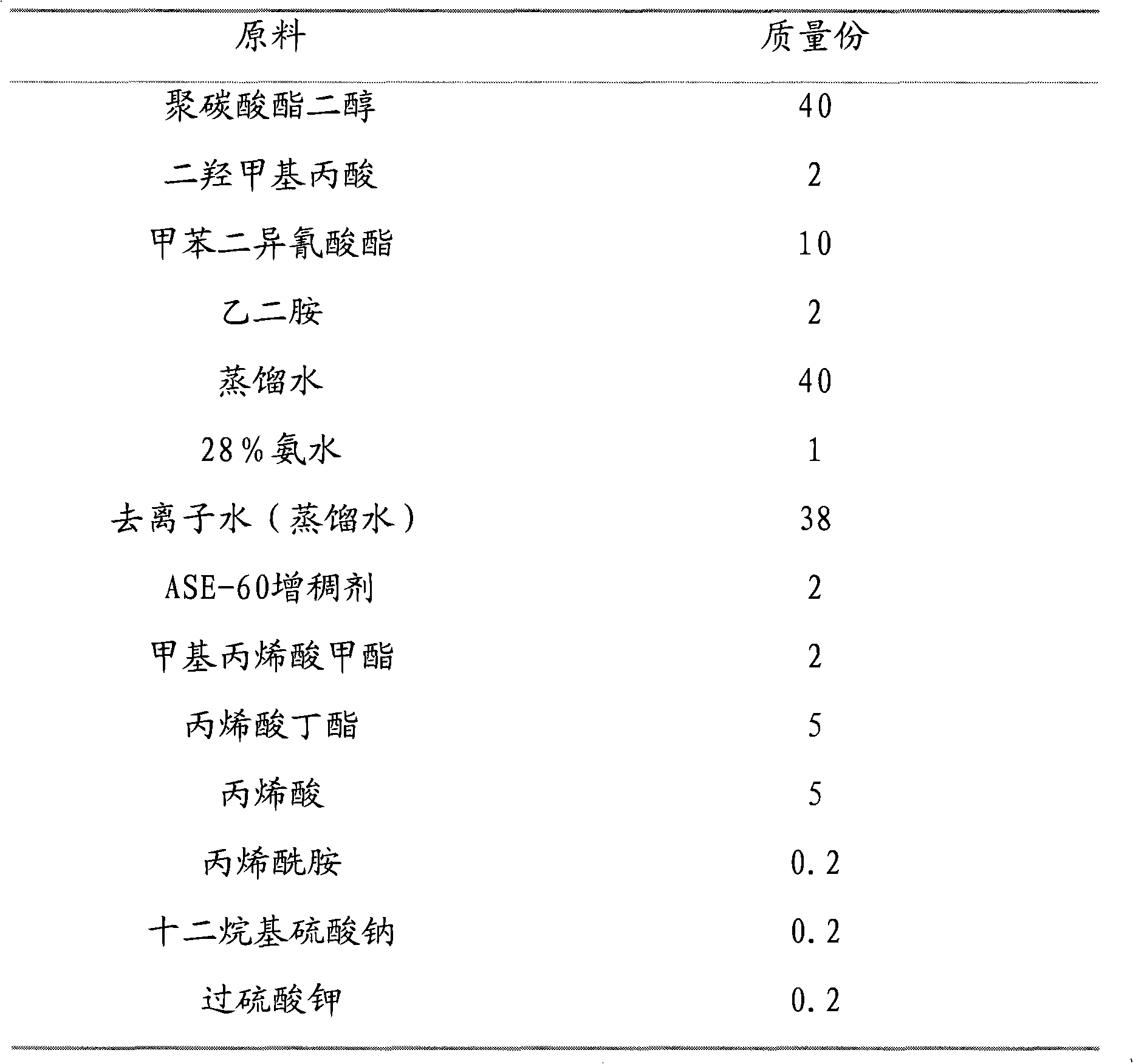

The invention discloses a method for preparing a binder resin for water-based ink and application thereof. The method comprises the following steps of: reacting polyester and / or polyether polyol, an ionized reagent and diisocyanate to prepare a prepolymer with NCO content of between 4 and 5 percent; dissolving a chain extender in cold water, and adding the mixture into the prepolymer under the stirring to obtain a polyurethane emulsion; stirring the obtained polyurethane emulsion, 28 percent ammonia water, deionized water and a thickening agent evenly to obtain an aqueous emulsion; and mixing methyl methacrylate, butyl acrylate, acrylic acid, acrylamide, sodium dodecyl sulfate and potassium peroxydisulfate with the aqueous emulsion to obtain the resin for the water-based ink. The method ensures that the water-based ink prepared by the obtained binder resin can be used for various plastic substrates and has excellent adhesion and good wetting property for polar and nonpolar substrates by synthesizing acrylic acid modified aqueous polyurethane, utilizing the temperature resistance and the flexibility of polyurethane, and introducing acrylic acid chain segments in a molecular structure at the same time.

Owner:BEIJING COMENS YANSHAN TECH +1

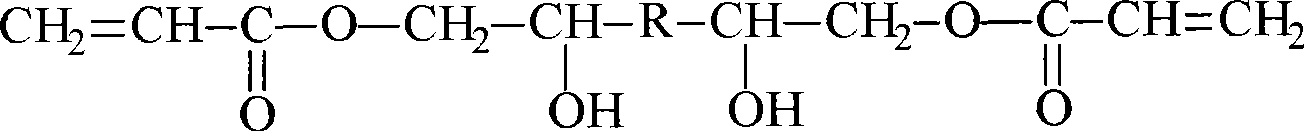

Double side coated solvent-free polyurethane laminating adhesive as well as preparation method, coating process and application thereof

InactiveCN106753172AGood adaptability to protectionWill not affect healthLiquid surface applicatorsLamination ancillary operationsEpoxyVegetable oil

The invention discloses a double side coated solvent-free polyurethane laminating adhesive, which comprises a component A and a component B, wherein the component B is prepared from one or a mixture of any two or above of polylol a of which the carbon chain length is C12 or below, polylol b with at least two degrees of functionality and above, vegetable oil modified polylol c, epoxy resin, acrylic resin and silicane resin, and a curing speed regulator d; besides being prepared from these ingredients, the component A is also prepared from a polyurethane prepolymer generated by the reaction of aromatic and / or aliphatic and / or alicyclic diisocyanate. The invention also discloses a preparation method, a coating process and application of the double side coated solvent-free polyurethane laminating adhesive. The problem that an existing solvent-free laminating adhesive needs to be previously mixed before being coated is solved.

Owner:康达新材料(集团)股份有限公司

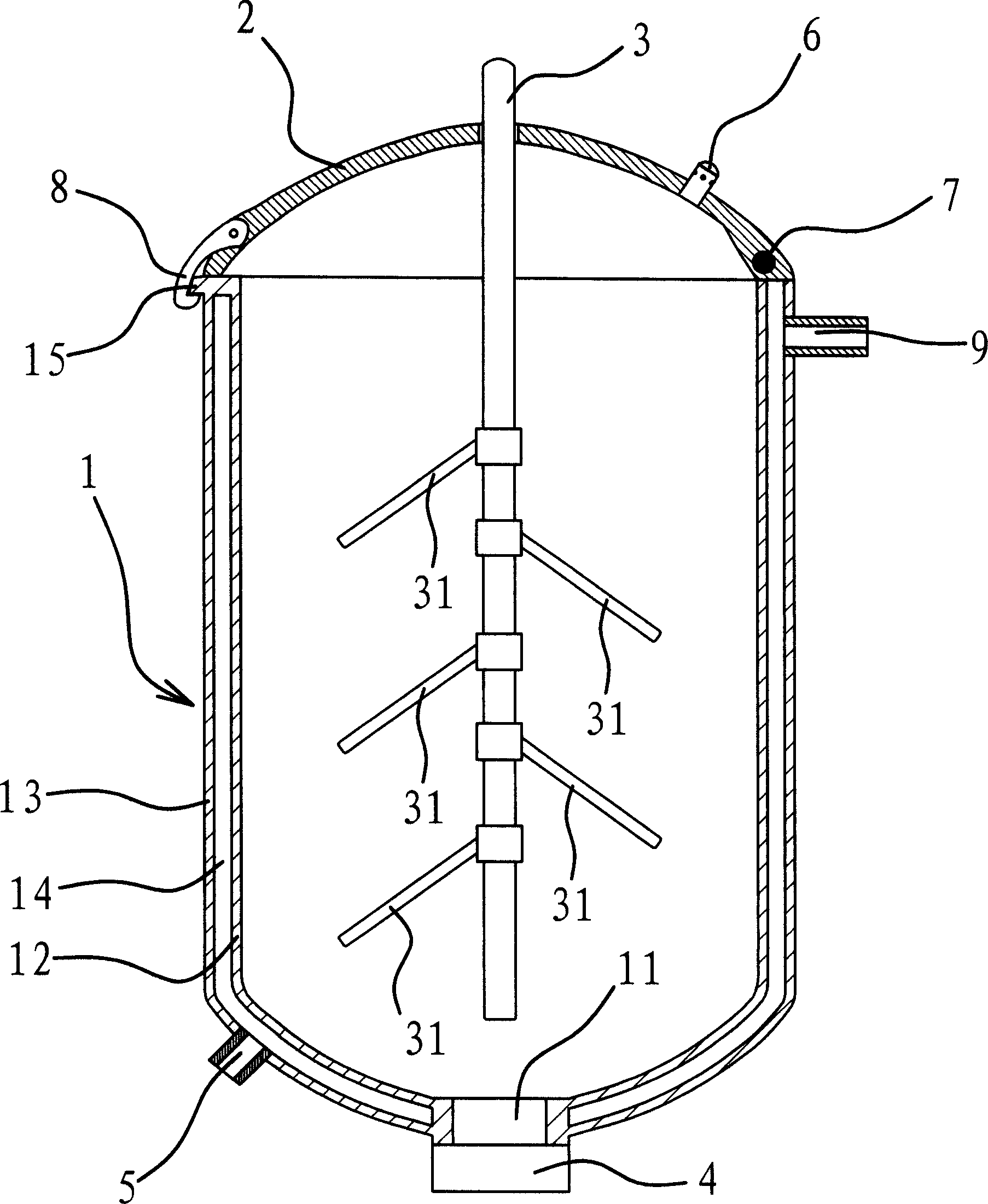

Animal shell substance treating method and device

InactiveCN1814772ANo wasteReduce wasteBioreactor/fermenter combinationsBiological substance pretreatmentsAnimal ShellsWastewater

This invention provides a method and a device for processing animal testa substances including the following steps: 1, putting animal testa substances in a fermentation device, 2, putting 0.1-0.4% enzyme preparation with the function of degration albumen, a microbe preparation with the fermentation function and microbe fermentation base materials in the device to be mixed and fermented in seal, 3, filtering said fermentation liquid and separating solid and solution to be dried to get the product. A device is disclosed including a shell, a cover on the top of the shell, a mixing rod with mixing blades is set in the shell and one end of the rod extends outside of the rod through the cover, an outlet is set at the bottom and a valve is set at the outlet.

Owner:YUHUAN MARINE BIOCHEM

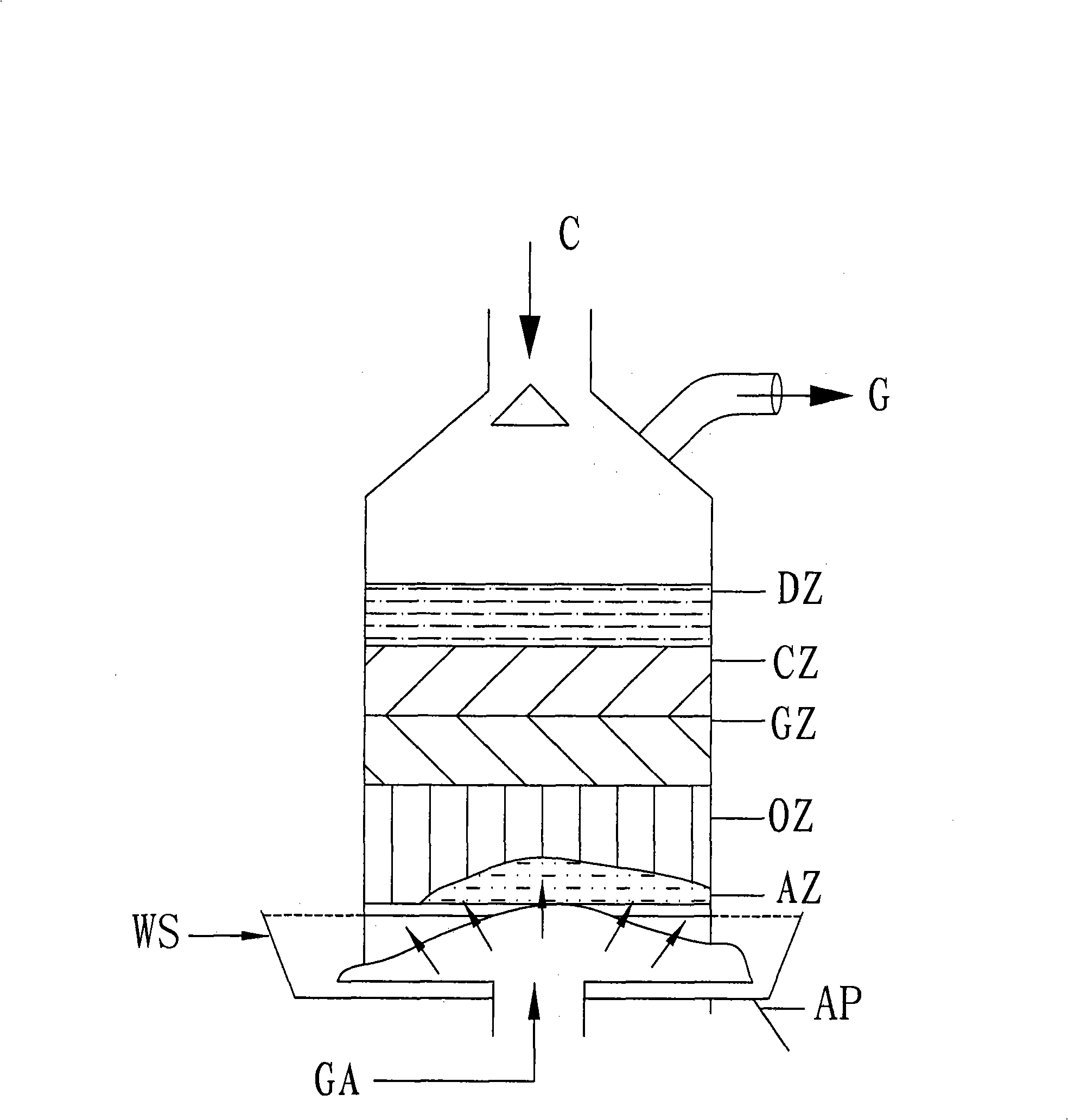

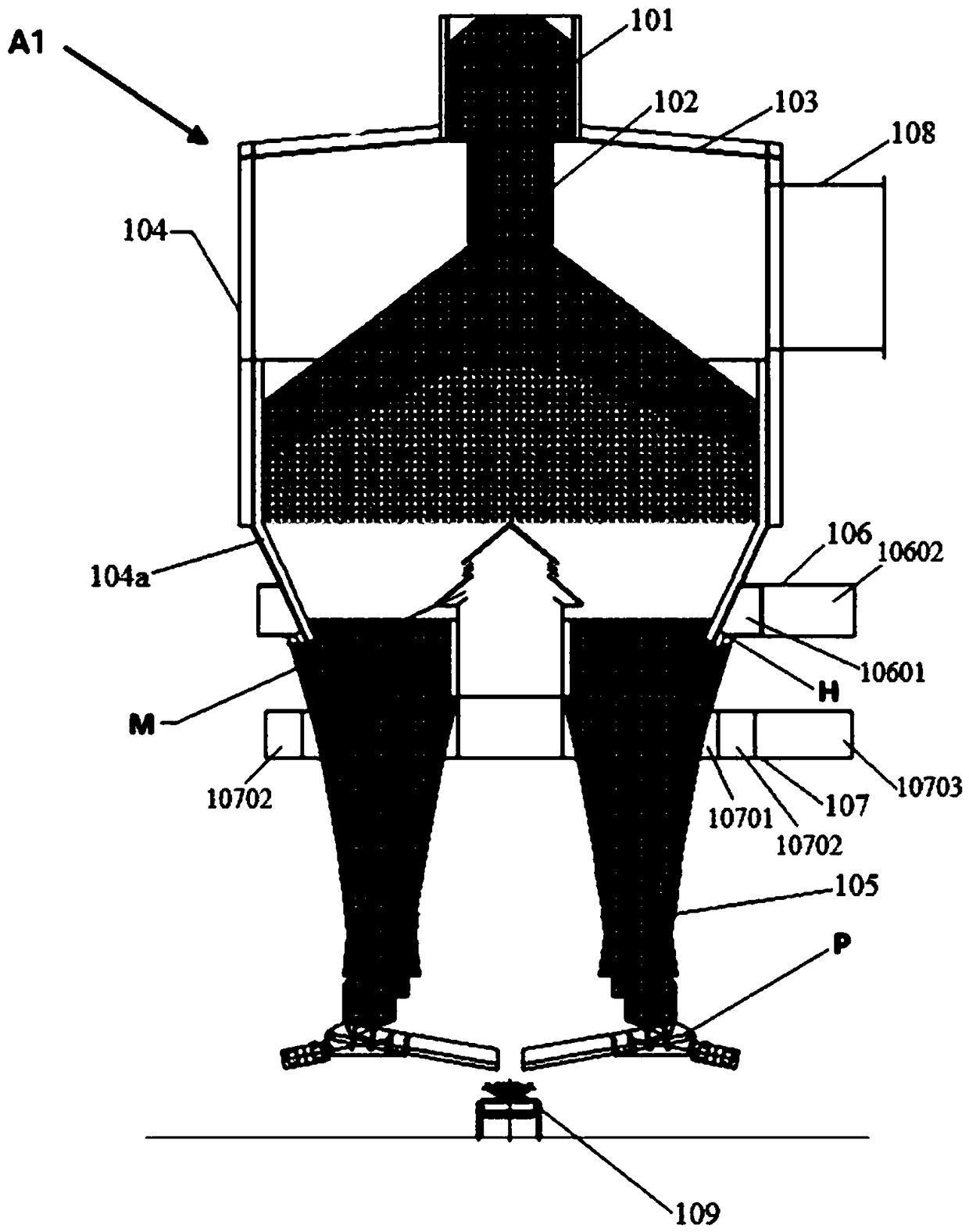

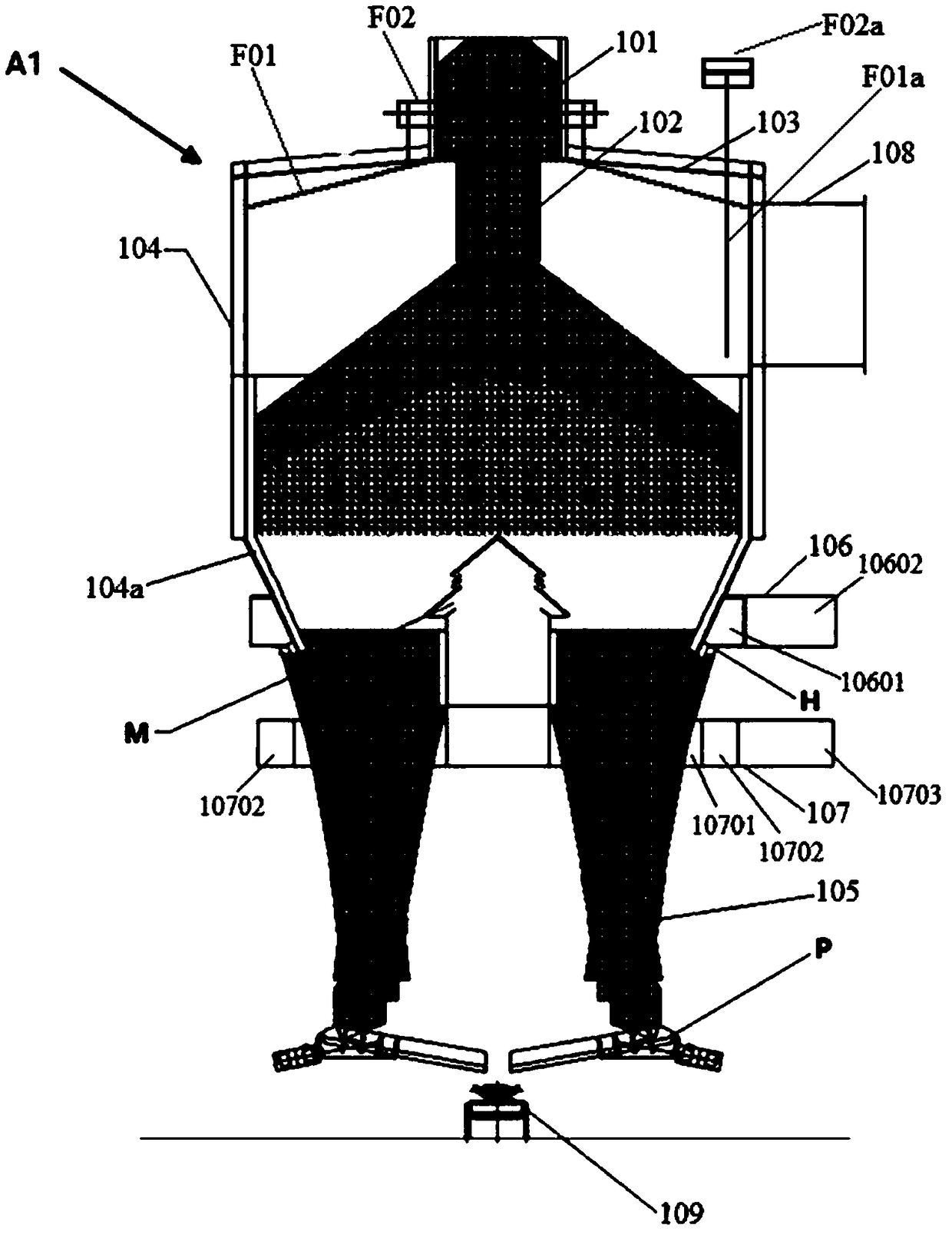

Method and apparatus for combustion replacing oil with coal

InactiveCN101324331ANo emission issuesImprove reliabilityFluidized bed combustionEnergy inputCombustionProcess engineering

The invention provides a burning method using coal as substitute of oil, which comprises following steps: coal gasification, coal gas burning, and optional coal gas purification, gas waste heat utilization and gas emission. The invention also provides burning equipment using coal as substitute of oil. The burning equipment can reduce the fuel cost by about 4 / 5, and can save petroleum and natural gas resources. Additionally, the burning method and the equipment have the advantages of good reliability, high heat efficiency, high automation level, high return on investment and good environmental benefit.

Owner:黄钟成 +2

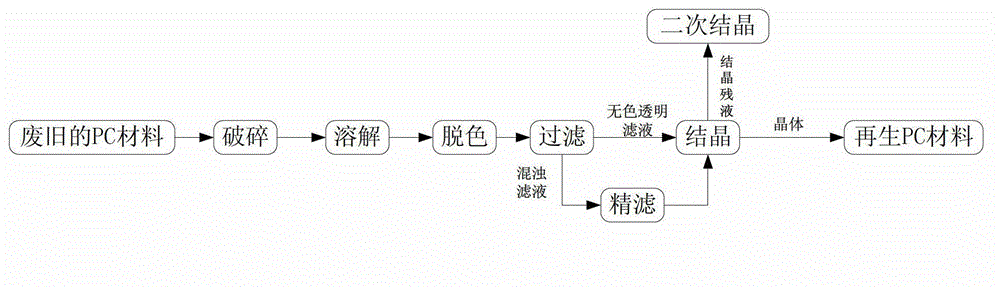

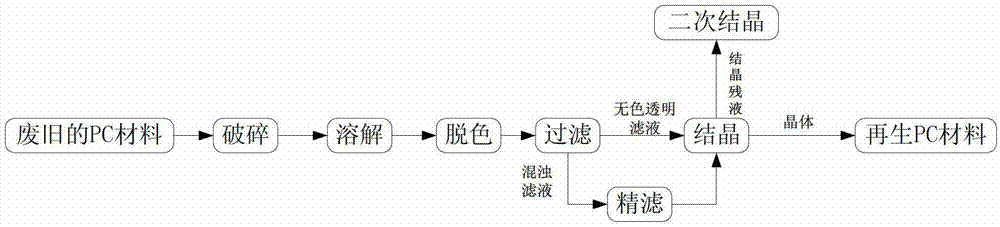

Process for recovering waste polycarbonate (PC) material

ActiveCN102911397ASolve control technologySolving Crystallization TechnologyPlastic recyclingPolyesterOrganic solvent

The invention discloses a process for recovering a waste polycarbonate (PC) material. The process is characterized by comprising the following steps of: crushing the waste PC material, dissolving the crushed PC material ion into an organic solvent to form a homogeneous solution; and adding an adsorbent into the homogeneous solution, discoloring and removing insoluble substances, and sequentially filtering and crystallizing to obtain the required crystallized PC material. According to the process for recovering the waste PC material, the recycled polyester intrinsic viscosity control technology, the crystallization technology and the impurity removal technology are realized, water is not required to be added in the whole process, the wastewater discharge is avoided, and the environmental pollution is reduced. The intrinsic viscosity of the recycled PC product reaches 0.77dL / g, the purity is 99.5 percent, and the recovered material reaches a novel level.

Owner:SHUYE ENVIRONMENTAL TECH CO LTD

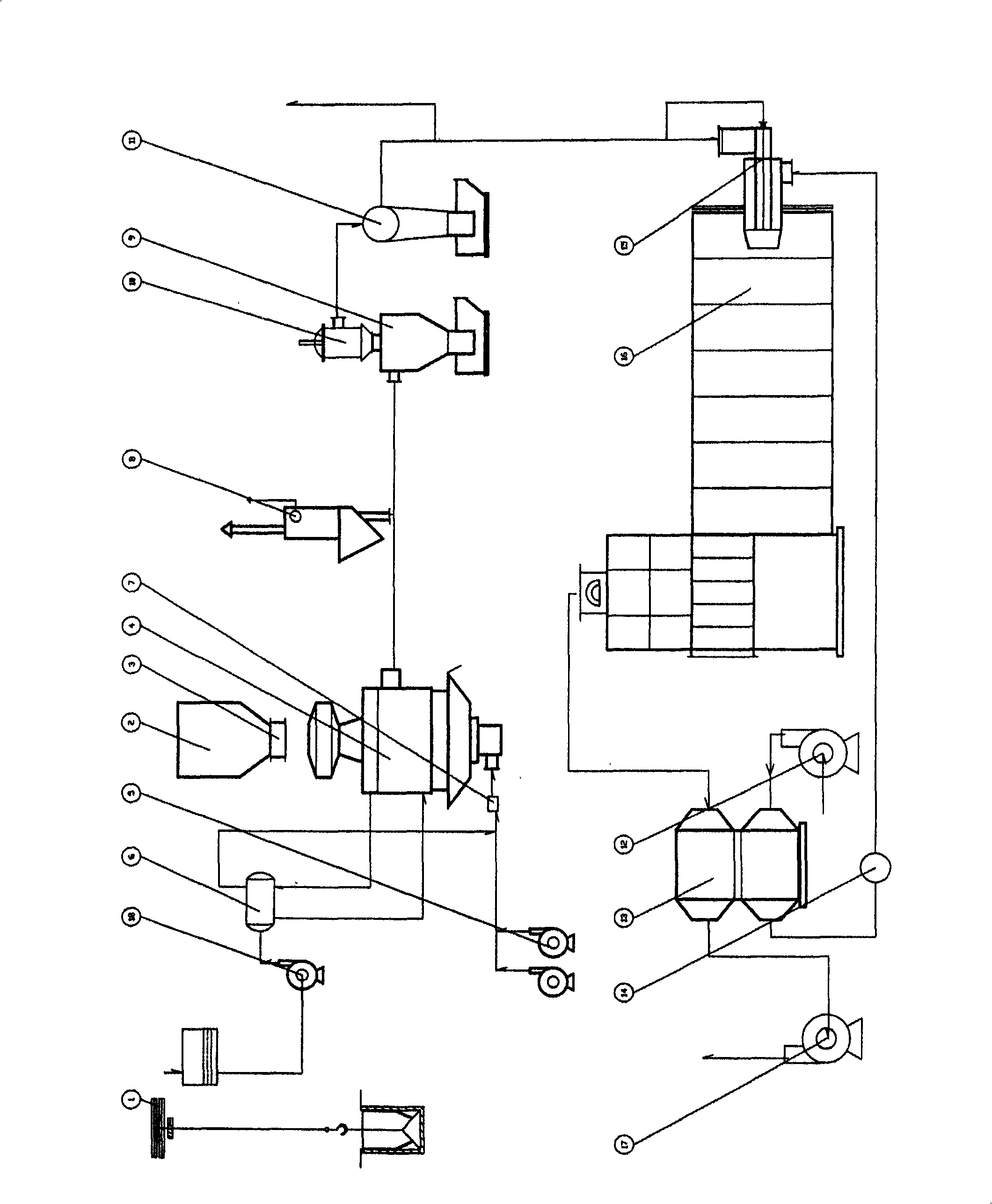

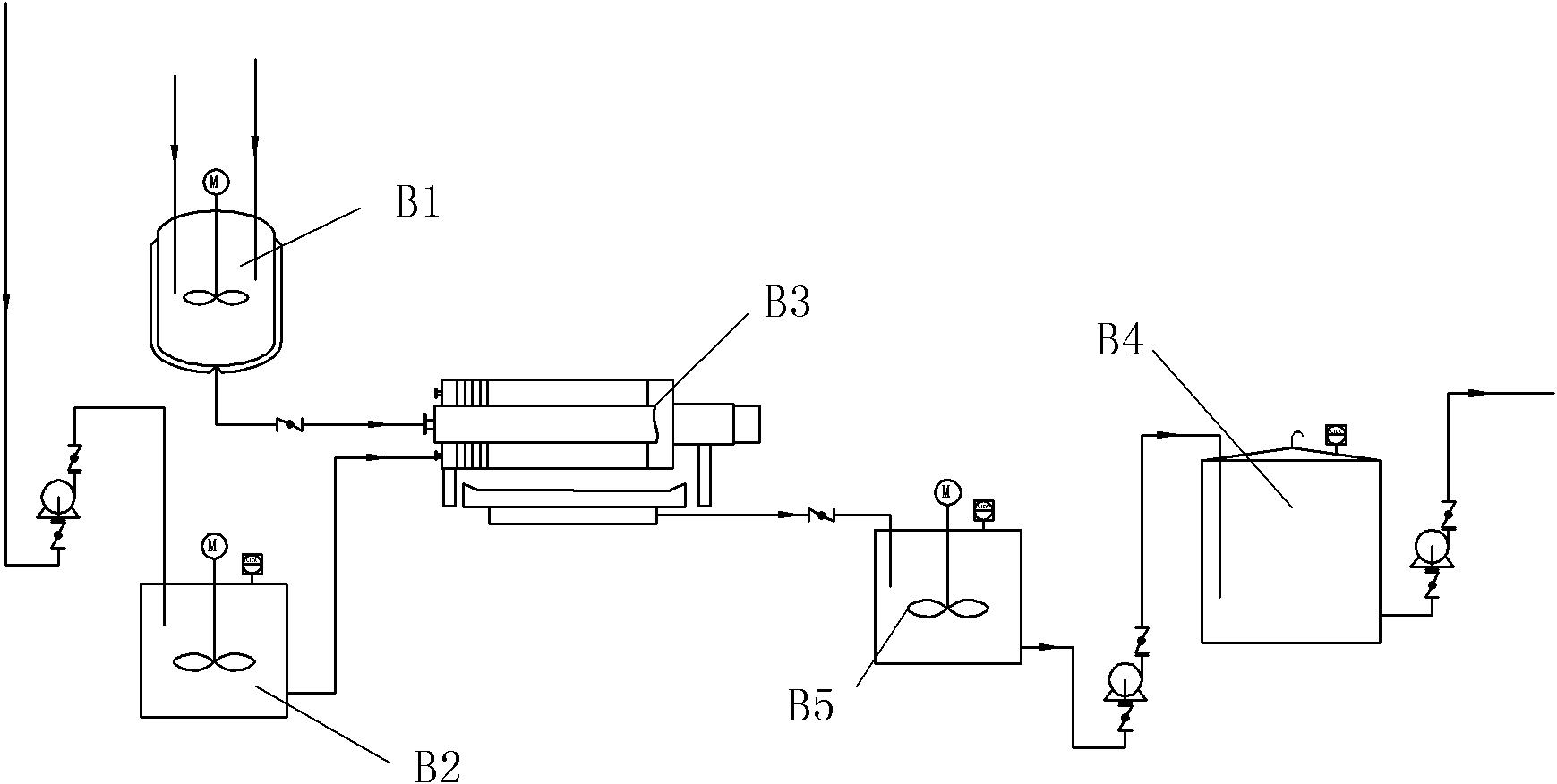

System for industrial waste gas treatment and salt regeneration

InactiveCN101862586AEasy to collectNo emission issuesChlorine/hydrogen-chlorideChloride preparationImpurityToxic industrial waste

The invention relates to a system for industrial waste gas treatment and salt regeneration, which comprises a waste gas treatment device, a neutralization deslagging device, a salt liquid concentration device, a main water supply pipe, an alkali liquid feeding tank and a hydrochloric acid storage tank, wherein the waste gas treatment device is provided with absorption towers No.1-No.5, a gas-liquid separator, a blender, an acid liquid clarifying tank and an alkali liquid transit tank; the neutralization deslagging device is provided with a neutralization mixing kettle, an impurity elimination tank, a filter press and a salt liquid transit tank; and the salt liquid concentration device is provided with a preheater, a heater, an evaporator, a crystallizer, a salt liquid mixing tank, a centrifuge, a condenser and a condensing water tank. The system can effectively treat industrial waste gas containing chlorine gas and hydrogen chloride gas. Since products are reclaimed from waste liquid, the added value of the system is improved, and simultaneously, problems on sewage discharge do not exist.

Owner:WUJIN COUNTY ANTISEPTIC EQUIP FACTORY

Graphene water-borne electrothermal film coating and preparation method thereof

InactiveCN107779085AImprove conductivitySmall impact on structureFireproof paintsAnti-corrosive paintsSulfateWhiskers

The invention relates to the field of novel electrothermal mateirals, and specifically relates to a graphene water-borne electrothermal film coating and a preparation method thereof. The coating comprises the following components: 40-60wt% of water-borne resin, 3-15wt% of nano graphene, 0.5-2.5wt% of mixture of calcium sulfate whisker and hydrogenated castor oil, 0.5-1.5wt% of polyaniline, 0.5-1.5wt% of polythiophene, 0.5-1.5wt% of a flatting agent, 0.5-1.5wt% of a defoaming agent, and 30-40wt% of water, totalling 100%. According to the coating, the mixture of calcium sulfate whisker and hydrogenated castor oil is added, so that the nano graphene can be prevented from agglomeration in the solution, and moreover, the defects of poor lapping of graphene laminates and incomplete power conducting and heat transferring network can be avoided, and as a result, the power conducting performance and the heating performance of the product can be improved.

Owner:厦门信果石墨烯科技有限公司

Carbonate-type collecting agent reverse flotation drug and preparation method thereof

ActiveCN104998761ANo emission issuesThere is no problem with the use of cooking oilFlotationAlcoholFoaming agent

The invention relates to a carbonate-type collecting agent reverse flotation drug and a preparation method thereof. The preparation method comprises the following steps: (1) taking low erucic acid rapeseed oil alkali refining and deacidification niger and short carbon chain fatty acids (6-14 carbon) as collecting agent raw materials; (2) taking mixed alcohols and 1,1,3-triethyl orthobutyrate as foaming agents; (3) mixing the collecting agent raw materials with excessive amounts of alkalies and a certain amount of water, reacting for 1.5 h in a reaction kettle at 80-100 DEG C, reducing the temperature of a reaction liquid to be 40-70 DEG C, adding the foaming agents, and continuously stirring for 30 min, so as to obtain the finished product, namely the collophanite reverse flotation drug, wherein the mass ratio of the collecting agents to the foaming agents in the finished product, namely the reverse flotation drug, is (7-9):1. The carbonate-type collecting agent reverse flotation drug and the preparation method have the advantages that the flotation performance of the low erucic acid rapeseed oil alkali refining and deacidification niger and the short carbon chain fatty acids in the carbonate-type collophanite reverse flotation operation can be improved remarkably, the flotation recovery rate and the concentrate grade are improved remarkably, and low-cost industrial greasy leftovers are sufficiently utilized.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

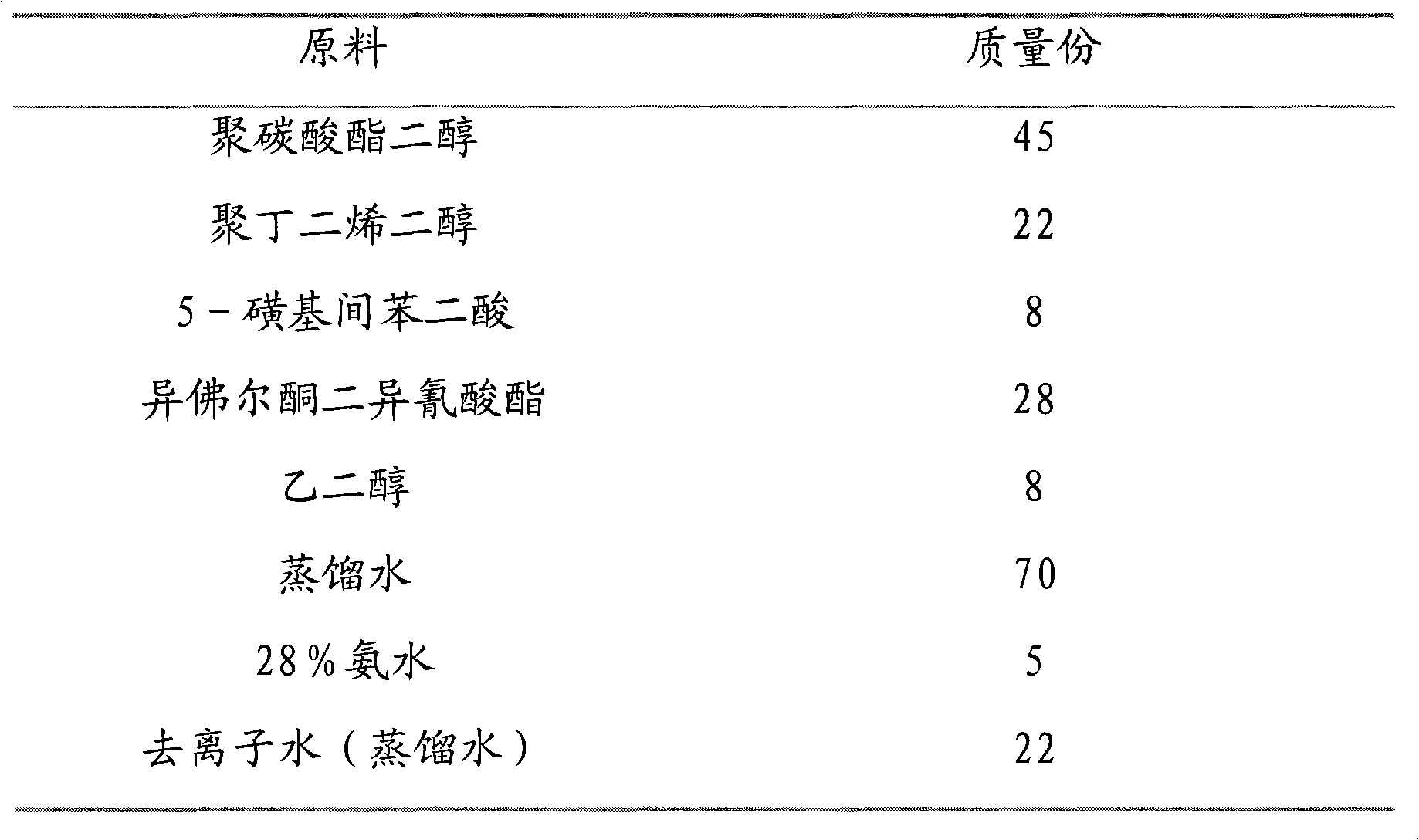

Water-resistant waterborne polyurethane ink vehicle and preparation method thereof

The invention discloses a water-resistant waterborne polyurethane ink vehicle and a preparation method thereof. The main components of the ink vehicle are bacterial cellulose after modification treatment by a silane coupling agent and waterborne polyurethane prepolymer, wherein the length of the bacterial cellulose is 200-500nm, and the diameter is 60-100nm. The preparation method comprises the following steps: hydrolysis of the silane coupling agent, modification of the bacterial cellulose, synthesis of the waterborne polyurethane prepolymer, synthesis of a waterborne polyurethane emulsion and preparation of the water-resistant waterborne polyurethane ink vehicle. According to the water-resistant waterborne polyurethane ink vehicle disclosed by the invention, the 24h water absorption is lower than 8.0%; and the preparation method is simple and conforms to the requirement of environmental protection for sustainable development.

Owner:禾瑞(漳州)助剂有限公司

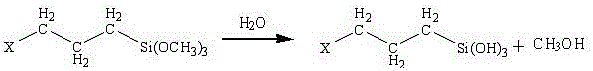

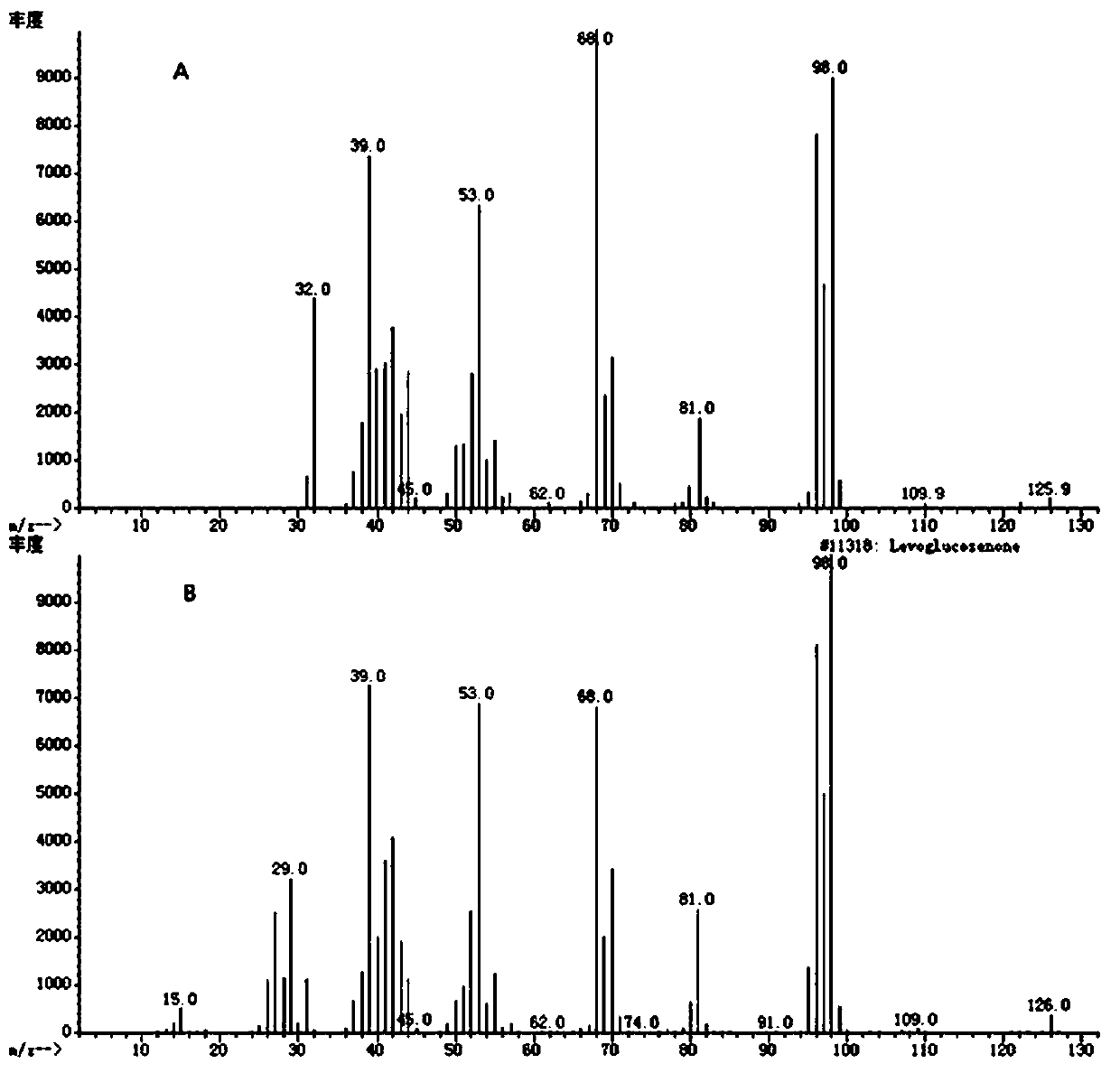

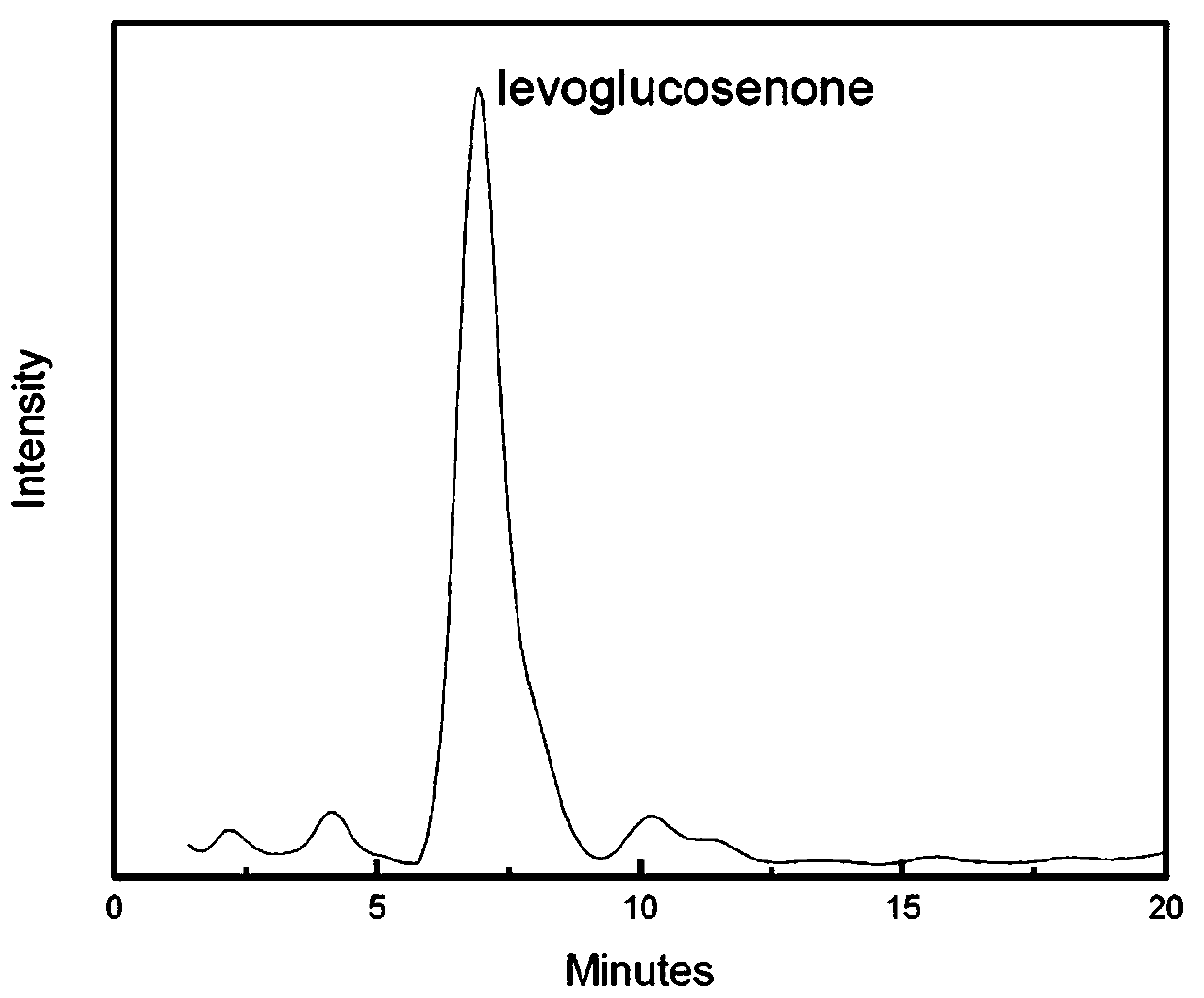

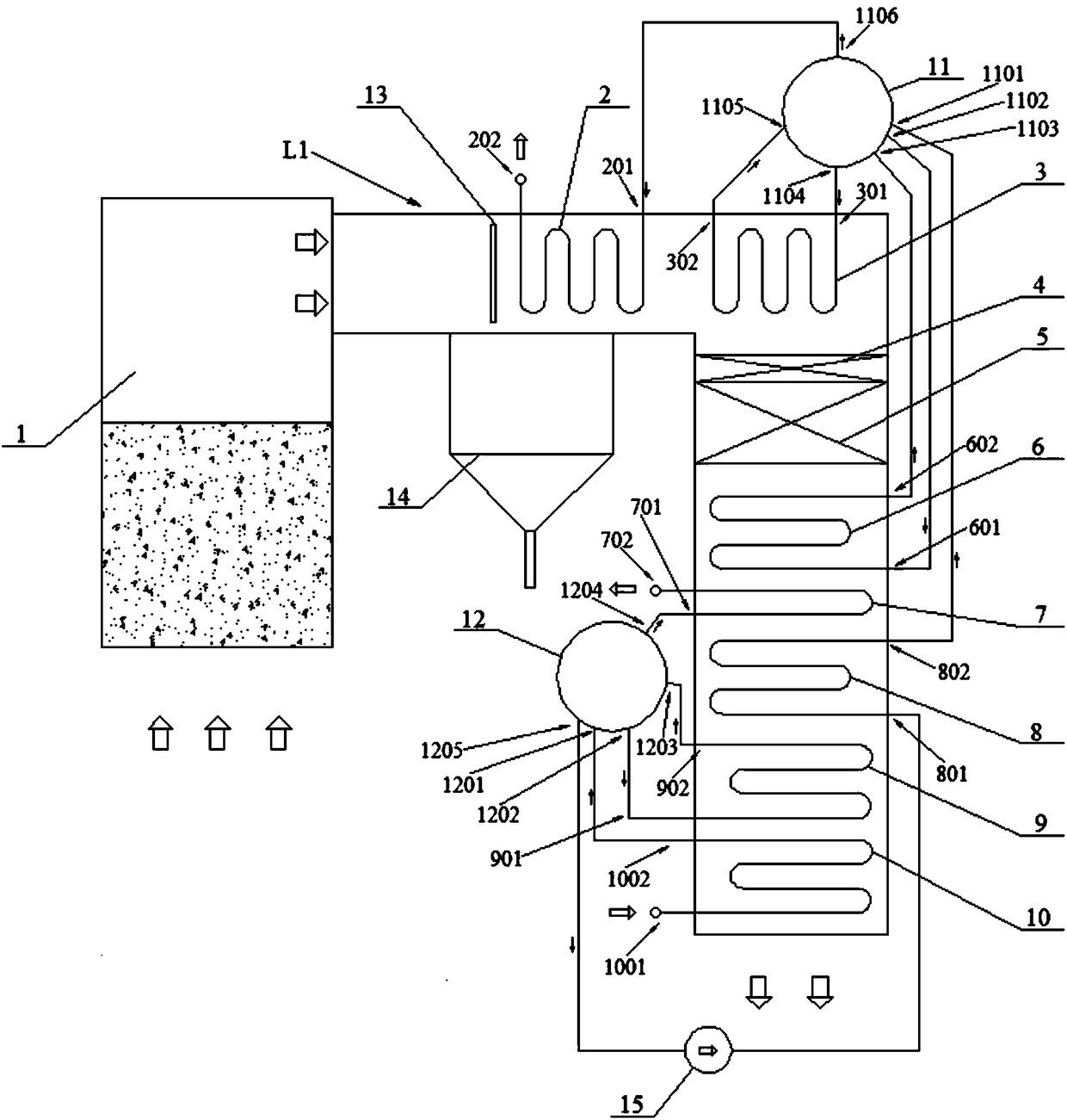

A kind of preparation method of L-glucosone

InactiveCN106977557BNo emission issuesNo emissionsSugar derivativesOrganic chemistry methodsCellulosePotassium hydroxide

The invention discloses a preparation method of levoglucosenone. The preparation method comprises the following steps of firstly, dissolving phosphoric acid in water to form a phosphoric acid solution; adding cellulose or cellulose-contained biomass, mixing and soaking; filtering the soaked cellulose or cellulose-contained biomass, pressing and extruding or centrifuging, and performing pyrolysis pretreatment on the treated matter, so as to obtain a dewatered intermediate product; cooling the obtained dewatered intermediate product to room temperature, cooling, putting into a sodium hydroxide or potassium hydroxide water solution, and fully mixing and soaking; filtering the mixed and soaked product, pressing and extruding or centrifuging, performing non-oxygen pyrolysis on the treated product, and collecting condensate in the pyrolysis process, so as to obtain a pyrolysate containing the levoglucosenone. The preparation method of the levoglucosenone has the advantages that by adopting two-step reaction, the yield rate is greatly increased and reaches about 40%; compared with the prior art, the cost is greatly reduced; by adopting the technical scheme, the large application prospect is realized.

Owner:HENAN UNIV OF URBAN CONSTR

Soil conditioning agent and preparation method thereof

ActiveCN106398698ASimple production processIncrease productionAgriculture tools and machinesOrganic fertilisersChemical structurePolyaspartic acid

The invention discloses a soil conditioning agent and a preparation method thereof. The soil conditioning agent comprises the following main components in percentage by weight: 90 to 96% of polyacrylamide (PAM), 1 to 3% of water soluble organic carbon (SOC), 2 to 4% of polyaspartic acid, and 1 to 3% of polyglutamic acid; the polyacrylamide (PAM) is water-in-water type anionic polyacrylamide emulsion, the molecular weight of PAM is 10,000,000 to 20,000,000, the solid content is 35 to 45%; and the water soluble organic carbon (SOC) is prepared from residues of plants. The provided soil conditioning agent can improve the physical and chemical structure of soil, increase the content of aggregates and organic matters in the soil, and enhance the water and fertilizer retaining performance of soil. Moreover, the preparation technology is simple, the production cost is low, the dissolution speed is quick, and the soil conditioning agent can be evenly applied.

Owner:上海永通生态工程股份有限公司

Metal stearate preparation method

InactiveCN103880639ANo emission issuesGood colorOrganic compound preparationChemical industryDecompositionStearic acid

The invention discloses a metal stearate preparation method. The method comprises the following steps: stirring stearic acid, sodium hydroxide, calcium carbonate and medium water at a temperature below the melting point of stearic acid under normal pressure for mixing, heating to a temperature 60-70DEG C higher than the melting point of stearic acid in order to carry out a reaction, carrying out dehydration drying on the above obtained product, dispersing, and drying to metal stearate. The preparation method has the following advantages: 1, the reaction is carried out in the water medium with a low temperature under normal pressure, so a simple routine double decomposition process production apparatus can be used, and the color of the finally obtained product is excellent; and 2, no byproducts are generated in the reaction, and no additives are used in the reaction, so the purity of the product is high, a wastewater emission problem does not exist, and the medium water and waste heat can be recovered and reused.

Owner:QINGDAO SHUAIWANG OIL CHEM

Method for dyeing leather

The invention provides a method for dyeing leather. The method comprises the following steps: in the effects of a coloring agent, leather is dyed by rollers, and the dyed leather is obtained. Roller dying technology replaces the traditional rotary drum dyeing technology, leather needs not to be completely immersed in dyeing bath liquid for dyeing, so that dyeing bath liquid is not needed, dying paste materials can be completely absorbed and combined by the leather, and no waste liquid is discharged; at the same time dyeing period is substantially reduced, dyeing time is short, and the production efficiency is high.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE CO LTD

Production method of organic liquid fertilizer

InactiveCN110590450AHigh in nutrientsEasy to measureAmmonium salt fertilisersFertilizer mixturesEnvironmental resistanceMicrobial agent

The invention provides a production method of an organic liquid fertilizer. The production method comprises the following steps: uniformly stirring 100-150 parts of excrement, 50-80 parts of straw, 30-50 parts of aquatic plants, 100-200 parts of biogas slurry and 0.5-2 parts of a microbial agent, performing composting fermentation for 20-30 days at room temperature so as to obtain a fermentation material, performing stirring extraction by using a sodium carbonate aqueous solution at 80-90 DEG C, performing filtering, performing evaporation concentration on the obtained filtrate till the density is 1.1-1.3 so as to obtain an extract, adding 0.1-0.2 part of a trace element, 5-10 parts of natural active organic matter, 1-5 parts of a natural surfactant and 0.5-2 parts of a soil improver, anduniformly mixing the components at the temperature of 45-60 DEG C, so as to obtain the organic liquid fertilizer. The fertilizer prepared by using the method has a good use effect and is an efficientenvironment-friendly organic liquid fertilizer.

Owner:GUIZHOU STANLEY FERTILIZER

Integrated device and method for denitration and dioxin removal of sintering flue gas and utilization of waste heat

InactiveCN108088270ALow costImprove waste heat utilizationIncreasing energy efficiencyWaste heat treatmentFlue gasSuperheater

The invention provides an integrated device and method for denitration and dioxin removal of sintering flue gas and utilization of waste heat. The device comprises a sinter cooling machine and a fluegas pipeline which communicates with the sinter cooling machine; the flue gas pipeline is provided with a high-parameter superheater, a first high-parameter evaporator, an ammonia injection grid, an SCR reactor, a second high-parameter evaporator, a low-parameter superheater, a high-parameter coal economizer, a low-parameter evaporator and a low-parameter coal economizer in the flue gas flow direction in sequence; and the device further comprises a high-parameter boiler barrel and a low-parameter boiler barrel which are arranged on the side of the flue gas pipeline. According to the integrateddevice provided by the invention, sintering untreated gas enters a denitration system after passing through the sinter cooling machine and sinter for heat exchange, and NOx-containing flue gas does not need to be additionally heated; the cost for dioxin removal by SCR denitration is reduced, and meanwhile the utilization rate of the waste heat of the sinter is improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

Method for producing seaweed liquid fertilizer specifically for rhizoma gastrodiae

InactiveCN106854112ADoes not affect listing and salesNo pollutionAmmonium salt fertilisersOrganic fertilisersFiltrationEvaporation

The invention provides a method for producing seaweed liquid fertilizer specifically for rhizoma gastrodiae. The method comprises uniformly mixing 100-150 parts of seaweed extract, 0.1 to 0.5 parts of trace elements, 1 to 5 parts of botanical pesticide extract, 5 to 10 parts of a natural active organic matter, 1 to 5 parts of a natural surfactant and 1 to 5 parts of a soil improver. A preparation method of the seaweed extract comprises uniformly stirring 100 to 150 parts of natural seaweed powder, 100 to 200 parts of washing water of rice, 0.1 to 2.0 parts of an EM bacterial fermentation solution and 0.1 to 2.0 parts of sugar, carrying out composting fermentation at the room temperature to obtain a fermented seaweed material, stirring the fermented seaweed material and a sodium carbonate aqueous solution, carrying out extraction, carrying out filtration to obtain a filtrate, and carrying out evaporation concentration until density of 1.2-1.3 to obtain seaweed extract. The seaweed liquid fertilizer has good use effects and is highly effective and eco-friendly seaweed liquid fertilizer.

Owner:GUIZHOU UNIV

Production method of seaweed liquid fertilizer special for pseudostellaria heterophylla

InactiveCN106748157ADoes not affect listing and salesNo pollution in the processAmmonium salt fertilisersOrganic fertilisersPseudostellariaEffective microorganism

The invention provides a production method of a seaweed liquid fertilizer special for pseudostellaria heterophylla. According to the method, the seaweed liquid fertilizer is prepared by uniformly mixing 100 to 150 parts of seaweed extracting liquid, 0.1 to 0.5 part of microelements, 1 to 10 parts of botanical pesticide extracting liquid, 1 to 5 parts of natural active organic matters, 1 to 2 parts of natural surfactants and 1 to 2 parts of soil improvement agents, wherein a preparation method of the seaweed extracting liquid comprises the steps that 100 to 150 parts of natural seaweed powder, 100 to 200 parts of rice washing water, 0.1 to 2.0 parts of EM (effective microorganism) flora fermentation liquid and 0.1 to 2.0 parts of sugar are uniformly stirred and are then subjected to composting fermentation at room temperature to obtain a fermented seaweed material; a sodium carbonate water solution is used for stirring and extraction; filtering is performed; the obtained filter liquor is evaporated and concentrated to reach the density being 1.2 to 1.3; the seaweed extracting liquid is obtained. The use effect is good; the seaweed liquid fertilizer belongs to an efficient and environment-friendly seaweed liquid fertilizer.

Owner:GUIZHOU UNIV

Environment-friendly method for improving fire resistance of cotton fabric

InactiveCN104532563AImprove flame retardant performanceNo emission issuesVegetal fibresWastewaterEngineering

The invention discloses an environment-friendly method for improving fire resistance of cotton fabric. The method comprises the following steps: selecting a flame-retardant reagent, and preparing a finishing liquid with certain concentration, wherein the formula of the finishing liquid comprises 5-400g / L of a polyphosphazene fire retardant and 0-20g / L of a super softening agent; transferring the fishing liquid into a spraying device, and evenly spraying on the cotton fabric, wherein the amount of the finishing liquid is 1%-30% of mass of the fabric; and putting the cotton fabric into a constant-temperature and constant-humidity room for 5-120 minutes, drying, roasting and then testing. The cotton fabric is processed by a spraying life-nourishing method. Compared with a traditional impregnating or padding operation method, the amount of the finishing liquid can be greatly reduced; the cost is reduced; emission of wastewater is reduced; the fire resistance of the finished cotton fabric is improved; and the fire retardant adopted by the technique is a halogen-free reagent, so that the cotton fabric is ecological, environmentally friendly, free of pollution to environment, low in price, simple in process and convenient to operate.

Owner:HENAN INST OF ENG

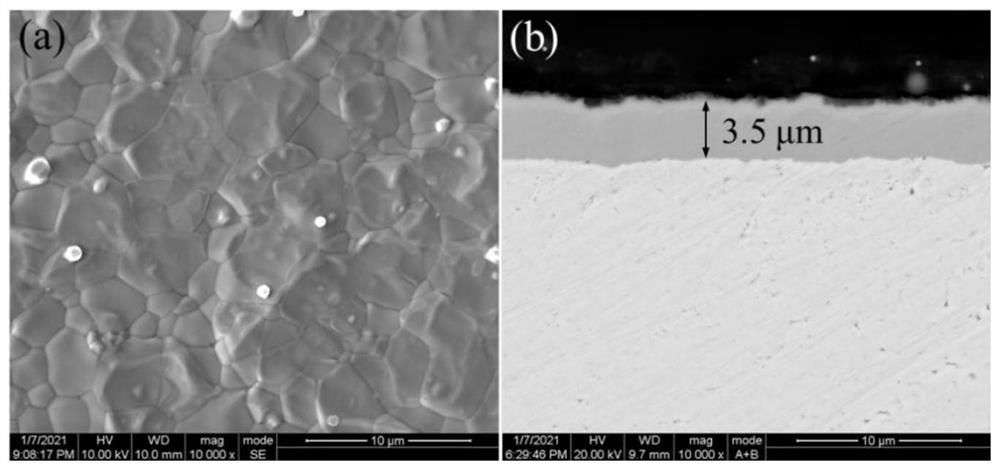

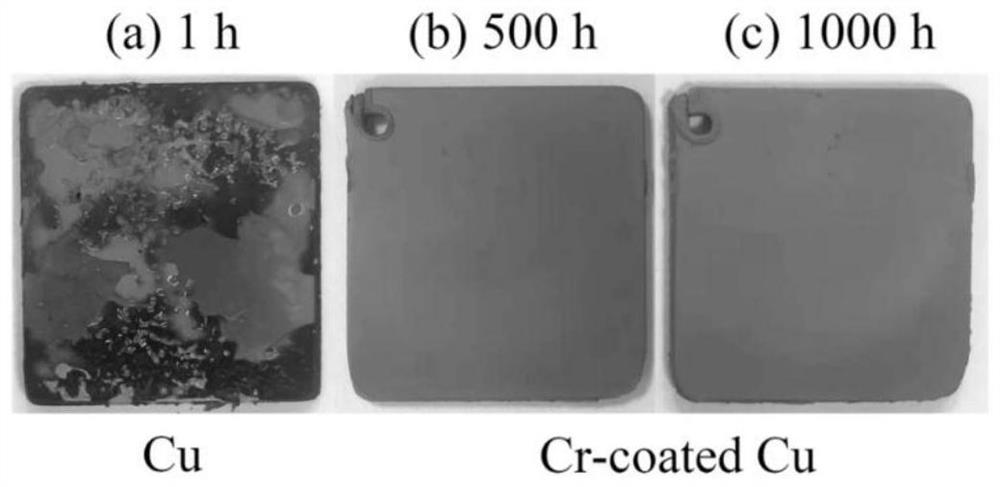

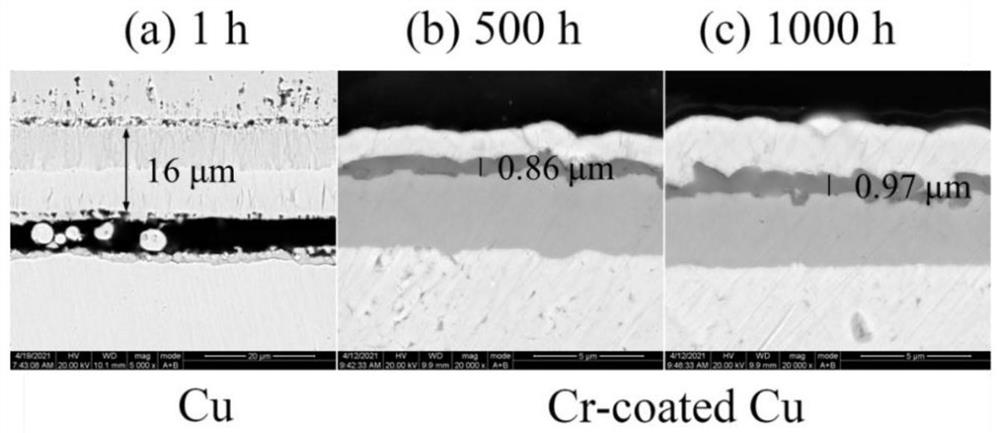

Low-mutual-diffusion and high-temperature-oxidation-resistant coating for copper conductor and preparation method thereof

PendingCN114231914ASolve serious oxidation problemsSolve the problem of reduced electrical conductivityVacuum evaporation coatingSputtering coatingCopper conductorCopper wire

A low-interdiffusion and high-temperature-oxidation-resistant coating for a copper conductor is characterized in that the chemical component of the low-interdiffusion and high-temperature-oxidation-resistant coating for the copper conductor is pure chromium or chromium alloy with the chromium atom percentage not lower than 95%, and the organization structure of the low-interdiffusion and high-temperature-oxidation-resistant coating is a single-layer or multi-layer fine grain organization with single preferred orientation. The preparation method of the low-mutual-diffusion high-temperature-oxidation-resistant coating for the copper conductor is carried out in vacuum, and the coating is deposited on the surface of a part through a chromium ion flow bombardment method with the density not lower than 4.6 * 10 < 20 > m <-2 > s <-1 > and the charge energy ranging from 90 eV to 900 eV. The method has the advantages that the problem of serious oxidation of the copper conductor during high-temperature application is solved, and the problem that the conductivity is reduced due to coating / matrix mutual diffusion when other high-temperature protective coatings are applied to the copper conductor is solved. Various chromium-based coatings can be efficiently prepared, the technological process is green and free of pollution, and the method is suitable for coating preparation of various copper conductor products such as blocky parts and copper wires.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

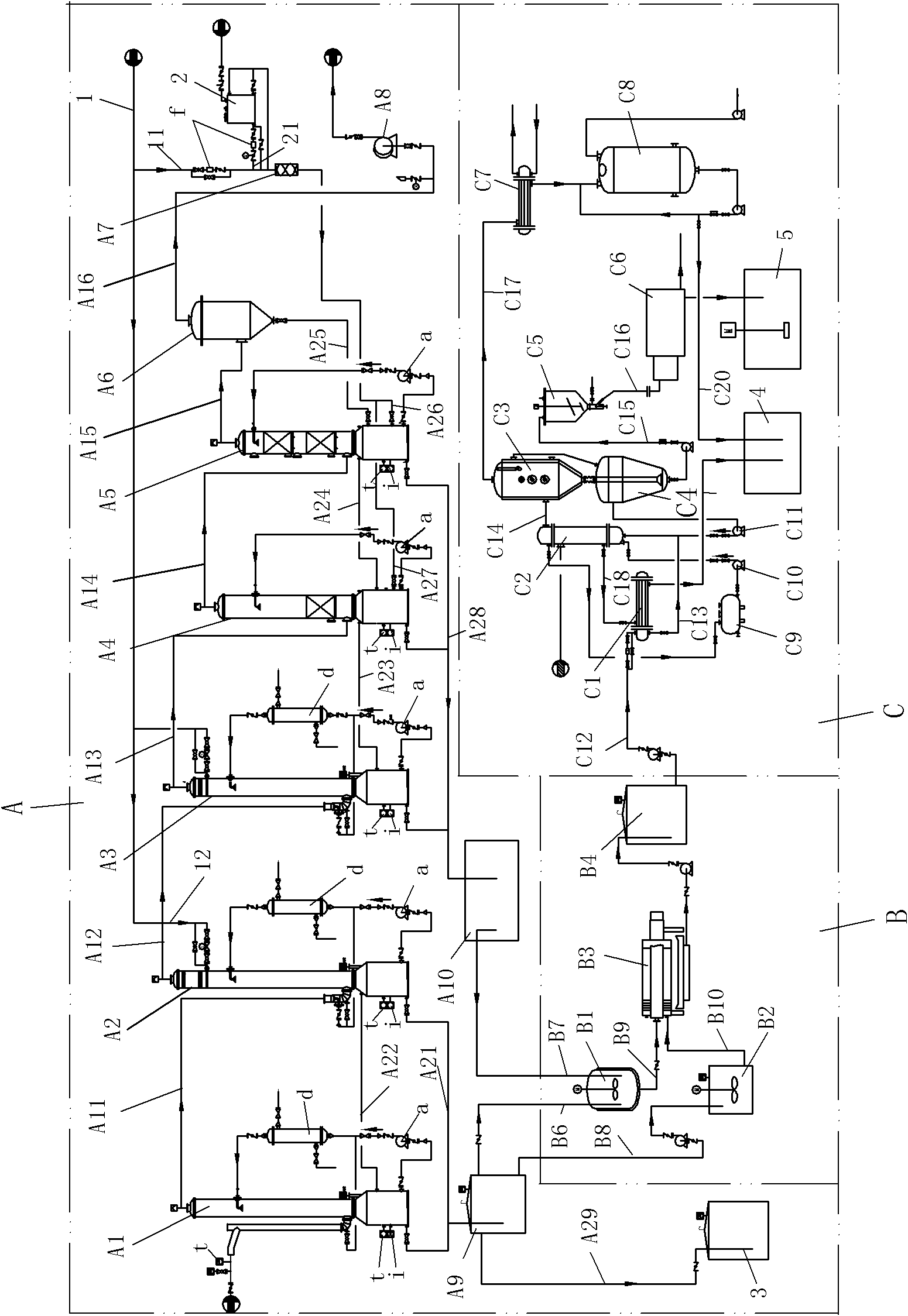

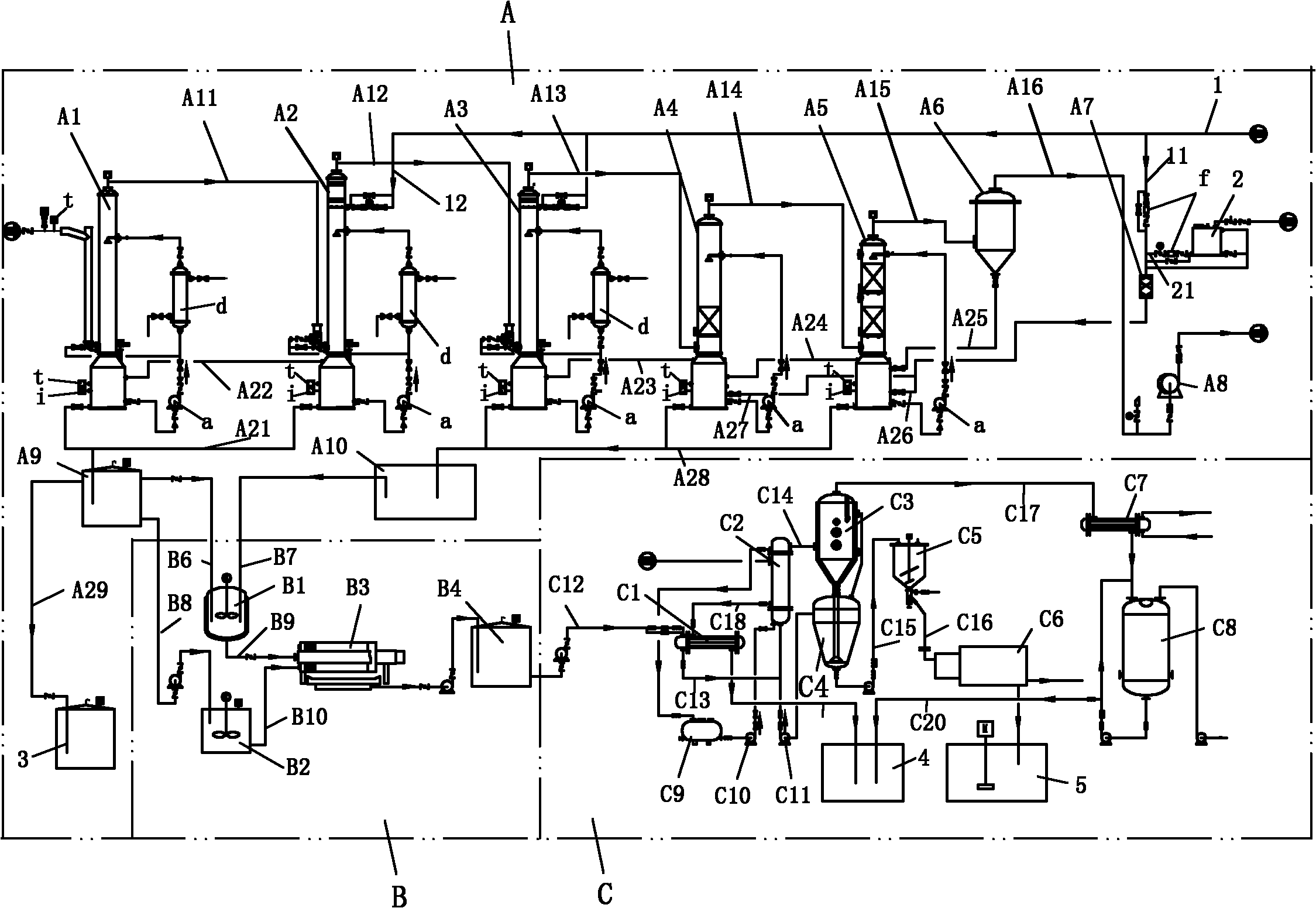

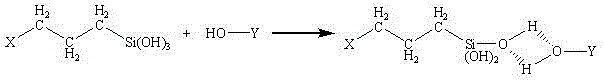

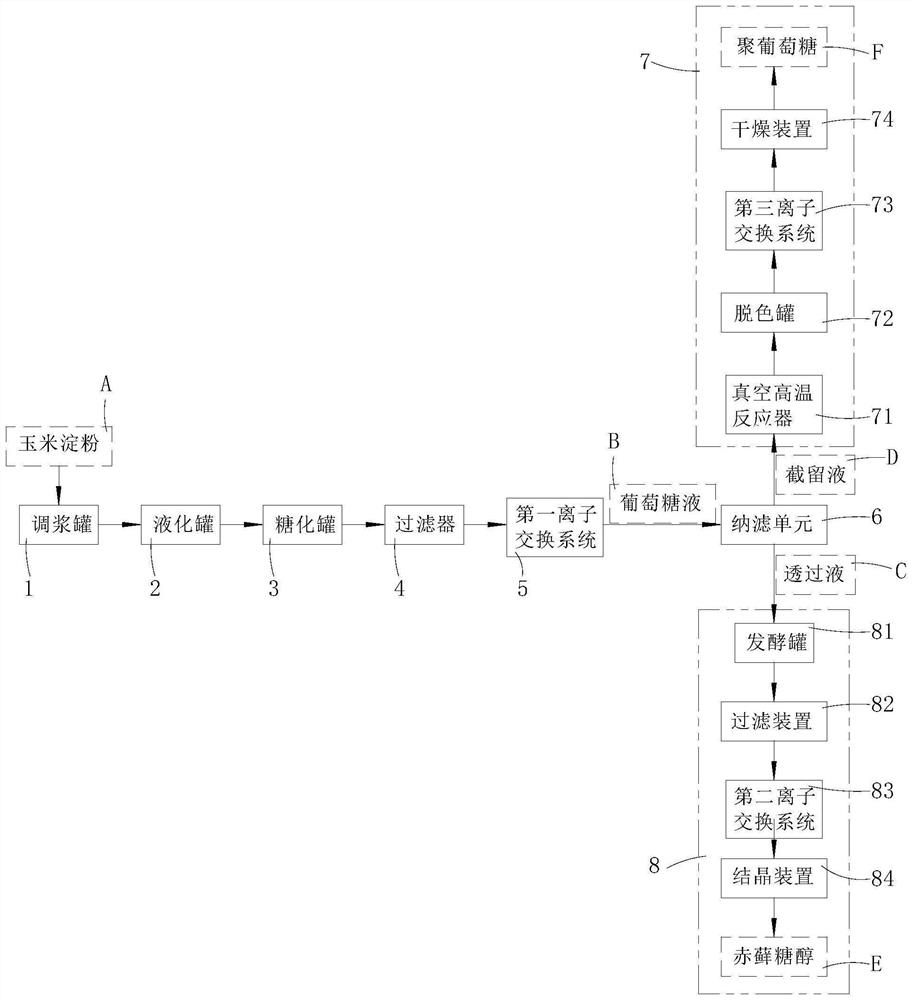

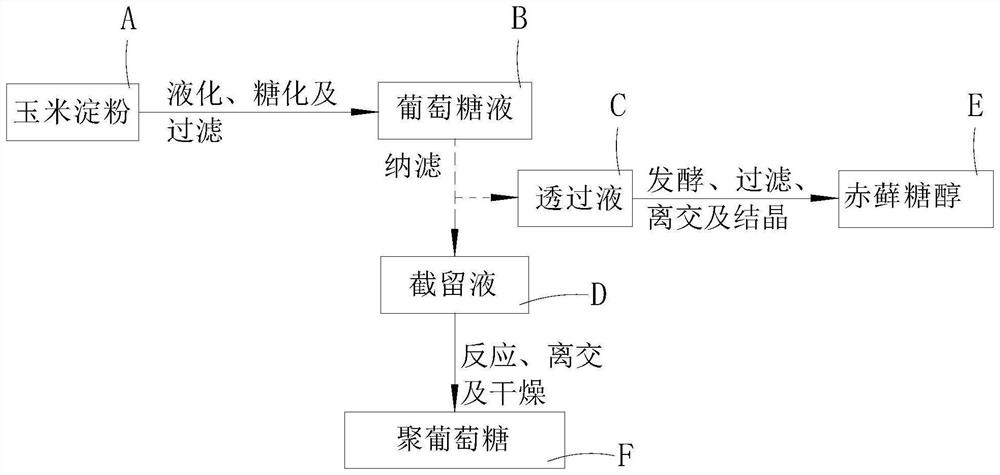

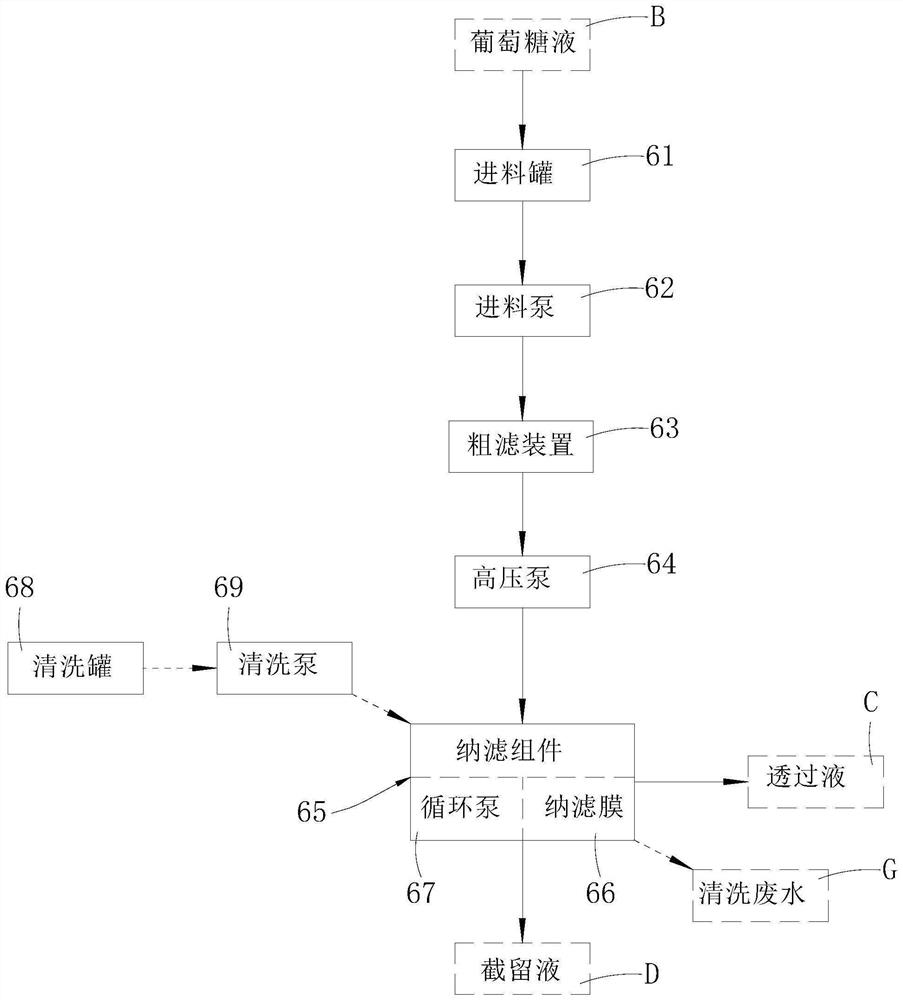

System and method for preparing erythritol and polydextrose from corn starch

PendingCN114107041ANo emission issuesReduce processing costsBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyChaptalization

The invention relates to a system and a method for preparing erythritol and polydextrose from corn starch. The system comprises a size mixing tank, a liquefying tank, a saccharifying tank, a filter, a first ion exchange system, a nanofiltration unit, a high-temperature polycondensation unit and a fermentation and crystallization unit. Corn starch is used as a raw material, glucose liquid is obtained after liquefaction and saccharification treatment, permeate containing high-concentration glucose and trapped fluid containing low-concentration glucose are obtained after treatment of a nanofiltration unit, the high-purity glucose liquid is used for preparing erythritol through fermentation, and the low-purity glucose liquid is used for preparing polydextrose. According to the method, two high-value products, namely erythritol and polydextrose, can be prepared at the same time, meanwhile, the problem of mother liquor discharge does not exist, the mother liquor treatment cost is reduced, and high-value utilization of low-purity glucose liquid is achieved to the maximum extent.

Owner:ZHEJIANG HUAKANG PHARMA

Multifunctional metal surface composite treatment agent and preparation method and use method thereof

ActiveCN106048622AReduce labor costsReduce equipment costsMetallic material coating processesSodium phosphatesNuclear chemistry

The invention provides a multifunctional metal surface composite treatment agent and a preparation method and a use method thereof. The multifunctional metal surface composite treatment agent comprises the following ingredients: water, manganese phosphate, magnesium chloride, sodium chloride, sodium alkyl benzene sulfonate, sodium tripolyphosphate, vegetable tannin, ethylene glycol, hydroxy acid, tartaric acid, methyl acid, polybrominated biphenyls, polybrominated diphenyl ethers, veratrole, sodium phosphate and peregal. Traditional metal surface treatment needs to adopt such processes as deoiling, dedusting and passivating, however, by use of the multifunctional metal surface composite treatment agent, only one process is needed, that is, effects of the multiple processes of the traditional metal surface treatment method can be achieved so long as metal to be treated is immersed into a soaking pool in which the multifunctional metal surface composite treatment agent is placed to be soaked for a period of time, so that the manual cost and the equipment cost are greatly lowered, and the working efficiency is improved.

Owner:三明市爱绿地节能环保有限公司

Mirror surface plating solution and immersion plating method

InactiveCN104862630ANo emission issuesGood weather resistanceHot-dipping/immersion processesHazardous substanceHydrazine compound

The invention discloses a mirror surface plating solution and an immersion plating method. The mirror surface plating solution comprises a photo stimulated activator and an immersion plating solution; the photo stimulated activator comprises the following raw materials: triethanolamine, gelatin, stannous chloride, a phosphate promoter and an alkyl coupling agent; the immersion plating solution comprises the following raw materials: silver nitrate, copper chloride, glucose, hydrazine hydrate, methane sulfonic acid, sodium hydroxide, gelatin and pyridine. The mirror surface plating solution adopts an aqueous solution, does not contain traditional cyanides, volatile organic solvents, and heavy metals such as lead, chromium and nickel, has no harmful substance emission problem, and is environmental-friendly, the immersion plating process is simple, the operation is easy, electricity utilization and heating are not needed, the working efficiency is improved greatly, the production cost is reduced, no expensive equipment is needed, and the immersion plating process is a low-investment and energy-saving new process.

Owner:陈徐丰

A recycling process for waste PC materials

ActiveCN102911397BSolve control technologyNo emission issuesPlastic recyclingPolymer recoveryPolyesterOrganic solvent

The invention discloses a process for recovering a waste polycarbonate (PC) material. The process is characterized by comprising the following steps of: crushing the waste PC material, dissolving the crushed PC material ion into an organic solvent to form a homogeneous solution; and adding an adsorbent into the homogeneous solution, discoloring and removing insoluble substances, and sequentially filtering and crystallizing to obtain the required crystallized PC material. According to the process for recovering the waste PC material, the recycled polyester intrinsic viscosity control technology, the crystallization technology and the impurity removal technology are realized, water is not required to be added in the whole process, the wastewater discharge is avoided, and the environmental pollution is reduced. The intrinsic viscosity of the recycled PC product reaches 0.77dL / g, the purity is 99.5 percent, and the recovered material reaches a novel level.

Owner:SHUYE ENVIRONMENTAL TECH CO LTD

Plane jet type metro tunnel blowing device

The invention relates to a metro tunnel ash cleaning device, belonging to the technical field of environmental protection of urban metro tunnels. Under the dispatching arrangement of the metro operation company, the plane jet type metro tunnel blowing device is quickly pulled from the blowing device parking place to the metro tunnel which has blowing and ash cleaning needs by a railway diesel locomotive, and the blowing and ash cleaning operation is carried out on the metro tunnel at a relatively low running speed. The plane jet type metro tunnel blowing device is mainly characterized in thata blowing nozzle (13) is arranged at the periphery of a pressure stabilizing box (8) and is close to the boundary of the metro vehicle, and the dust on the inner wall of the metro tunnel and adhered to various facilities is blown in a plane jet mode. The outer edge of an air suction port (9) is close to the metro vehicle gauge, and sucks the plane jet air discharged from the blowing nozzle (13) into a dust removing device (12) together with the raised dust, so that the dust is filtered down and the clean air is returned to the metro tunnel.

Owner:CHINA RAILWAY HUATIE ENG DESIGN GRP CO LTD

Calcium sulfate whisker and production method of raw material calcium sulfate thereof

ActiveCN110565172BHigh aspect ratioNo emission issuesAfter-treatment apparatusPolycrystalline material growthSulfatePhysical chemistry

Owner:YIBIN TIANYUAN GRP CO LTD +1

A kind of preparation of organic vegetable dye and dyeing method thereof

ActiveCN111607249BAchieve preliminary extractionFast extractionBiochemical fibre treatmentLight resistant fibresColour fastnessOrganic matter

The invention discloses a preparation of an organic plant dye and a dyeing method thereof. The preparation method comprises the following steps: (1) mixing the extraction raw material with a solvent, keeping warm, and extracting in countercurrent; (2) centrifuging the initial extract to obtain the first The first filtrate is adsorbed under ultrasonic; (3) the first filter residue and the first effluent are respectively returned to the countercurrent extraction equipment for countercurrent extraction, and then processed according to step (2); (4) the second filter residue and the second The effluent is processed according to step (3); the three solid-phase extraction columns are desorbed respectively; (5) the pigment extract is transported to a vacuum reaction kettle, minerals and organic matter are added, and complexation is stirred; (6) The complexed primary product is dried, sieved, and ground for 3 to 10 hours. The preparation method of the invention has the characteristics of high pigment extraction rate, low solvent consumption, low energy consumption, high yield and high quality, the obtained dye can improve the color fastness of textiles, and the dyeing method has low energy consumption and production cost.

Owner:东阳市神农纺织品有限公司

A kind of carbonate type collector reverse flotation agent and preparation method thereof

ActiveCN104998761BNo emission issuesThere is no problem with the use of cooking oilFlotationOil and greaseFoaming agent

The invention relates to a carbonate-type collecting agent reverse flotation drug and a preparation method thereof. The preparation method comprises the following steps: (1) taking low erucic acid rapeseed oil alkali refining and deacidification niger and short carbon chain fatty acids (6-14 carbon) as collecting agent raw materials; (2) taking mixed alcohols and 1,1,3-triethyl orthobutyrate as foaming agents; (3) mixing the collecting agent raw materials with excessive amounts of alkalies and a certain amount of water, reacting for 1.5 h in a reaction kettle at 80-100 DEG C, reducing the temperature of a reaction liquid to be 40-70 DEG C, adding the foaming agents, and continuously stirring for 30 min, so as to obtain the finished product, namely the collophanite reverse flotation drug, wherein the mass ratio of the collecting agents to the foaming agents in the finished product, namely the reverse flotation drug, is (7-9):1. The carbonate-type collecting agent reverse flotation drug and the preparation method have the advantages that the flotation performance of the low erucic acid rapeseed oil alkali refining and deacidification niger and the short carbon chain fatty acids in the carbonate-type collophanite reverse flotation operation can be improved remarkably, the flotation recovery rate and the concentrate grade are improved remarkably, and low-cost industrial greasy leftovers are sufficiently utilized.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com