Method and apparatus for combustion replacing oil with coal

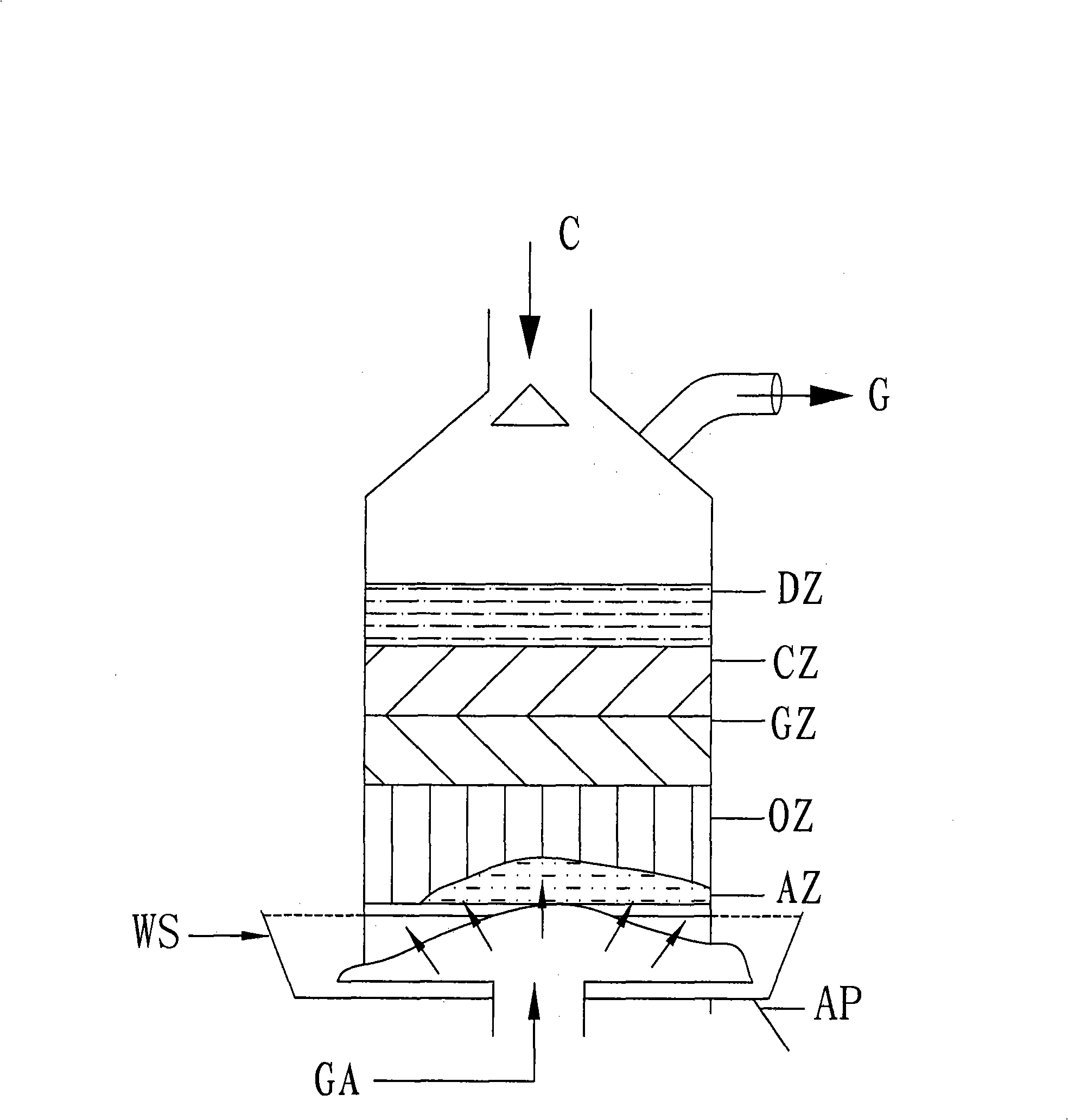

A technology of combustion method and equipment, applied in the direction of combustion method, combustion equipment, fluidized bed combustion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

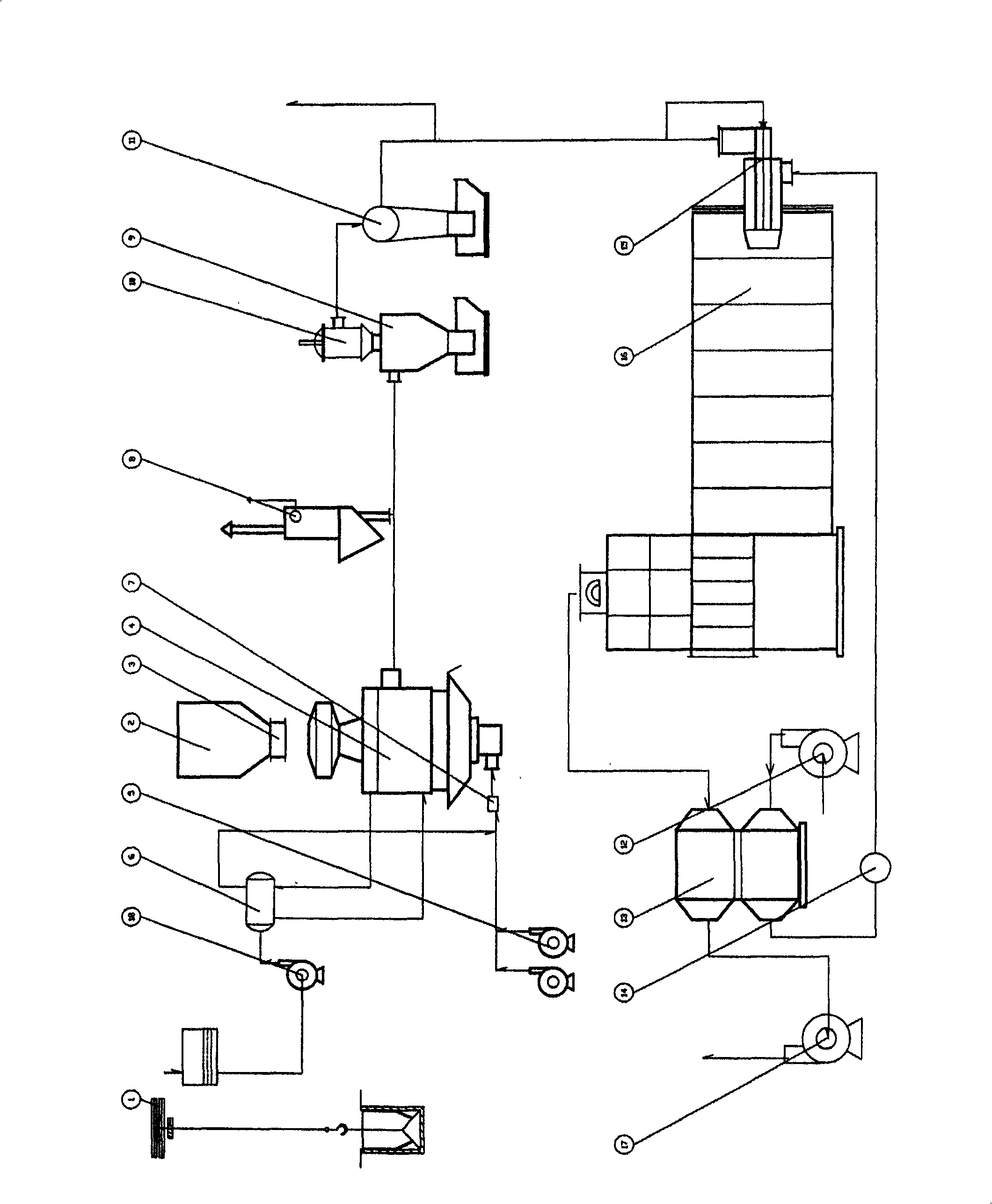

[0045] In this embodiment, two American-made SG50-NDS-26 oil-fired steam-injection boilers are transformed to burn low calorific value hot gas, so as to implement the combustion method of replacing oil with coal according to the present invention.

[0046] Specifically, according to a preferred embodiment, the coal-substituted oil combustion method of the present invention is implemented through the following stages:

[0047] Briquette preparation

[0048] Using pulverized coal with an ash content of 16wt% from Datong Coal Mine in China as raw material, it was first pulverized to a particle size below 3mm using a PX-64 impact crusher; then 3wt% coal ash fusibility regulator was added to it , so that the difference between the deformation temperature DT and the softening temperature ST of the briquette is about 250°C; then add 6wt% of binder to it, and the resulting mixture is uniformly mixed by SH-10 type twin-shaft mixer, and passed through Stir with ST-10 vertical mixer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com