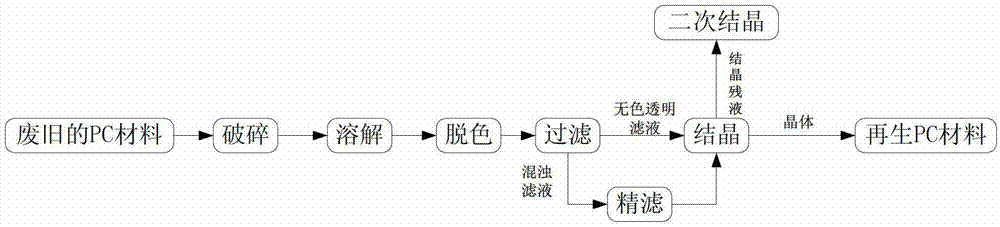

A recycling process for waste PC materials

A waste and process technology, applied in the field of waste polycarbonate (PC) material recycling process, can solve the problems of low product added value, high energy consumption, complex plastic recycling process, etc., achieve fast dissolution, less consumption, The effect of low solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The recovery process of waste polycarbonate material described in the present embodiment, comprises the steps:

[0038] (1) Collect waste polycarbonate bottles, add them to the pulverizer, and pulverize them to obtain waste particles with a particle size of 1-1.5cm;

[0039] (2) At room temperature, put the waste particles into an airtight container containing dichloromethane and stir for 30 minutes to dissolve the waste particles quickly and form a homogeneous solution. During the stirring process, control the mixture of waste particles and dichloromethane The temperature of the mixed solution does not exceed 35°C, and the weight ratio of dichloromethane to waste particles in this step is 1:10;

[0040] (3) Add activated carbon to the homogeneous solution to absorb the pigment in the homogeneous solution and the waste gas generated during the dissolution of waste particles. After stirring for 20 minutes, stand still to obtain a standing liquid, which is described in th...

Embodiment 2

[0046] (1) Collect waste polycarbonate bottles, add them to a pulverizer, and pulverize them to obtain waste particles with a particle size of 1.5 cm;

[0047] (2) At room temperature, put the waste particles into a closed container with dichloromethane and stir for 25 minutes to dissolve the waste particles quickly and form a homogeneous solution. During the stirring process, control the mixture of waste particles and dichloromethane The temperature of the mixed solution does not exceed 35°C, and the weight ratio of dichloromethane to waste particles in this step is 1:9;

[0048] (3) Add activated carbon to the homogeneous solution to absorb the pigment in the homogeneous solution and the exhaust gas generated during the dissolution of waste particles. After stirring for 18 minutes, stand still to obtain a standing liquid, which is described in this step The weight ratio of activated carbon to waste particles is 1:70;

[0049] (4) Add the static liquid to the first filter wi...

Embodiment 3

[0055] (1) Collect the waste polycarbonate film, add it to the pulverizer, and pulverize it to obtain waste particles with a particle size of 1-1.5cm;

[0056] (2) At room temperature, put the waste particles into a closed container with dichloromethane and stir for 35 minutes to quickly dissolve the waste particles to form a homogeneous solution. During the stirring process, control the mixture of waste particles and dichloromethane The temperature of the mixed solution does not exceed 35°C, and the weight ratio of dichloromethane to waste particles in this step is 1:12;

[0057] (3) Add activated carbon to the homogeneous solution to absorb the pigment in the homogeneous solution and the exhaust gas generated during the dissolution of waste particles. After stirring for 15 minutes, stand still to obtain a standing liquid, which is described in this step The weight ratio of activated carbon to waste particles is 1:200;

[0058] (4) Add the static liquid to the first filter w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com